A light metal matrix composite component and its preparation method

A composite material component and light metal technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor reinforcement effect, low production efficiency, and difficult processing, and achieve good deposition efficiency and less processing. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

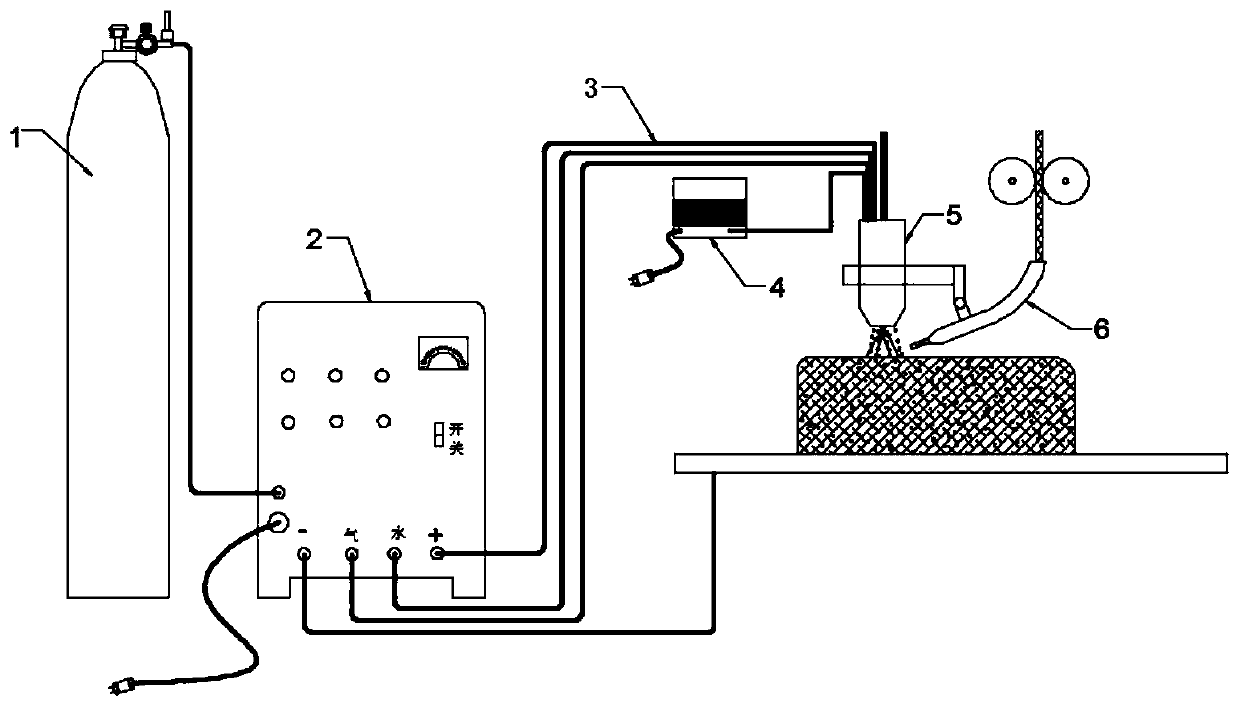

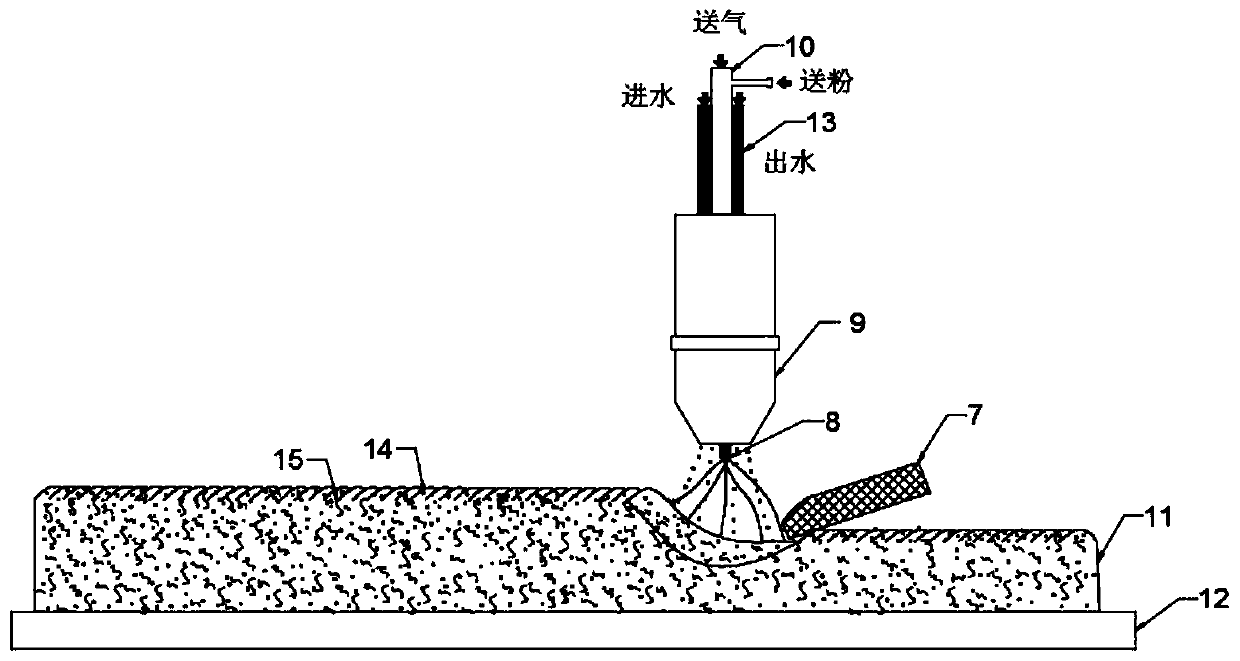

[0035] Based on the preparation method of the present invention, the present invention provides figure 1 The structural schematic diagram of the preparation device shown, figure 2 Schematic diagram of the deposition process.

[0036] Such as figure 1 As shown, the device for preparing light metal matrix composite components of the present invention includes: a gas cylinder 1 , a welding machine 2 , a conduit 3 (bottom line), a powder feeder 4 , a welding torch 5 and a wire feeding device 6 . The gas cylinder 1, welding machine 2 and welding torch 5 are connected and arranged in a conventional manner through a conduit 3. The powder feeder 4 communicates with the feeder pipe 10 (arc shielding gas delivery pipeline) of the welding torch 5, and is used to send the particle reinforcement into the pipeline, and then blow it into the liquid molten pool under the action of inert gas. The wire feeding outlet of the wire feeding device 6 is located directly in front of the moving di...

Embodiment 1

[0039] The preparation method of the present embodiment comprises the following specific steps:

[0040] (1) Surface pretreatment: polish the surface of the light metal substrate to be deposited, remove the oil stain on the surface of the substrate, and then air dry;

[0041] (2) Preparation of composite welding wire: the light metal matrix and linear / flaky reinforcement are prepared by powder metallurgy, stirred casting or squeeze casting, and then the bulk material is extruded into a composite welding wire with a diameter of 0.5mm ; Wherein, the mass percentage of the linear / flaky reinforcements in the composite welding wire is 1%, and the linear / flaky reinforcements are carbon nanotubes and graphene;

[0042] (3) Arc additive manufacturing of tungsten inert gas shielded welding:

[0043] (31) Coaxial powder feeding: place the dried granular reinforcement in a powder feeder connected to the arc protection gas delivery pipeline, and the powder feeder delivers the granular re...

Embodiment 2

[0048] The preparation method of the present embodiment comprises the following specific steps:

[0049] (1) Surface pretreatment: polish the surface of the light metal substrate to be deposited, remove the oil stain on the surface of the substrate, and then air dry;

[0050] (2) Preparation of composite welding wire: prepare bulk material by powder metallurgy, stir casting or squeeze casting with light metal matrix and linear / flaky reinforcement, and then extrude the bulk material into a composite welding wire with a diameter of 4mm; Among them, the mass percentage of the linear / flaky reinforcement in the composite welding wire is 15%, the linear / flaky reinforcement is whisker and graphene, and the whisker is AlO, BeO, SiC or SiN;

[0051] (3) Arc additive manufacturing of tungsten inert gas shielded welding:

[0052] (31) Coaxial powder feeding: place the dried granular reinforcement in a powder feeder connected to the arc protection gas delivery pipeline, and the powder fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com