Rotational wave nozzle

A technology of nozzles and rotating cylinders, applied in the field of rotating wave nozzles, which can solve the problems of poor drying quality and achieve the effects of prolonged life, high quality and high speed drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

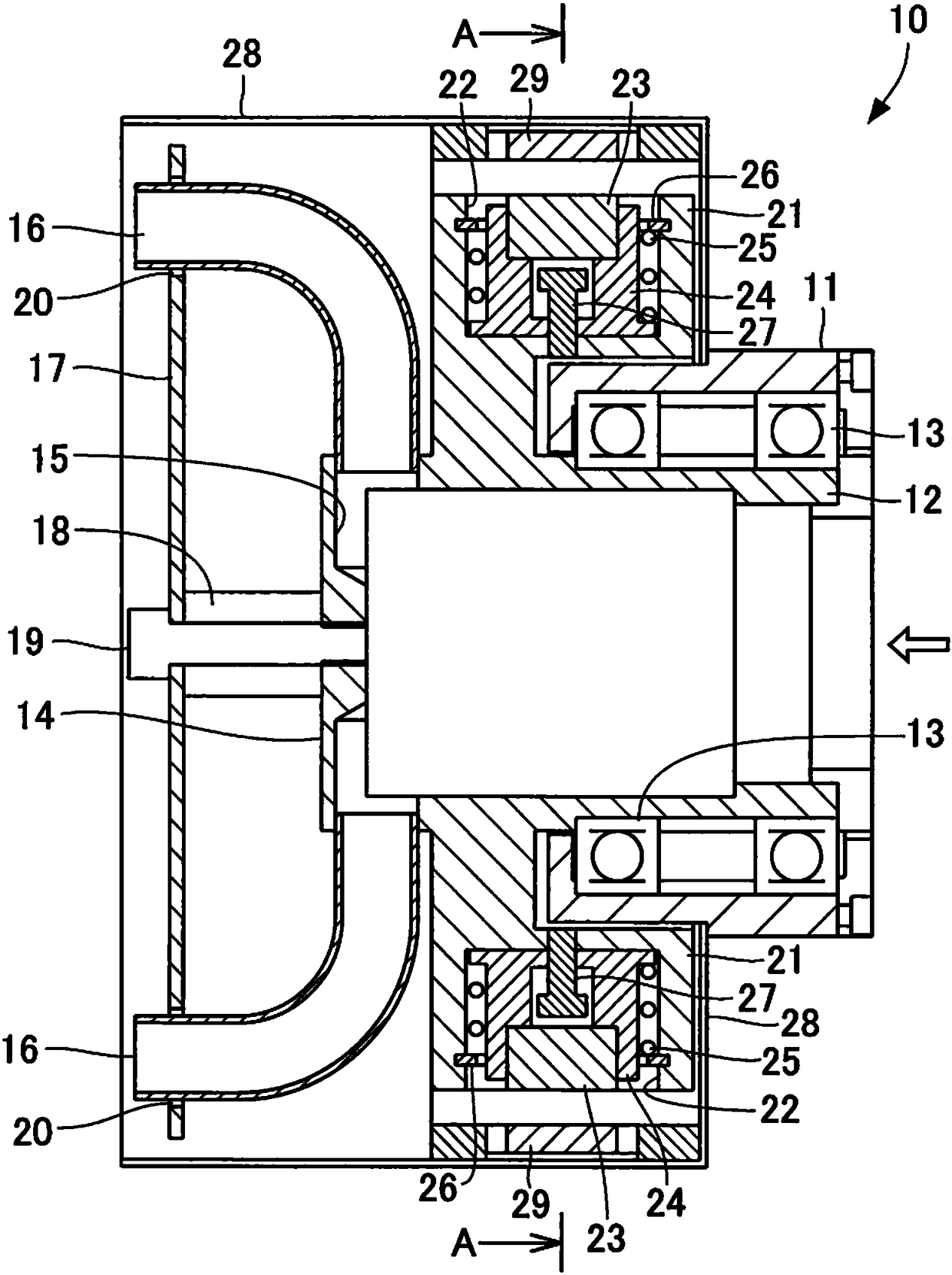

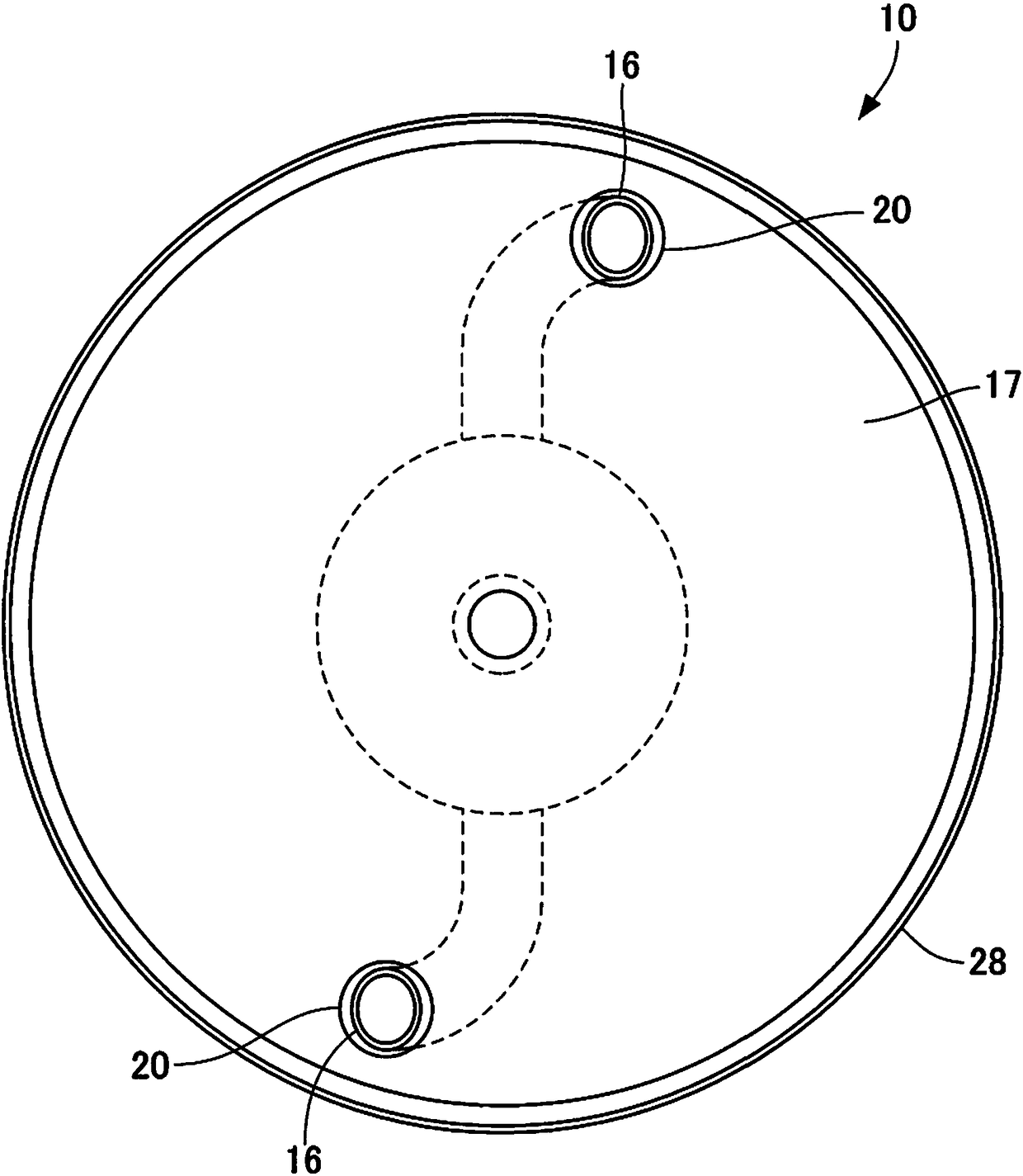

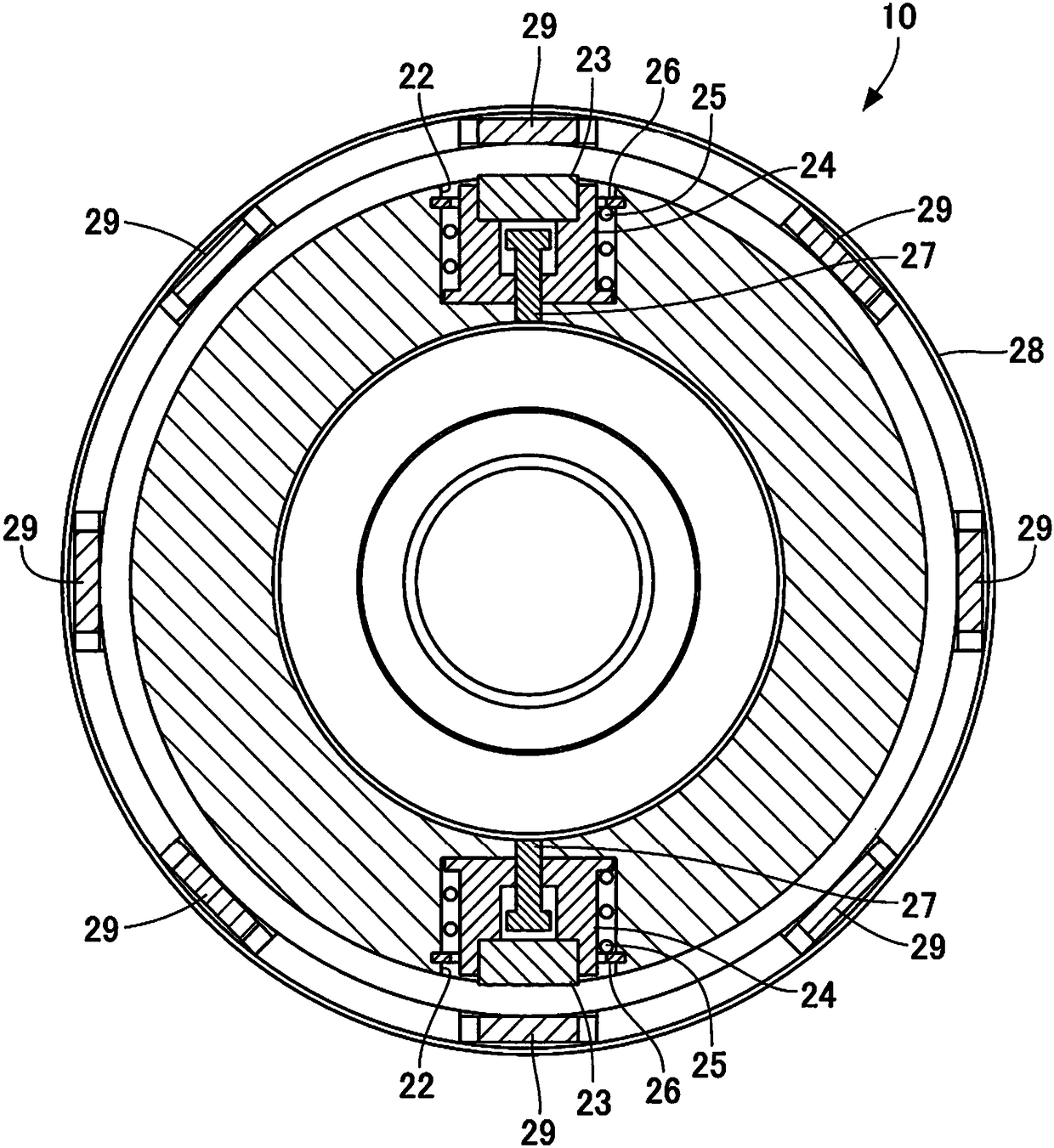

[0036] figure 1 It is a cross-sectional view showing the rotary wave nozzle according to the first embodiment, figure 2 is a side view of the rotating wave nozzle viewed from the jet nozzle side, image 3 is the rotational fluctuation of the nozzle when it is stopped figure 1 A-A sectional view, Figure 4 Indicates the rotating wave nozzle at the time of operation figure 1 A-A to see the sectional view.

[0037] Such as figure 1 As shown, the rotary wave nozzle 10 according to the first embodiment has a hollow cylindrical fixed housing 11 . A hollow cylindrical rotating cylinder 12 is concentrically arranged in the fixed housing 11 , and the rotating cylinder 12 is rotatably supported by two bearings 13 separated in the axial direction inside the fixed housing 11 .

[0038]One end of the rotary cylinder 12 is open, and the other end is closed by an integrally formed closing member 14 . A pipe joint portion 15 is formed at the rotary cylinder 12 on the side closed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com