Ultrahigh-load aluminum alloy wheel extrusion-forming and spinning wheel mechanism

A technology of extrusion forming and spinning wheel, which is applied in the field of special spinning wheel mechanism for aluminum alloy wheel extrusion and stretch forming machine, can solve the problems of thick product, heavy product weight, high fuel consumption of automobile, improve surface finish, guarantee Rolling accuracy and service life, the effect of improving the spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

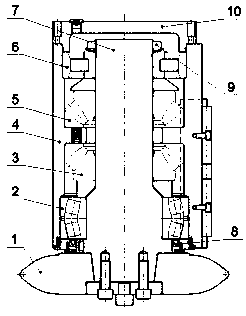

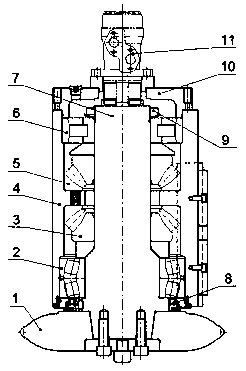

[0011] Depend on figure 1 It is a schematic diagram of the structure of the non-spinning wheel drive. It includes spinning wheel 1, wheel seat 4, mandrel 7, lock nut 9 and upper end cover 10, wherein wheel seat 4 is installed with high-load radial bearing I2, high-load thrust bearing I3, high-load Thrust bearing Ⅱ5 and high-load radial bearing Ⅱ6, the function of radial bearing Ⅰ2 is to withstand the radial force generated in the process of extrusion and stretching, thrust bearing Ⅰ3 is used to bear axial force in one direction, thrust bearing Ⅱ5 is used To withstand the axial force in the opposite direction, the radial bearing II6 is used to support the radial force at the tail of the mandrel 7, and the mandrel 7 is supported by the radial bearing I2, thrust bearing I3, thrust bearing II5 and high-load radial bearing II6 Rotatable, the lock nut 9 is used to fix the mandrel 7, the sealing ring 9 is used to seal the lower end of the mandrel 7, the upper end cover 10 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com