A kind of preparation method and application of solid condensation catalyst

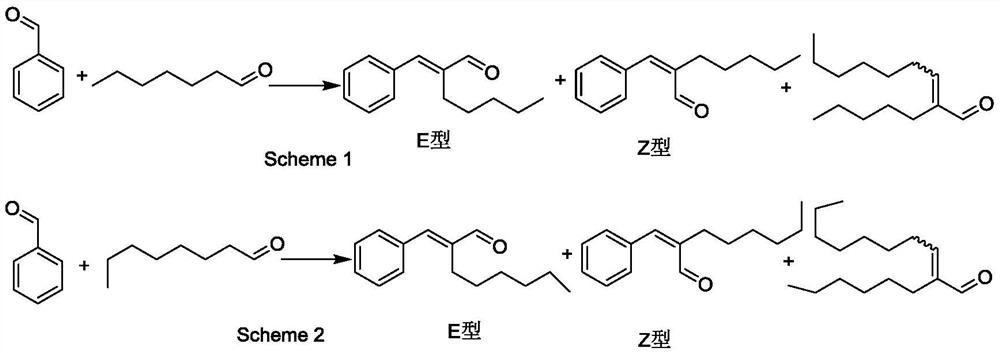

A condensation catalyst and solid technology, applied in the field of spices, can solve the problems of low conversion rate of raw materials, low product selectivity, large amount of waste water, etc., and achieve the effects of high catalytic activity, high product purity and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

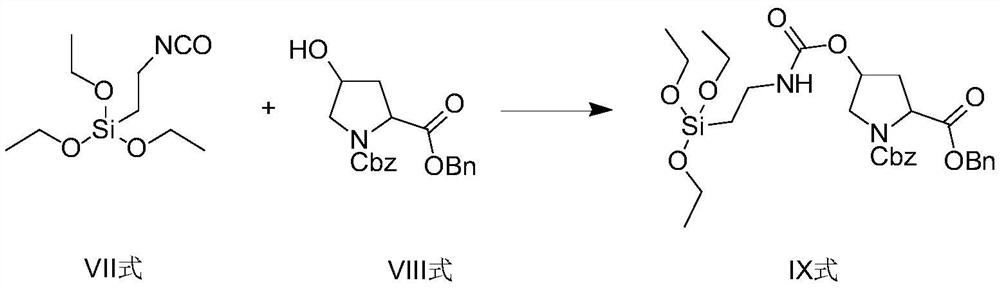

[0031] 1) Preparation of N-Cbz-4-(2-triethoxysilylethylcarbamoyl)oxa-L-proline benzyl ester IX

[0032] Triethoxysilylethyl isocyanate VII 23.3g and N-Cbz-4-hydroxy-L-proline benzyl ester Ⅷ 35.5g in dichloromethane solvent; stirred and reacted at 10°C for 15h, evaporated the solvent to dryness Purified directly for next step reaction;

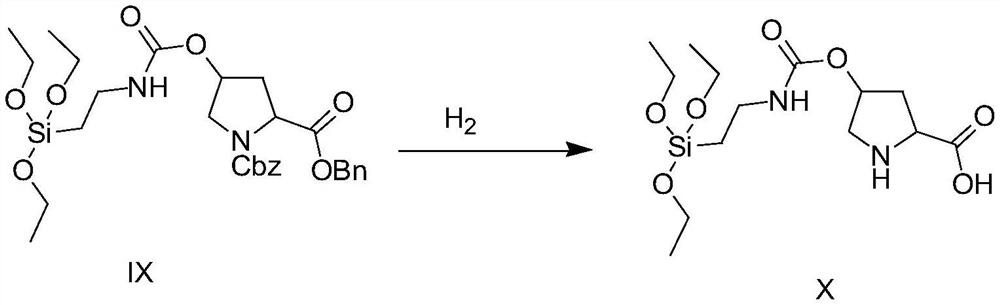

[0033] 2) Preparation of 4-(2-triethoxysilylethylcarbamoyl)oxa-L-proline X

[0034] Step 1) Add 59 g of product IX to a mixed solution of 200 ml of ethanol and 70 ml of cyclohexane, add 59 mg of palladium carbon, feed hydrogen gas to 1.0 MPa, heat up to 100 ° C for 2 hours, cool down and filter to remove the catalyst, and distill off the solvent to obtain a light yellow color The solid X was directly used in the next reaction without purification.

[0035] 3) Preparation of condensation catalyst

[0036] Add 500ml of toluene to 30g of MCM-41 and stir; Step 2) Dissolve X3g of the product in 100ml of toluene, then add it to the suspension of MCM...

Embodiment 2

[0040] 1) Preparation of N-Cbz-4-(2-triethoxysilylethylcarbamoyl)oxa-L-proline benzyl ester IX

[0041] 11.8 g of triethoxysilylethyl isocyanate VII and 17.8 g of N-Cbz-4-hydroxy-L-proline benzyl ester VIII in toluene as a solvent. React at 70°C for 4 hours, evaporate the solvent to dryness and use it directly for the next reaction;

[0042] 2) Preparation of 4-(2-triethoxysilylethylcarbamoyl)oxa-L-proline X

[0043] Step 1) Add 72g of product IX to a mixed solution of 210ml of methanol and 80ml of toluene, add 59mg of Raney nickel, feed hydrogen to 1.6MPa, heat up to 60°C and react for 4 hours, cool down and filter to remove the catalyst, distill off the solvent to obtain a light yellow solid X, directly used in the next reaction without purification.

[0044] 3) Preparation of condensation catalyst

[0045] Add 500ml of toluene to 30g of MCM-41 and stir; Step 2) Dissolve X3g of the product in 100ml of toluene, then add it to the suspension of MCM-41 under stirring, heat a...

Embodiment 3

[0049] 1) Preparation of N-Cbz-4-(2-triethoxysilylethylcarbamoyl)oxa-L-proline benzyl ester IX

[0050] Triethoxysilylethyl isocyanate VII 11.8 g and N-Cbz-4-hydroxy-L-proline benzyl ester VIII 17.8 g in the solvent cyclohexane. React at 50°C for 7h, evaporate the solvent to dryness and directly use in the next reaction;

[0051] 2) Preparation of 4-(2-triethoxysilylethylcarbamoyl)oxa-L-proline X

[0052] Step 1) Add 100 g of product IX to a mixed solution of 350 ml of ethanol and 120 ml of toluene, add 100 mg of palladium carbon, feed hydrogen gas to 0.8 MPa, heat up to 75 ° C for 2 hours, cool down and filter to remove the catalyst, and distill off the solvent to obtain a light yellow solid X , directly used in the next reaction without purification.

[0053] 3) Preparation of condensation catalyst

[0054] Add 500ml of toluene to 30g of MCM-41 and stir; Step 2) Dissolve X3g of the product in 100ml of toluene, then add it to the suspension of MCM-41 under stirring, heat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com