A screw-driven flap gate

A flap gate and screw drive technology, applied in the field of flap gates, can solve problems such as difficulty in accurately controlling the opening, slow hydraulic oil return speed, affecting flood safety, etc., achieve precise water level and flow control, and fast opening and closing speed. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the present invention will be further elaborated in combination with specific implementation and with reference to the accompanying drawings.

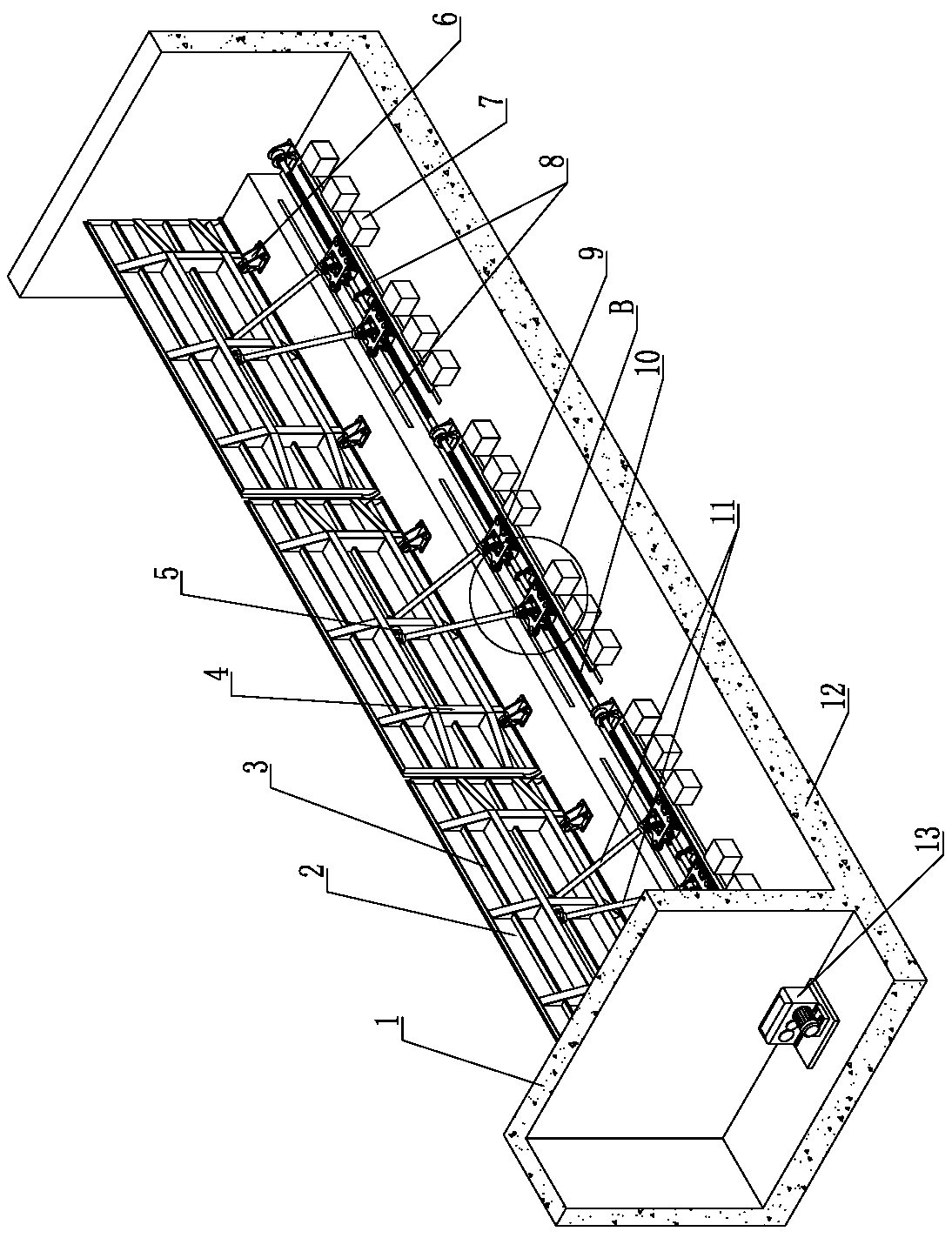

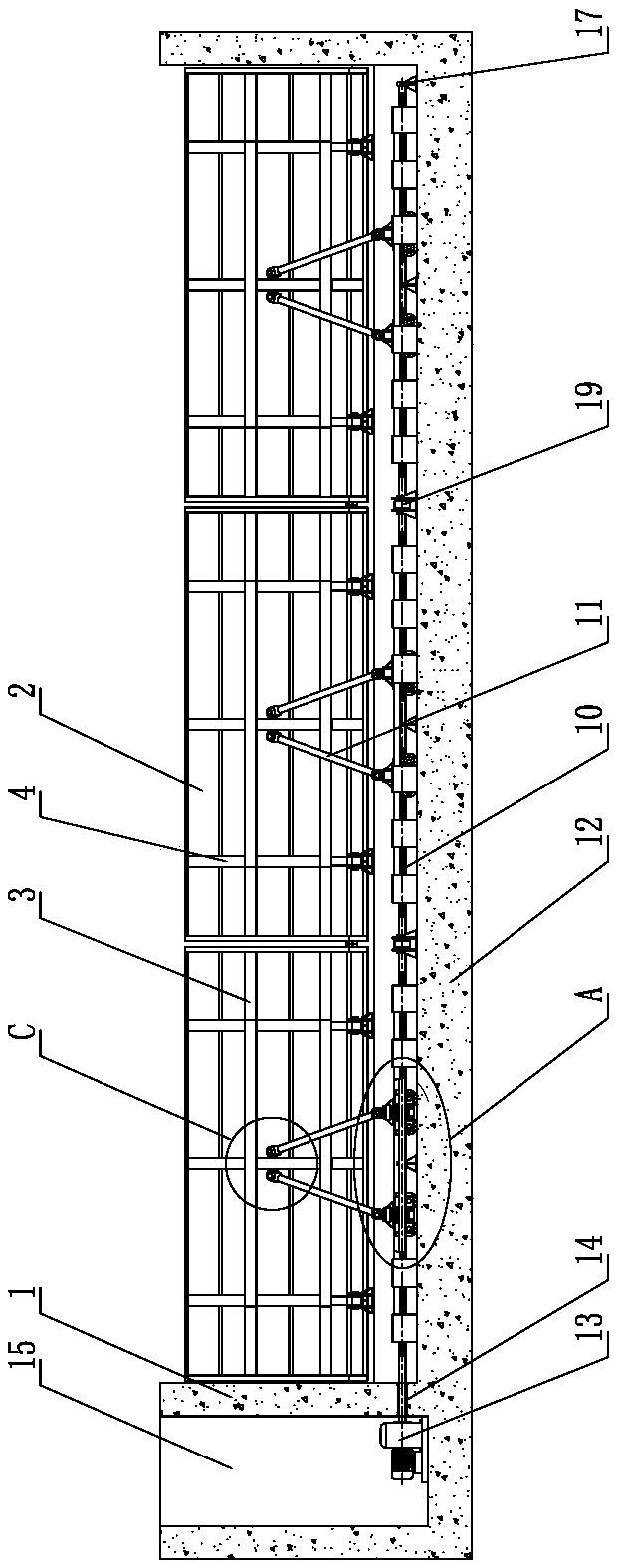

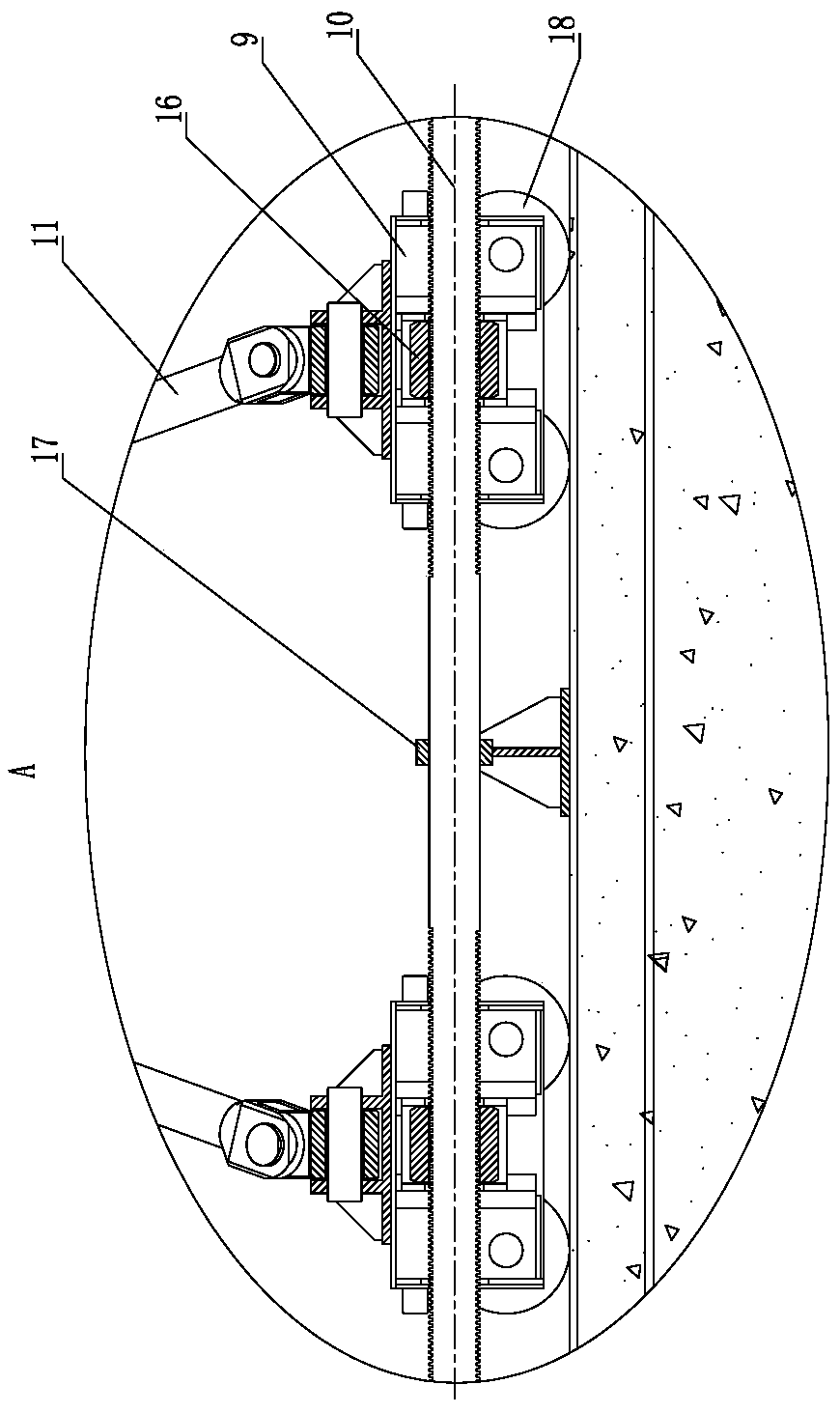

[0037] as attached Figure 1-9 As shown, the structure of a spiral-driven flap gate of the present invention mainly includes gate walls 1 arranged on both sides of the river channel, a bottom plate 12 arranged at the bottom of the river channel, and a gate body 2 arranged between the gate wall 1 and the bottom plate 12, The bottom plate 12 is provided with several hinge seats 6 at intervals, and the bottom of the door body 2 is hinged on the hinge seats 6, so that the door body 2 can rotate around the hinge seats 6 as a whole. The bottom of the body 2 can be hinged with the hinge seat 6 one by one with pin shafts; for the convenience of manufacture and installation, the door body 2 is composed of several unit door leaves, as shown in the figure, the door body 2 is composed of three unit door leaves, and the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com