Gas purification method for vulcanization work of rubber tire

A technology of gas purification and rubber tires, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as difficult hygiene, physical hazards, and irritation of respiratory mucosa, so as to prevent uneven concentration of raw materials and protect the body. Effects of health and air quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

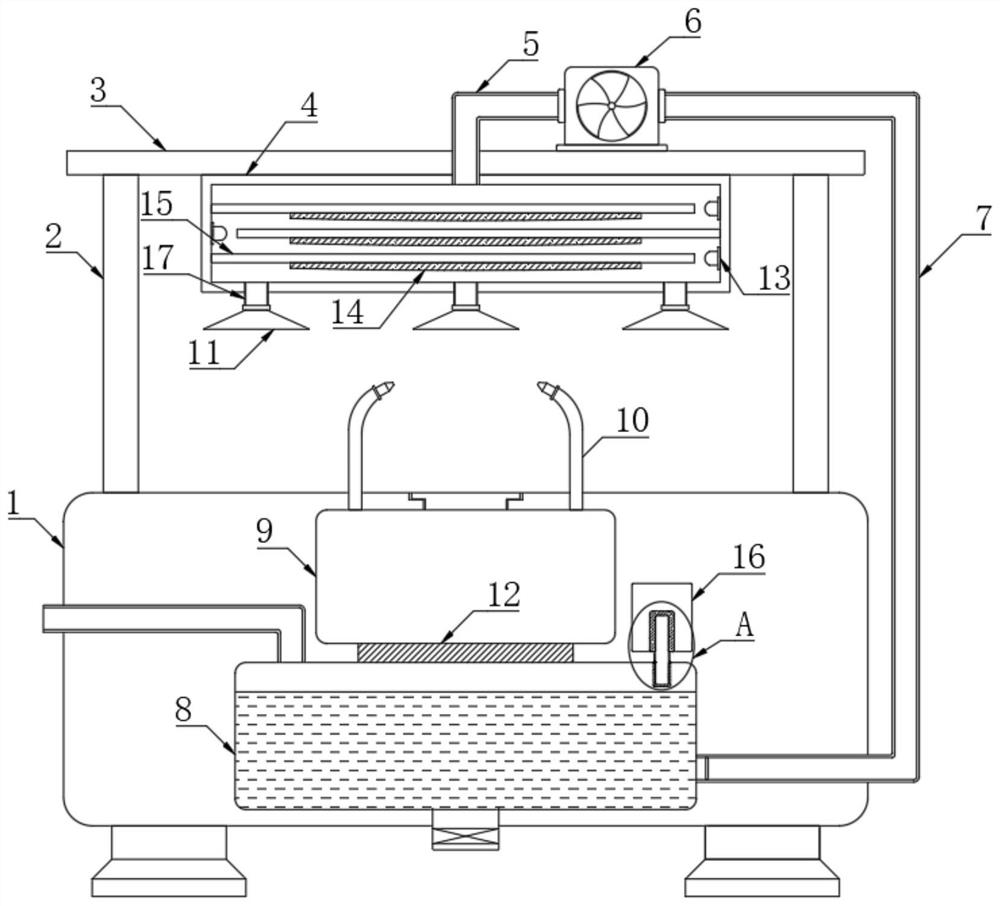

[0028] refer to Figure 1-2 , a gas purification method for rubber tire vulcanization work, the specific method is as follows:

[0029] S1, inhalation, first start the suction fan 6, and the suction fan 6 sucks the irritating gas generated in the vulcanization process into the filter box 4 through the suction cover 11, and then enters the filter box through the suction pipe 5 and the air outlet pipe 7 in turn. Inside chamber 8;

[0030] S2, reaction filtration, the gas entering the filter cavity 8 will be mixed with the sodium hydroxide solution inside, and the sulfur dioxide contained in the gas will react with the sodium hydroxide solution, thereby removing the sulfur dioxide in the gas;

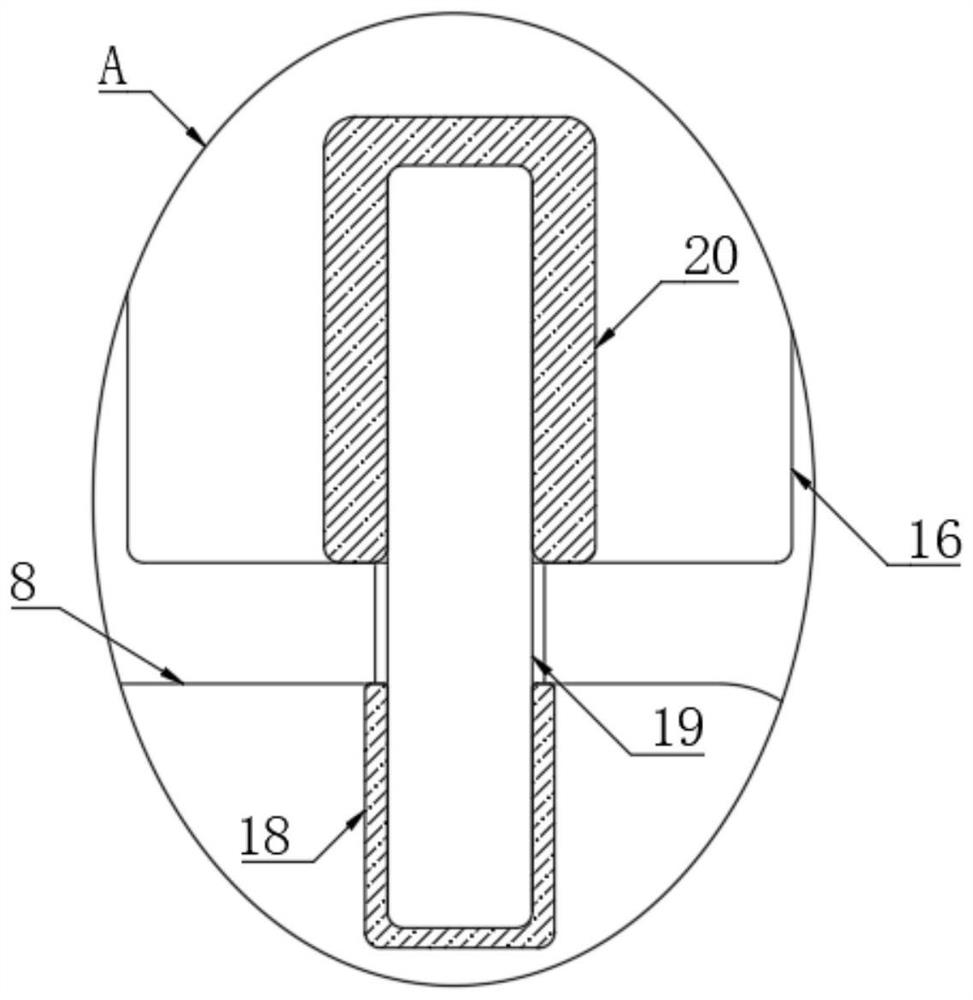

[0031] S3, generate electric current, a large amount of heat can be produced when sulfur dioxide reacts with sodium hydroxide, makes the temperature in the filter chamber 8 rise, makes the ambient temperature of the lower end of the thermoelectric power generation board 19 rise, and the u...

Embodiment 2

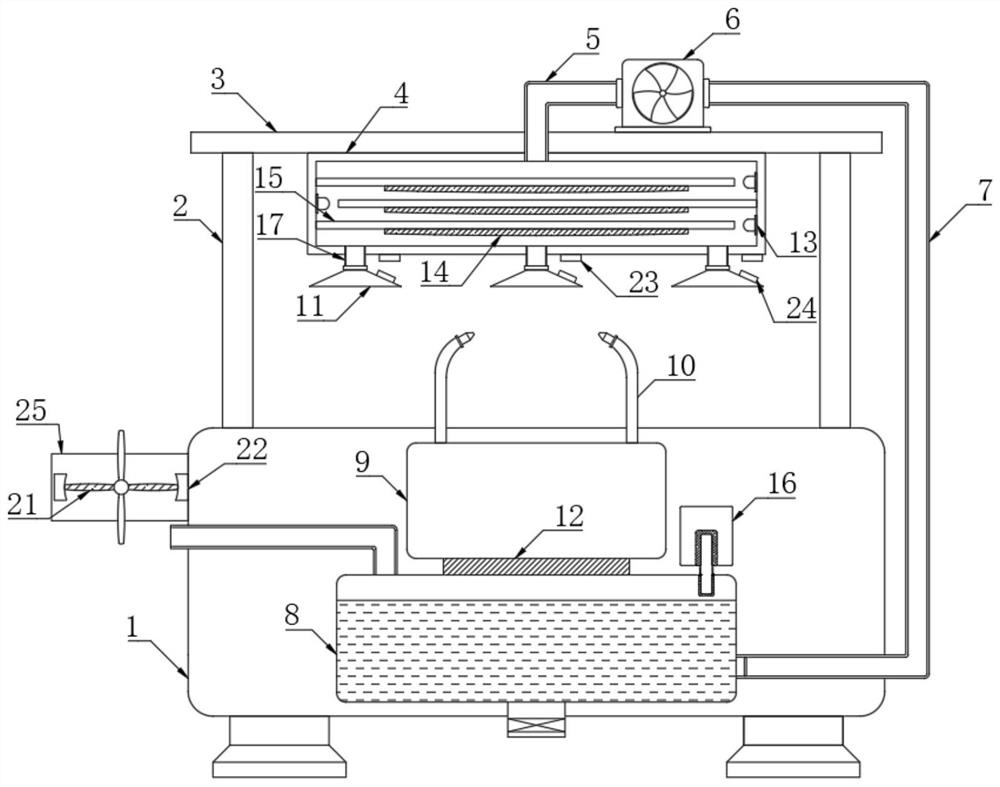

[0042] refer to image 3 , a gas purification method for rubber tire vulcanization work, the side wall of the workbench 1 is fixedly connected with a fixed plate 25, the side wall of the fixed plate 25 is rotatably connected with a rotating rod, and the side wall of the rotating rod is fixedly connected with a plurality of rotating blades 21, Wherein the two facing rotating blades 21 are made of conductive material, the rotating blade 21 located at the lower end is arranged facing the exhaust pipe, the side wall of the fixed plate 25 is fixedly connected with two conductive blocks 22, and the opposite sides of the two conductive blocks 22 The walls are all provided with arc surfaces, and the two rotating vanes 21 located in the horizontal direction are respectively in contact with the side walls of the two conductive blocks 22, the air intake pipe 17 is made of rubber material, and the lower side wall of the filter box 4 is fixedly connected with a plurality of electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com