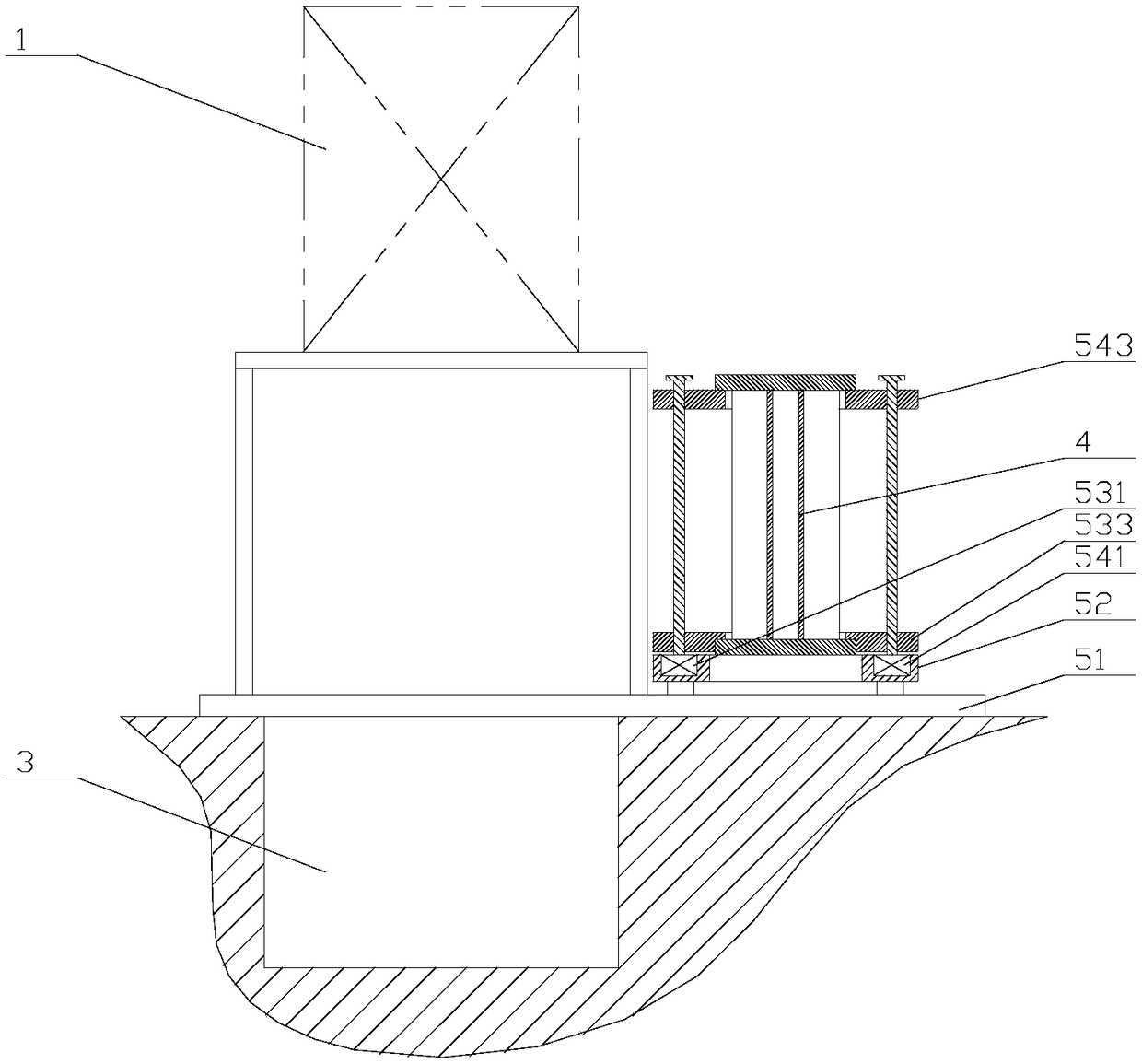

Feeding component for quenching furnace

A technology of quenching furnace and components, applied in the direction of quenching devices, furnaces, heat treatment furnaces, etc., can solve problems such as hidden safety hazards, troubles, etc., and achieve the effect of convenient operation, exquisite structure, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

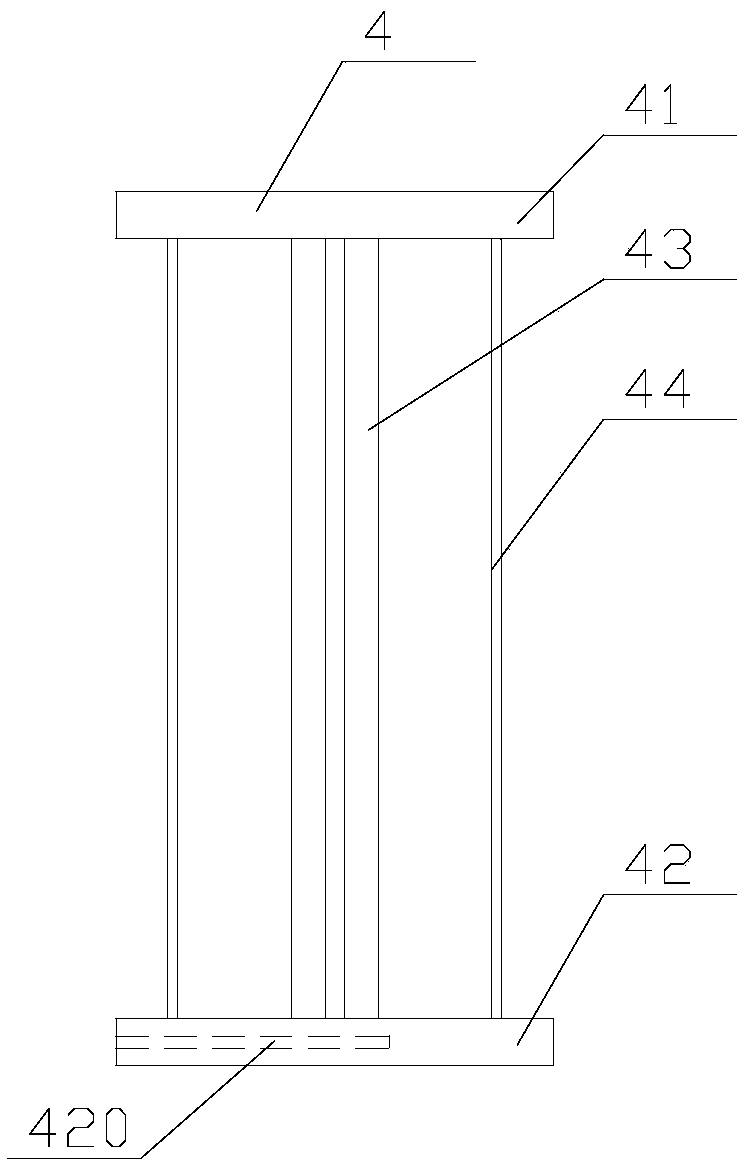

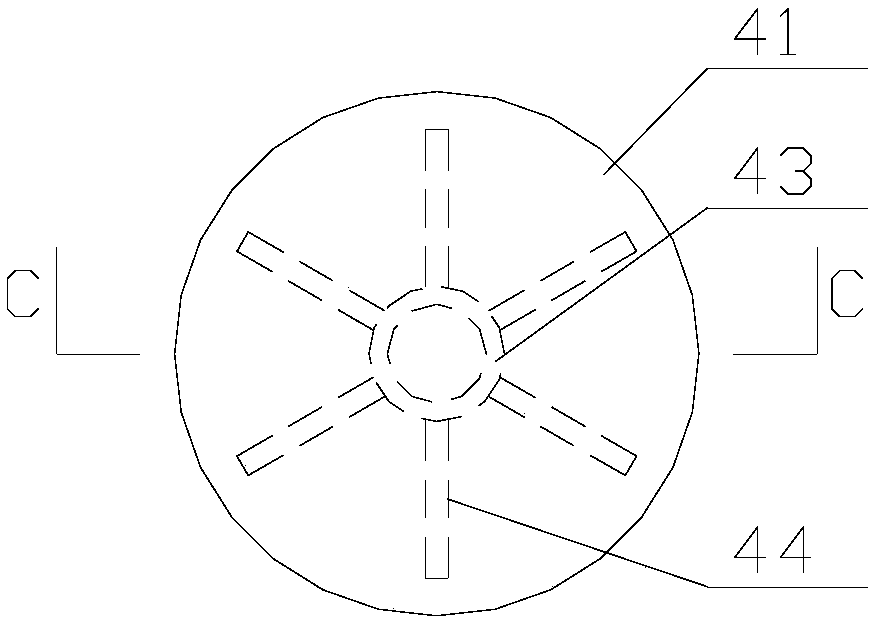

Examples

Embodiment approach

[0036] A plurality of hydraulic struts 56 are fixedly connected to the bottom surface of the trolley 52 , the top ends of the hydraulic struts 56 are fixedly connected to the bottom surface of the trolley 52 , and the bottom ends of the hydraulic struts 56 are hinged to the traveling wheels 55 . In this way, when the second motor is turned off and the motor is turned on, during the process of sending the holding frame into the quenching furnace, the hydraulic strut can be opened to make it jack up upwards, so that all the holding frames enter the quenching furnace, which can effectively guarantee The heating efficiency of the aluminum tube shortens the heating time and ensures the uniformity of the temperature on the aluminum tube.

[0037]The end of the guide rail away from the quenching pool is fixedly connected with a linear drive mechanism, such as a hydraulic push rod, a pneumatic push rod, etc., and the linear drive mechanism is connected between the guide rail and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com