Patents

Literature

33results about How to "Guaranteed vulcanization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-elasticity wear-resistant dual-density in-mold foaming rubber tire and manufacturing process thereof

ActiveCN109318445AIncrease elasticitySlow down elastic fatigue decayWith separate inflatable insertsWith multiple inflatable chambersRubber materialHigh density

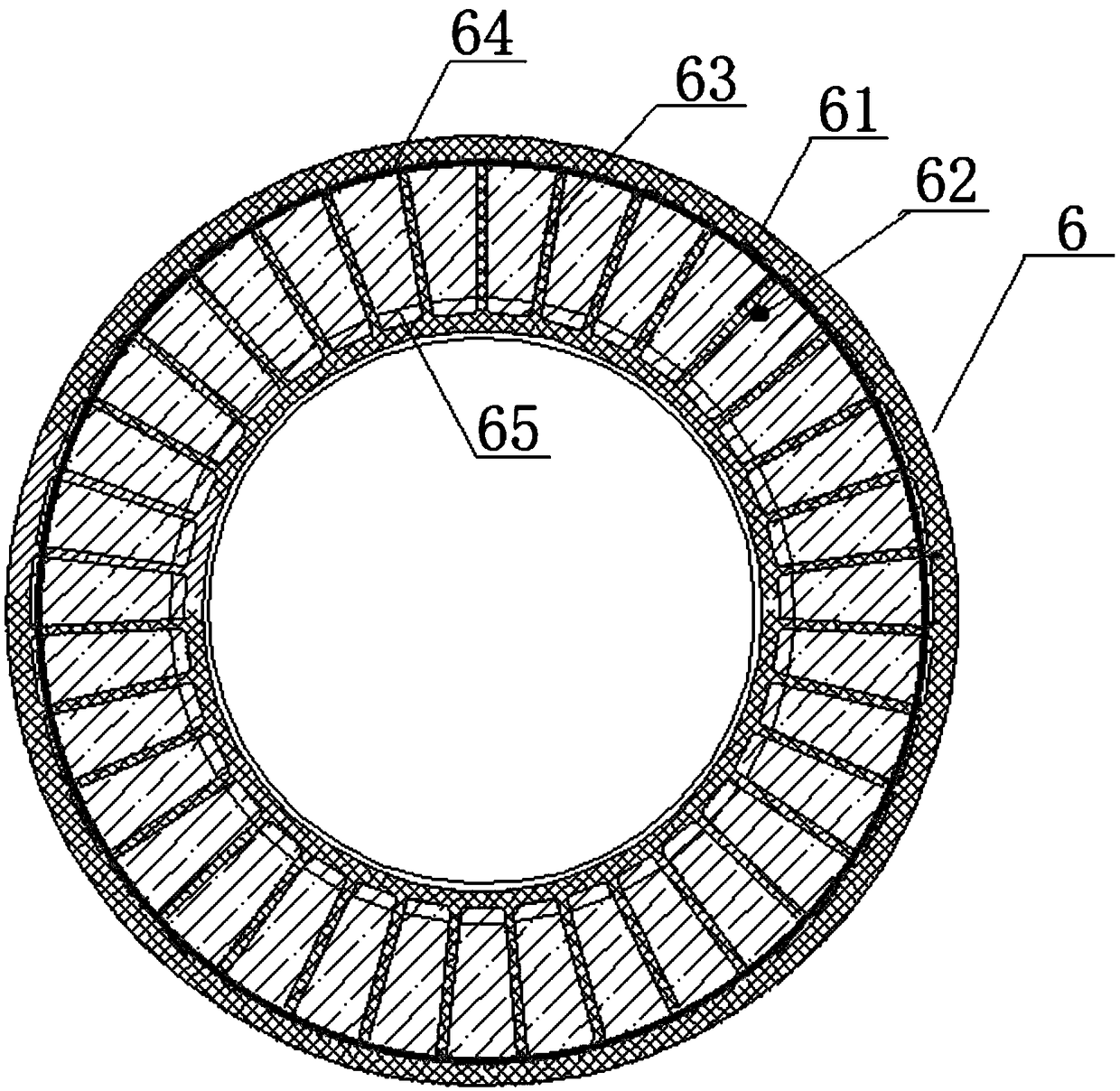

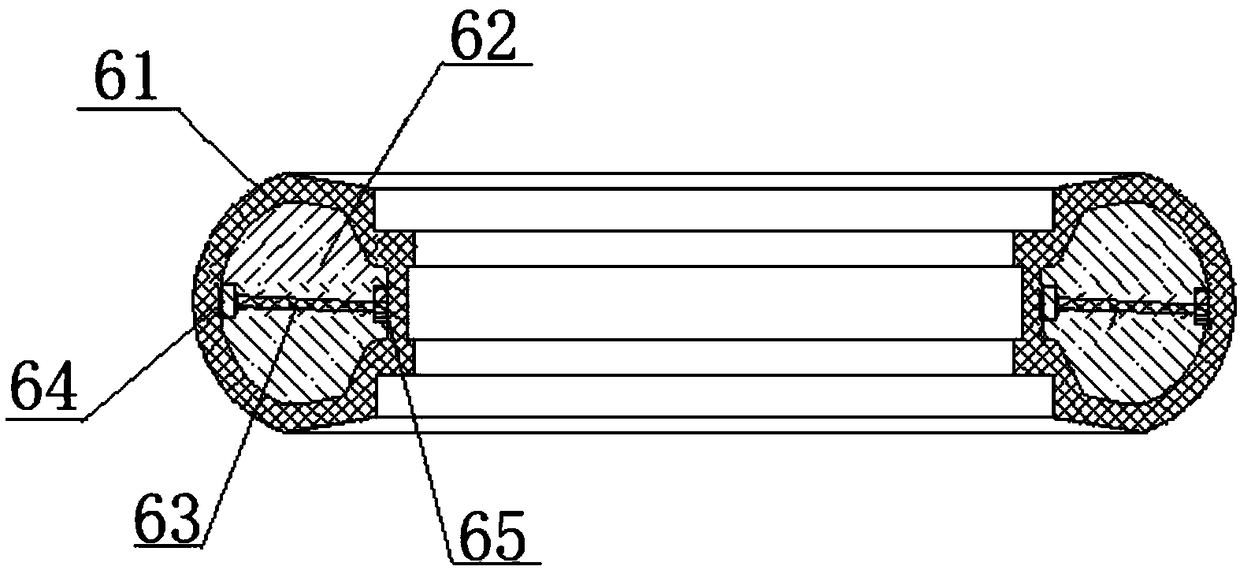

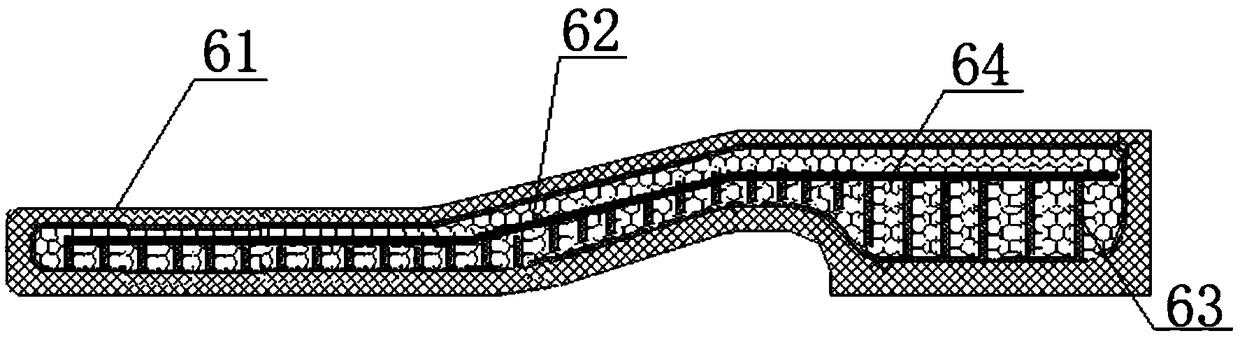

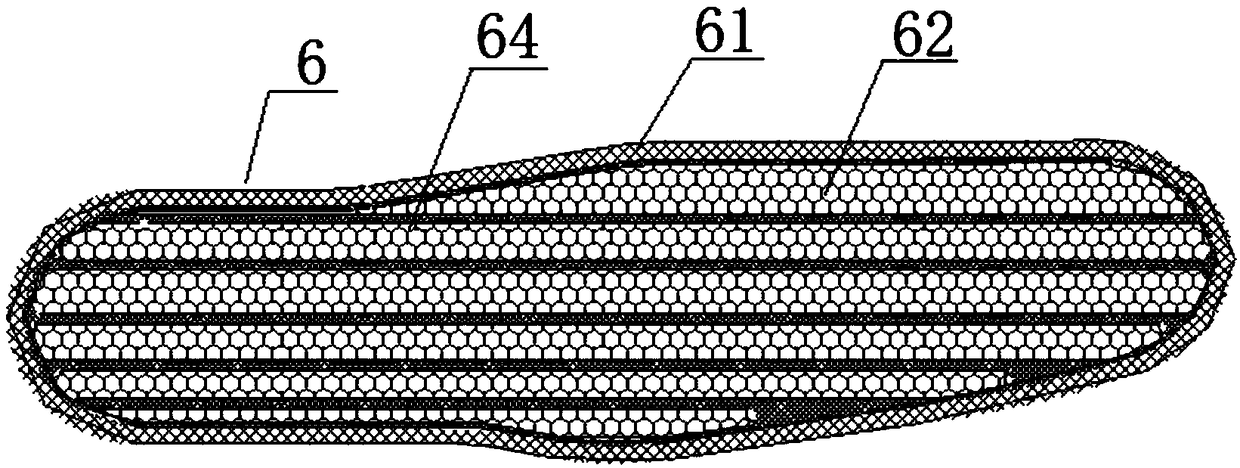

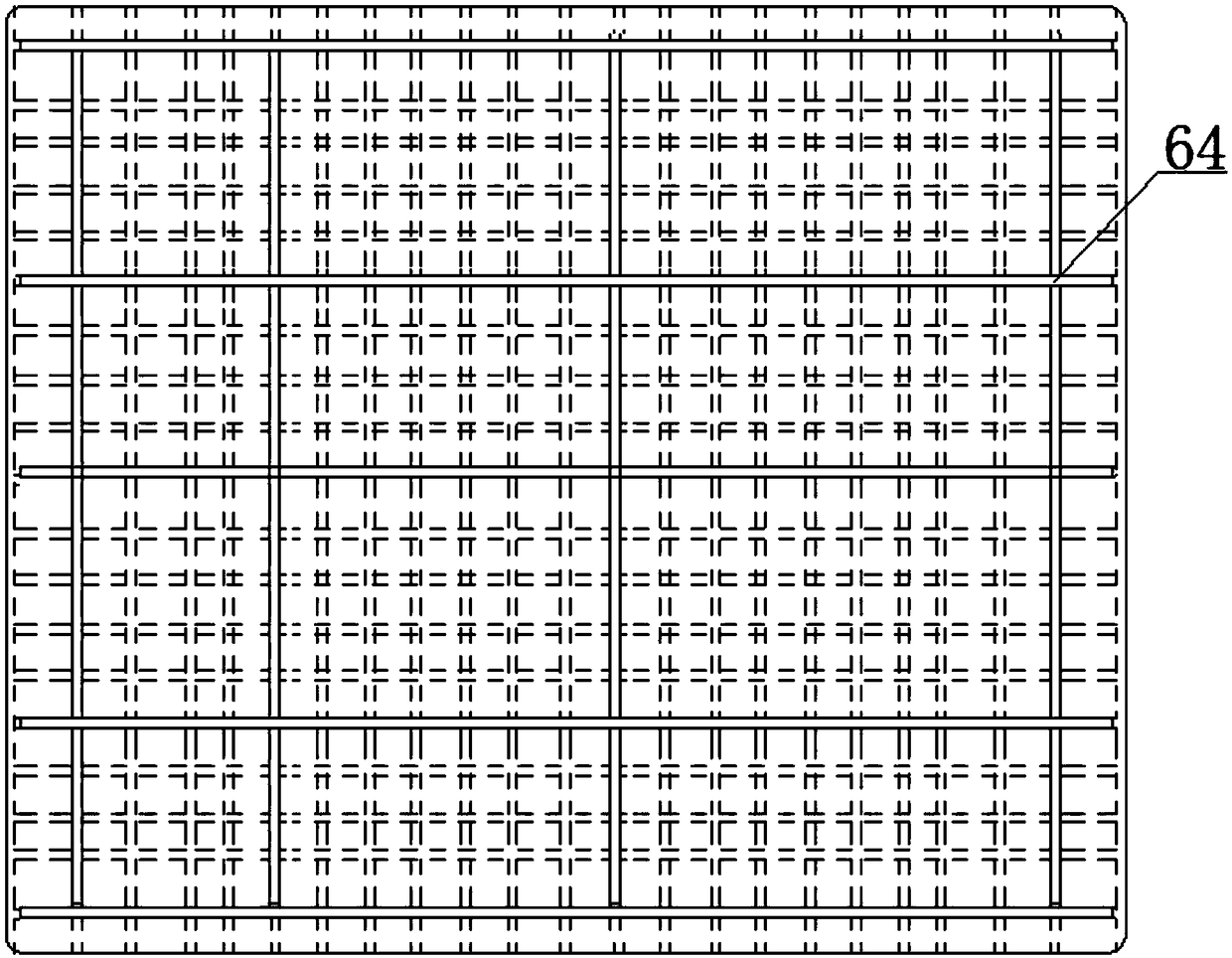

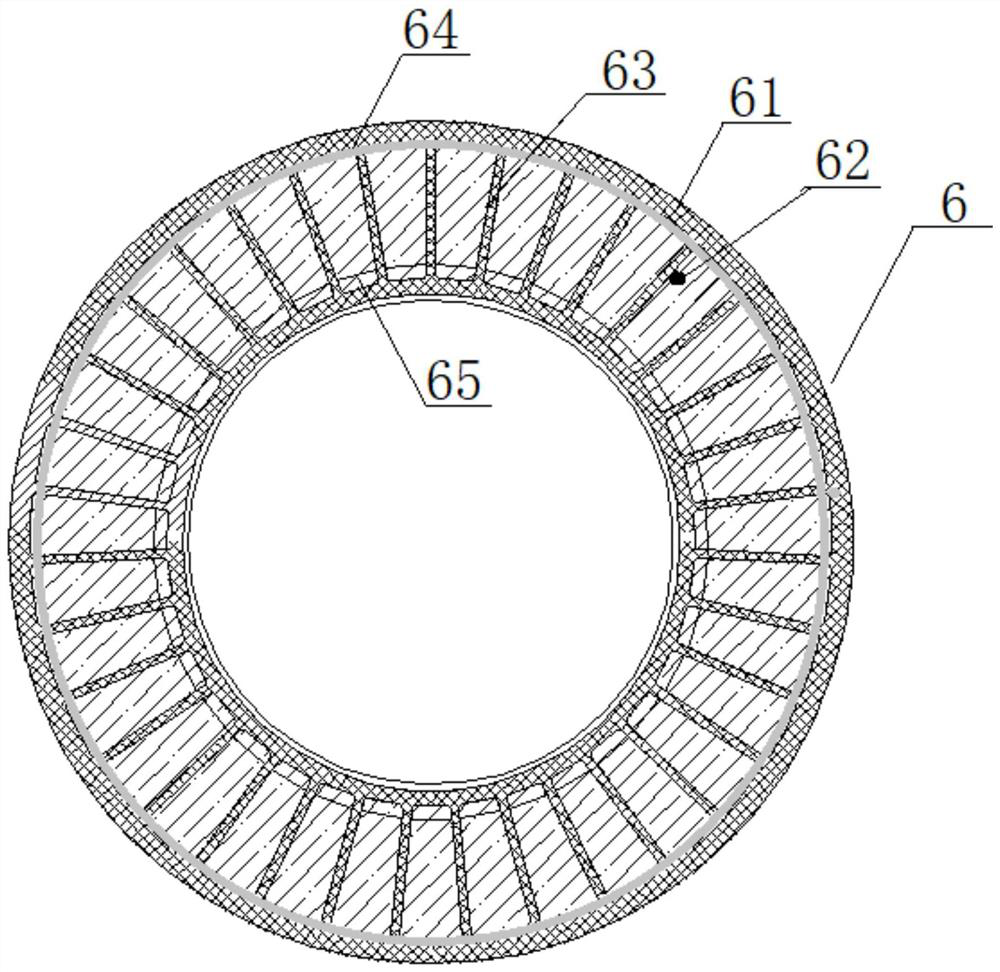

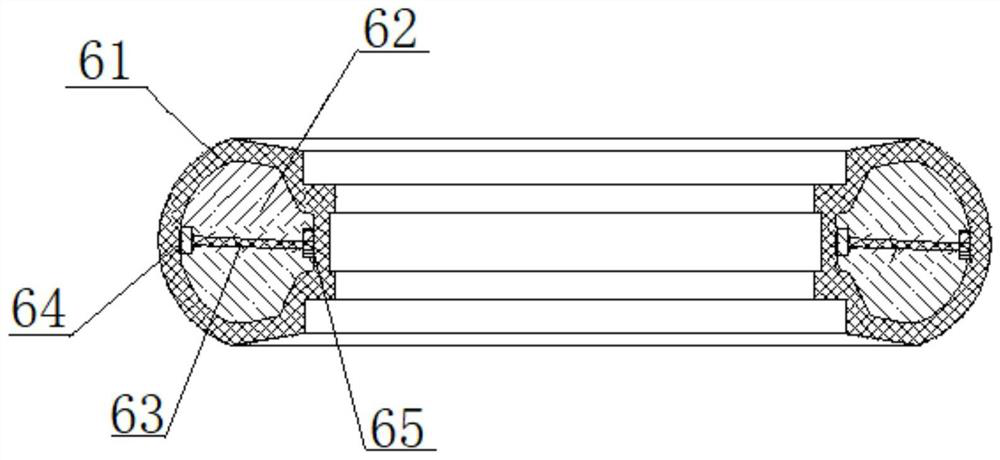

The invention discloses a high-elasticity wear-resistant dual-density in-mold foaming rubber tire and a manufacturing process of the high-elasticity wear-resistant dual-density in-mold foaming rubbertire, and belongs to the technical field of rubber product processes. The high-elasticity wear-resistant dual-density in-mold foaming rubber tire comprises a high-density outer layer and a low-densityinner layer, and is of an integrated structure with the same mold for discharging. The high-density outer layer and the low-density inner layer are made of high-density rubber materials and low-density rubber materials correspondingly. Spring supports in a radial state are uniformly embedded in the low-density inner layer so as to play the role of framework support, and the elasticity of springscan be selected to be consistent with the elasticity of low-density rubber so as to enhance the supporting strength of the low-density inner layer. In addition, a dual-density bi-directional injectionin-mold forming-vulcanizing tire production system is applied to complete dual-density glue bi-directional injection, foaming and vulcanizing processes in one mold and obtain the manufactured tire. The problems of the insufficient elasticity of a rubber tire, the separate operation of injection, foaming and vulcanizing of a dual-density tire, energy consumption, time consumption and the high costare solved.

Owner:东营睿港招商服务有限责任公司

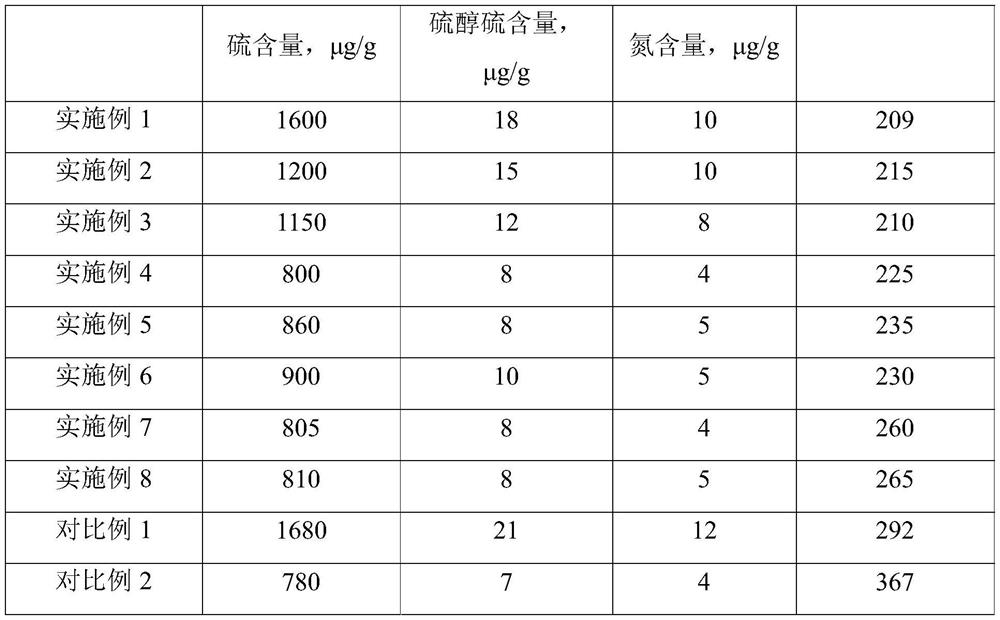

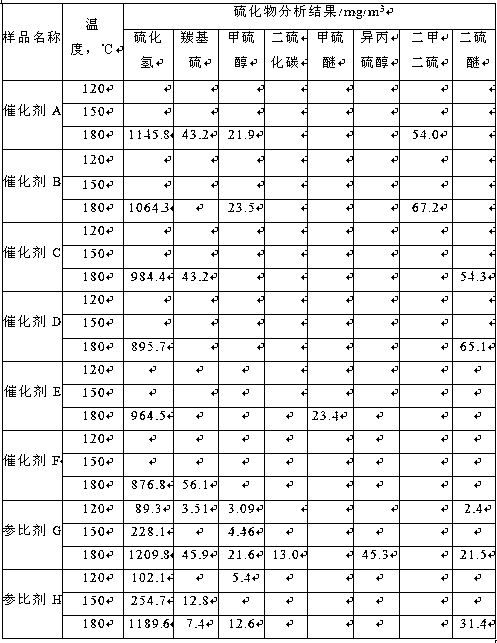

Wet startup sulfuration method of hydrocracking unit

ActiveCN103102929AGreat effect on activityGuaranteed vulcanization effectHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

The invention relates to a wet startup sulfuration method of a hydrocracking unit. The method comprises the following steps that: (a) light fraction startup oil is introduced at a low temperature; (b) a vulcanizing agent is introduced when a temperature at an inlet of a reactor reaches a decomposition temperature of the vulcanizing agent; (c) after hydrogen sulfide penetrates a catalyst bed in the reactor, heating is carried out according to a conventional hydrogenation catalyst sulfuration process, then heavy fraction sulfur-containing startup oil is introduced instead when the catalyst bed reaches a temperature of 235 to 300 DEG C, liquefied ammonia is introduced at the same time, and introduction of the vulcanizing agent is stopped; (d) after introduction of the heavy fraction sulfur-containing startup oil, final sulfuration of a catalyst is completed by using hydrogen sulfide obtained in a hydrogenolysis reaction of a sulfide in the startup oil; and (e) raw oil is directly introduced instead step by step after sulfuration is finished, and when 60 to 85% of raw oil is introduced, introduction of liquefied ammonia is stopped and normal production is started. Compared with the prior art, the method provided by the invention enables startup time to be shortened while guaranteeing performance of the catalyst and realizes safe and smooth startup.

Owner:CHINA PETROLEUM & CHEM CORP +1

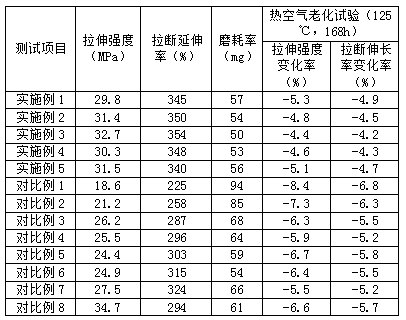

Heat-conducting and shock-absorbing rubber material and preparation method thereof

InactiveCN111825890AGuaranteed performanceVulcanization temperature ensuresHeat-exchange elementsRubber materialPolymer science

The invention provides a heat-conducting and shock-absorbing rubber material, and is used for preparing the rubber shock absorption product with the thickness larger than 25 mm. The heat-conducting and shock-absorbing rubber material comprises the following components in parts by weight: 70-100 parts of natural rubber, 0-30 parts of synthetic diene rubber, 10-30 parts of carbon black, 3-10 parts of a plasticizer, 0.5-2 parts of an anti-aging agent RD, 0.5-3 parts of an anti-aging agent 4020, 3-5 parts of zinc oxide, 0.5-2 parts of stearic acid, 1-8 parts of carbon nanotubes, 50-80 parts of silane modified silica, 1.0-1.8 parts of sulfur and 0.5-3 parts of a dithiophosphate accelerator. The invention also provides a preparation method of the heat-conducting and shock-absorbing rubber material, the vulcanization efficiency of the heat-conducting and shock-absorbing rubber material can be improved, and the quality problems of excessive vulcanization outside a product and insufficient vulcanization inside the product during vulcanization can be effectively solved.

Owner:NUOBO RUBBER PRODION

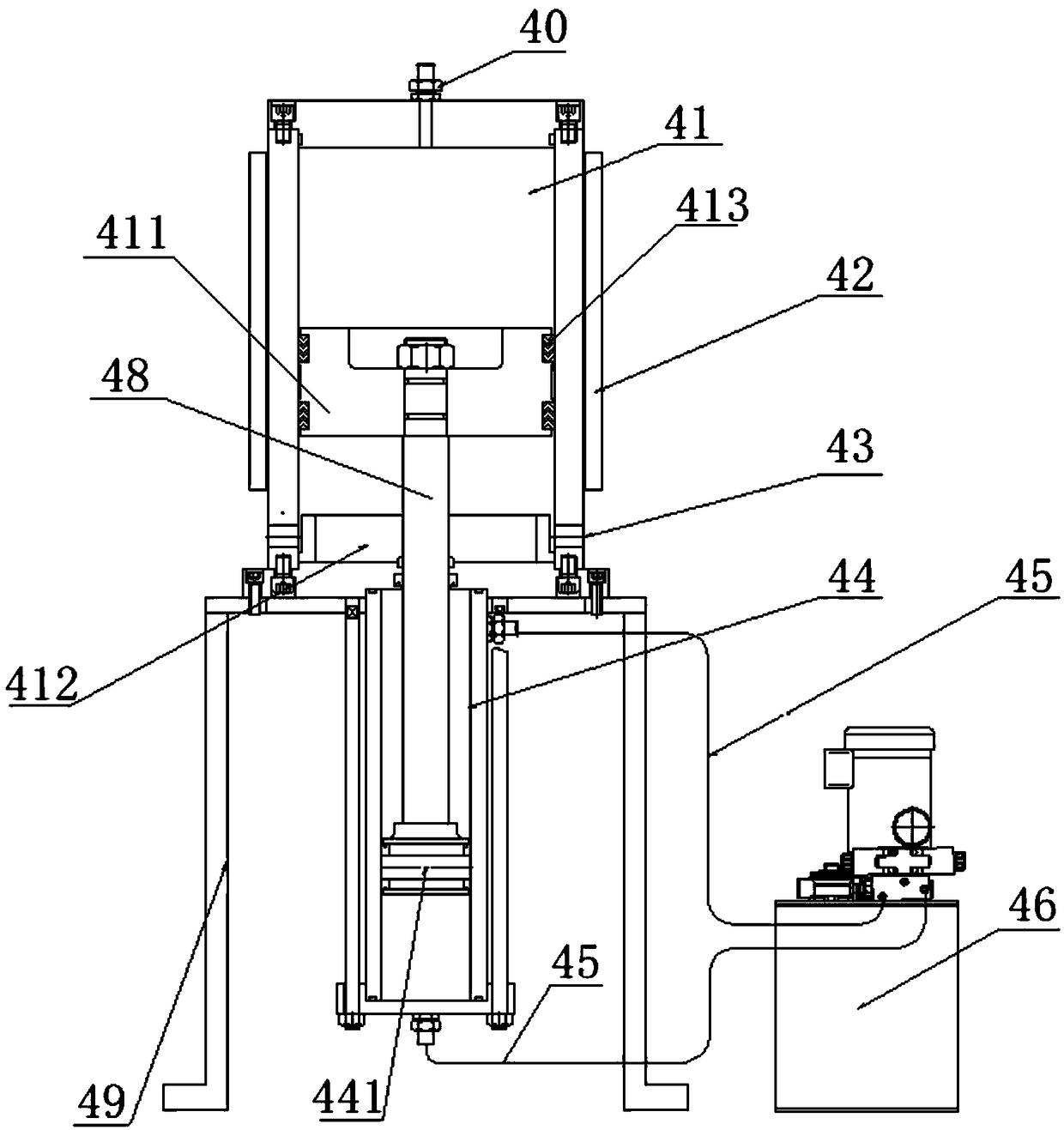

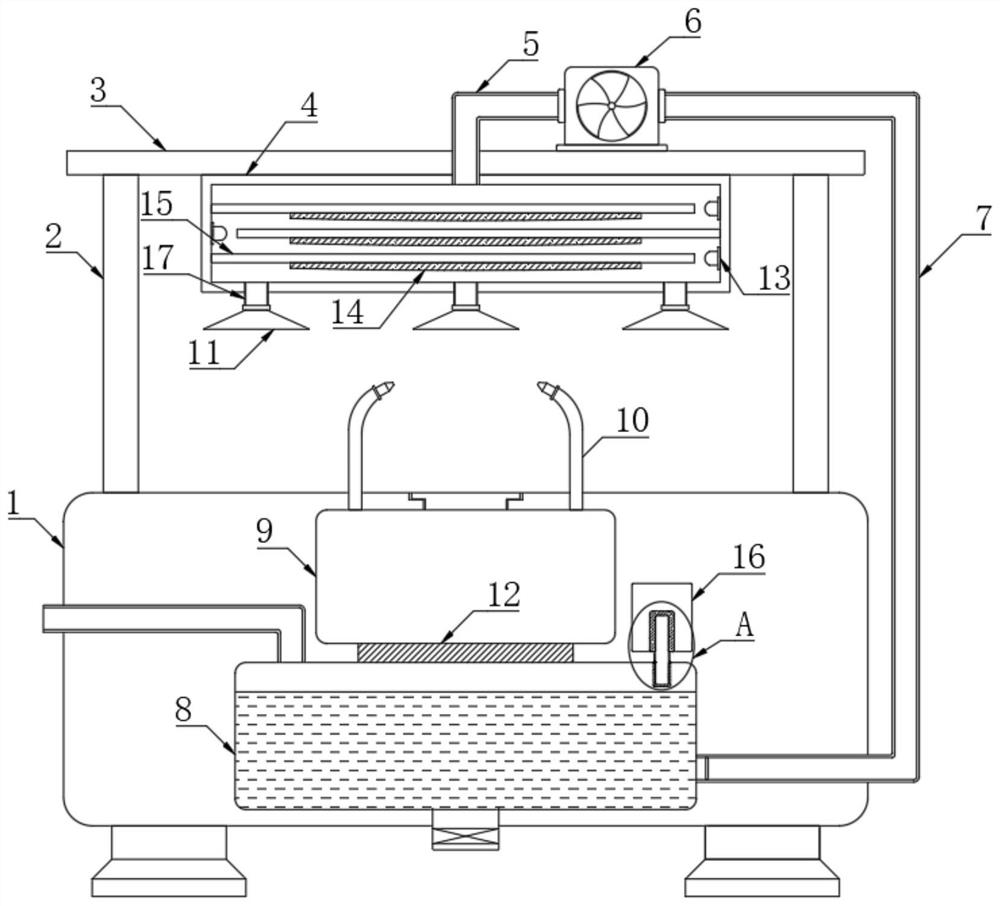

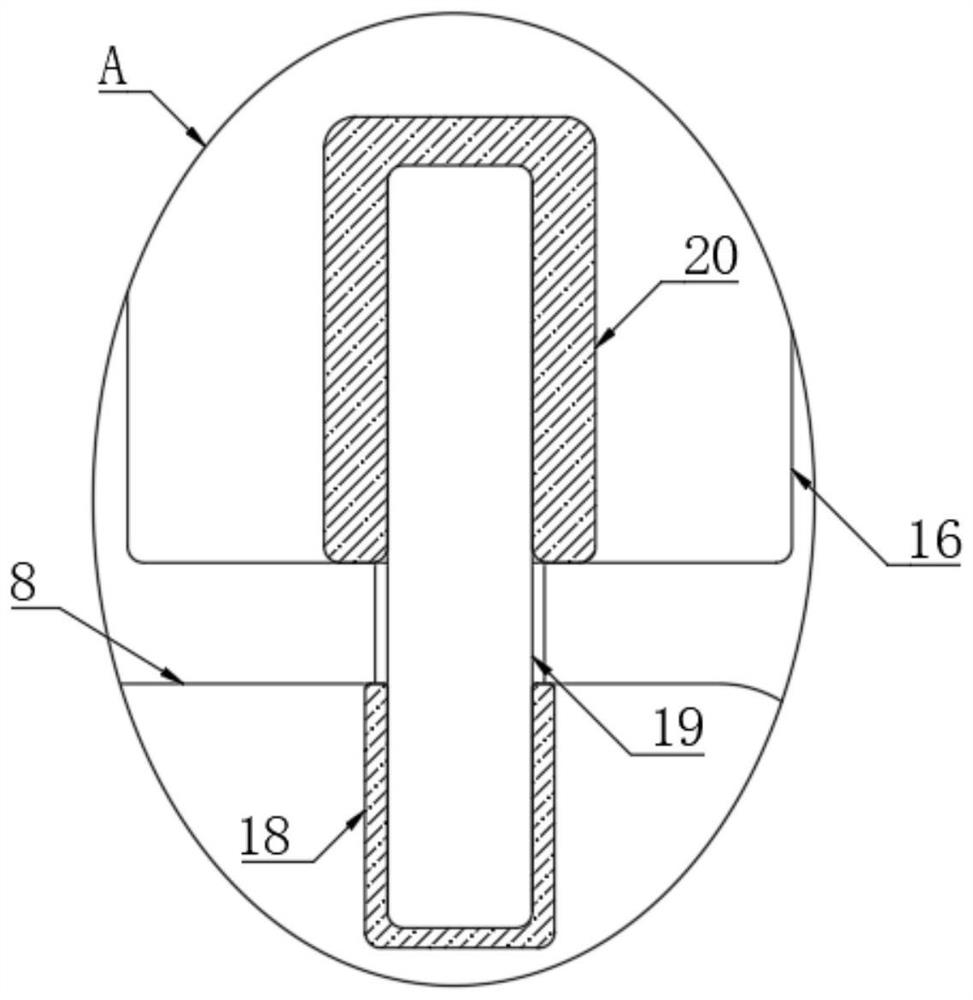

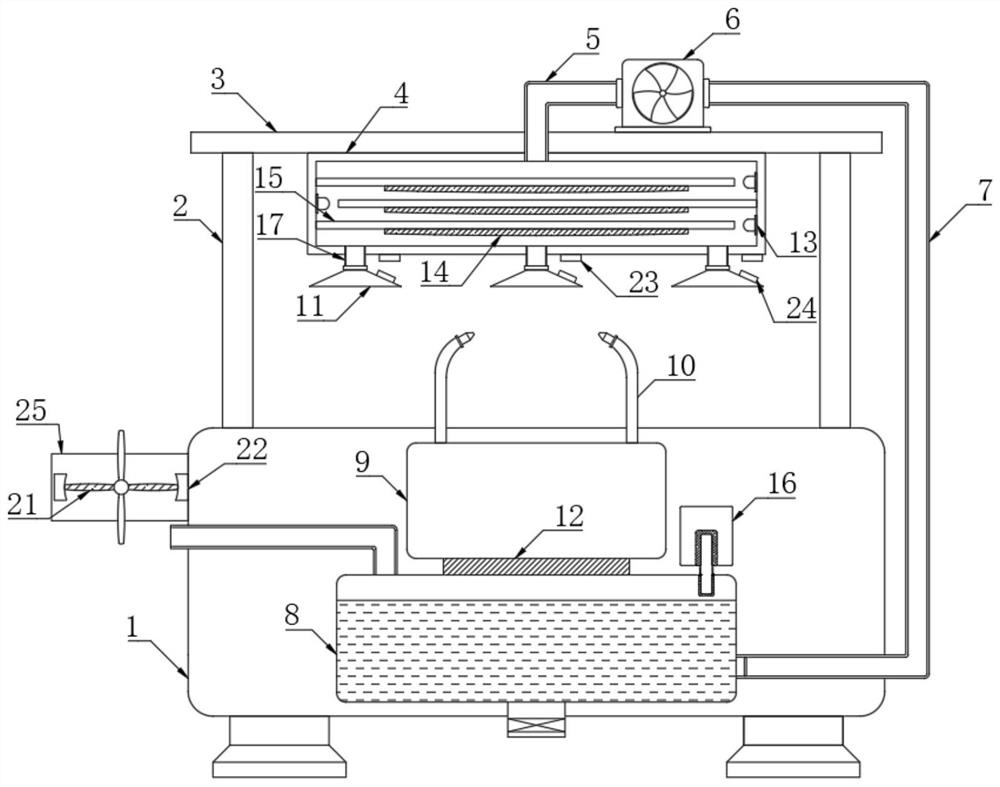

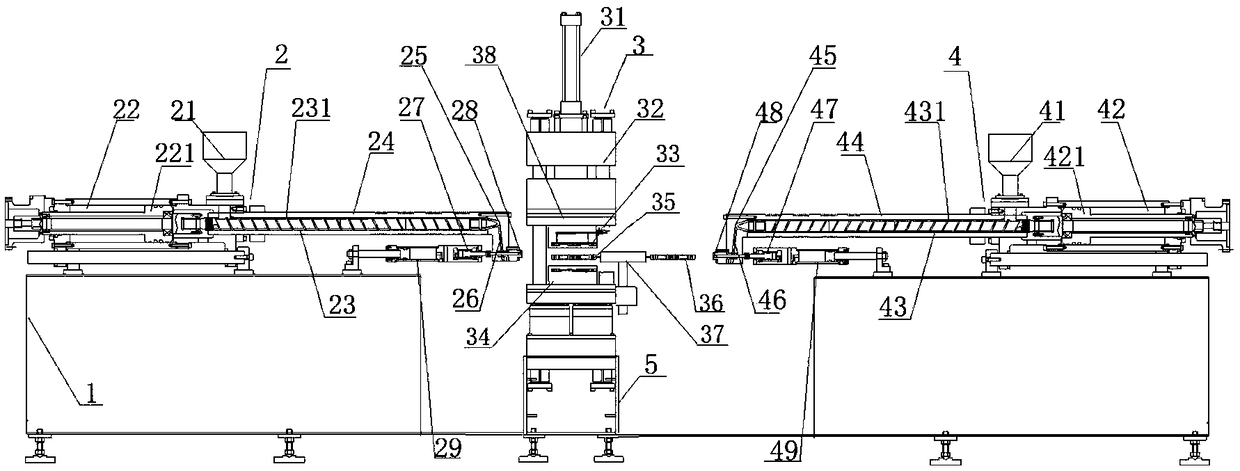

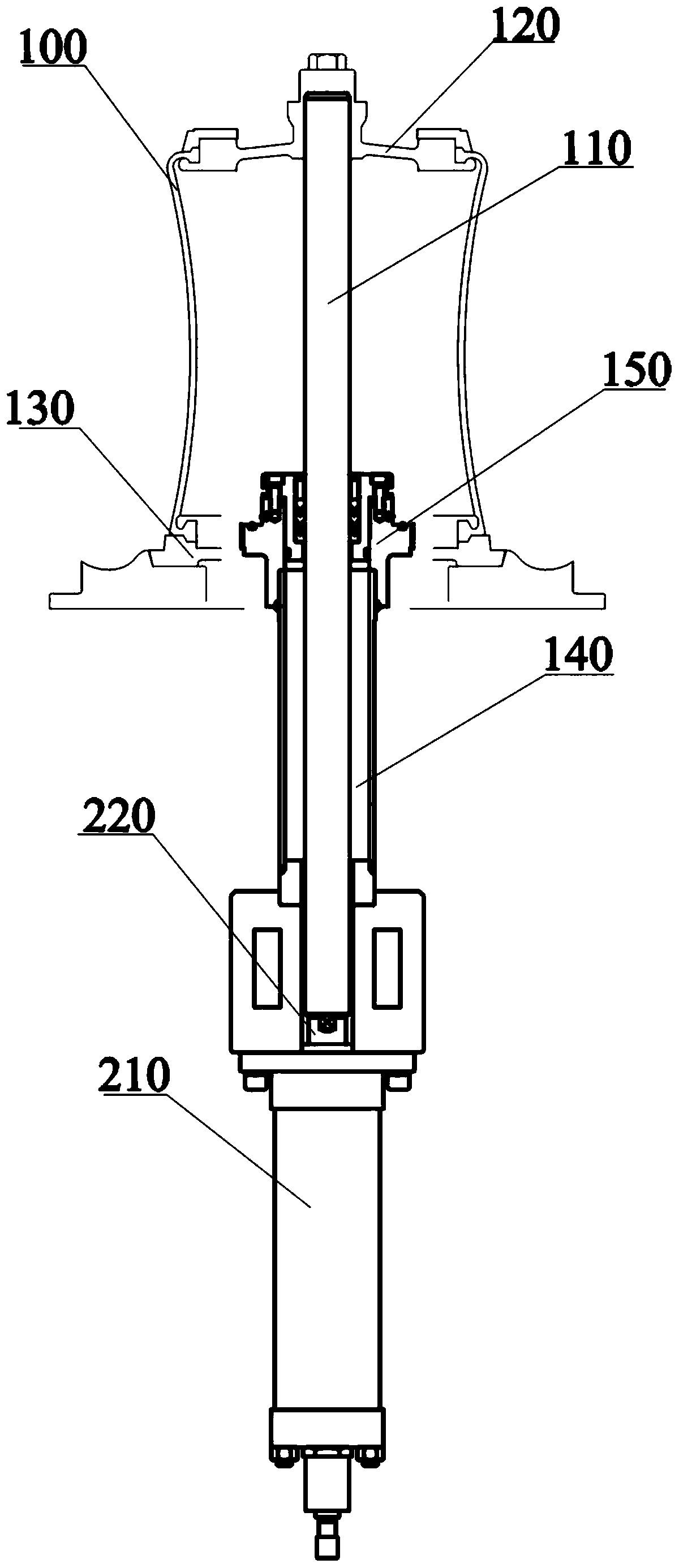

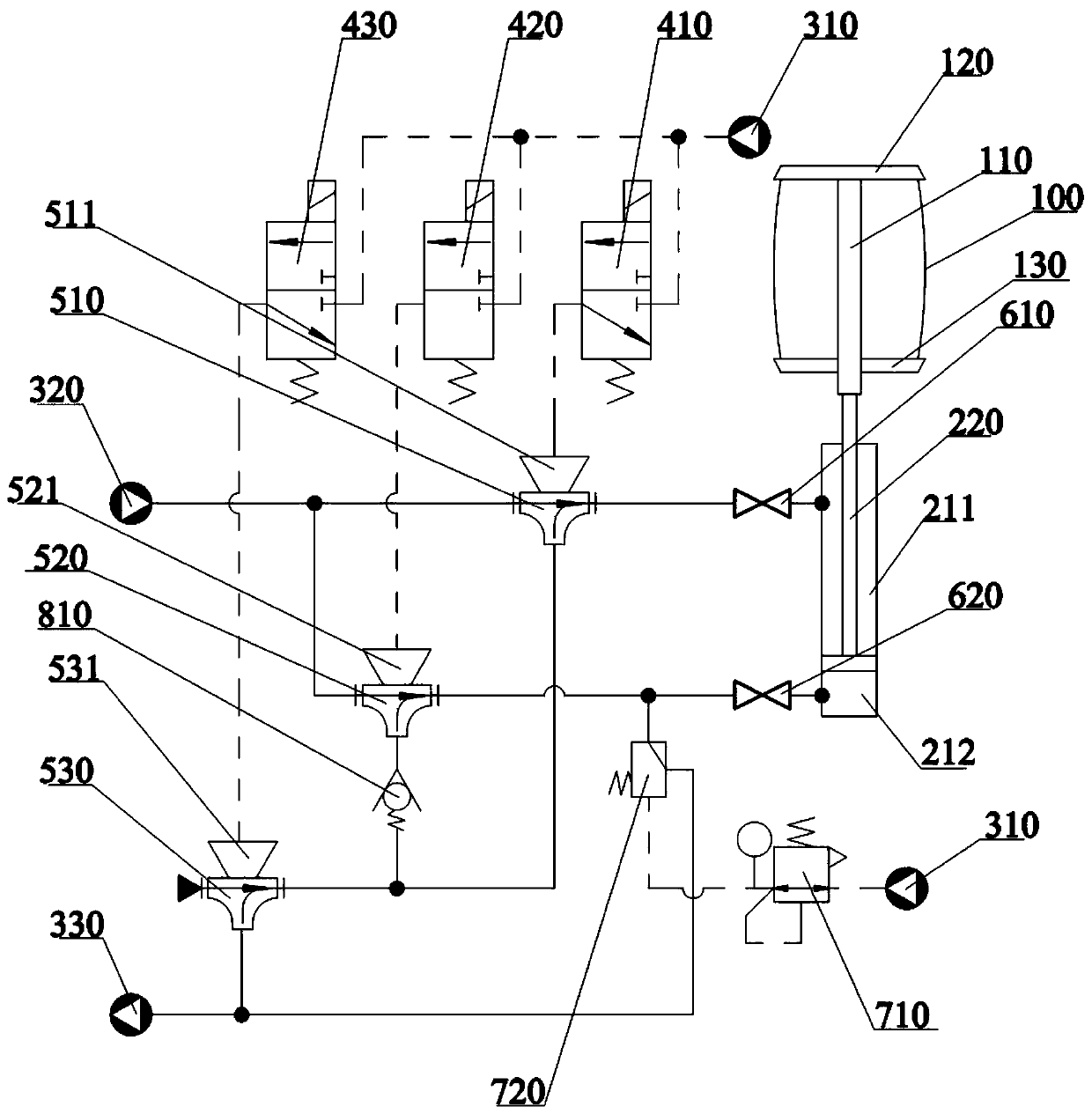

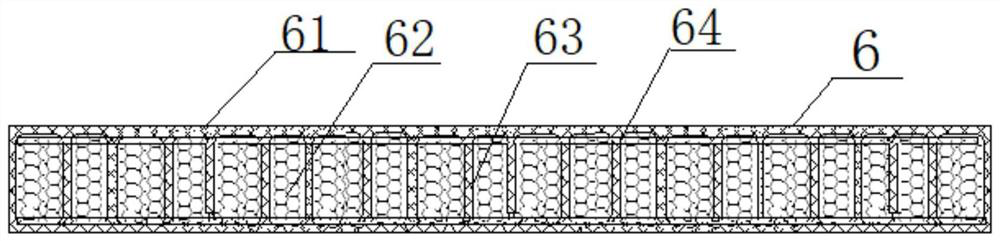

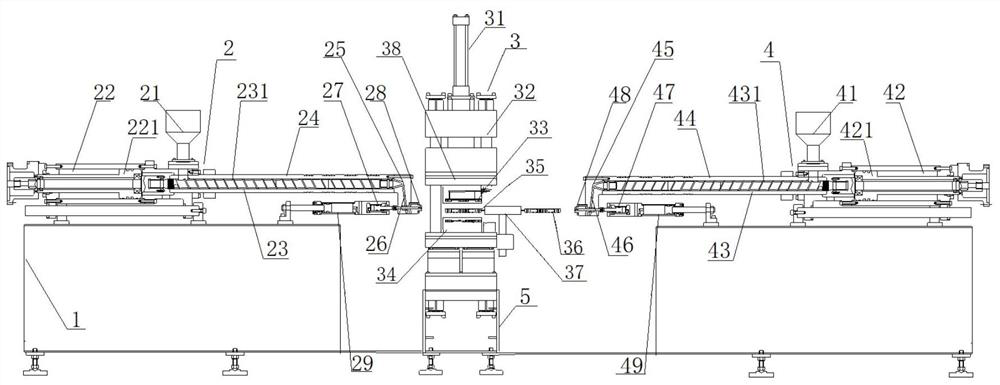

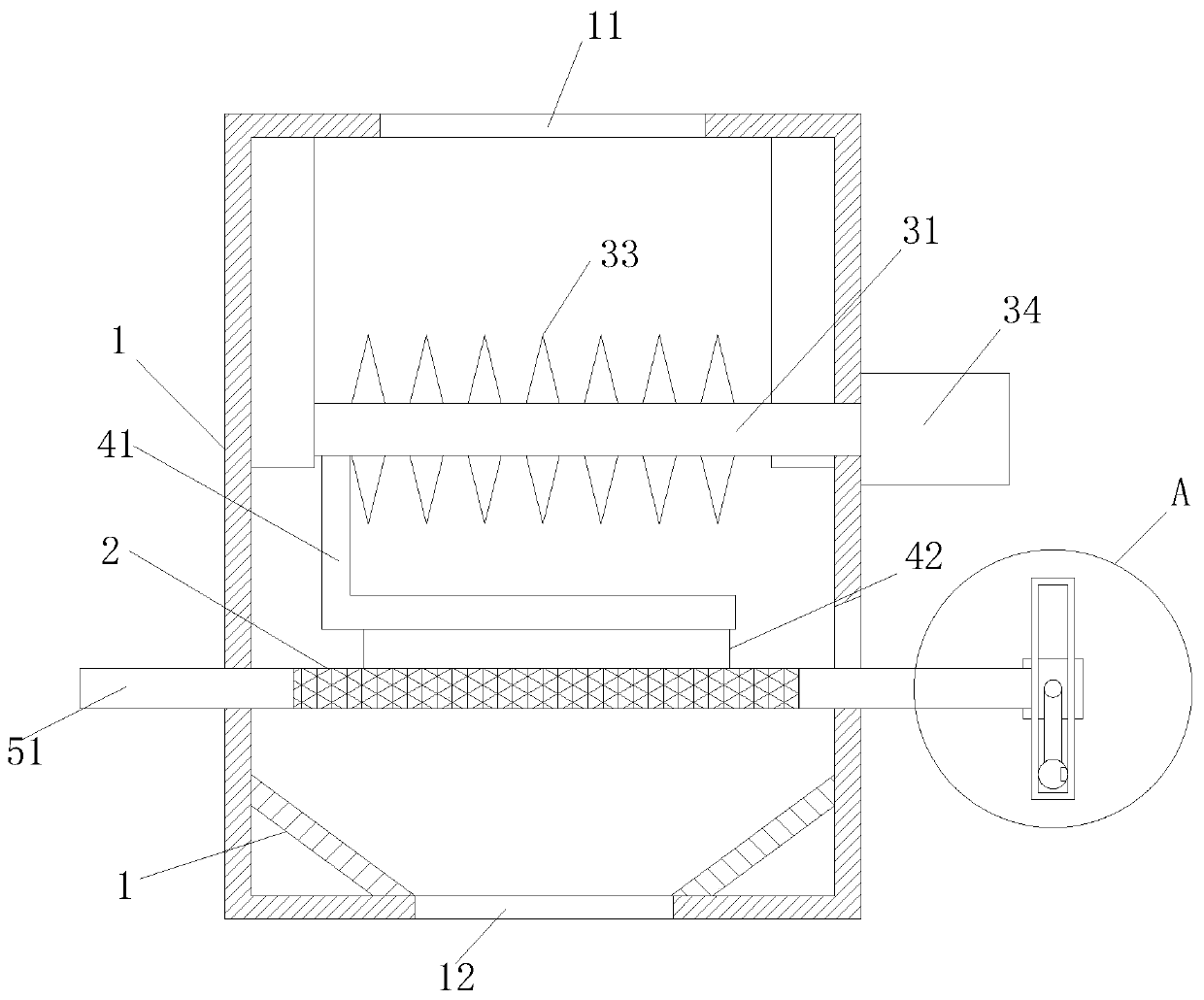

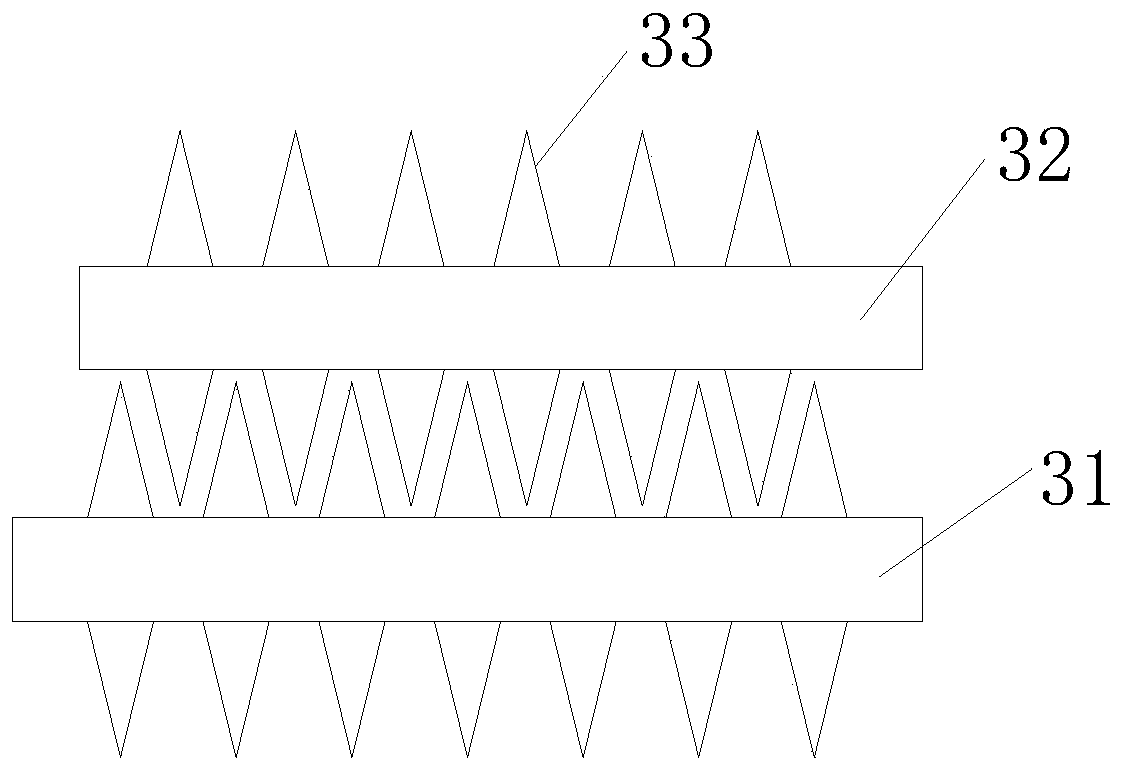

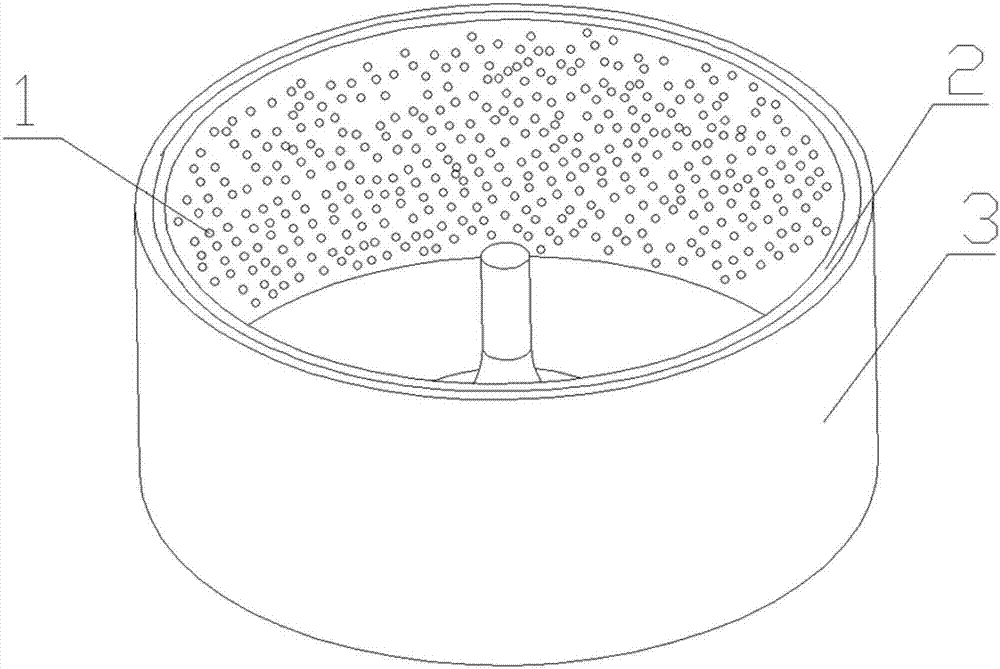

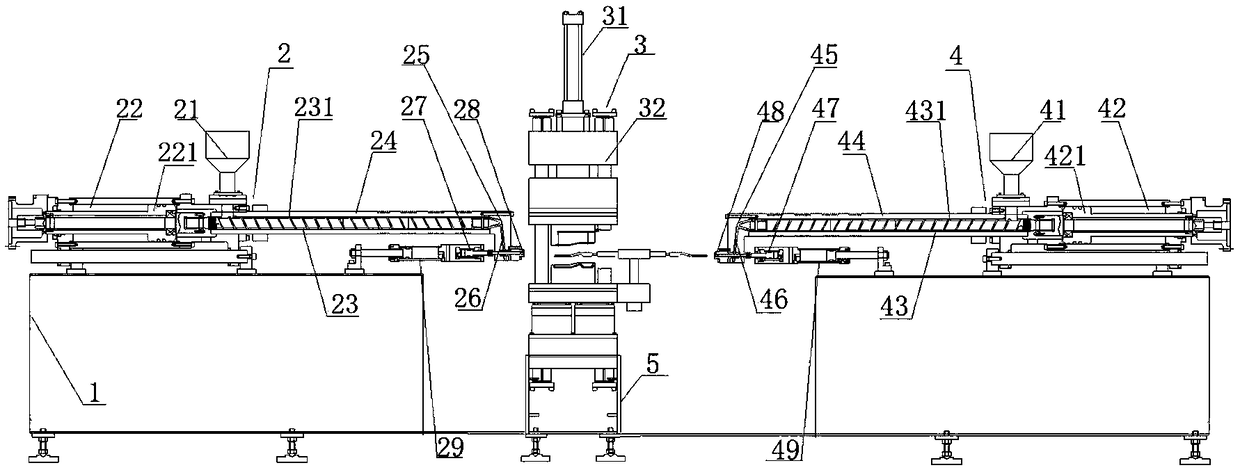

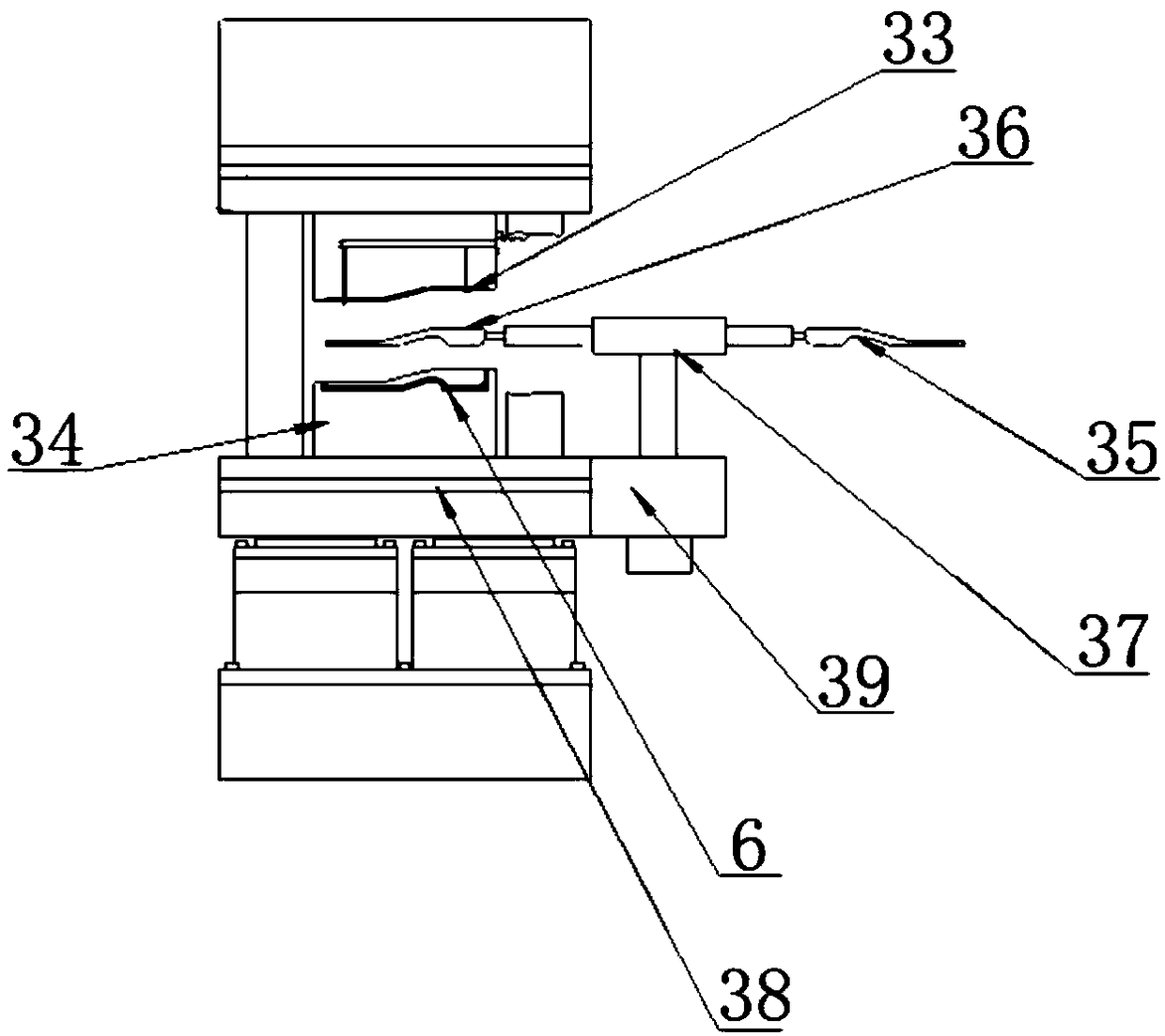

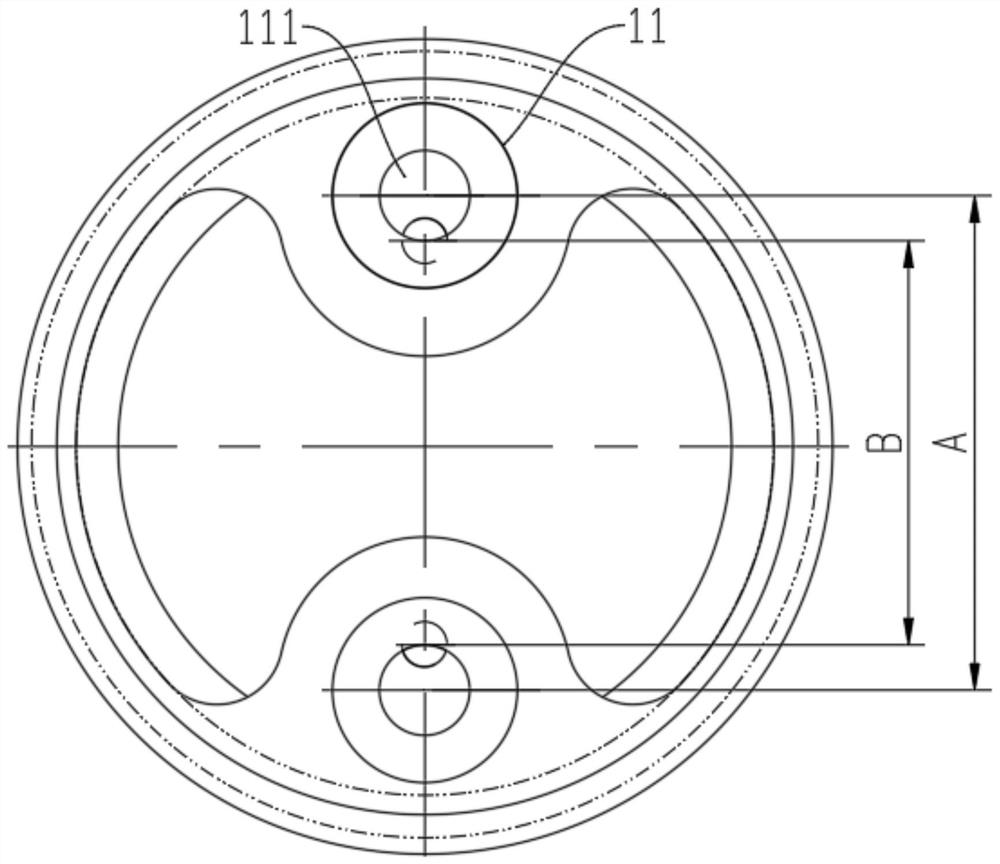

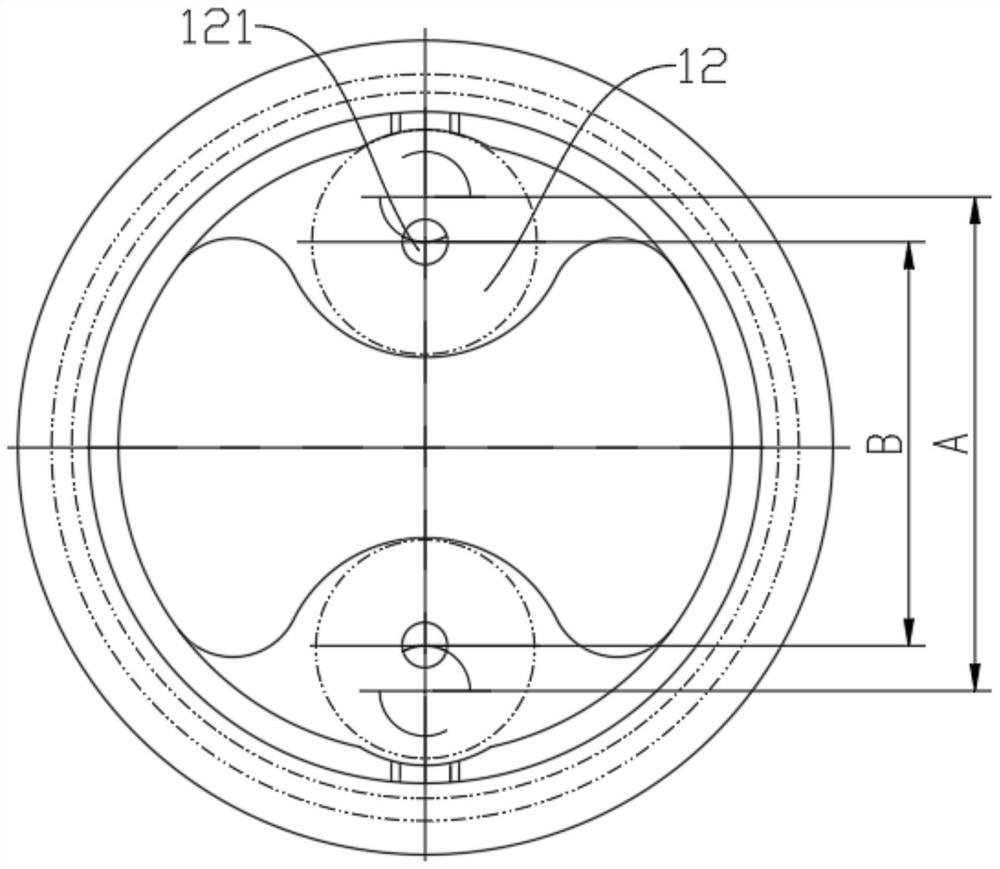

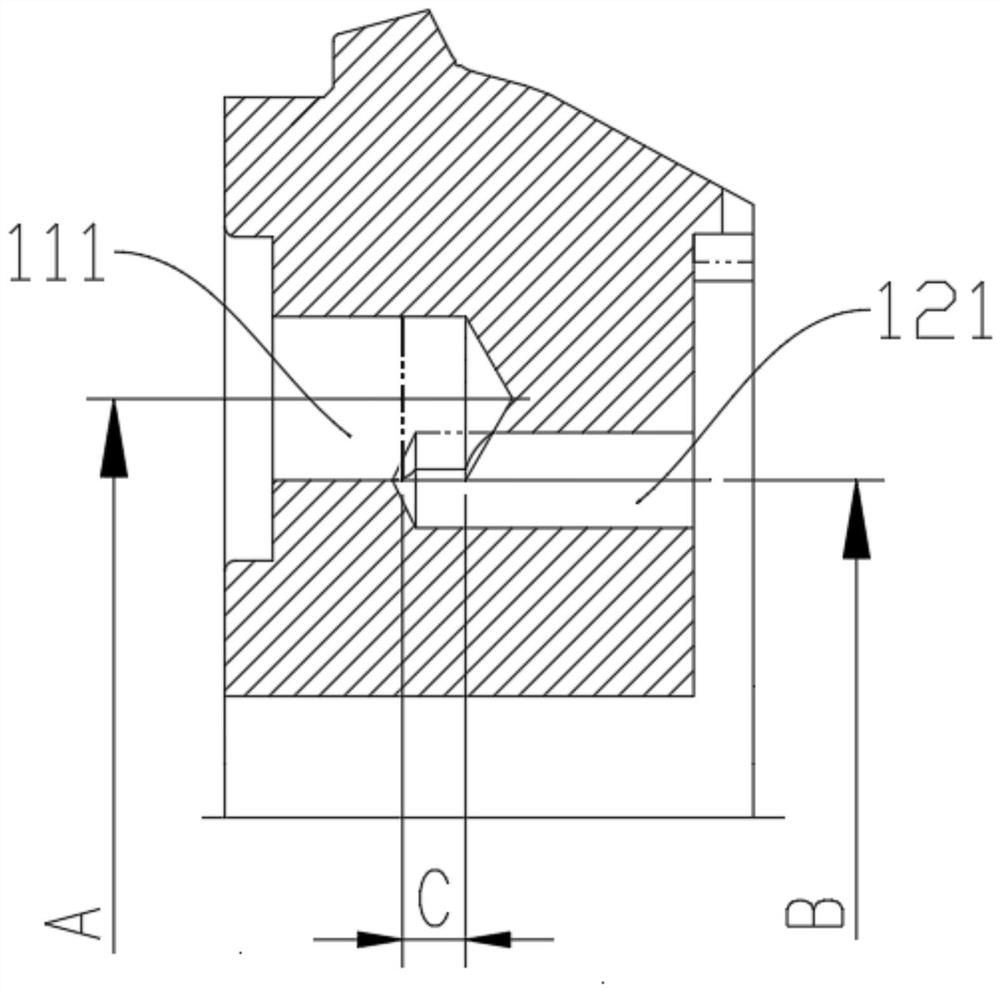

In-mold foaming forming system and technology for rubber double-density product

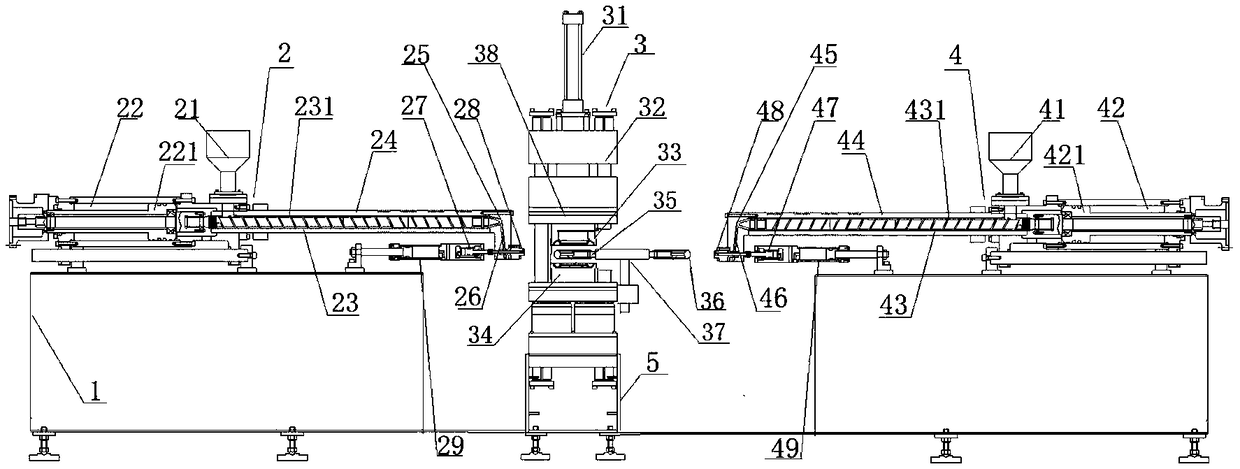

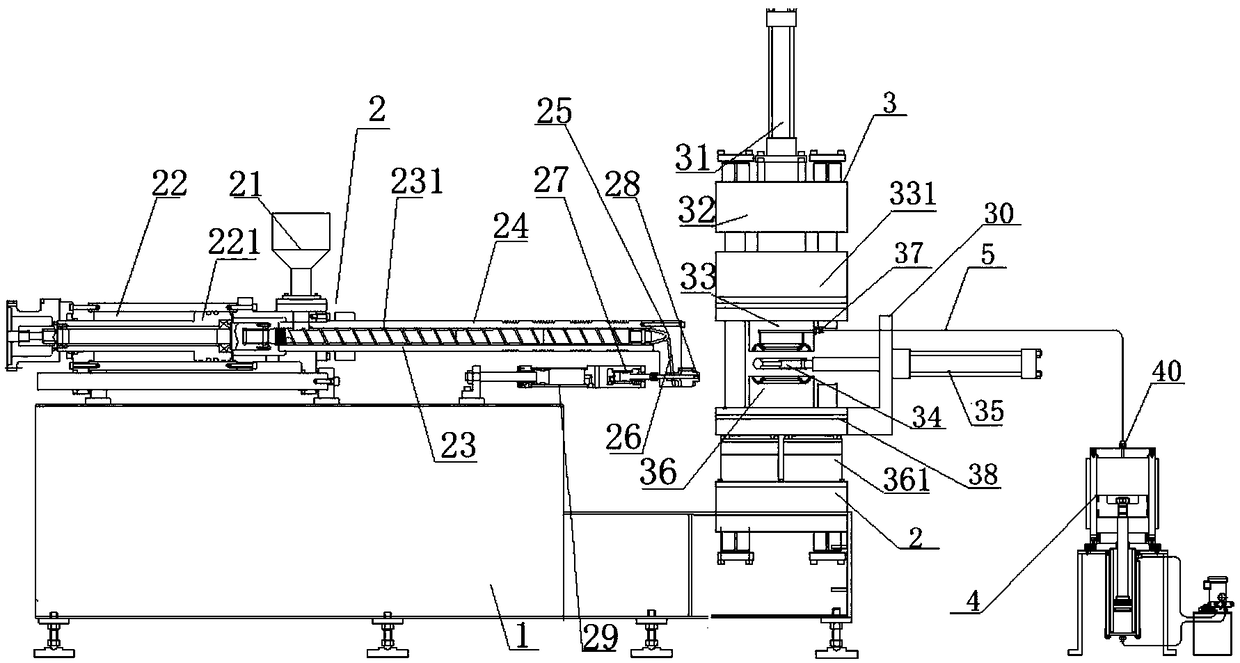

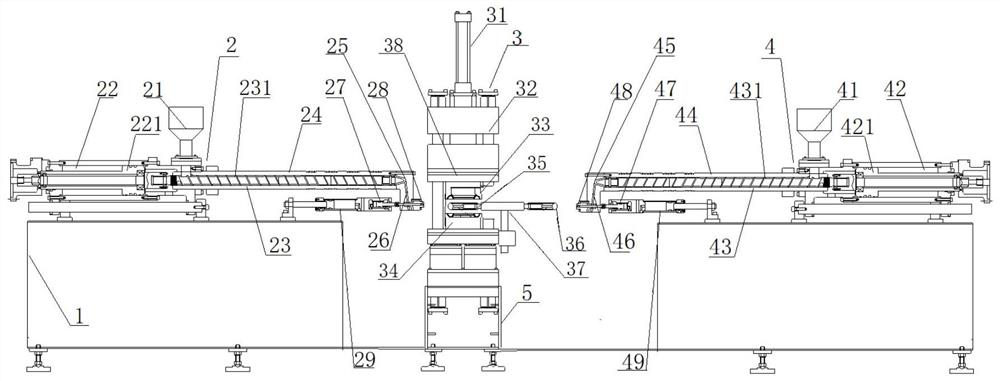

The invention discloses an in-mold foaming forming system and technology for a rubber double-density product, and belongs to the technical field of rubber product technologies. The system comprises amold exhaust and hollow inflation mechanism, and further comprises an injection machine base, a foaming and vulcanization molding pedestal, an injection device and a foaming and vulcanization moldingdevice, wherein the injection device and the foaming and vulcanization molding device are fixed to the injection machine base and the foaming and vulcanization molding pedestal, wherein the injectiondevice is communicated with a mold of the foaming and vulcanization molding device correspondingly; the mold exhaust and hollow inflation mechanism comprises a support, an air cylinder, an oil cylinder body and a hydraulic station; the support is an annular rack with a through hole in the middle; the air cylinder is fixed to an annular table board of the support; the oil cylinder body is fixed tothe bottom of the annular table board of the support; the air cylinder and the oil cylinder body are internally connected with a cylinder piston and an oil cylinder piston of a piston rod correspondingly; and the top of the air cylinder communicates with an inner cavity of a mold of the foaming and vulcanization molding device through an air pipe. According to the system and the technology, injection, foaming and vulcanization of the rubber product can be completed in one mold, the circulation of the product in each process is avoided, and therefore the production cost is lowered.

Owner:安徽世界村智能装备有限公司

High-elastic double-density in-mold foamed rubber sole and production process thereof

InactiveCN109480381ASlow down elastic fatigue decayPlay a supporting roleSolesDomestic footwearHigh densityVulcanization

The invention discloses a high-elastic double-density in-mold foamed rubber sole and a production process thereof, and belongs to the technical field of rubber products. The rubber sole comprises a high-density outer layer and a low-density inner layer and is an integrated structure molded with a same mold; the high-density outer layer is made from high-density rubber, the low-density inner layeris made from low-density rubber, spring supports in a vertical state are buried in the low-density inner layer to achieve the functions of framework supporting, massage and healthcare, and the elasticity of springs can be selected to be consistent with that of the low-density rubber to strengthen the supporting strength of the low-density inner layer. The rubber sole is prepared by performing double-density rubber two-way injection, foaming and vulcanization in the mold by applying a double-density two-way injection in-mold foaming molding-vulcanization production system, and the problems aresolved that the elasticity of the rubber sole is insufficient, and separate operation of injection, foaming and vulcanization of the double-density sole consumes energy and time and is high in cost.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Gas purification method for vulcanization work of rubber tire

InactiveCN112107979AGuarantee air qualityKeep healthyGas treatmentDispersed particle separationVulcanizationProcess engineering

The invention discloses a gas purification method for vulcanization work of a rubber tire. The gas purification method comprises the following specific steps: air suction, reactive filtration, currentgeneration, and disinfection. The process of purification also involves a purification device. The purification device comprises a workbench, wherein a raw material cavity is arranged in the workbench; the inner wall of the raw material cavity communicates with two serpentine pipes; two supporting plates are fixedly connected to the upper side wall of the workbench; a mounting plate is fixedly connected to the upper side walls of the two supporting plates jointly; a filter box is fixedly connected to the lower side wall of the mounting plate; a suction fan is fixedly connected to the upper side wall of the mounting plate; the air inlet end of the suction fan communicates with a filter box through an air suction pipe; a plurality of air inlet pipes are arranged on the lower side wall of the filter box in a communicating mode; and air suction covers are arranged at the lower ends of the air inlet pipes in a communicating mode. According to the invention, sulfur dioxide gas in the gas can be removed, bacteria contained in the gas can be killed, air quality in a workshop is ensured, and the body health of workers is thus ensured.

Owner:郑新辉

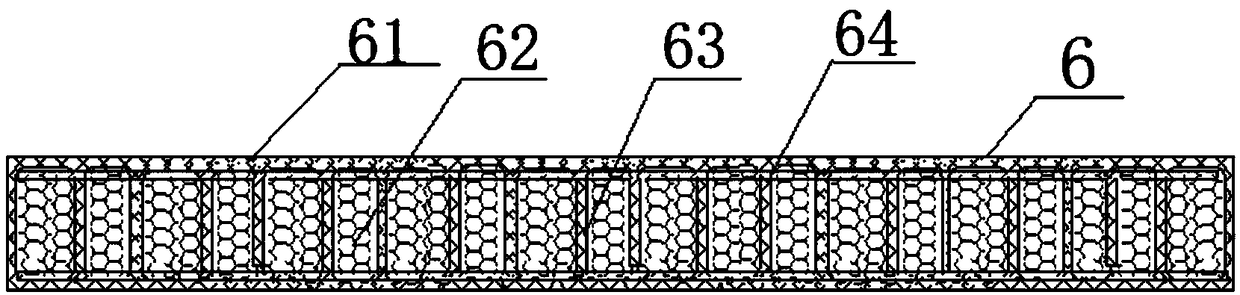

High-strength high-elasticity dual-density in-mold foaming rubber-plastic tray and manufacturing process thereof

ActiveCN109318444ALow costShorten molding timeDomestic articlesRigid containersRubber materialHigh density

The invention discloses a high-strength high-elasticity dual-density in-mold foaming rubber-plastic tray and a manufacturing process of the high-strength high-elasticity dual-density in-mold foaming rubber-plastic tray, and belongs to the technical field of rubber product processes. The high-strength high-elasticity dual-density in-mold foaming rubber-plastic tray comprises a high-density outer layer and a low-density inner layer, and is of an integrated structure with the same mold for discharging. The high-density outer layer and the low-density inner layer are made of high-density rubber materials and low-density rubber materials correspondingly. Spring supports distributed vertically and / or transversely and perpendicular to the horizontal plane of a tray body are uniformly embedded inthe low-density inner layer. In addition, a dual-density bi-directional injection in-mold forming-vulcanizing tray production system is applied to complete dual-density glue bi-directional injection,foaming and vulcanizing processes in one mold and obtain the manufactured tray. The problems of the insufficient elasticity of a rubber tray, the separate operation of injection, foaming and vulcanizing of a dual-density tray, energy consumption, time consumption and the high cost are solved.

Owner:东营睿港招商服务有限责任公司

Wet startup sulfuration method of hydrocracking unit

ActiveCN103102931AGreat effect on activityGuaranteed vulcanization effectHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

The invention relates to a wet startup sulfuration method of a hydrocracking unit. According to the invention, a part of recycle gas is heated by using a heating furnace, then a vulcanizing agent is introduced, and hydrogen sulfide is obtained after decomposition of the vulcanizing agent; then recycle gas rich in hydrogen sulfide is mixed with a second part of recycle gas, and mixed gas passes through a catalyst bed after reaching a desired temperature; light fraction startup oil is introduced at a low temperature, heavy fraction startup oil is introduced instead when the catalyst bed reaches a temperature of 235 to 300 DEG C, liquefied ammonia is introduced at the same time, and introduction of the vulcanizing agent is stopped; after introduction of the heavy fraction startup oil, final sulfuration of a catalyst is completed by using hydrogen sulfide obtained in a hydrogenolysis reaction of a sulfide in the startup oil, raw oil is directly introduced instead step by step after sulfuration is finished, and when 60 to 80% of raw oil is introduced, introduction of liquefied ammonia is stopped and normal production is started. Compared with the prior art, the method provided by the invention enables startup time to be shortened while guaranteeing performance of the catalyst and realizes safe and smooth startup.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength heat-resistant cable jacket material and preparation method thereof

InactiveCN108948460AGood capacity increaseImprove heat resistanceRubber insulatorsPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant cable jacket material and a preparation method thereof and belongs to the technical field of cable jacket materials. The high-strength heat-resistant cable jacket material is prepared from the following raw materials: nitrile rubber, EPDM, chlorosulfonated polyethylene, a vulcanizing agent, tetramethyl thiuram disulfide, benzoyl peroxide, an ethylene-vinyl acetate copolymer, zinc stearate, activated zinc oxide, N,N'-m-phenylene bismaleimide, highly dispersed white carbon black, modified sepiolite powder, nano silicon dioxide, hydroxyl silicone oil, calcined metakaolin powder, modified phenolic resin, antimonous oxide, magnesium hydroxide, an accelerant, an anti-aging agent and a plasticizer. The cable jacket material is high in strength, good in heat resistance, ageing-resistant and long in service life.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

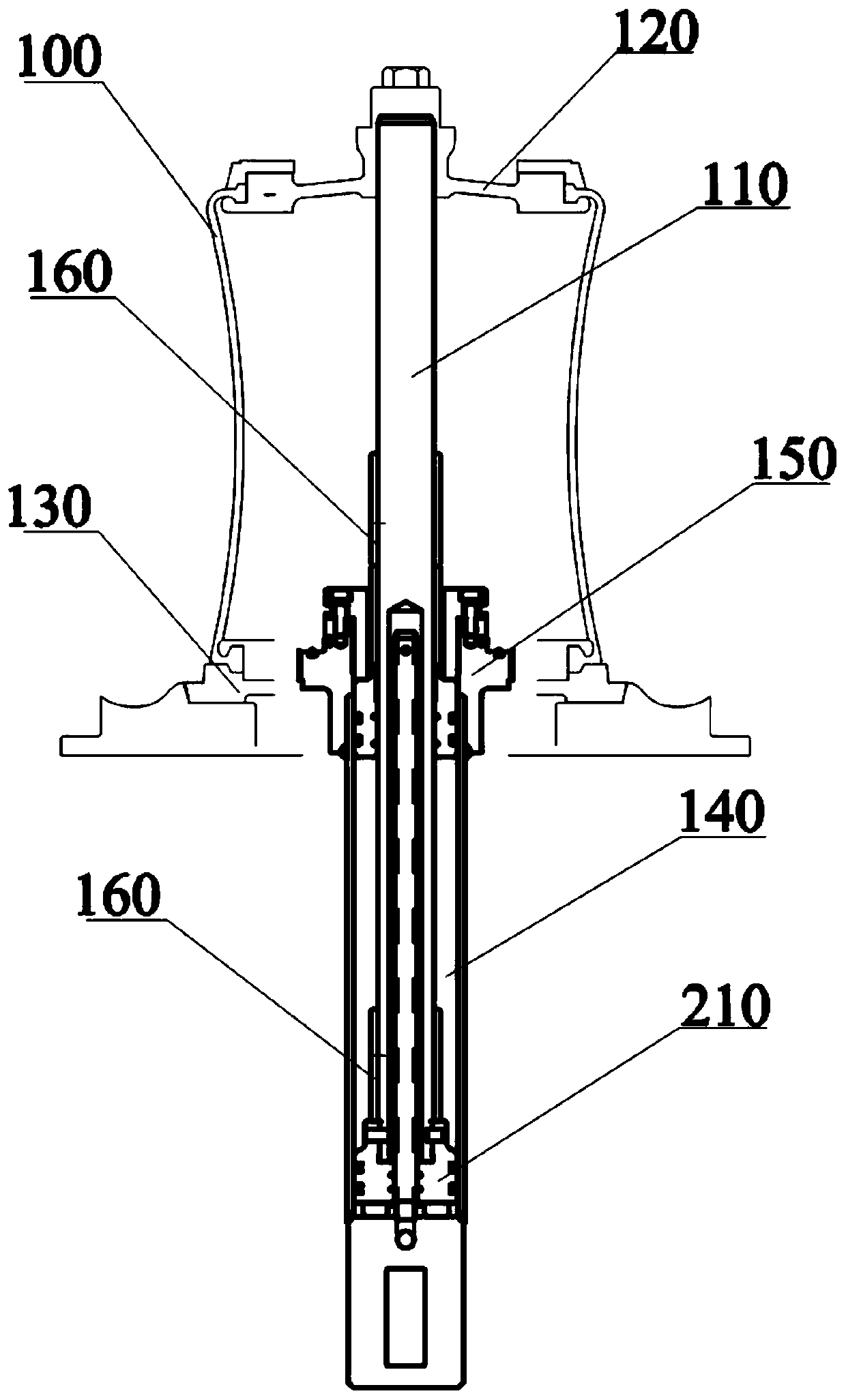

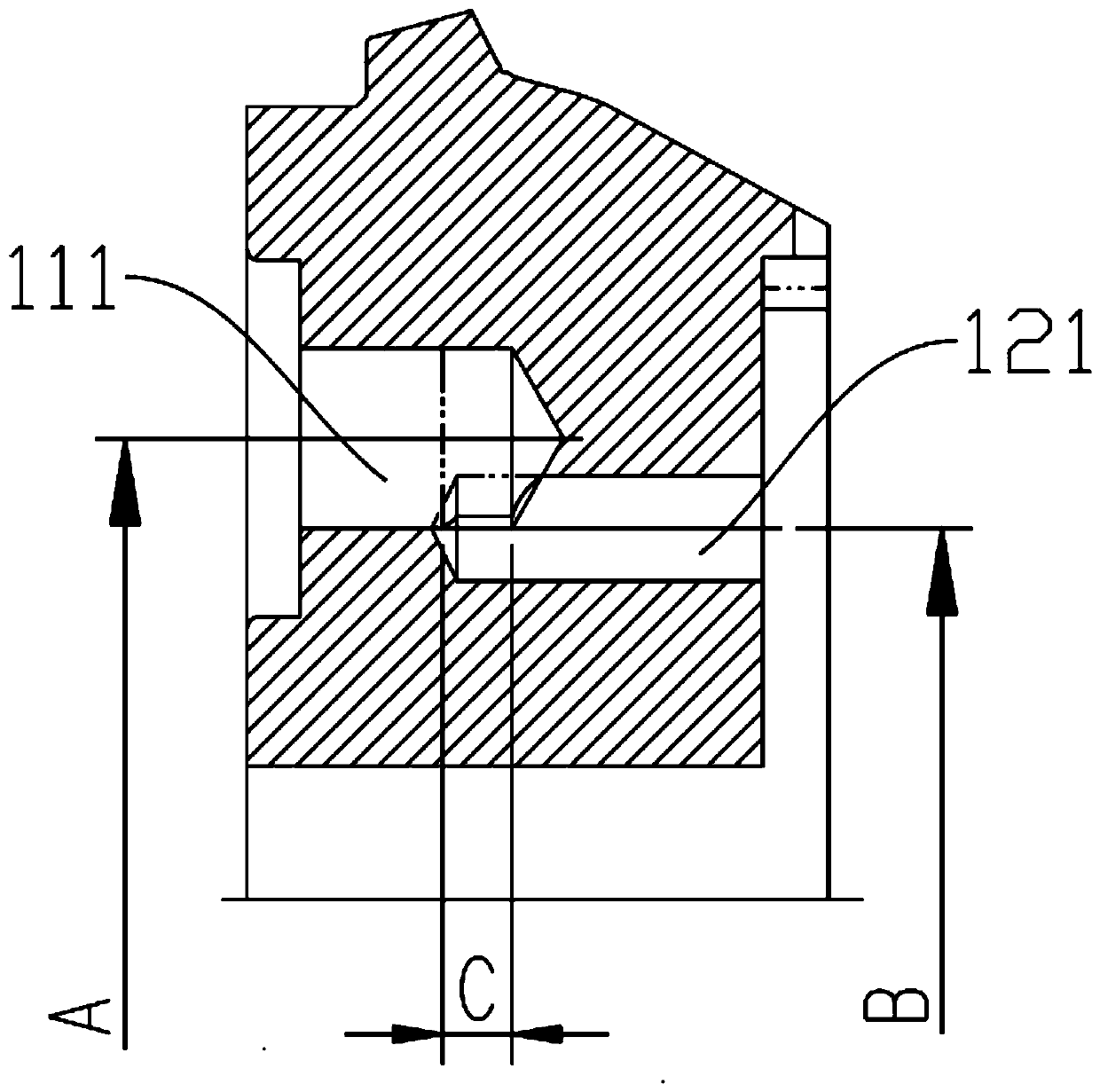

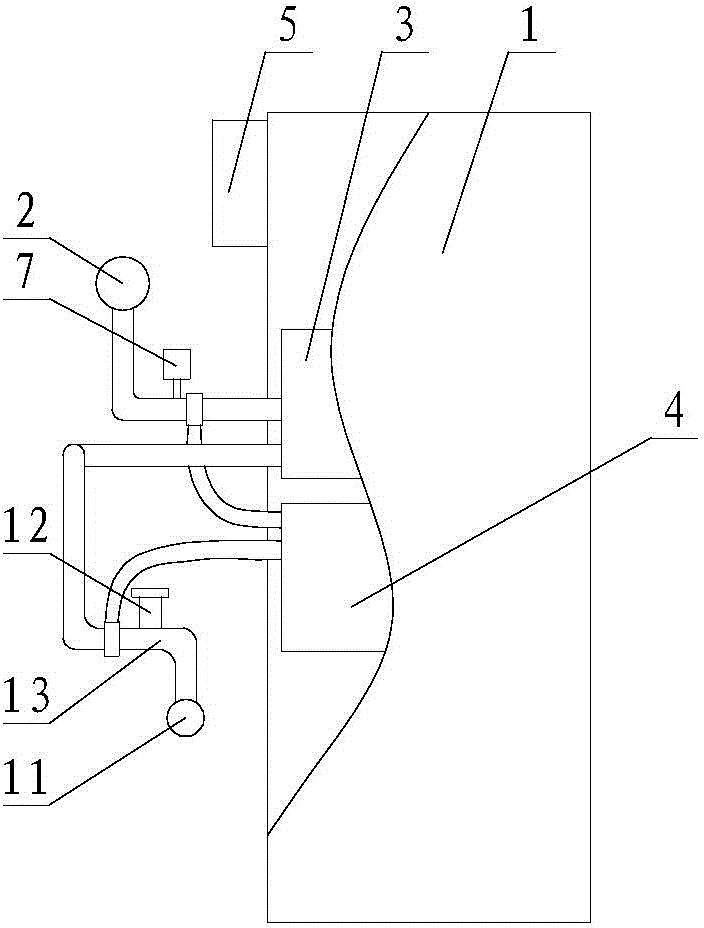

Center mechanism capsule height control device and method for tyre vulcanizer

The invention discloses a center mechanism capsule height control device and method for a tyre vulcanizer. The device comprises a center mechanism, a pressure water cylinder assembly and a control assembly. The center mechanism comprises a cylinder body and a lifting rod. The lifting rod is sleeved with the cylinder body in a vertical sliding manner. The top of the lifting rod is used for being connected with an upper ring. The bottom end of the lifting rod stretches out of the cylinder body. The pressure water cylinder assembly comprises a pressure water cylinder and a piston rod. One end ofthe piston rod is slidably embedded into the pressure water cylinder. The other end of the piston rod is connected to the bottom of the lifting rod. The internal space of the pressure water cylinder is divided into a first cavity and a second cavity by the piston rod. According to the center mechanism capsule height control device for the tyre vulcanizer, due to the fact that the pressure water cylinder and the cylinder body are designed separately, that is, the pressure water cylinder is independently arranged below the cylinder body, the problem that the pressure water in the pressure watercylinder enters a capsule, and the vulcanization effect of a tyre is reduced is avoided.

Owner:YIYANG YISHEN RUBBER MACHINERY

Wet startup sulfuration method of hydrocracking unit

ActiveCN103102929BGreat effect on activityGuaranteed vulcanization effectHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

Steel ring for tire vulcanization and pot-type model for small-sized and medium-sized tire vulcanization

ActiveCN110978582AExpand the scope of productionMeet flexible production requirementsTyresTire beadPolymer science

The invention provides a steel ring for tire vulcanization and a pot-type model for small-sized and medium-sized tire vulcanization and relates to the technical field of tire vulcanization. Two waternozzle seats and water nozzle seat bottom holes are formed in one side of the steel ring for tire vulcanization, a seal ring seat is arranged on the other side of the steel ring for tire vulcanization, and a seal ring base hole is formed in the seal ring seat and communicates to the water nozzle seat bottom holes separately. The center distance between the two water nozzle seat bottom holes is greater than that between the two seal ring seat bottom holes, and one of the water nozzle seat bottom hole is connected to a water inlet pipe of a vulcanization pot as a water inlet and the other waternozzle seat bottom hole is connected to a water outlet pipe of the vulcanization pot as a water outlet. The pot-type model for small-sized and medium-sized tire vulcanization comprises the steel ringfor tire vulcanization and can be connected to the vulcanization pot through the steel ring for tire vulcanization. The product specification tire bead model can be reduced to 13 inches in a pot-typeconventional production condition, so that the production range of the vulcanization pot is expanded, and a flexible production demand is met.

Owner:SICHUAN TYRE & RUBBER CO LTD

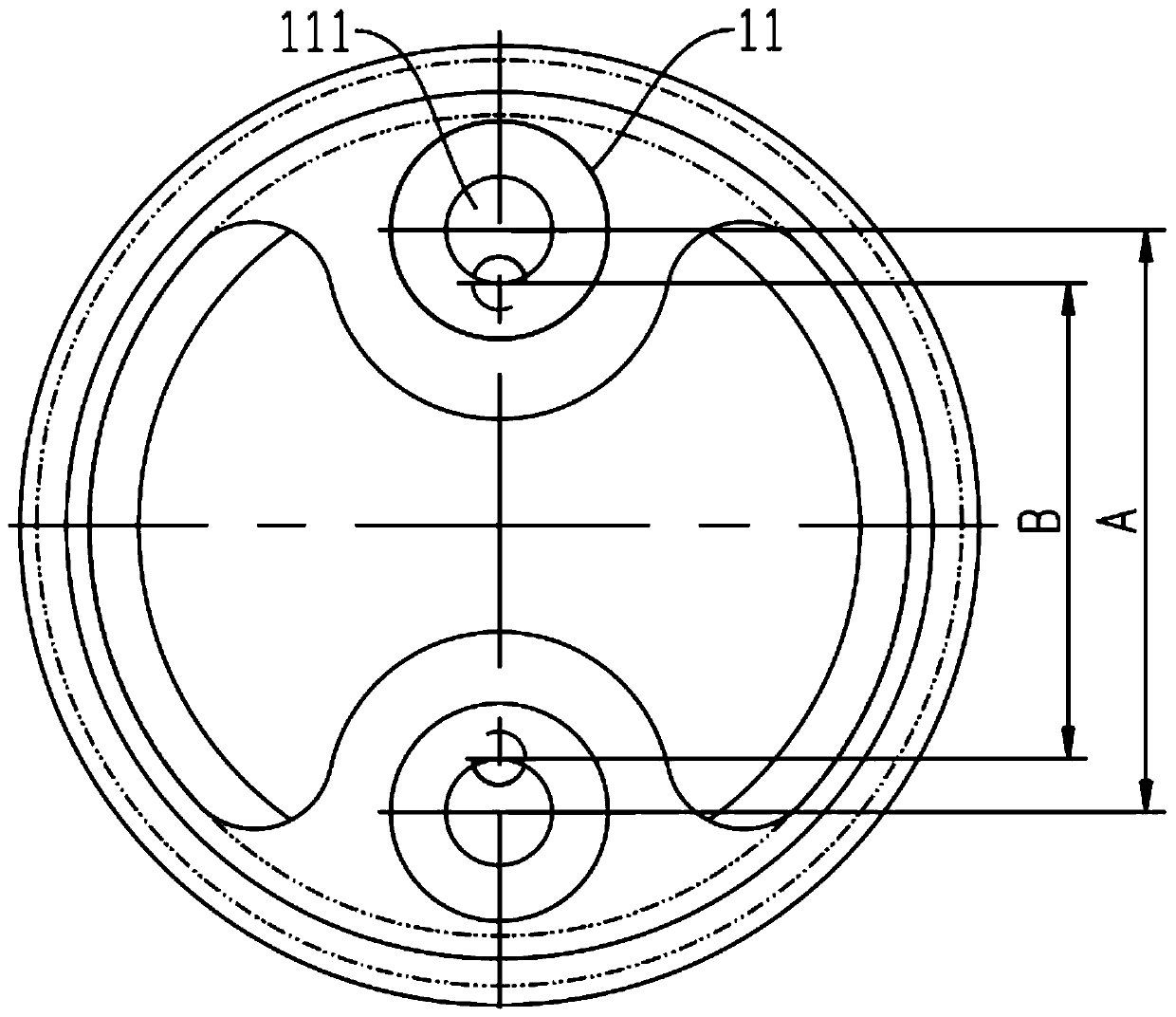

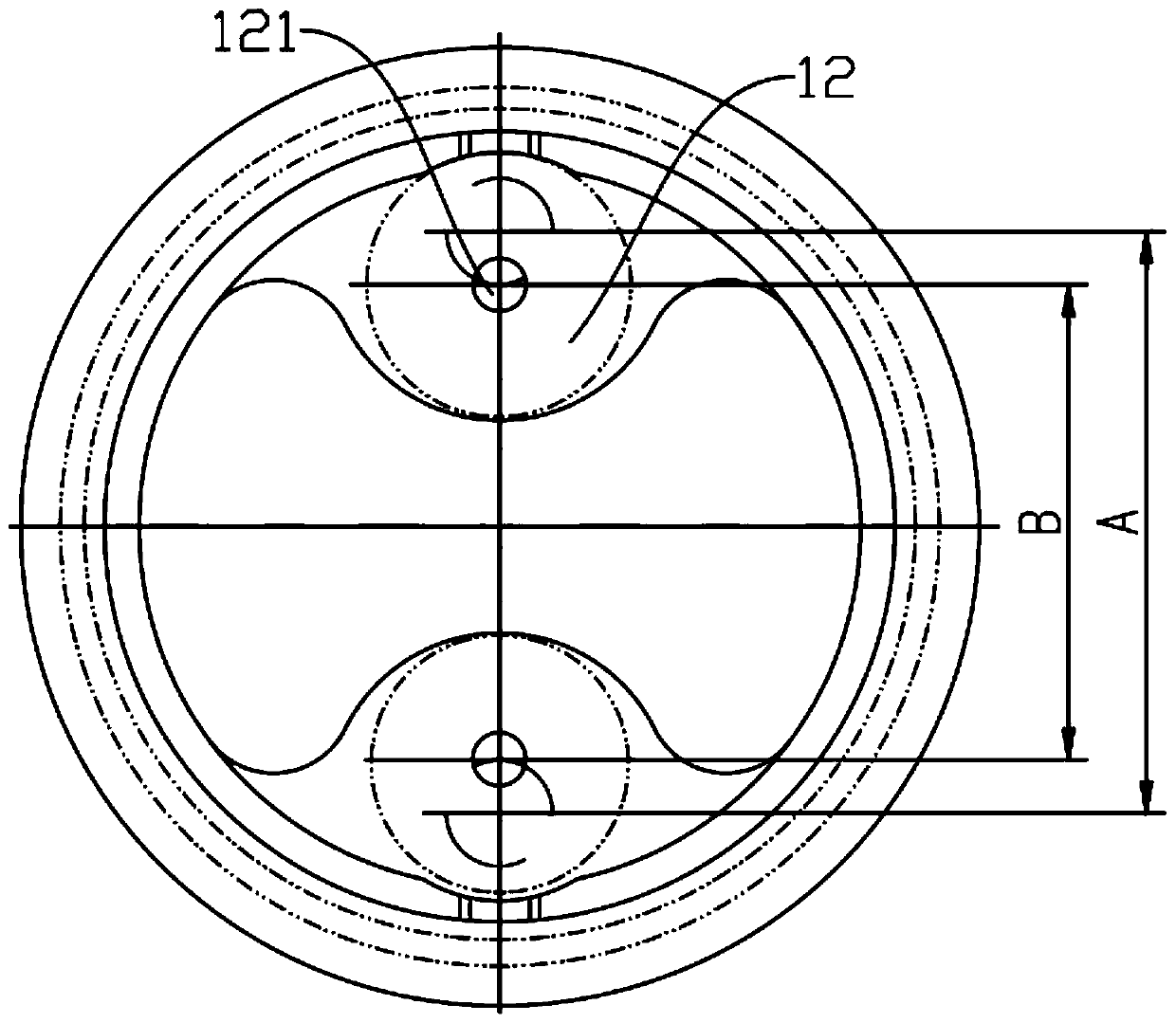

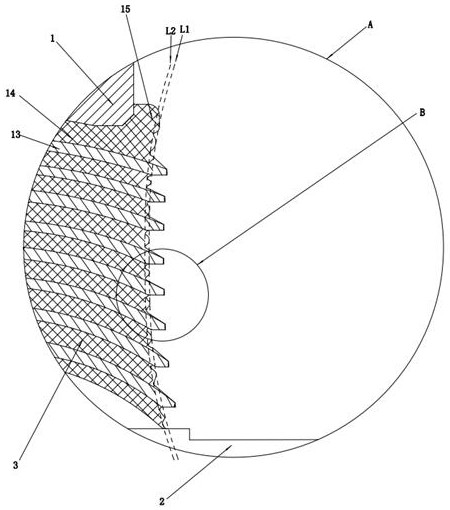

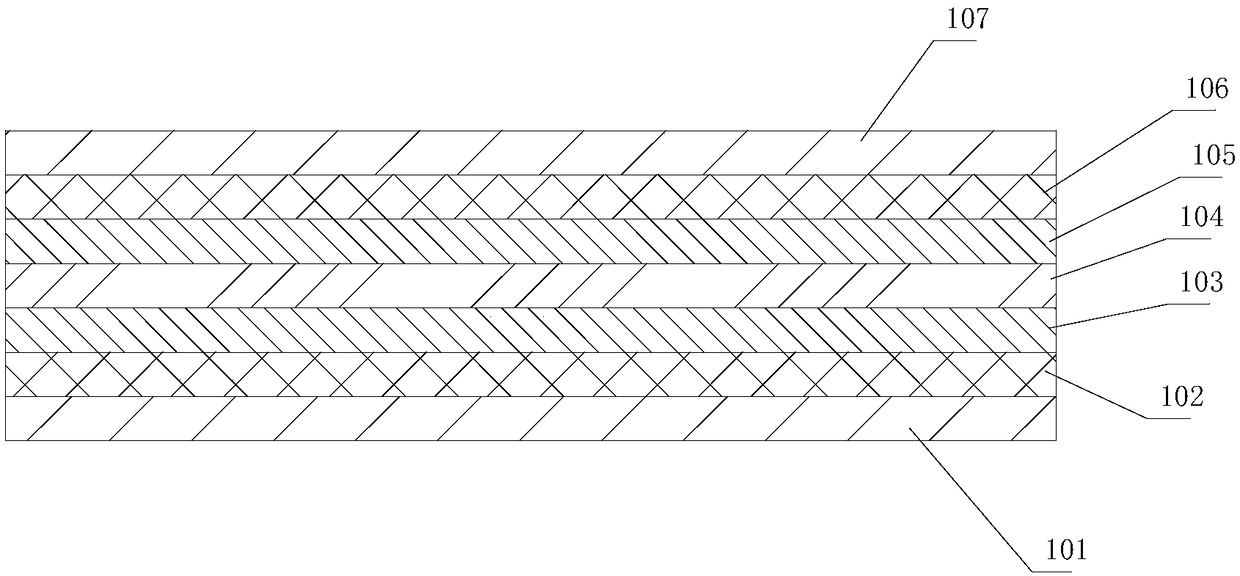

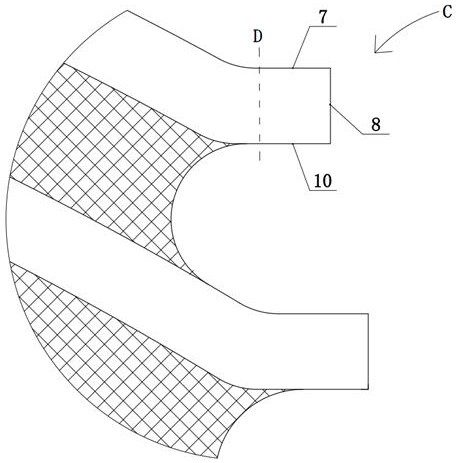

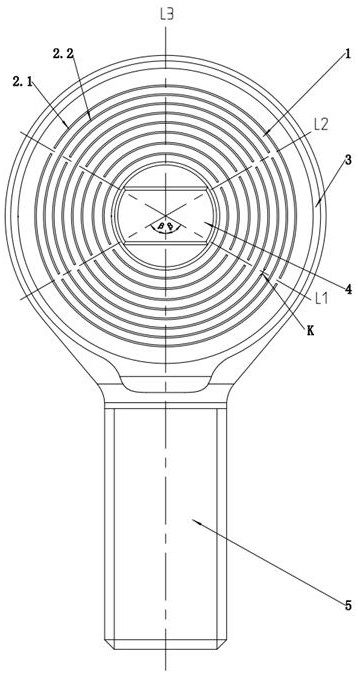

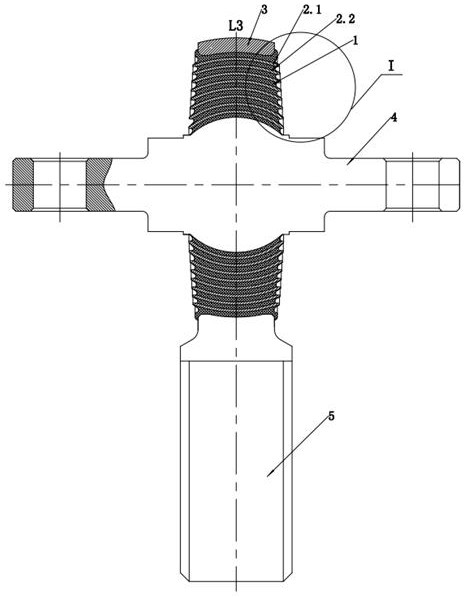

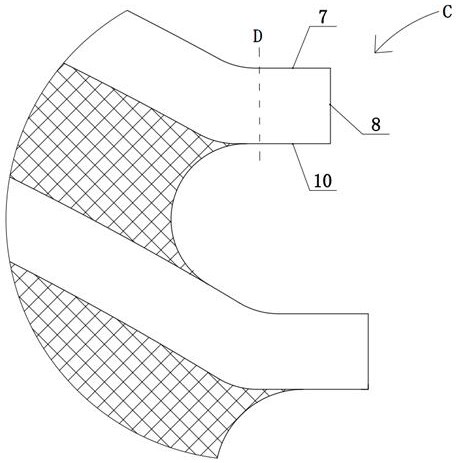

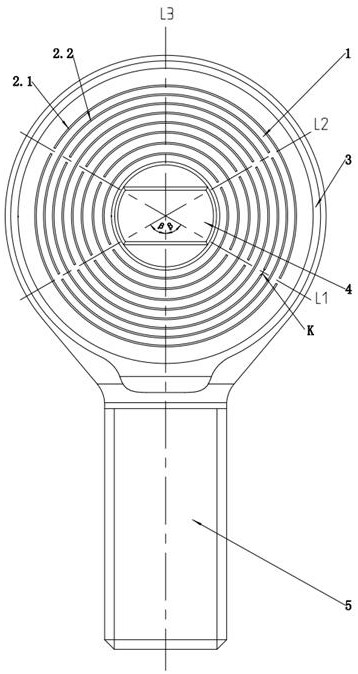

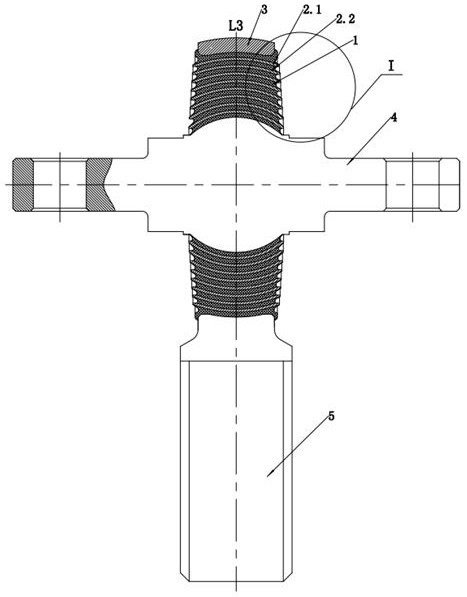

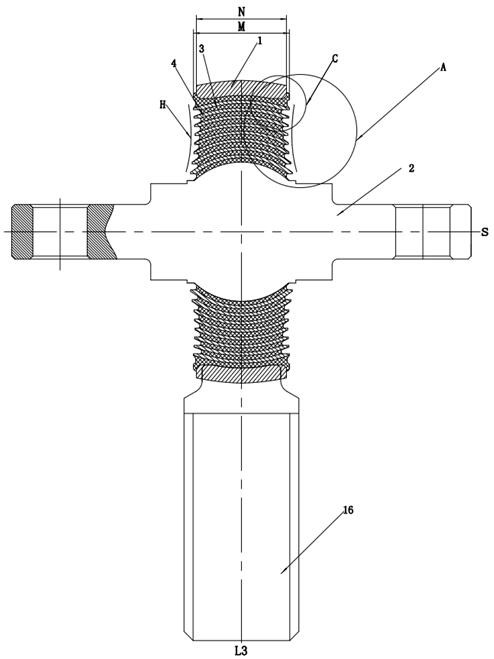

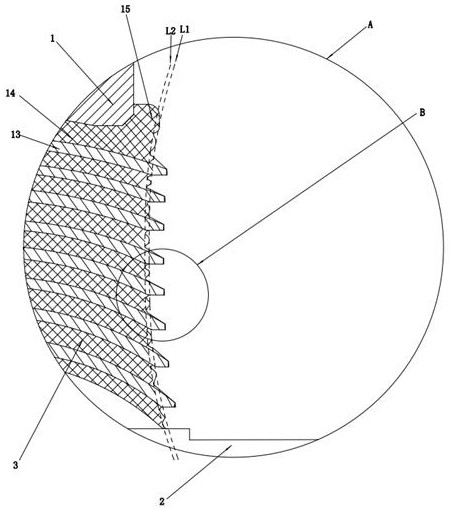

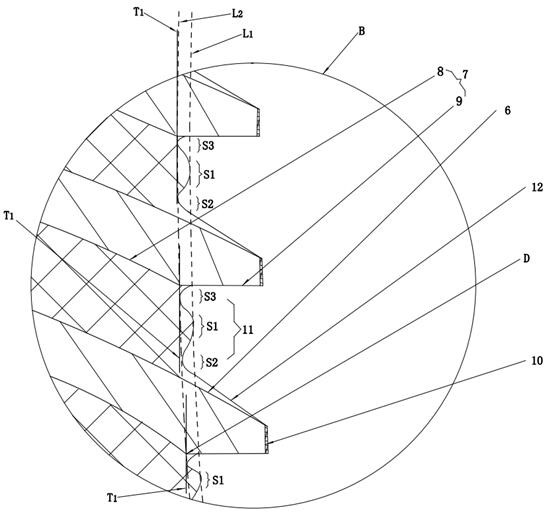

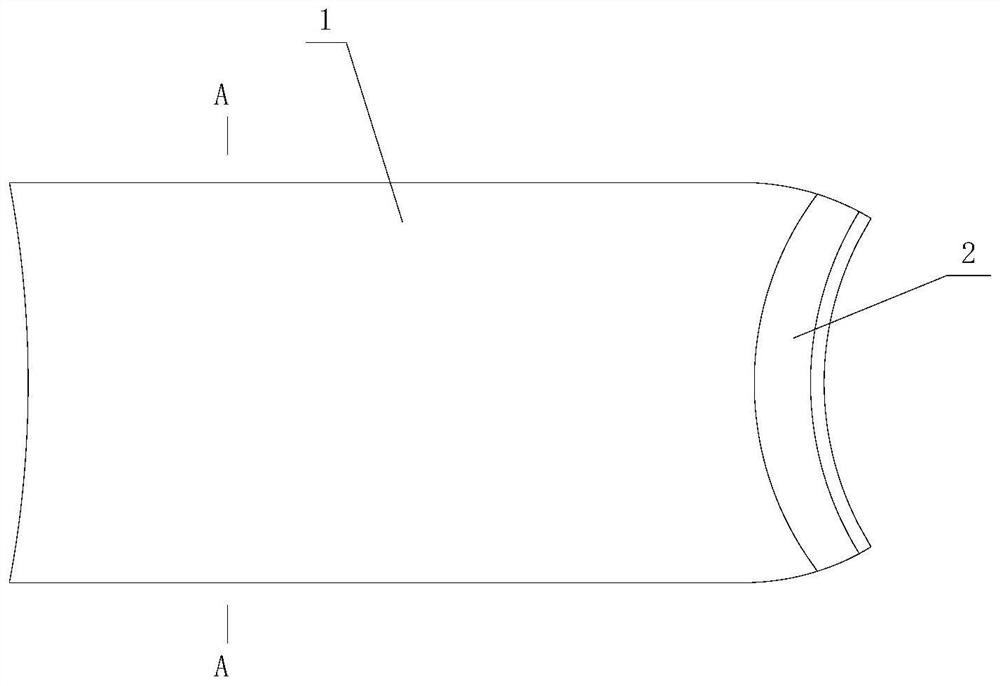

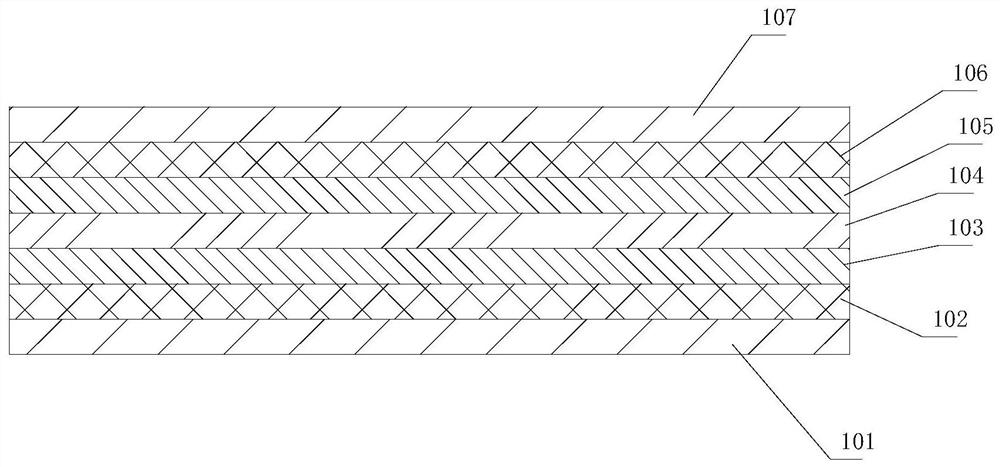

Overall design method of multilayer rod end spherical hinge

ActiveCN113530964AAvoid breakingExtended service lifeNon-rotating vibration suppressionPivotal connectionsVulcanizationClassical mechanics

The invention relates to the technical field of vibration reduction of elastic rubber parts, in particular to an overall design method of a multilayer rod end spherical hinge. The overall design method is characterized in that the overall performance of the spherical hinge is improved through the structural design of a rubber profile, a spacer bush and an outer sleeve, and specifically, the service life of the spherical hinge is prolonged through the design of the rubber profile, the service life of the spherical hinge is prolonged or the processing technology difficulty of the spherical hinge before vulcanization is reduced through the design of the spacer bush, and the processing technology difficulty of the spherical hinge before the vulcanization is reduced or the service life of the spherical hinge is prolonged through the design of the outer sleeve.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A high-elastic wear-resistant double-density in-mold foam rubber tire and its manufacturing process

ActiveCN109318445BIncrease elasticitySlow down elastic fatigue decayWith separate inflatable insertsWith multiple inflatable chambersRubber materialVulcanization

The invention discloses a high-elasticity wear-resistant dual-density in-mold foaming rubber tire and a manufacturing process of the high-elasticity wear-resistant dual-density in-mold foaming rubbertire, and belongs to the technical field of rubber product processes. The high-elasticity wear-resistant dual-density in-mold foaming rubber tire comprises a high-density outer layer and a low-densityinner layer, and is of an integrated structure with the same mold for discharging. The high-density outer layer and the low-density inner layer are made of high-density rubber materials and low-density rubber materials correspondingly. Spring supports in a radial state are uniformly embedded in the low-density inner layer so as to play the role of framework support, and the elasticity of springscan be selected to be consistent with the elasticity of low-density rubber so as to enhance the supporting strength of the low-density inner layer. In addition, a dual-density bi-directional injectionin-mold forming-vulcanizing tire production system is applied to complete dual-density glue bi-directional injection, foaming and vulcanizing processes in one mold and obtain the manufactured tire. The problems of the insufficient elasticity of a rubber tire, the separate operation of injection, foaming and vulcanizing of a dual-density tire, energy consumption, time consumption and the high costare solved.

Owner:东营睿港招商服务有限责任公司

Vulcanization box capable of automatically adjusting sulphur concentration

The invention relates to the technical field of vulcanization boxes and in particular relates to a vulcanization box capable of automatically adjusting sulphur concentration. The vulcanization box capable of automatically adjusting sulphur concentration comprises a vulcanization box, wherein a detector is arranged in the vulcanization box; and a vulcanization gas injector is arranged at the left side of the vulcanization box. When the vulcanization box capable of automatically adjusting sulphur concentration works, the concentration of the vulcanization gas in the vulcanization box is monitored by the detector which is arranged in the vulcanization box, and the concentration in the vulcanization box is adjusted by controlling the vulcanization gas injector, so that the vulcanization effect is ensured, and the using effect is good.

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

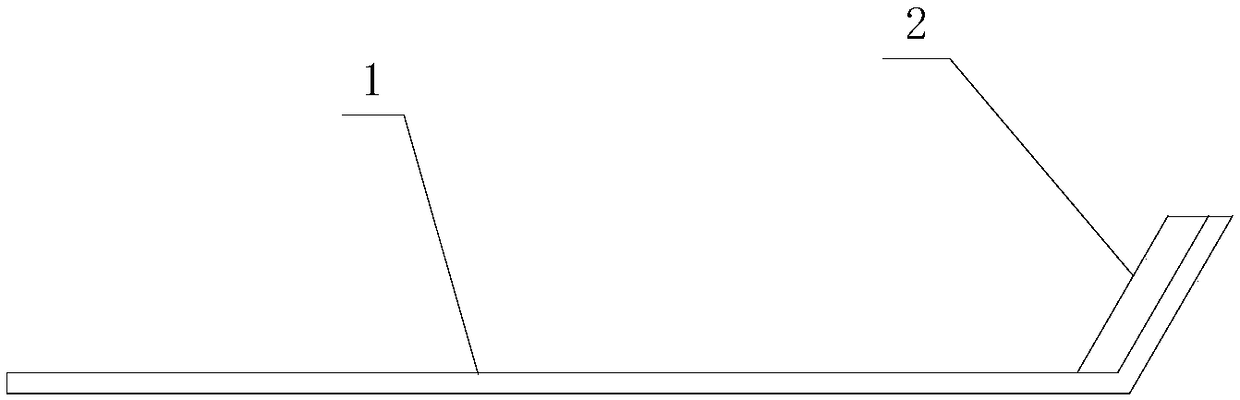

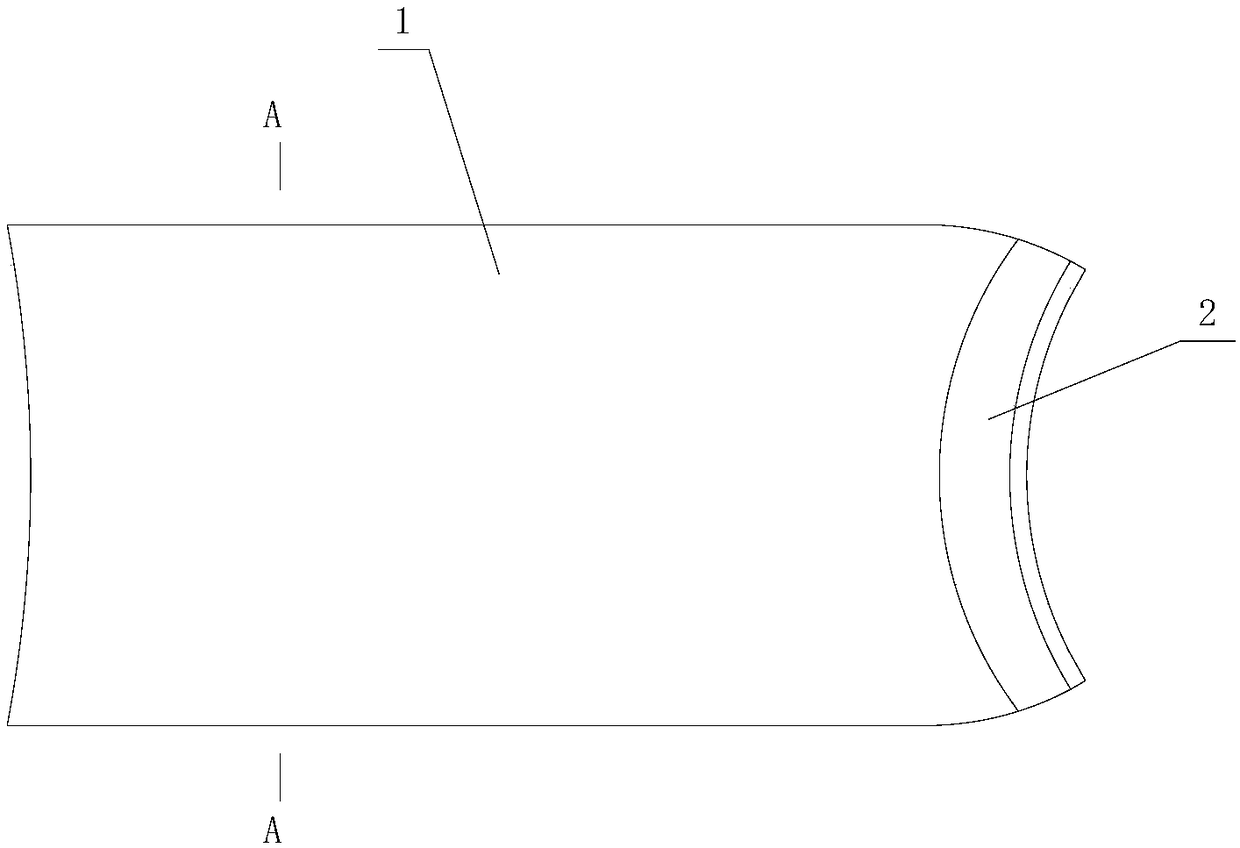

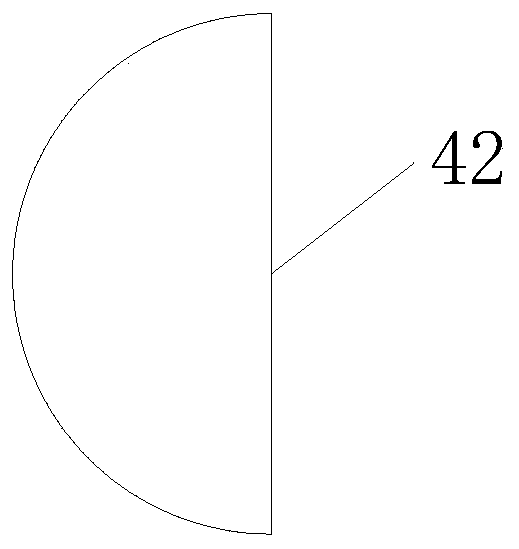

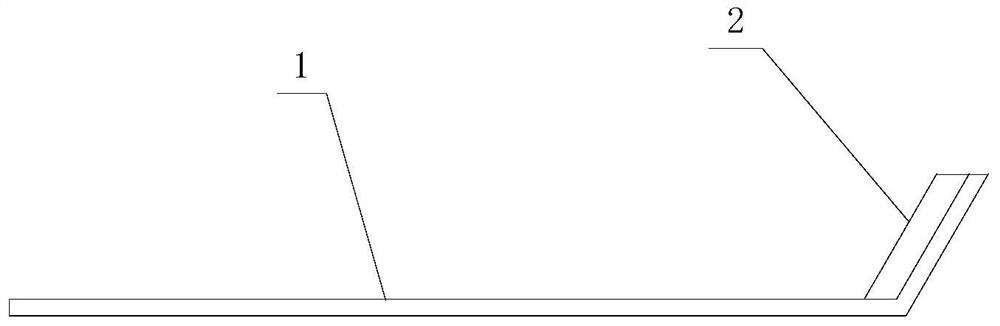

Heating sheet for tire repairing

The invention discloses a heating sheet for tire repairing. The heating sheet comprises a heating sheet main body, wherein an arc-shaped turnup is arranged at one end of the heating sheet main body. The arc-shaped turnup is an arc-shaped component arranged in a width direction of the heating sheet main body, and the circle center of the arc-shaped component is located on the outer side of the heating sheet main body. The heating sheet is simple in structure and reasonable in design; the heating sheet can be better located at a toe of a tire, so as to guarantee a vulcanizing effect of a patch at the toe position.

Owner:SICHUAN JIALUN RENEWABLE RESOURCES TECH CO LTD

A high-strength, high-elasticity double-density in-mold foamed rubber-plastic tray and its manufacturing process

ActiveCN109318444BImprove support strengthSlow down elastic fatigue decayDomestic articlesRigid containersRubber materialVulcanization

The invention discloses a high-strength high-elasticity dual-density in-mold foaming rubber-plastic tray and a manufacturing process of the high-strength high-elasticity dual-density in-mold foaming rubber-plastic tray, and belongs to the technical field of rubber product processes. The high-strength high-elasticity dual-density in-mold foaming rubber-plastic tray comprises a high-density outer layer and a low-density inner layer, and is of an integrated structure with the same mold for discharging. The high-density outer layer and the low-density inner layer are made of high-density rubber materials and low-density rubber materials correspondingly. Spring supports distributed vertically and / or transversely and perpendicular to the horizontal plane of a tray body are uniformly embedded inthe low-density inner layer. In addition, a dual-density bi-directional injection in-mold forming-vulcanizing tray production system is applied to complete dual-density glue bi-directional injection,foaming and vulcanizing processes in one mold and obtain the manufactured tray. The problems of the insufficient elasticity of a rubber tray, the separate operation of injection, foaming and vulcanizing of a dual-density tray, energy consumption, time consumption and the high cost are solved.

Owner:东营睿港招商服务有限责任公司

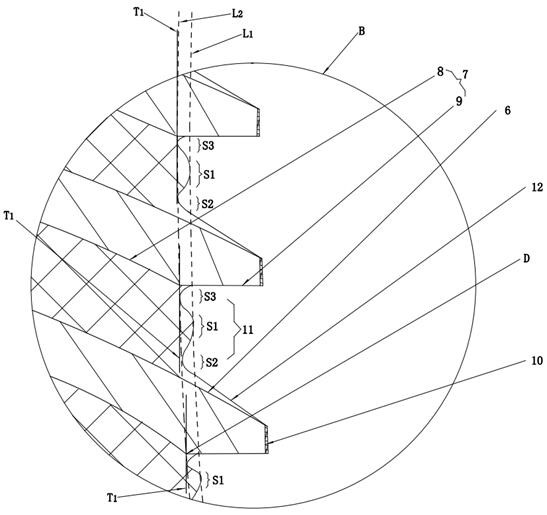

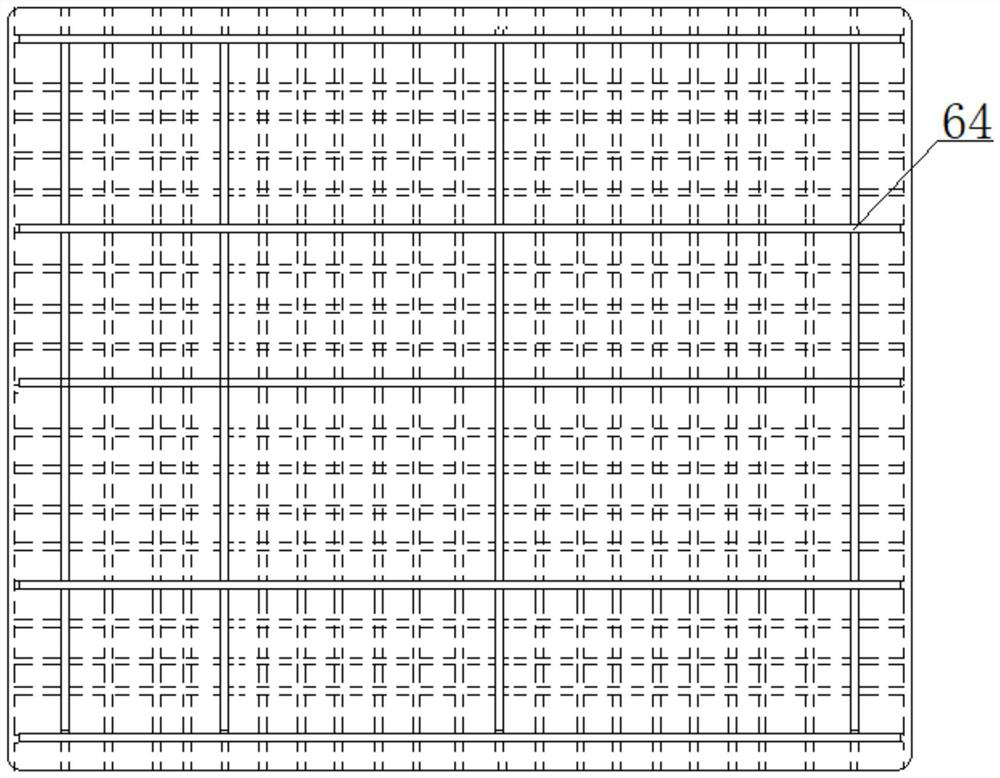

A spacer design method for rod end ball joint

ActiveCN113550995BPrecise positioningReduced service lifeGeometric CADSprings/dampers design characteristicsVulcanizationClassical mechanics

The invention relates to the field of damping of elastic rubber parts, in particular to a spacer design method for a rod end ball hinge. The rod end ball hinge comprises a jacket, a mandrel and a rubber layer, a spacer is arranged in the rubber layer, and the spacer is on the spacer. Set the upper side of the spacer, the lower side of the spacer and the end face of the spacer, connect one end of the end face of the spacer to the upper side of the spacer, and connect the other end of the end face of the spacer with the lower side of the spacer relative to the upper side of the spacer. A tip B1 is formed between the end face and the upper side of the spacer, and the tip B1 between the upper side of the spacer and the end face of the spacer forms point contact with the mold, and the tip B1 is used to make point contact with the mold. Axial positioning reduces spacer tolerance requirements.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

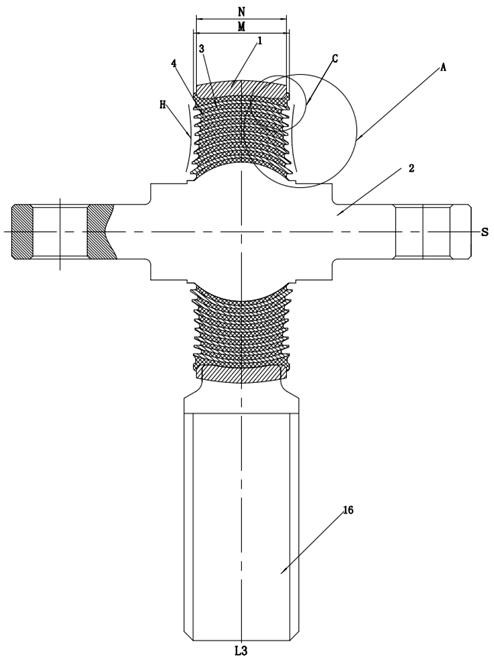

Method for designing spacer bush of rod end spherical hinge

ActiveCN113550995APrevent affecting vulcanization effectSolution to short lifeGeometric CADSprings/dampers design characteristicsVulcanizationStructural engineering

The invention relates to the field of damping of elastic rubber parts, and particularly relates to a method for designing a spacer bush of a rod end spherical hinge. The rod end spherical hinge comprises an outer sleeve, a mandrel and a rubber layer, the spacer bush is arranged in the rubber layer, the spacer bush is provided with a spacer bush upper side surface, a spacer bush lower side surface and a spacer bush end surface, one end of the spacer bush end surface is connected with the spacer bush upper side surface, the other end, opposite to the upper side surface of the spacer bush, of the spacer bush end surface is connected with the spacer bush lower side surface, a tip B1 is formed between the spacer bush end surface and the spacer bush upper side surface, the tip B1 between the spacer bush upper side surface and the spacer bush end surface is in point contact with a mold, the spacer bush is axially located in the vulcanization process by adopting point contact between the tip B1 and the mold, and the requirement on the tolerance of the spacer bush is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

An Integral Design Method of Multilayer Rod-end Spherical Joint

ActiveCN113530964BAvoid breakingExtended service lifeNon-rotating vibration suppressionPivotal connectionsVulcanizationBall joint

The invention relates to the technical field of shock absorption of elastic rubber parts, in particular to an overall design method of a multi-layer rod-end ball joint. Performance, specifically to improve the service life of the ball joint through the design of the rubber profile; to improve the service life of the ball joint or reduce the processing difficulty of the ball joint before vulcanization through the design of the spacer sleeve; to reduce the The difficulty of processing the ball joint before vulcanization may improve the service life of the ball joint.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Reclaimed rubber crushing device

InactiveCN110561654AGuaranteed sizeImprove crushing effectSievingScreeningEngineeringMechanical engineering

The invention discloses a reclaimed rubber crushing device, and relates to the technical field of reclaimed rubber processing. The reclaimed rubber crushing device comprises a box body, a crushing part, a transferring part and a screen, wherein the crushing part comprises a first rotating shaft and a second rotating shaft which are arranged in parallel, the length of the first rotating shaft is greater than that of the second rotating shaft, the first rotating shaft is rotationally connected in the box body, one end of the second rotating shaft is rotationally connected in the box body, crushing tools are arranged on the first rotating shaft and the second rotating shaft, the same ends of the first rotating shaft and the second rotating shaft are in power connection with a first motor anda second motor respectively, the transferring part comprises a connecting piece fixedly connected to the end, away from the first motor, of the first rotating shaft, the bottom of the connecting pieceis fixedly connected with a transferring hopper, and the screen is arranged in the box body, and when the transferring hopper is in the lowest position, the transferring hopper is in contact with thetop of the screen. According to the device, the large reclaimed rubber can be automatically and repeatedly crushed, so that the crushing of the reclaimed rubber can reach the crushing requirement, and therefore the crushing effect of the reclaimed rubber is improved.

Owner:安徽丰运高分子材料有限公司

A method for preventing viton o-ring from sticking during secondary vulcanization

InactiveCN104817712BImprove inspection efficiencyReduce risk of multiple assembliesPretreated surfacesCoatingsEmulsionVulcanization

The invention discloses a method for preventing fluorine rubber O-rings from sticking during secondary vulcanization, and belongs to the field of surface treatment of rubber products. A method for preventing fluorine rubber O-rings from sticking during secondary vulcanization of the present invention, through the steps of cleaning→feeding→spraying release agent→coating, drying→curing, and secondary vulcanization, the coating of emulsified silicone oil is reasonably applied , drying machine and curing process, to achieve the purpose of solving the sticking phenomenon of fluorine rubber O-rings after secondary vulcanization, so as to improve the inspection efficiency of O-rings and reduce the risk of missing inspections. The surface of the fluorine rubber O-ring after secondary vulcanization by the method of the invention has no sticking phenomenon, which greatly improves the inspection efficiency.

Owner:南京金三力橡塑有限公司

Hydrogenation catalyst start-up sulfidation method

ActiveCN110653007BSolve the problem of heat sourceReduce consumptionCatalyst activation/preparationPtru catalystFixed bed

The present disclosure relates to a method for starting sulfidation of a hydrogenation catalyst. The method comprises the following steps: a. introducing hydrogen into a fixed-bed reactor filled with a hydrogenation catalyst to establish a hydrogen cycle; b. hydrogenating the hydrogenation catalyst in the reactor The temperature of the catalyst bed is raised to 110-175°C, and then the start-up sulfide oil is introduced to wet the hydrogenation catalyst bed, and a closed-circuit cycle of the start-up sulfidation is established; c. Introduce a sulfidizing agent into the reactor, and increase the temperature according to the sulfidation. The hydrogenation catalyst is sulfided according to the program, and liquefied gas is introduced into the reactor in the heating stage of the sulfide temperature increase program. Based on the total circulating amount of the hydrogen, the amount of the liquefied gas is 5~ 20% by volume. The method can achieve a higher final sulfidation temperature of the hydrogenation catalyst under the condition that the heating capacity of the existing equipment in the refinery is limited, and at the same time, the energy consumption can be significantly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A heating pad for tire repair

The invention discloses a heating sheet for tire repairing. The heating sheet comprises a heating sheet main body, wherein an arc-shaped turnup is arranged at one end of the heating sheet main body. The arc-shaped turnup is an arc-shaped component arranged in a width direction of the heating sheet main body, and the circle center of the arc-shaped component is located on the outer side of the heating sheet main body. The heating sheet is simple in structure and reasonable in design; the heating sheet can be better located at a toe of a tire, so as to guarantee a vulcanizing effect of a patch at the toe position.

Owner:SICHUAN JIALUN RENEWABLE RESOURCES TECH CO LTD

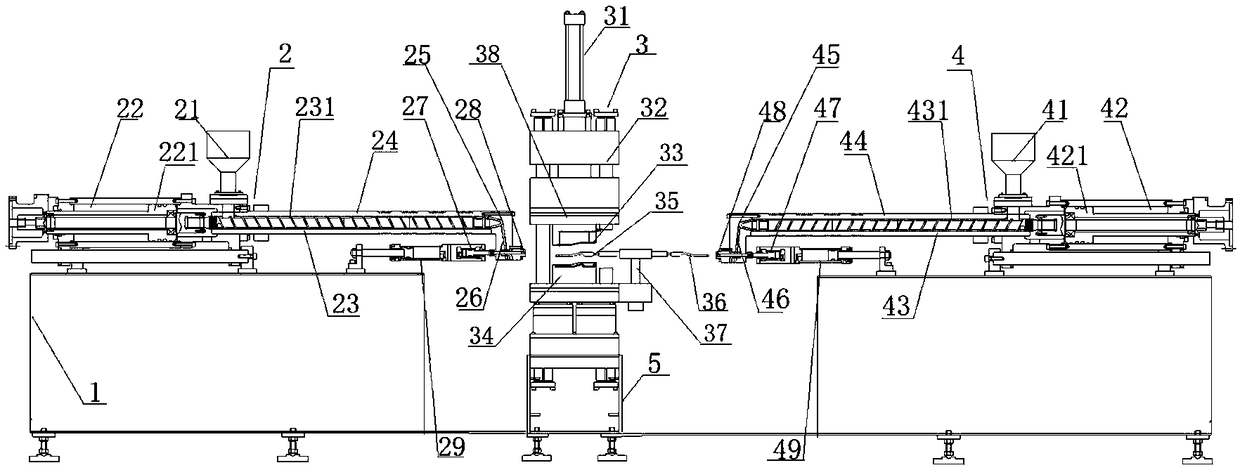

Rubber double-density double-injection product intra-mold foaming and sulfuration molding system and process

The invention discloses a rubber double-density double-injection product intra-mold foaming and sulfuration molding system and process and belongs to the technical field of rubber product processes. The rubber double-density double-injection product intra-mold foaming and sulfuration molding system comprises a compression molding sulfuration table and two injection machine bases, wherein the two injection machine bases are symmetrically arranged at the two sides of the compression molding sulfuration table. A compression molding sulfuration device is fixed to the compression molding sulfuration table. The two injection machine bases are each fixedly provided with a rubber material injection device. The two rubber material injection devices are arranged oppositely, one is the high-density rubber material injection device, and the other is the low-density rubber material injection device. The compression molding sulfuration device comprises two mold inner cores which are the same in shape and different in specification. By means of the high-density rubber material injection device and the low-density rubber material injection device, two types of plastified rubber materials differentin density are matched with the different mold inner cores and sequentially injected into a mold of the compression molding sulfuration device. Compression molding foaming and sulfuration are conducted on the plastified rubber materials in the mold through the compression molding sulfuration device; injection, foaming and sulfuration of double-density rubber products are completed in the same mold; product transfer among all procedures is avoided; and the production cost is lowered.

Owner:安徽世界村智能装备有限公司

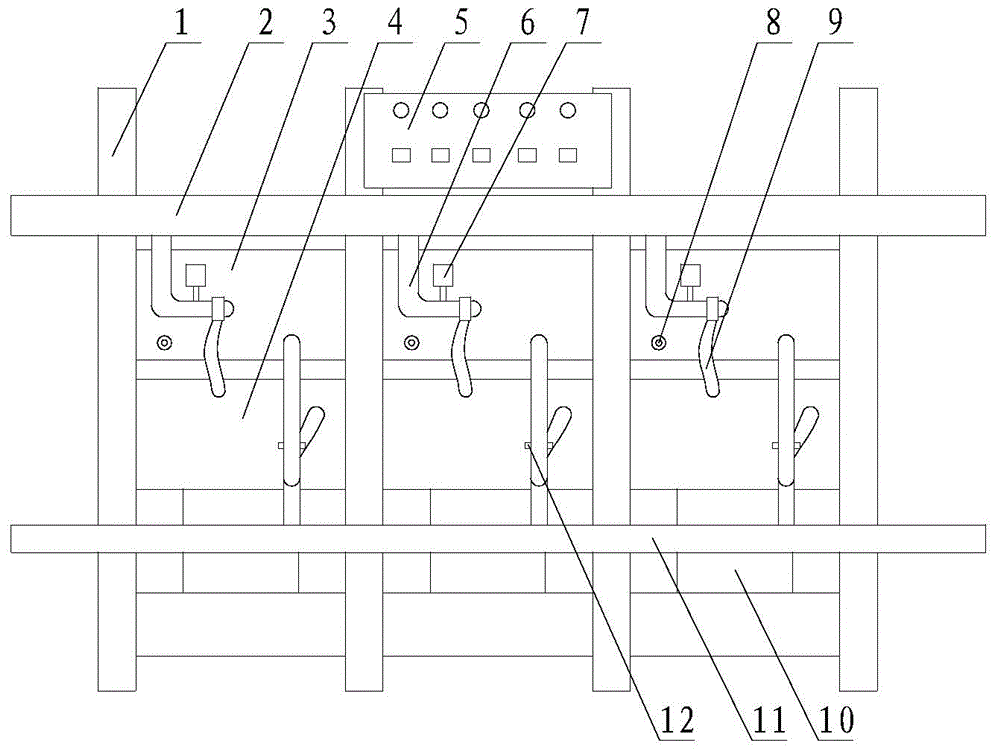

Multifunctional vulcanizing machine

The invention relates to a multifunctional vulcanizing machine. The multifunctional vulcanizing machine comprises an outer frame, upper heating plates, lower heating plates, a hydraulic cylinder, water draining valves, a main gas inlet pipeline and a main gas outlet pipeline, wherein the upper heating plate and the lower heating plate of each heating unit are connected on a same branch gas inlet pipe by a pipeline; the branch gas inlet pipe is connected with the main gas inlet pipeline; each branch gas inlet pipe is provided with an electromagnetic valve; the upper heating plates are provided with temperature control probes, the outer frame is provided with temperature controllers, and the temperature control probes, the temperature controllers and the electromagnetic valves are electrically connected; outlets of the upper heating plate and the lower heating plate of each heating unit are connected on a same branch gas outlet pipe by a pipeline; the branch gas outlet pipe is connected with the main gas outlet pipeline; and each branch gas outlet pipe is provided with one water draining valve. The multifunctional vulcanizing machine has the advantages that the design is reasonable, the improvement is ingenious and the control is convenient; by use of the vulcanizing machine, the temperature can be automatically controlled, the energy is saved, the economic cost can be reduced and independent maintenance for each heating unit is realized.

Owner:天津市渤海胶带有限公司

Electroforming solution for gold cyanide-free electroforming process and electroforming process

PendingCN113046790AGuaranteed vulcanization effectStable hardnessElectroforming processesO-Phosphoric AcidSulfite salt

The invention provides an electroforming solution for a gold cyanide-free electroforming process and an electroforming process. 1 liter of the electroforming solution comprises 25-30 g of gold chloride gold salt, 60-80 g of anhydrous sodium sulfite, 50-70 g of sodium chloride, a hardening agent, anhydrous saccharin sodium salt, tellurium dioxide, ammonia water and phosphoric acid, wherein a mass ratio of an addition amount of the hardening agent to an addition amount of gold trichloride gold salt is 1: 1, and a mass ratio of an addition amount of the anhydrous saccharin sodium salt to an addition amount of the gold chloride gold salt is 1: (45-55). The process comprises the following steps of taking a wax mold as an electroforming model, and conducting copper plating after silver oil soaking, so as to plate the wax mold with a bright copper coating; conducting electrolytic degreasing, acid pickling activation and water washing deacidification; and conducting gold electroforming through the electroforming solution, and removing a mold core of the electroforming model after electroforming, so as to obtain a gold product. According to the electroforming solution and the electroforming process, an electroforming liquid system is stable, the service life is long, and the high-frequency problems of brittle fracture, soft surface collapse, interlayer peeling, hard spots and roughing, pores and needle holes and the like of products cast by an existing similar sulfite casting liquid system are solved.

Owner:DECENT GOLD GRP CO LTD

Wet startup sulfuration method of hydrocracking unit

ActiveCN103102931BGreat effect on activityGuaranteed vulcanization effectHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenDecomposition

The invention relates to a wet startup sulfuration method of a hydrocracking unit. According to the invention, a part of recycle gas is heated by using a heating furnace, then a vulcanizing agent is introduced, and hydrogen sulfide is obtained after decomposition of the vulcanizing agent; then recycle gas rich in hydrogen sulfide is mixed with a second part of recycle gas, and mixed gas passes through a catalyst bed after reaching a desired temperature; light fraction startup oil is introduced at a low temperature, heavy fraction startup oil is introduced instead when the catalyst bed reaches a temperature of 235 to 300 DEG C, liquefied ammonia is introduced at the same time, and introduction of the vulcanizing agent is stopped; after introduction of the heavy fraction startup oil, final sulfuration of a catalyst is completed by using hydrogen sulfide obtained in a hydrogenolysis reaction of a sulfide in the startup oil, raw oil is directly introduced instead step by step after sulfuration is finished, and when 60 to 80% of raw oil is introduced, introduction of liquefied ammonia is stopped and normal production is started. Compared with the prior art, the method provided by the invention enables startup time to be shortened while guaranteeing performance of the catalyst and realizes safe and smooth startup.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steel rings for tire vulcanization and tank models for medium and small tire vulcanization

ActiveCN110978582BExpand the scope of productionMeet flexible production requirementsTyresTire beadVulcanization

The application provides a steel ring for tire vulcanization and a tank model for vulcanization of small and medium-sized tires, which relate to the technical field of tire vulcanization. One side of the steel ring for tire vulcanization is provided with two nozzle seats and the bottom hole of the nozzle seat, and the opposite side of the steel ring for tire vulcanization is provided with a sealing ring seat, and the sealing ring seat is provided with a sealing ring seat bottom The holes are respectively connected with the bottom hole of a faucet seat. The center distance between the bottom holes of the two nozzle seats is greater than the center distance between the two holes of the sealing ring seat. The hole is used to connect with the water outlet pipe of the autoclave and serves as the water outlet. The tank model of small and medium-sized tire vulcanization includes the steel ring for tire vulcanization and can be connected with the vulcanization tank through the steel ring for tire vulcanization. Under the normal production conditions of the tank type, the product specification bead model can be reduced to 13 inches, and the size of the bead can be expanded. The range of vulcanization tank production is expanded, which meets the requirements of flexible production.

Owner:SICHUAN TYRE & RUBBER CO LTD

Hydrogenation catalyst composition and preparation method thereof

ActiveCN109926102AGuarantee vulcanization qualityAvoid flying temperatureOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationVulcanizationSulfur

The present invention discloses a hydrogenation catalyst composition and a preparation method thereof, wherein the hydrogenation catalyst composition comprises an oxidation state catalyst, solid sulfur, an auxiliary agent, an organic compound and hydrazine hydrate. The preparation method comprises: loading an organic compound onto a catalyst, introducing solid sulfur and an auxiliary material, carrying out low-temperature heat treatment, loading hydrazine hydrate, and carrying out low-temperature heat treatment; or introducing solid sulfur and an auxiliary material, introducing an organic compound, carrying out low-temperature heat treatment, introducing hydrazine hydrate, and carrying out low-temperature heat treatment. According to the present invention, with the application of the catalyst composition, the complete vulcanization can be ensured, and the problem of airtightness of the device can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com