Building concrete mixer

A technology for concrete mixers and construction, applied in the field of concrete mixing, can solve the problems of reducing the mixing quality and cleaning the inner wall of the mixer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

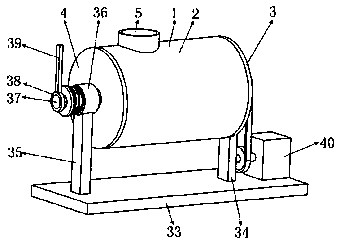

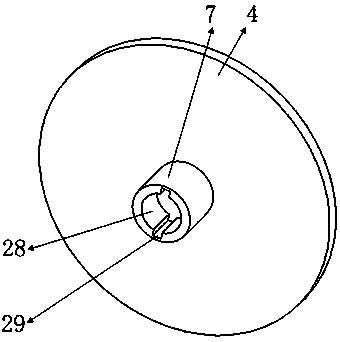

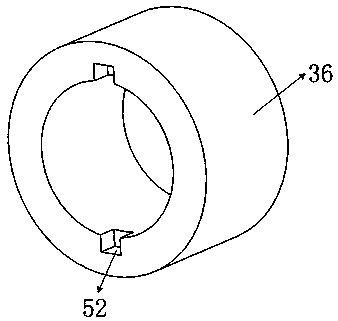

[0076] Specific implementation method: before the mixer is ready to mix concrete, the feed port ring shell 5 faces upwards and the feed port ring shell 5 is connected with the charging mechanism; the first spring 49 is not stretched, and the two limit plates 50 on the rotating rod 37 They are respectively located in the two limiting grooves 52 of the second support ring 36 ; the slider spring 31 is always in a compressed state, and the slider 30 is located at the end of the guide rail 27 away from the first rotating shaft 9 .

[0077] When the mixer is mixing concrete, the raw materials of the concrete enter the mixing space 55 through the charging mechanism and the material opening ring shell 5; then start the reduction motor 40, and the reduction motor 40 drives the first pulley 43 to rotate through the drive shaft 44, and the first pulley 43 passes through The belt 42 drives the second pulley 6 to rotate, and the second pulley 6 drives the first rotating shaft 9 to rotate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com