Anti-skid plastic conveying chain plate and production method thereof

A technology for conveying chain plates and production methods, which is applied in the direction of conveyors, transportation and packaging, etc., which can solve the problems of low friction on the conveying surface, material slippage, and movement, and achieve the effect of improving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

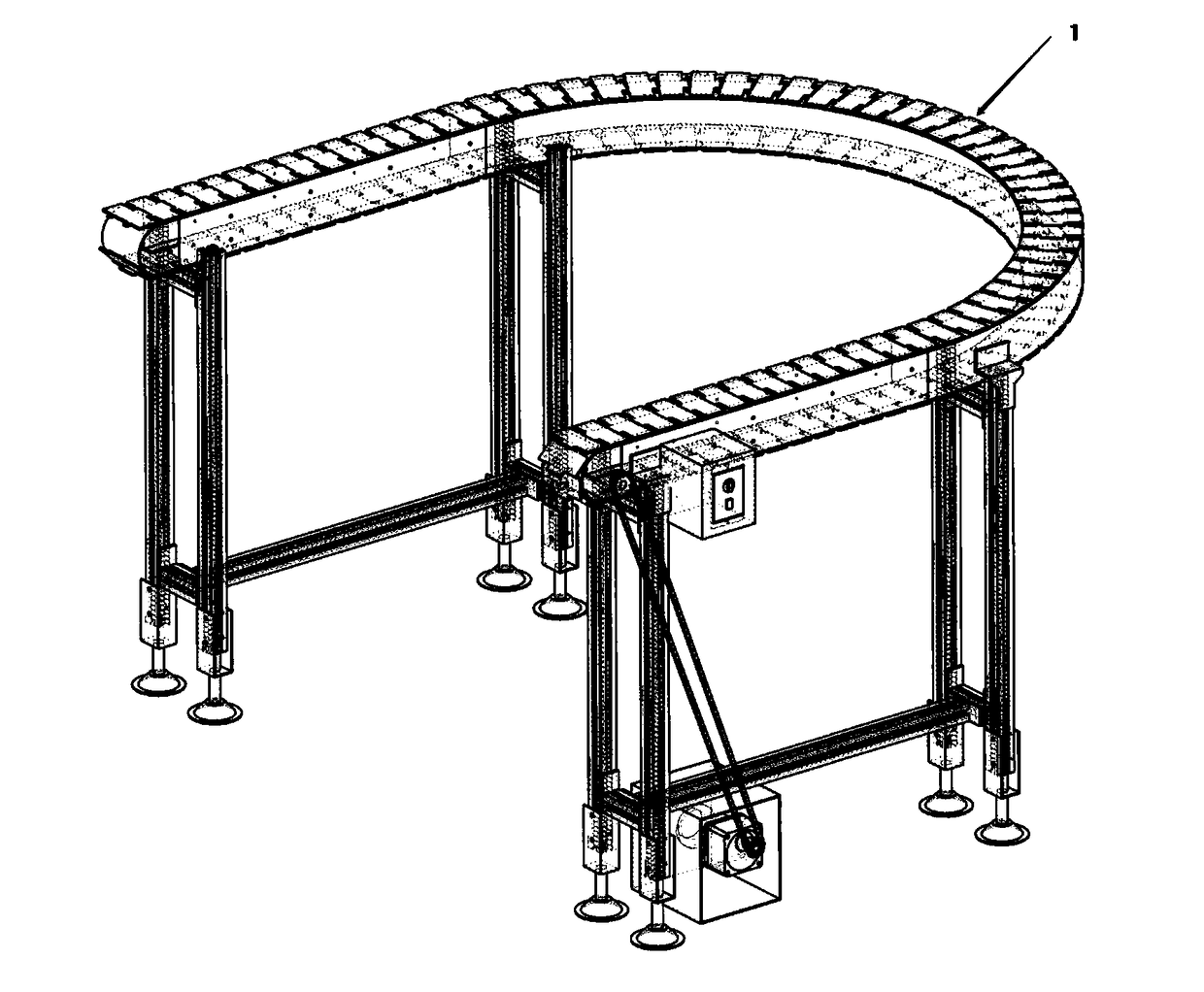

[0032] Such as figure 1 As shown, it is the overall structure of the present plastic chain plate conveyor chain, which is connected by several chain plate bodies 1 through connecting pin shafts 3, each chain plate body 1 has a conveying surface, and each chain plate body 1 The conveying surfaces are connected to form a complete conveyor belt.

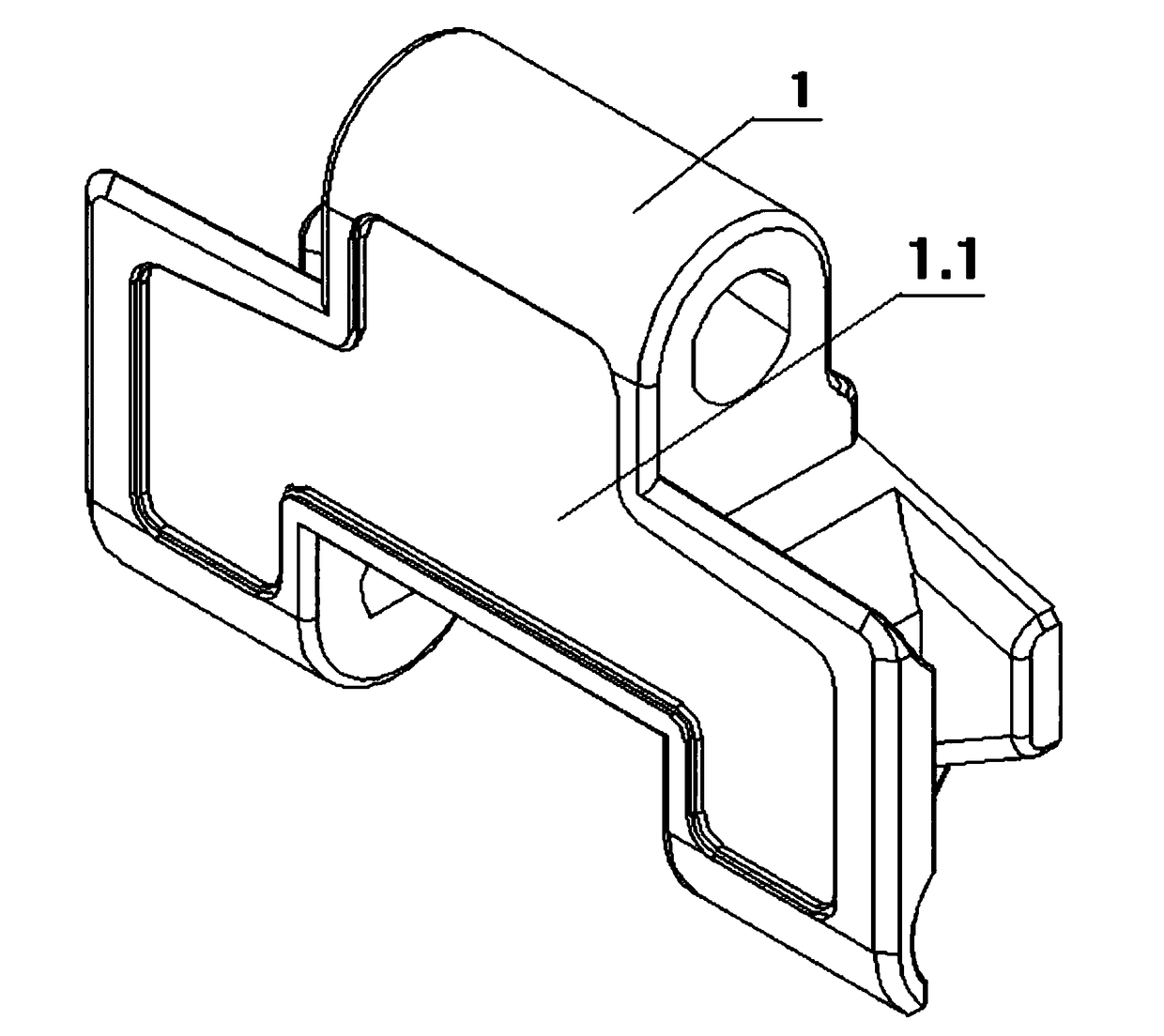

[0033] Such as Image 6 As shown, a non-slip plastic conveyor chain provided by the present invention includes a chain body 1 having a conveying surface on which an anti-skid layer 2 is provided.

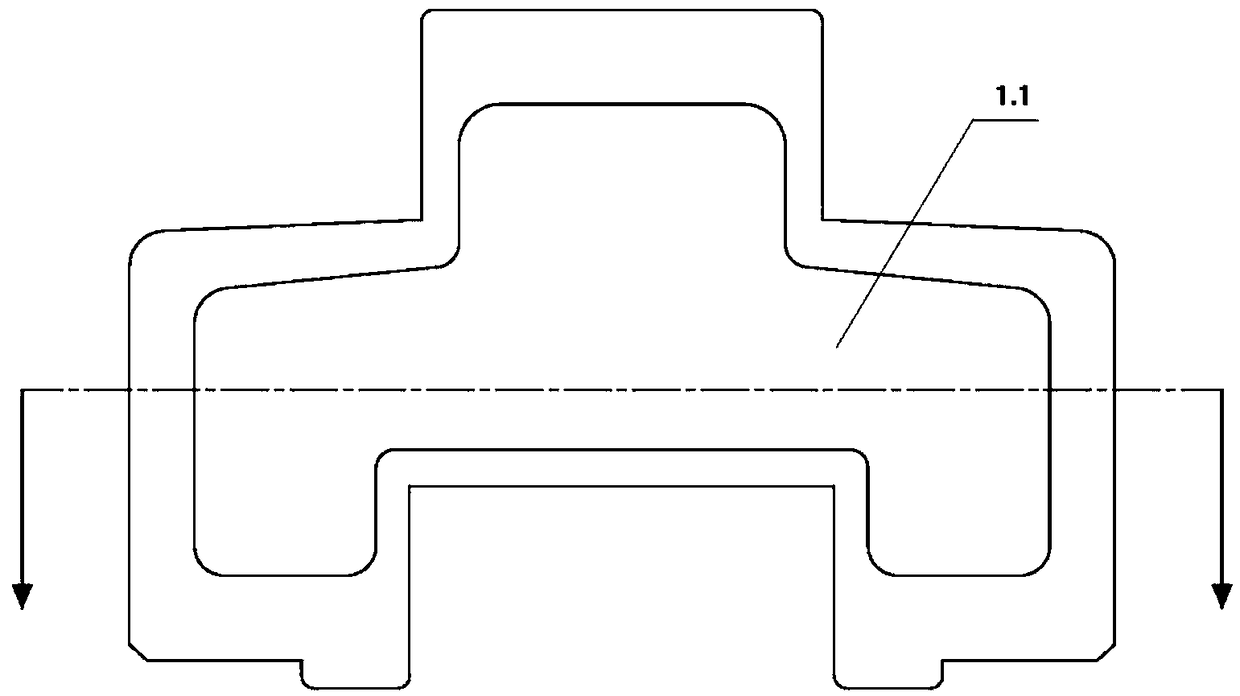

[0034] In this example, if figure 2 As shown, the anti-slip layer 2 is connected to the chain plate body 1 through the concave platform 1.1. Specifically, the structure of the anti-skid layer 2 is that a concave platform 1.1 extending into the chain plate body 1 is provided on the conveying surface. , An anti-slip layer 2 is provided inside the concave platform 1.1.

[0035] In this embodiment, the chain plate body 1 is made of polyoxyme...

Embodiment 2

[0039] On the basis of embodiment 1, in order to improve the fixing effect between the anti-slip layer 2 and the concave platform 1.1, as image 3 , Figure 4 , Figure 5 As shown, the edge of the concave platform 1.1 is arranged at an angle to the inner plane of the concave platform 1.1 to form a dovetail groove structure for buckling the anti-skid layer 2 in the concave platform 1.1.

[0040] Through the dovetail structure, the anti-slip layer 2 is stably attached to the inside of the conveying surface, making the conveying of articles more stable.

Embodiment 3

[0042] In order to further improve the fixing effect between the anti-skid layer 2 and the recessed platform 1.1, a pattern structure is provided on the inner plane of the said concave platform 1.1 to increase the contact area and adhesion effect between it and the anti-slip layer 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com