Preparation method of flame-retardant rattan

A rattan, flame retardant liquid technology, used in manufacturing tools, mechanical equipment, reed/straw treatment, etc., can solve problems such as fire and hidden dangers, and achieve the effect of consolidating the flame retardant effect and improving fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

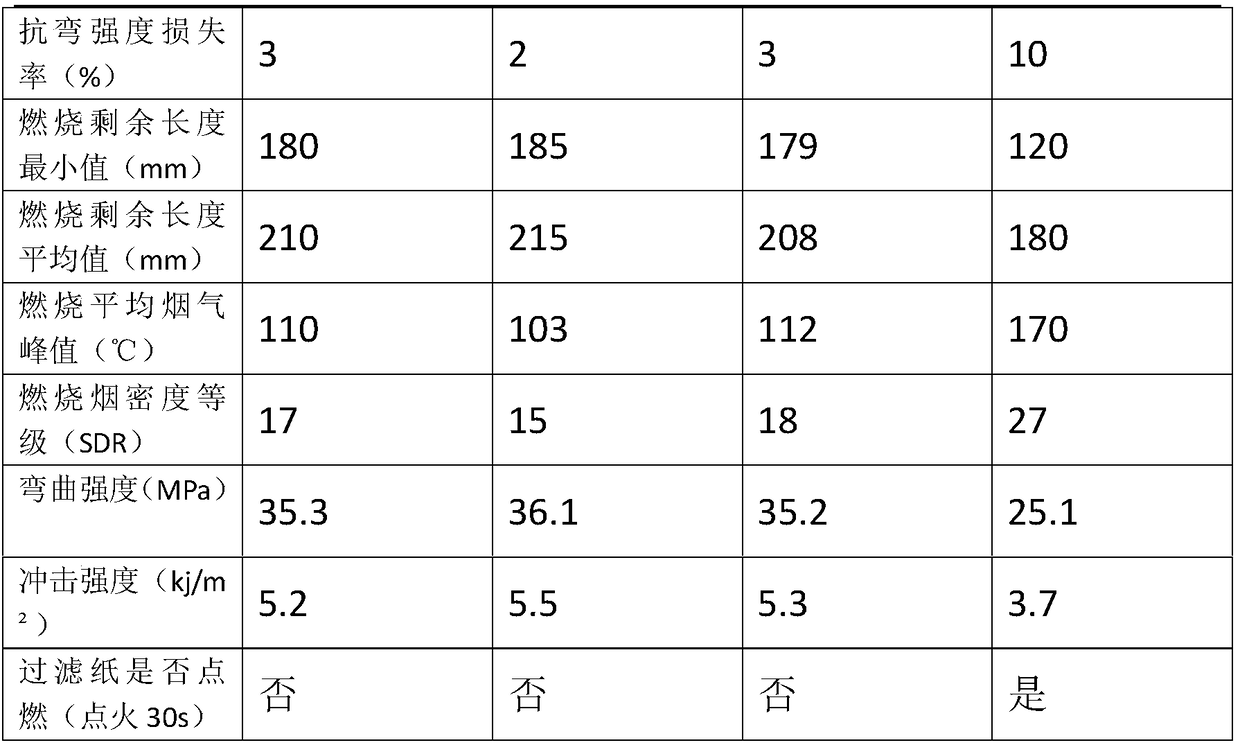

Embodiment 1

[0017] 1) Saw off the log, open the pieces, smooth the burrs on the side of the rattan, and the width of a single rattan is 2cm;

[0018] 2) Put the rattan treated in step 1) into -25°C for quick freezing for 10 minutes, take it out and soak it in a flame retardant solution at 30°C for 12 hours, specifically, soak the rattan in a flame retardant solution after quick freezing, and soak it in a flame retardant solution at 30°C Soak in heat preservation for 6 hours, slowly raise the temperature to 40°C, and soak in heat preservation for 6 hours;

[0019] The flame retardant solution is: 25 parts of ureidophosphate GUP, 4 parts of microencapsulated red phosphorus, 10 parts of phosphoric acid, 4 parts of phosphorylated castor oil, 6 parts of multidirectional complexing central atom zinc, and 3 parts of sodium lauryl sulfate;

[0020] The components of ureidophosphate GUP are: 20% phosphorus oxyacid, 20% dicyandiamide, and the balance is water.

[0021] 3) Dry the soaked rattan in ...

Embodiment 2

[0025] 1) Saw off the log, open the pieces, smooth the burrs on the side of the rattan, and the width of a single rattan is 3cm;

[0026] 2) Put the treated rattan in step 1) into -25°C for quick freezing for 12 minutes, take it out and soak it in a fire-retardant solution at 35°C for 18 hours, specifically, put the rattan into the fire-retardant solution after quick-freezing and soak at 30°C Soak in heat preservation for 9 hours, slowly raise the temperature to 40°C, and soak in heat preservation for 9 hours;

[0027] The flame retardant solution is: 25 parts of ureidophosphate GUP, 5 parts of microencapsulated red phosphorus, 13 parts of phosphoric acid, 5 parts of phosphorylated castor oil, 6 parts of multidirectional complexing central atom zinc, and 3 parts of sodium lauryl sulfate;

[0028] The components of ureidophosphate GUP are: 30% phosphorus oxyacid, 30% dicyandiamide, and the balance is water.

[0029] 3) Dry the soaked rattan in step 2, at a drying temperature o...

Embodiment 3

[0033] 1) Saw off the log, open the pieces, smooth the burrs on the side of the rattan, and the width of a single rattan is 4cm;

[0034] 2) Put the treated rattan in step 1) into -25°C for quick freezing for 15 minutes, take it out and soak it in a flame retardant solution at 40°C for 24 hours. Soak in heat preservation for 12 hours, slowly raise the temperature to 40°C, and soak in heat preservation for 12 hours;

[0035] The flame retardant solution is: 25 parts of ureidophosphate GUP, 6 parts of microencapsulated red phosphorus, 16 parts of phosphoric acid, 6 parts of phosphorylated castor oil, 6 parts of multidirectional complexing central atom zinc, and 3 parts of sodium lauryl sulfate;

[0036] The components of ureidophosphate GUP are: 40% phosphorus oxyacid, 40% dicyandiamide, and the balance is water.

[0037] 3) Dry the soaked rattan in step 2, at a drying temperature of 60°C, keep it warm for 30 minutes until the water content is 40%, lower the temperature to 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com