Manufacturing method of flame-retardant bamboos

A technology of bamboo wood and flame retardant liquid, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve fire hazards and other problems, achieve the effect of consolidating flame retardant effect, improving fire resistance and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

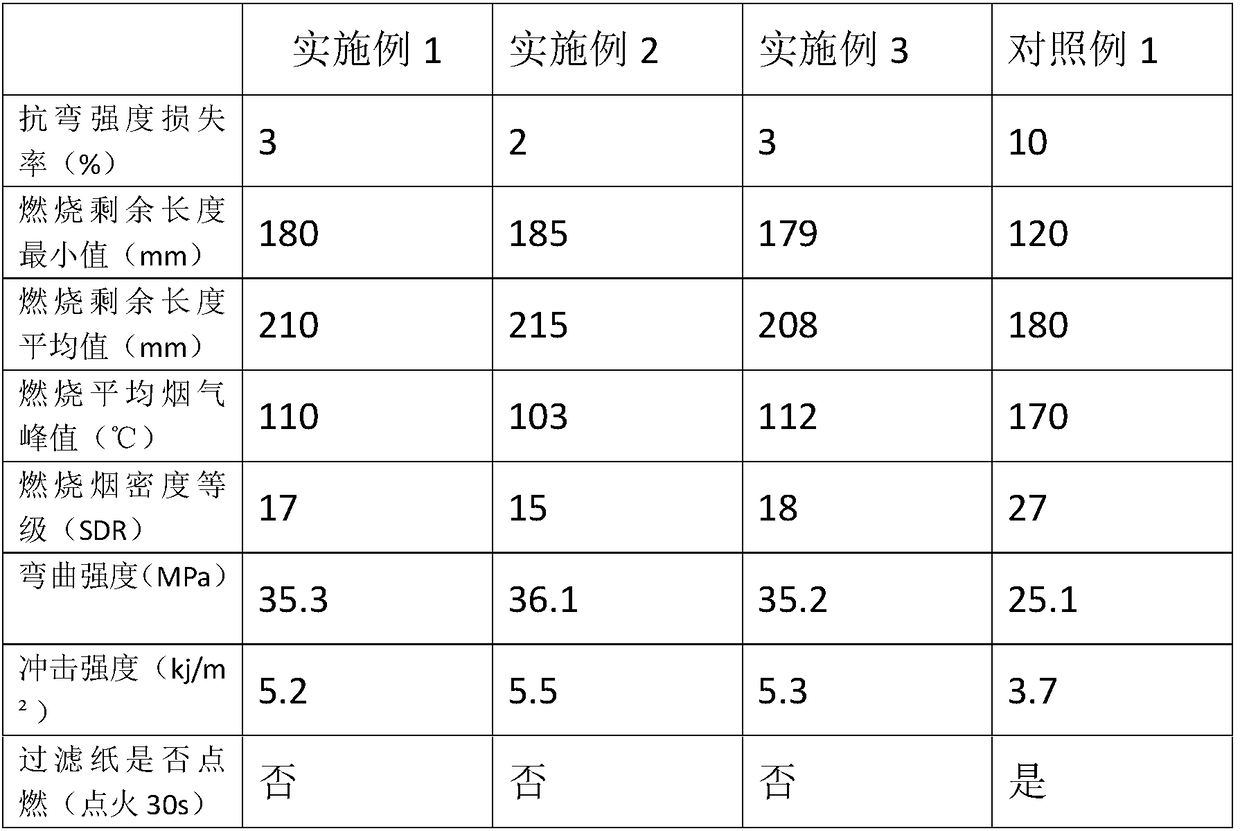

Examples

Embodiment 1

[0018] 1) sawing off the log, splitting it into pieces, processing the log into strips, smoothing the burrs on the side of the bamboo, and the width of a single bamboo is 2cm;

[0019] 2) Put the bamboo slices treated in step 1) into -25°C for quick freezing for 10 minutes, take them out and soak them in a fire-retardant solution at 30°C for 12 hours, specifically, put the bamboo slices into the fire-retardant solution after quick-freezing and soak them at 30°C Soak in heat preservation for 6 hours, slowly raise the temperature to 40°C, and soak in heat preservation for 6 hours;

[0020] The flame retardant solution is: 25 parts of ureidophosphate GUP, 4 parts of microencapsulated red phosphorus, 10 parts of phosphoric acid, 4 parts of phosphorylated castor oil, 6 parts of multidirectional complexing central atom zinc, and 3 parts of sodium lauryl sulfate;

[0021] The components of ureidophosphate GUP are: 20% phosphorus oxyacid, 20% dicyandiamide, and the balance is water. ...

Embodiment 2

[0026] 1) Saw the log, split it, process the log into strips, grind the burrs on the side of the bamboo, and the width of a single bamboo is 3cm;

[0027] 2) Put the bamboo slices processed in step 1) into -25°C for quick freezing for 12 minutes, take them out and soak them in a fire retardant solution at 35°C for 18 hours. Soak in heat preservation for 9 hours, slowly raise the temperature to 40°C, and soak in heat preservation for 9 hours;

[0028] The flame retardant solution is: 25 parts of ureidophosphate GUP, 5 parts of microencapsulated red phosphorus, 13 parts of phosphoric acid, 5 parts of phosphorylated castor oil, 6 parts of multidirectional complexing central atom zinc, and 3 parts of sodium lauryl sulfate;

[0029] The components of ureidophosphate GUP are: 30% phosphorus oxyacid, 30% dicyandiamide, and the balance is water.

[0030] 3) Dry the soaked bamboo chips in step 2, at a drying temperature of 60°C, keep warm for 25 minutes, until the moisture content is ...

Embodiment 3

[0034] 1) Saw off the log, split it, process the log into strips, grind the burrs on the side of the bamboo, and the width of a single bamboo is 4cm;

[0035] 2) Put the bamboo slices treated in step 1) into -25°C for quick freezing for 15 minutes, take them out and soak them in a flame retardant solution at 40°C for 24 hours, specifically, put the bamboo slices into the flame retardant solution after quick freezing, soak at 30°C Soak in heat preservation for 12 hours, slowly raise the temperature to 40°C, and soak in heat preservation for 12 hours;

[0036] The flame retardant solution is: 25 parts of ureidophosphate GUP, 6 parts of microencapsulated red phosphorus, 16 parts of phosphoric acid, 6 parts of phosphorylated castor oil, 6 parts of multidirectional complexing central atom zinc, and 3 parts of sodium lauryl sulfate;

[0037] The components of ureidophosphate GUP are: 40% phosphorus oxyacid, 40% dicyandiamide, and the balance is water.

[0038] 3) Dry the soaked bam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com