Device based on multi-motor electric control for grinding plate-shaped material and control method thereof

A multi-motor, flat-plate technology, used in automatic grinding control devices, grinding machines, manufacturing tools, etc., can solve the problems of low processing efficiency, high processing cost, low precision, etc., and achieve good grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

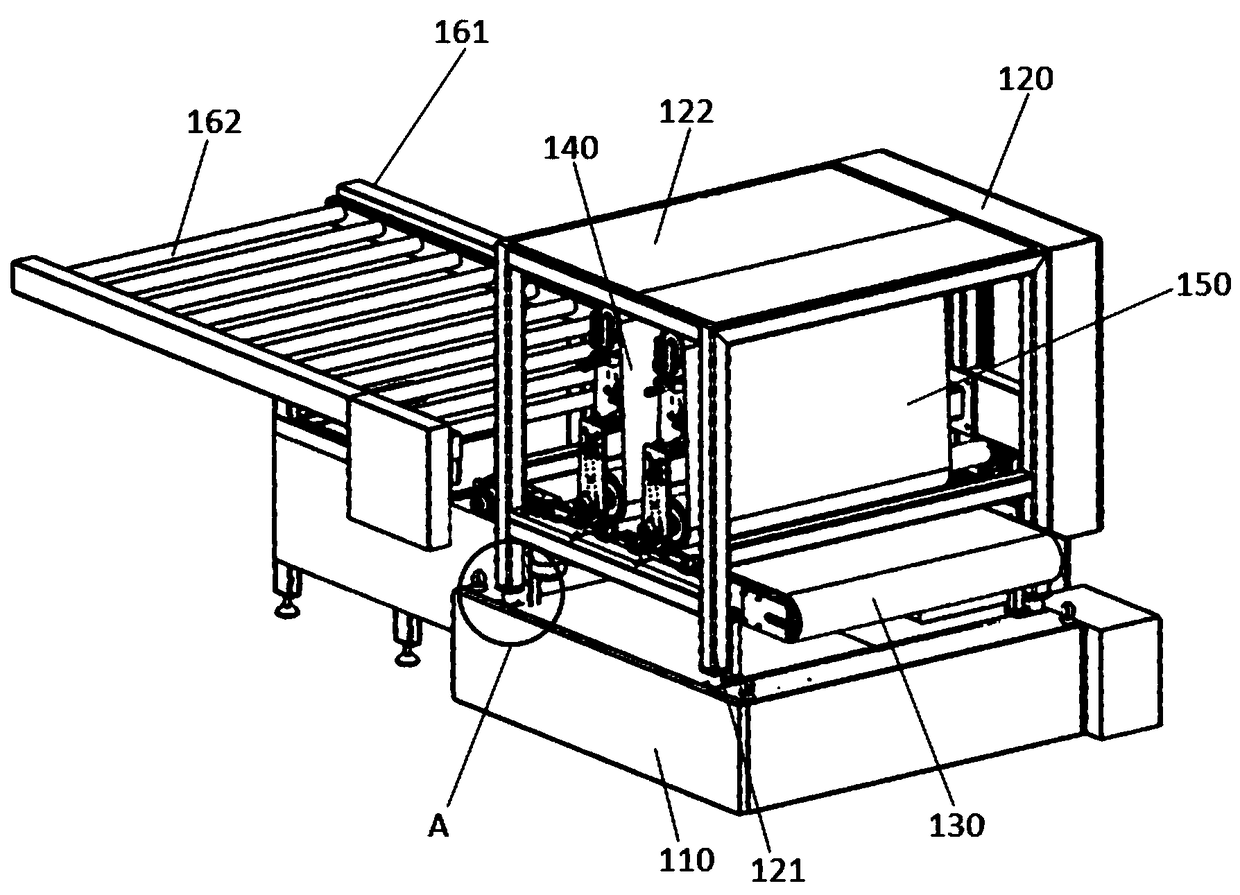

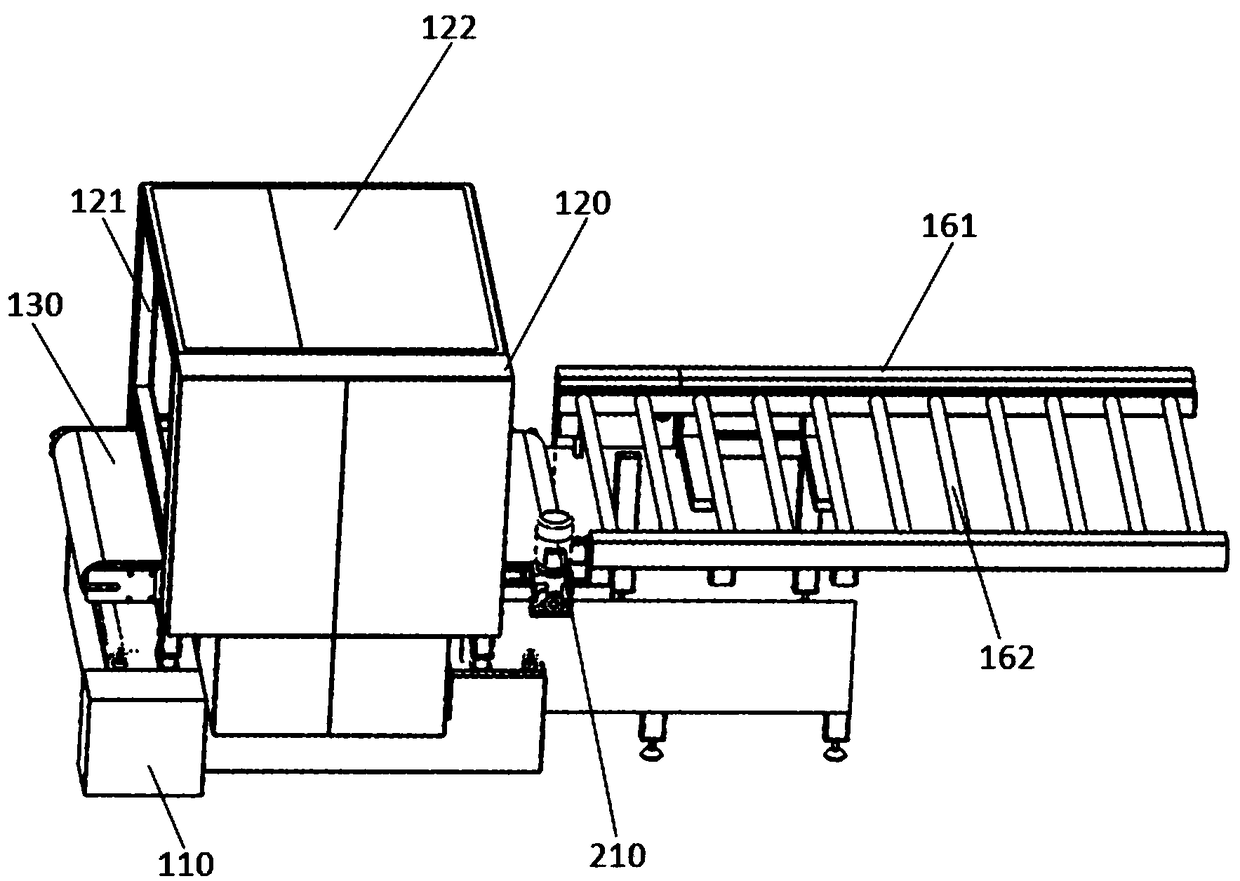

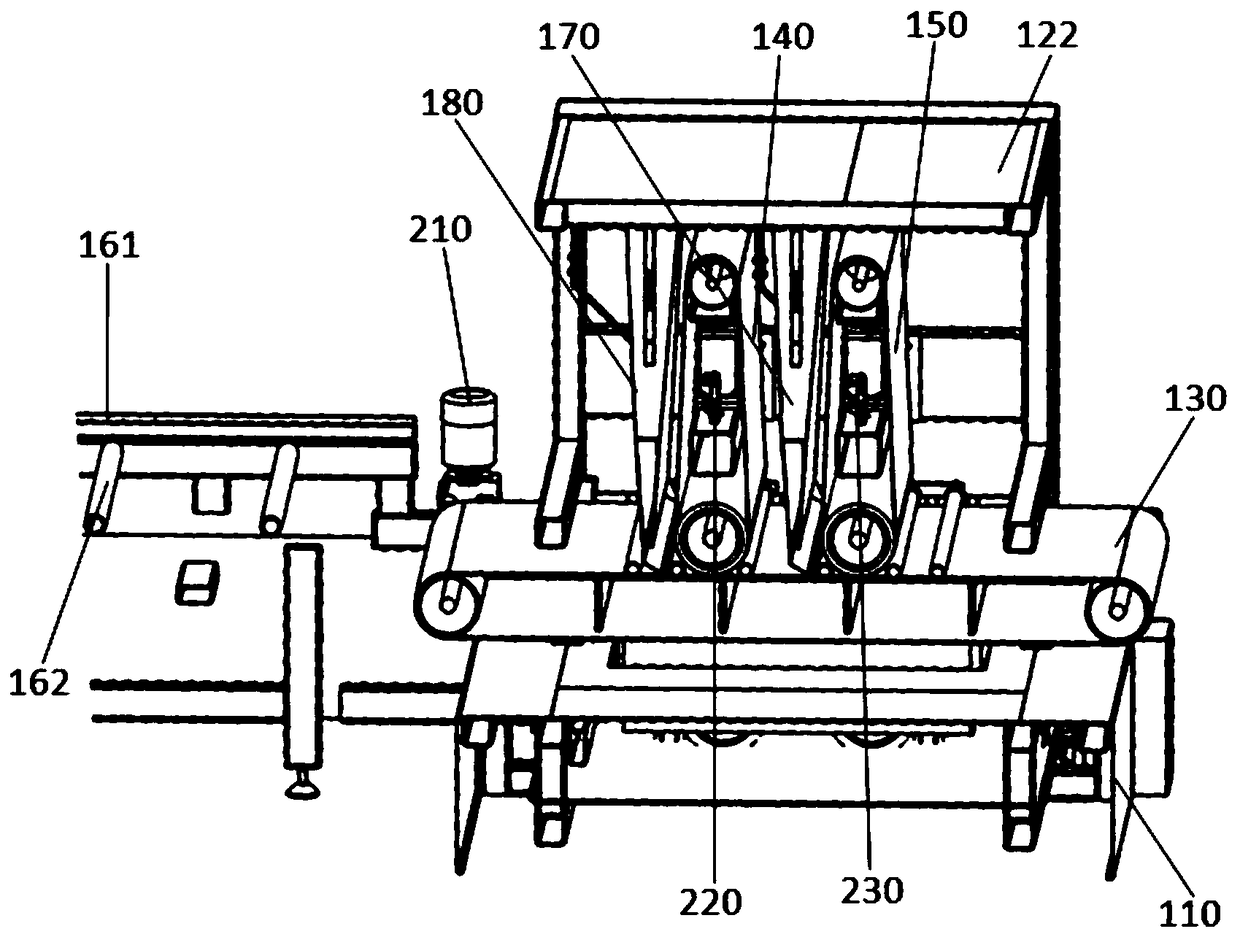

[0051] Such as Figure 1~3 As shown, the present invention provides a flat material device based on multi-motor electric control, and its main structure includes: a base 110, a support frame 120, a conveyor belt 130, a first grinding belt 140 and a second grinding belt 150, The support frame 120 includes a support plate 122 and four support columns 121, the support plate 122 and the four support columns 121 are fixedly connected by welding, and the four support columns 121 are respectively detachably fixed on the base 110 through the support base, and the support base The height is adjustable, the transmission belt 130 is fixed on the base 110 through the bracket, the first grinding belt 140 is fixedly connected with the support frame 120 through the bracket, and the second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com