Electrically operated gate and fitting room applying same

A technology of electric doors and brake motors, which is applied to the layout of windows/doors, door/window accessories, and wing leaves, etc., which can solve problems such as wasting time and not being able to quickly observe the dressing effect, achieve a large adsorption area, and reduce operational risks , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

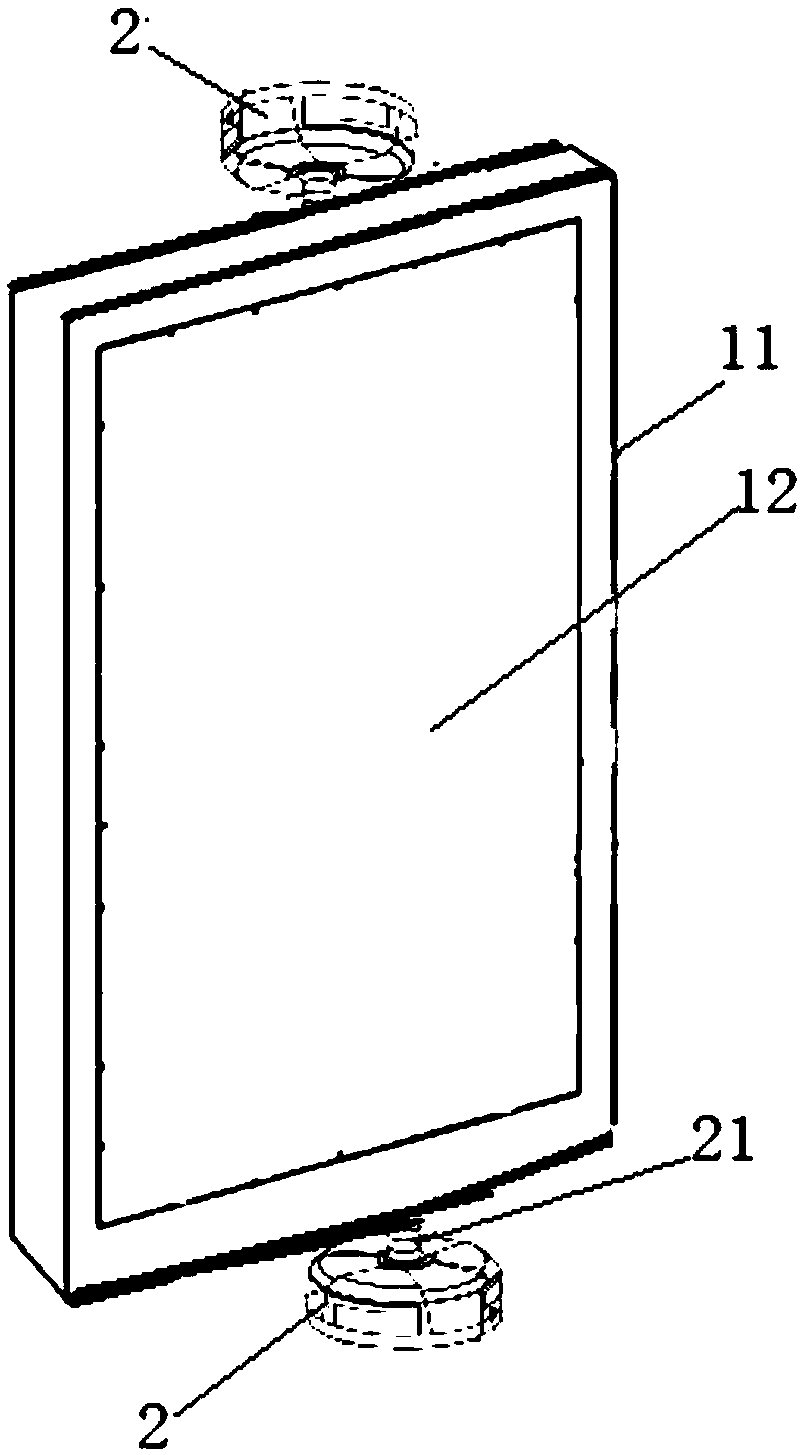

[0020] like figure 1 As shown, the electric door of this embodiment includes circular rotating seats 2 arranged in pairs, a rectangular frame 11 and a double-sided mirror 12 fixedly arranged in the frame 11 .

[0021] The frame 11 includes an upper frame, a right frame, a lower frame, and a left frame that are fixed and connected in turn. The rectangular door frame can be made of aluminum alloy profile or stainless steel, which is durable and beautiful.

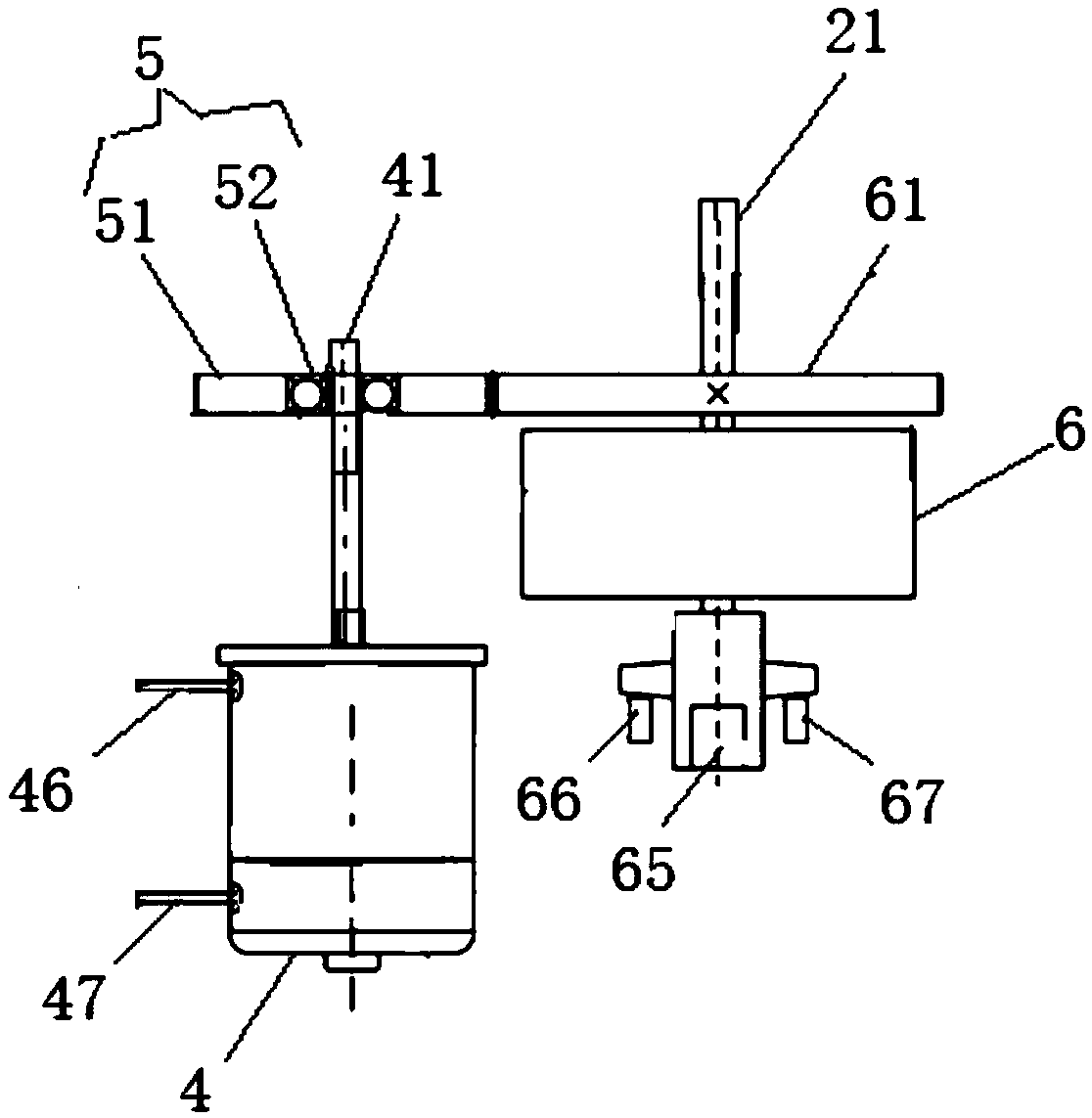

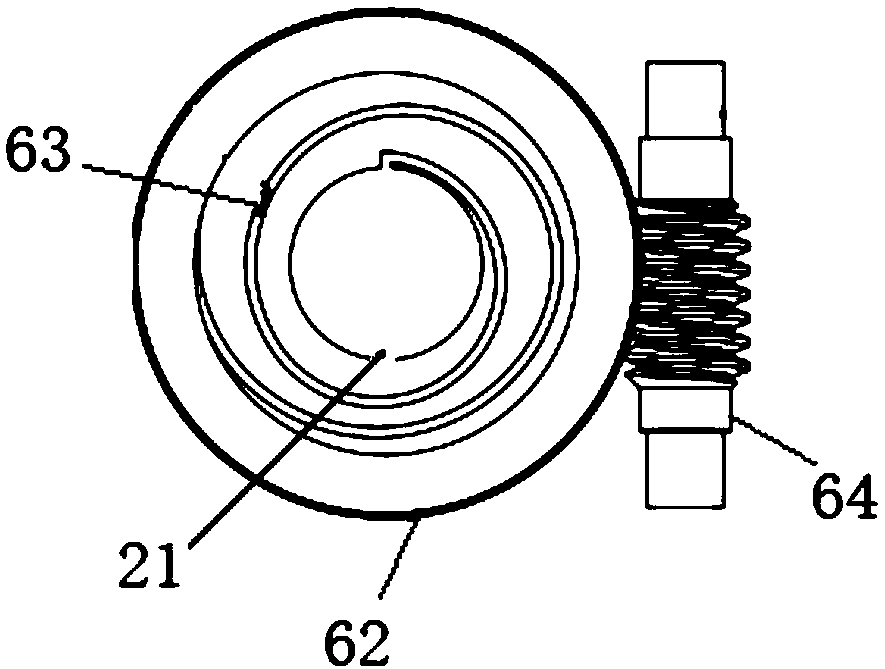

[0022] like figure 2 As shown, a brake motor 4, a reset device 6, a rotating shaft 21, a one-way clutch 5, and an engaging gear 61 are arranged in each rotating seat 2, and the output shaft 41 of the brake motor 4 is fixedly connected with the inner ring 52 of the one-way clutch 5, and the one-way The outer ring 51 of the clutch 5 meshes with the meshing gear 61, and the rotating shaft 21 is fixedly connected with the shaft center of the meshing gear 61, so that the brake motor 4 can drive the rotating shaft 21 to rotate th...

Embodiment 2

[0030] A fitting room includes the electric door in Embodiment 1, and also includes a rectangular door frame, a rotating seat 2 is embedded in the rectangular door frame, and each rotating shaft 21 protrudes and is fixedly connected with the frame 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com