Filling technology capable of making slurry uniformly distributed between inner wall and outer wall of freezing shaft

A technology for evenly distributing and freezing wells, applied in wellbore lining, shaft equipment, mining equipment, etc., to solve problems such as uneven filling of cement slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

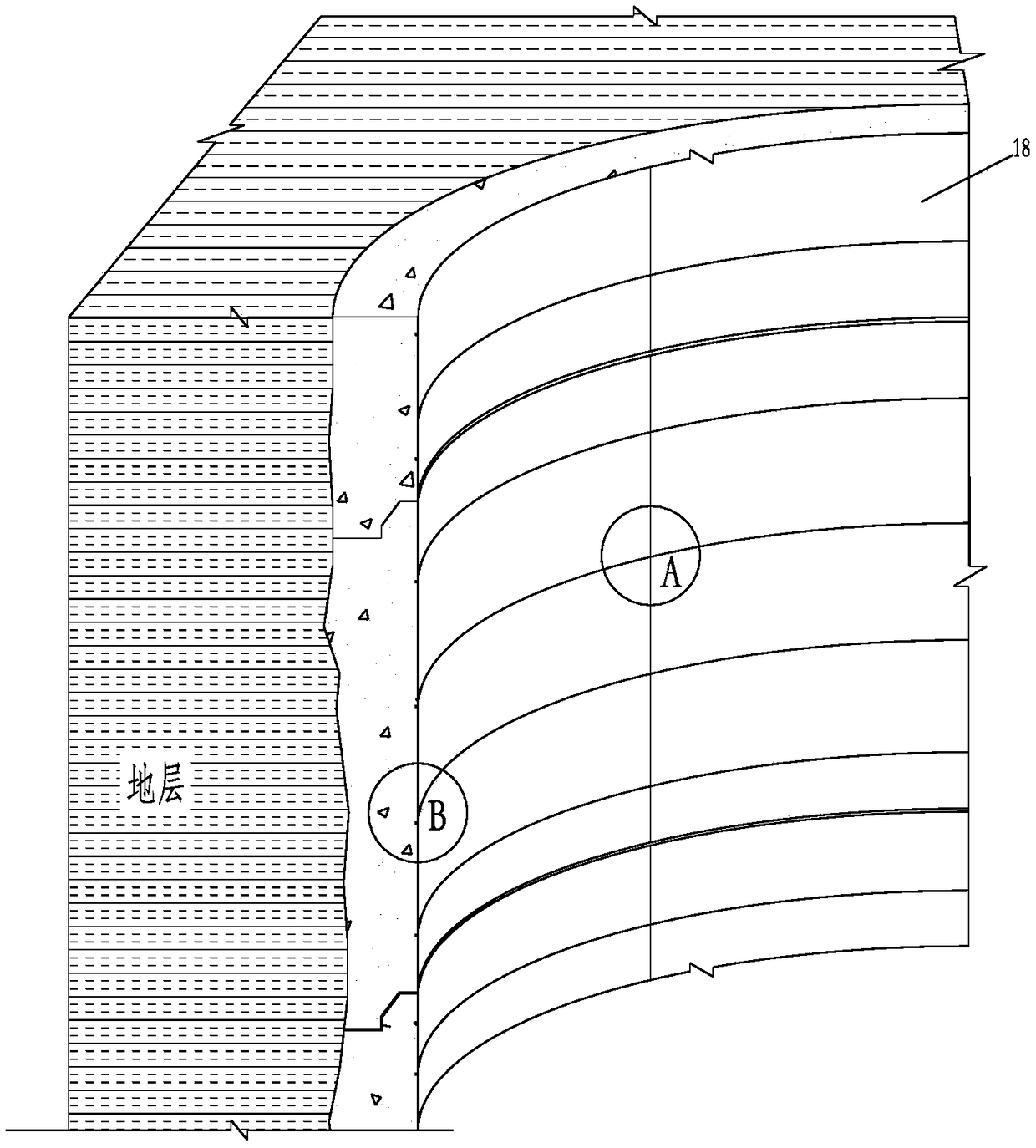

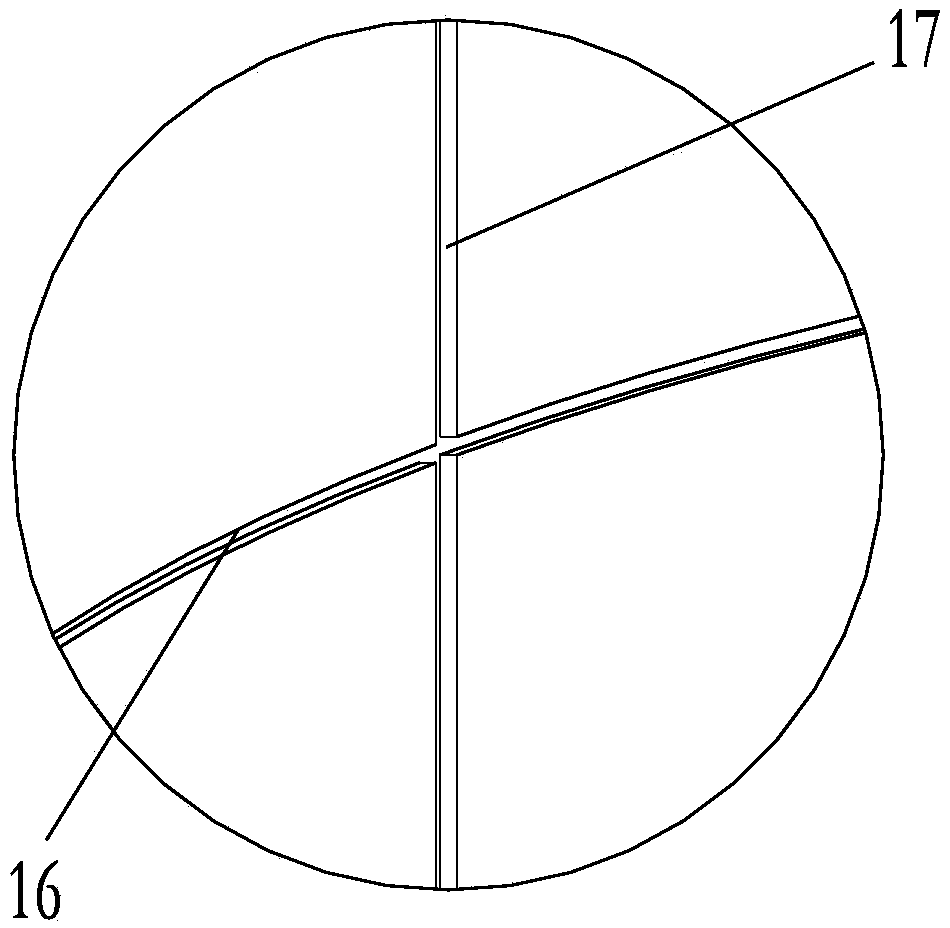

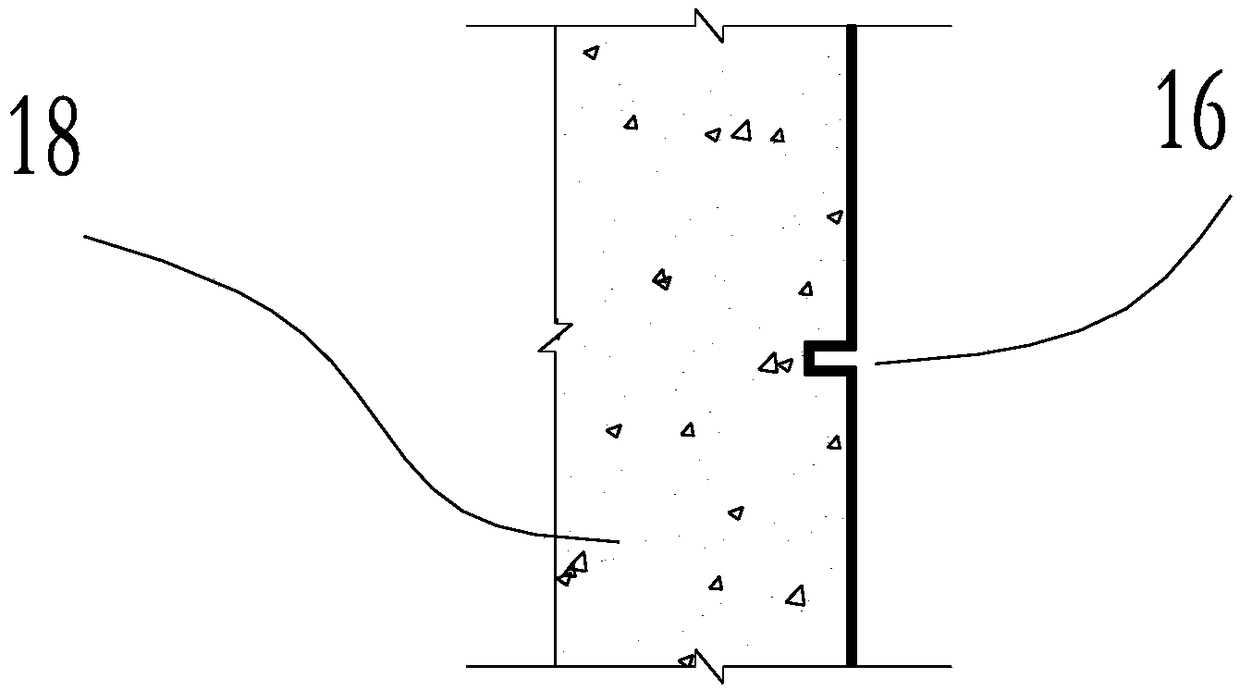

[0038] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0039] In this embodiment, the filling process capable of evenly distributing the slurry between the inner and outer walls of the frozen wellbore includes the following steps:

[0040] (S1) Outer wall formwork installation: install an outer wall formwork that can form a diffusion groove on the outer wall surface at the position of the frozen shaft excavation work face; the notch width of the diffusion groove is 15-20mm, and the groove depth is 20-30mm; The width of the notch is 15-20mm, which can effectively prevent the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com