Carrying trolley

A technology for handling trolleys and trolleys, which is applied in the direction of lifting devices, lighting devices, crowbars, etc., which can solve problems such as unfavorable worker safety, low handling efficiency, and potential safety hazards, so as to improve economic benefits, ensure personal safety, and reduce burdens. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

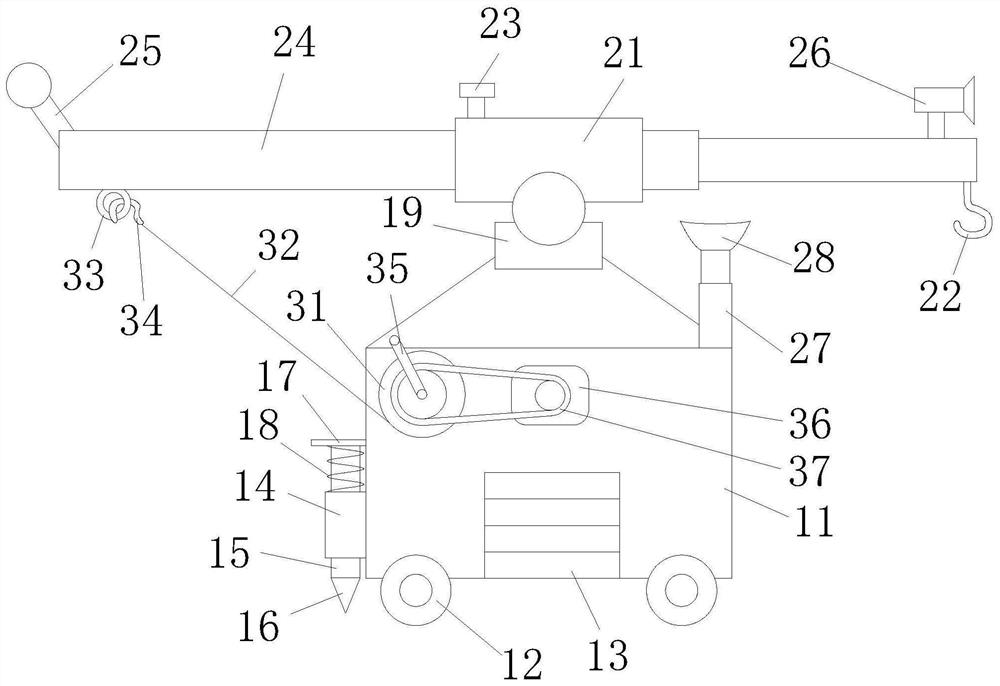

[0018] Such as figure 1 As shown, the embodiment provides a transport trolley, including a trolley and power components. The trolley includes a base 11 , a sleeve 21 , a roller 12 , a lever 24 , a hook 22 and a turntable 19 . The roller 12 is fixed on the bottom of the base 11, the rotating disc 19 is fixed on the top of the base 11, the sleeve 21 is rotatably connected to the free end of the rotating disc 19, the lever 24 passes through the sleeve 21, and the sleeve 21 is provided with a handle for fixing the lever 24. The bolt 23 and the hook 22 are rotatably connected to one end of the lever 24 . Power part comprises hinged wheel 31, motor 36, hand rocker 35, stay cord 32, draw ring 33 and transmission belt 37, hinged wheel 31 is rotatably connected on the base 11, draw ring 33 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com