Vertical mill feeding chute device with fluidization function

A function and feeding technology, applied in the direction of grain processing, etc., can solve the problems of increasing the workload of the vertical mill, energy waste, and reducing the working efficiency of the vertical mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The core of the invention is to provide a vertical mill feeding chute device with a fluidization function.

[0027] Below in conjunction with accompanying drawing, content of the present invention will be further described:

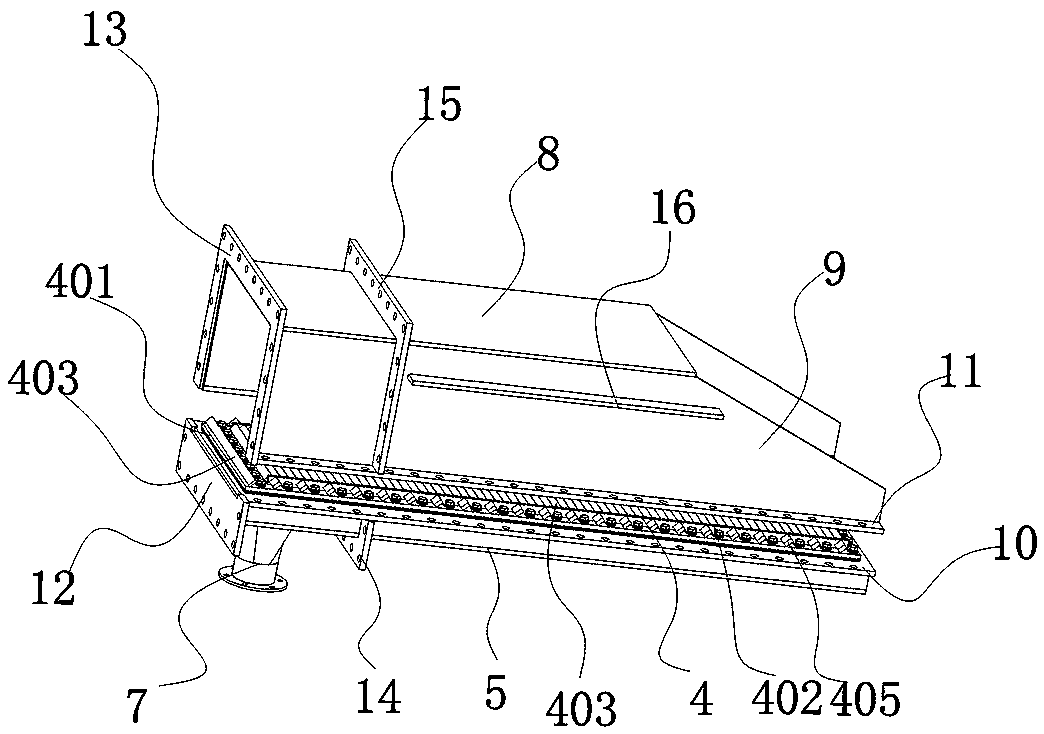

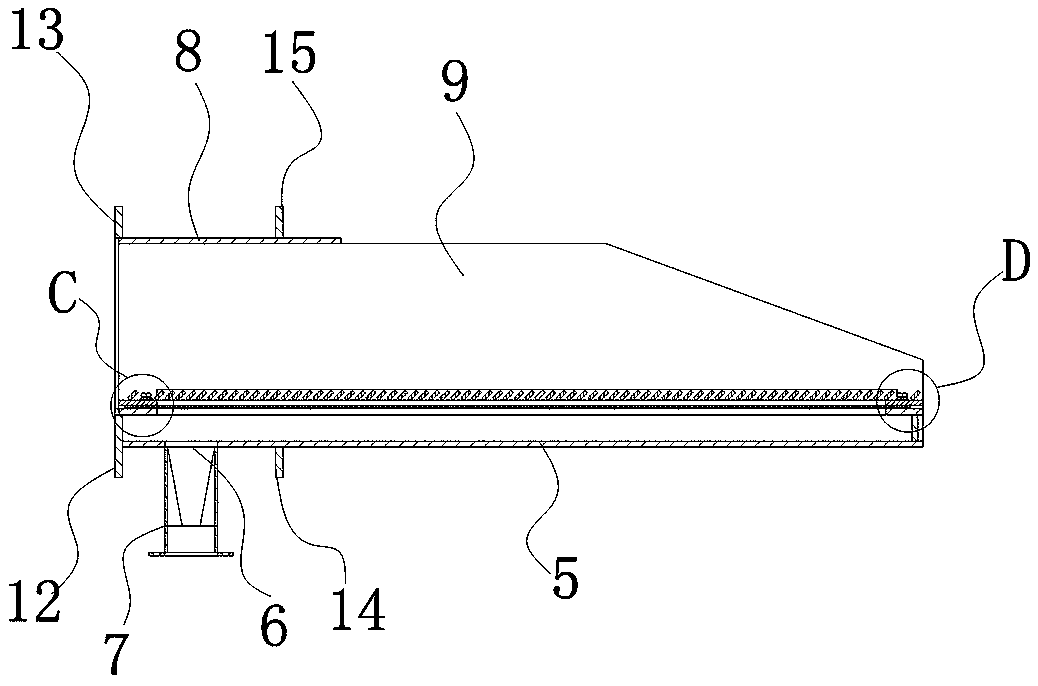

[0028] A vertical mill feed chute device with fluidization function, such as Figure 1~7As shown, it includes the lower assembly and the upper assembly set above the lower assembly, and the lower assembly and the upper assembly are connected by bolts;

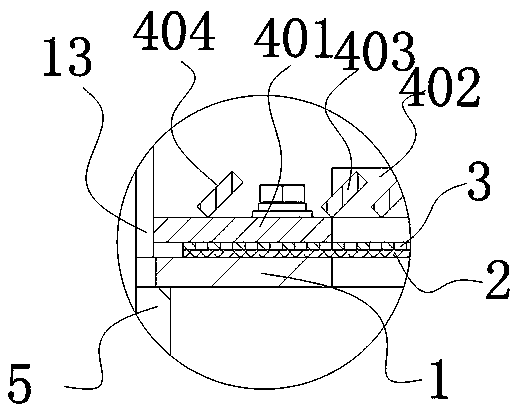

[0029] Wherein the lower assembly comprises an upper plate 1 of a rectangular plate-like structure, the upper plate 1 is provided with a rectangular first air vent, the first air vent is arranged along the long direction of the upper plate 1, and the upper plate 1 is located at the first air vent On the top, there are breathable cloth 2, cloth protection net 3 and protective grille 4 in sequence from bottom to top. The opening of the cloth protection net used is a square hole with a diameter of 5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com