Connector system for lighting assembly

A connector and end cap assembly technology, which is applied in the field of LED lighting and tubular light-emitting components, can solve problems such as easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

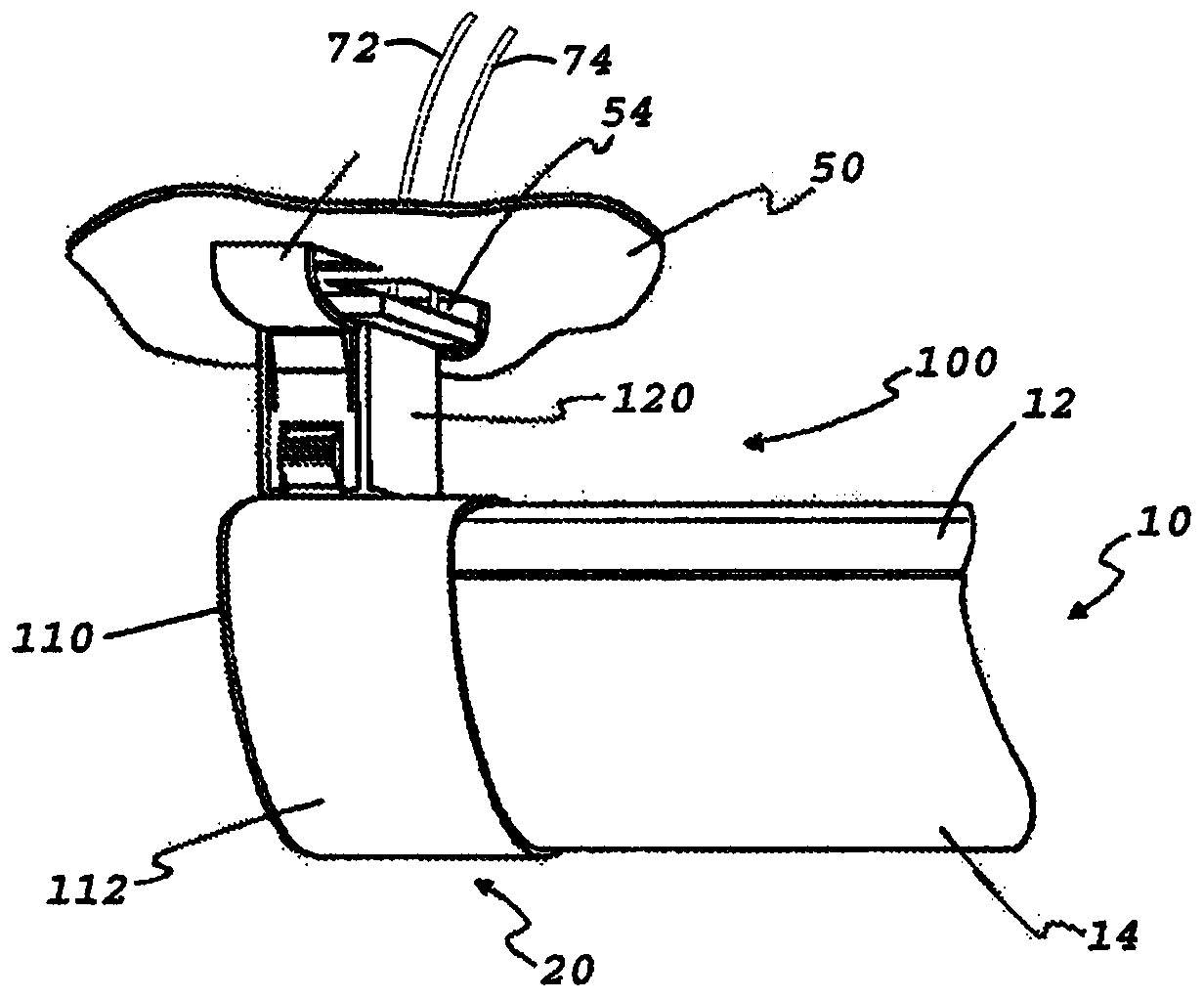

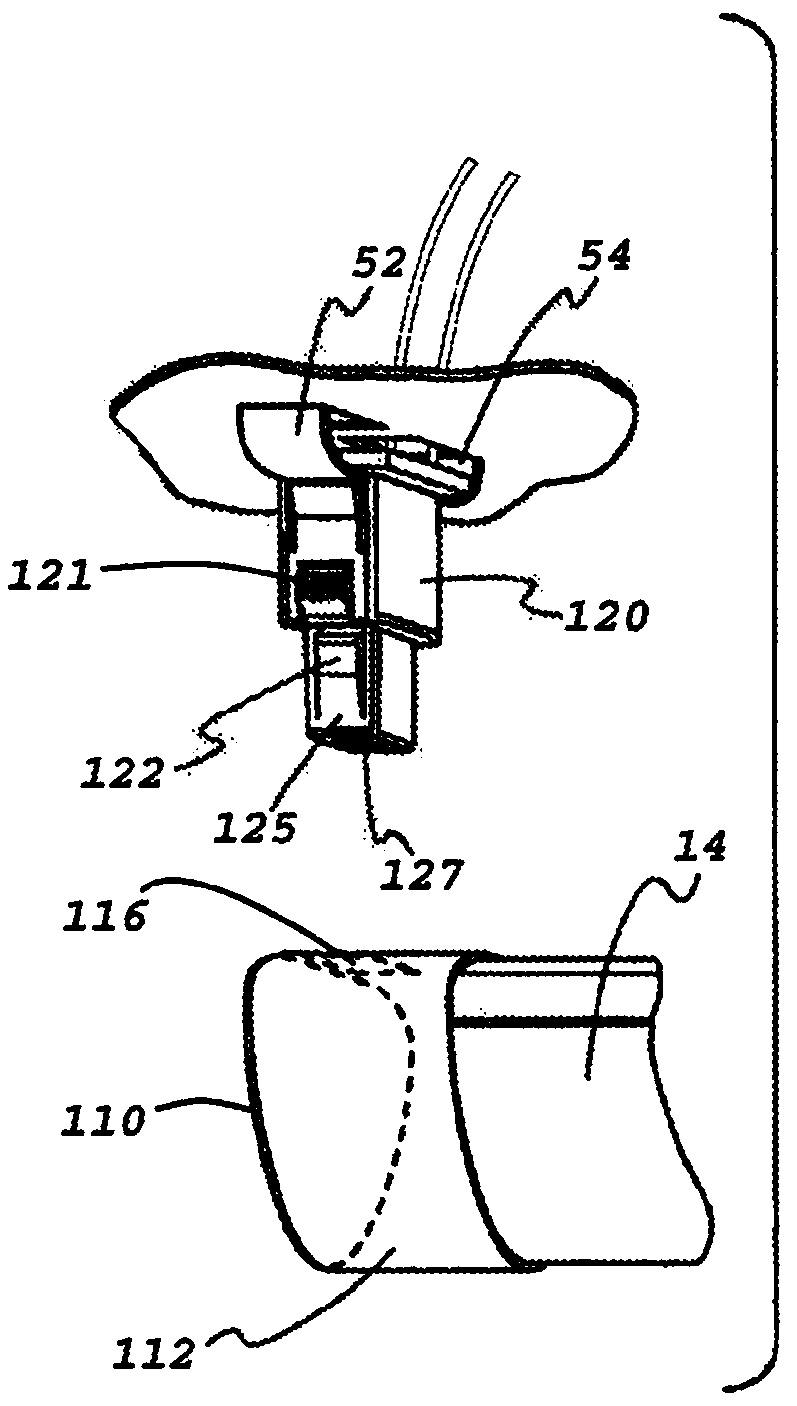

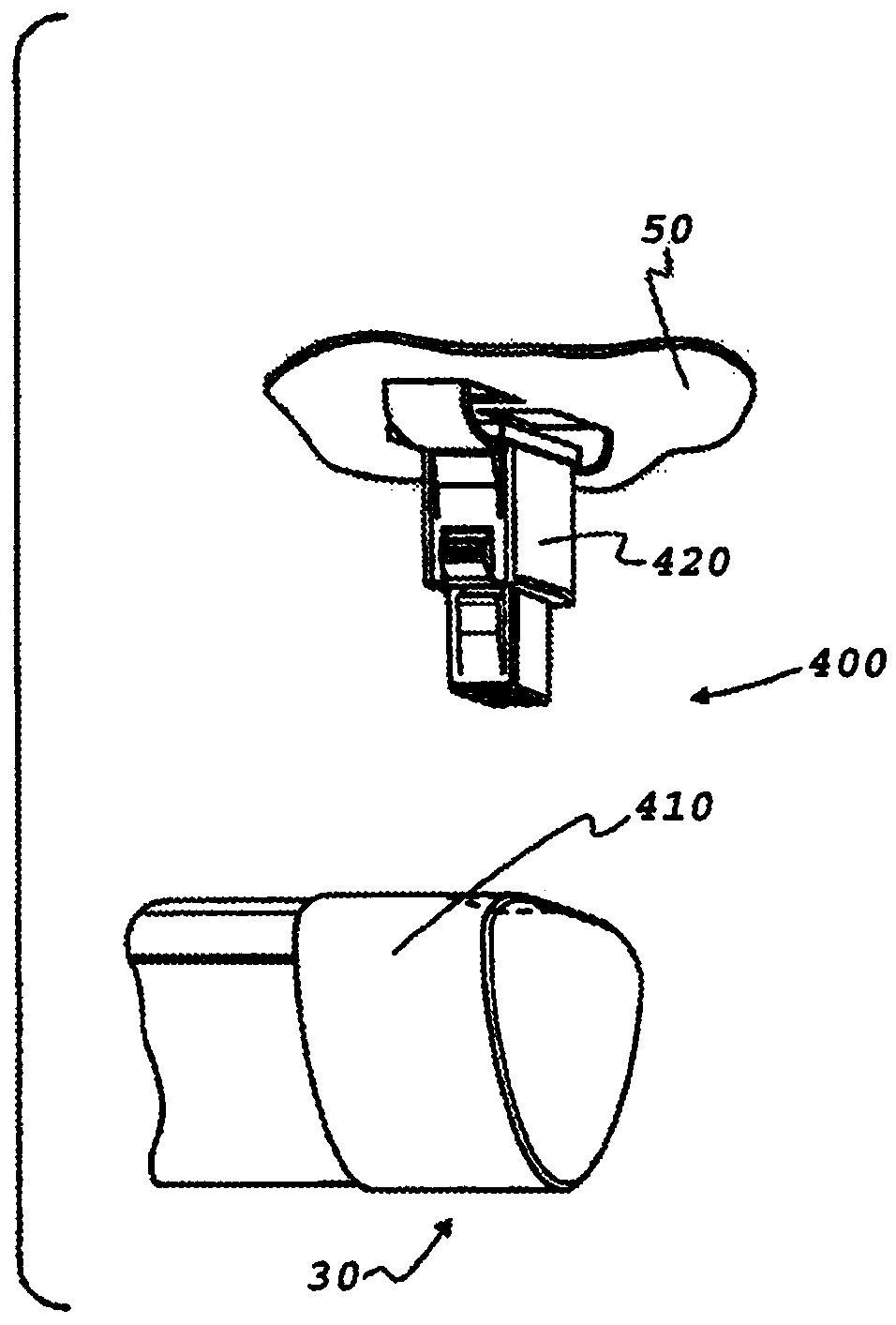

[0045] For the purpose of promoting an understanding of the principles of the present invention, reference will now be made to the embodiments illustrated in the drawings, and language will be used to describe the embodiments in detail. It should be understood, however, that no limitation of the scope of the invention is thereby intended. Any such variations and further modifications in the apparatus shown, and such further applications of the principles of the invention as shown herein, will generally occur to those skilled in the art to which the invention pertains.

[0046] There is a need for an improved lamp holder and connector system that addresses all safety concerns and provides a grounded LED lighting system in a linear tube format widely developed in the lighting industry. As used herein, the terms "LED tube light" and "straight LED light" and similar variations are used interchangeably to describe an LED light having an exterior mounted with a narrow and elongated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com