Intelligent air valve

A damper and intelligent technology, applied in the field of smart dampers, can solve the problems of bad influence on the quality of stored goods, bad influence on the accuracy of valve position adjustment, and influence on the opening and closing of dampers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

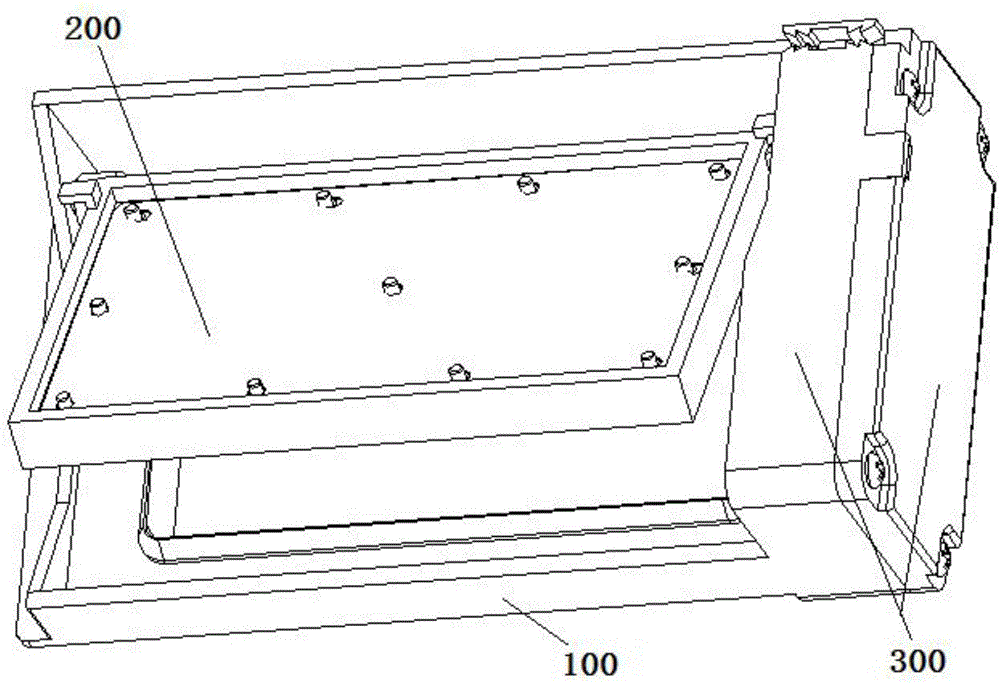

[0030] Without loss of generality, as figure 1 As shown, the present invention provides a smart damper, including: a damper frame 100, a damper baffle 200 and a stepping drive device 300; the damper baffle 200 is hinged in the damper frame 100 through a hinge shaft; The shaft is firmly connected with the damper baffle 200 ;

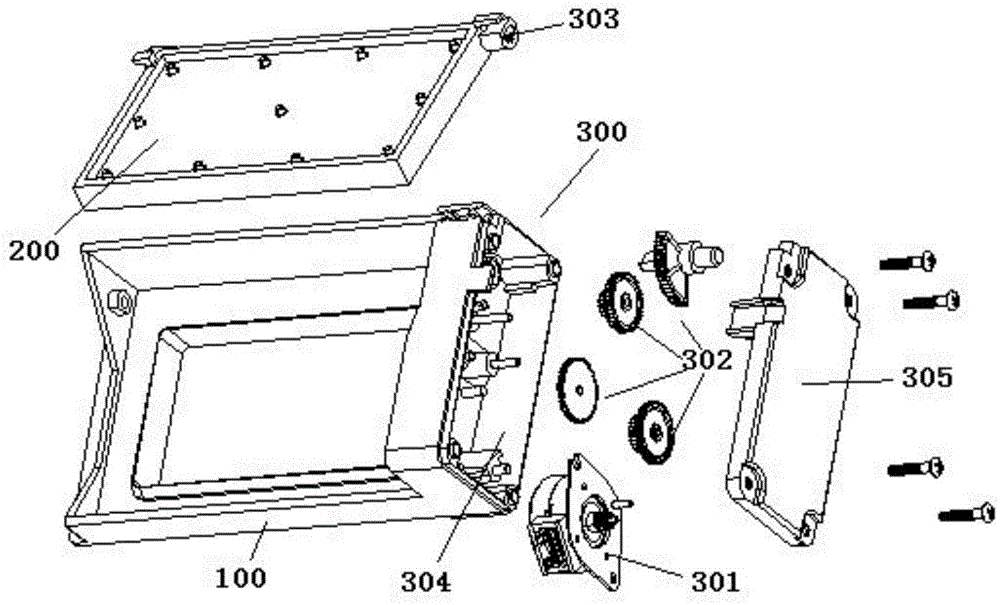

[0031] figure 2 In the present embodiment shown, the damper baffle 200 is hinged in the damper frame 100 through a rotating shaft, and one side of the damper frame 100 is provided with a stepping drive device 300, and the stepping motor 301 in the stepping drive device 300 is hinged with the gear 302. The shaft 303 is connected by transmission, and the stepping motor 301 and the transmission gear 302 are both arranged in the housing 304 on one side of the damper frame 100 , and the housing 304 is snapped and sealed by an end cover 305 . It should be noted that since the power source of the stepping drive device is not limited to the stepping motor, and...

Embodiment 2

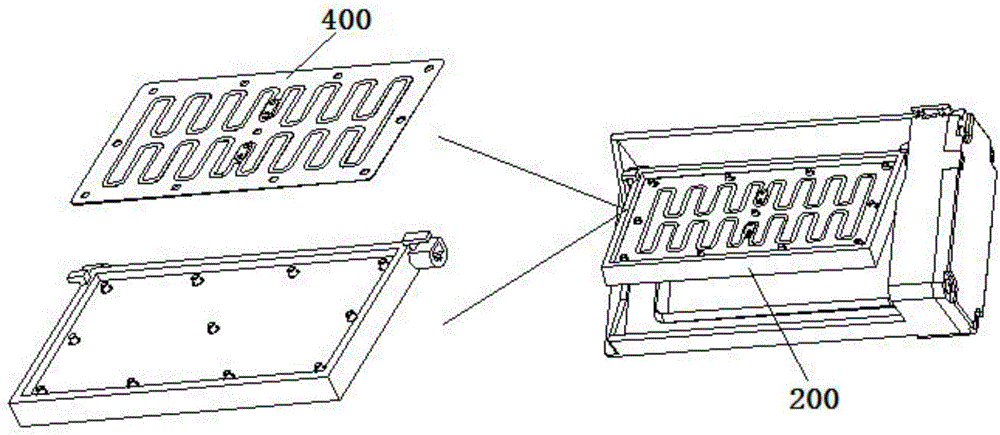

[0037] Figure 5 As shown, on the basis of Embodiment 1, the present embodiment is provided with multiple damper baffles 200 , and each damper baffle 200 is provided with an independent stepping drive device 300 . In the present invention, by setting the number of damper baffles in the same damper frame to multiple pieces, it is helpful to achieve the technical effect of improving the control accuracy of the intelligent damper, and the stepwise regulation and control of ventilation can be achieved by sequentially opening the damper baffles arranged in the damper frame Quantitative technical effects.

[0038] Preferably, in a preferred technical solution of this embodiment, the damper frame is provided with a frame heating device. The present invention helps to achieve the technical effect of melting and condensing frost on the damper frame by providing a heating device on the damper frame. The closed smart damper will also cause the damper to fail to open automatically, whic...

Embodiment 3

[0040] Such as Image 6 As shown, in this embodiment, on the basis of Embodiment 1, one side of the damper frame 100 is provided with a V-shaped groove 110, and a temperature sensor 111 and a wind speed sensor 112 are arranged in the V-shaped groove 110, and the temperature sensor 111 and the wind speed sensor 112 are respectively connected with the controller signal of the stepping drive device. The present invention provides a strong structural support for setting a temperature sensor and a wind speed sensor in the V-shaped groove by setting a V-shaped groove on one side of the damper frame, and the temperature sensor installed in the V-shaped groove can realize real-time Monitoring, the controller of the stepping drive device can adjust the valve opening of the smart air valve in real time according to the feedback of the airflow temperature and the storage temperature in the refrigerating room, thereby achieving the technical effect of intelligently regulating the room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com