Building cement mixing device

A technology of mixing device and building cement, applied in cement mixing device, control device, unloading device, etc., can solve the problems of raw materials not meeting the requirements, slow mixing speed, slow mixing speed, etc., to achieve convenient operation and improve cement quality , to avoid the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

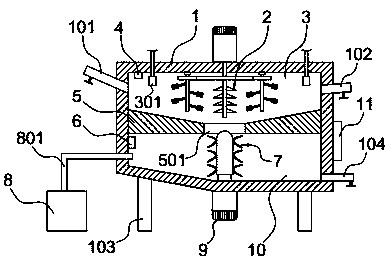

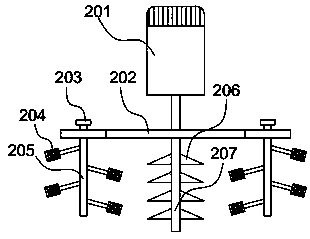

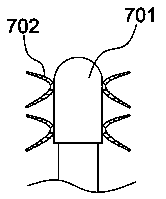

[0035] Such as Figure 1-3 As shown, a building cement mixing device includes a mixing box 1 connected to a support column 103 at the bottom, and the inside of the mixing box 1 is divided into a mixing chamber 3 and a discharge chamber 10 up and down by a partition plate 501, and a flow hole is provided in the middle of the partition plate 501 501, the stirring chamber 3 is provided with a stirring mechanism 2, the stirring box 1 on both sides of the stirring chamber 3 is respectively provided with a feed pipe 101 and a liquid inlet pipe 102, and the bottom of the discharge chamber 10 is connected with a discharge pipe whose outlet is located outside the stirring box 1 The material pipe 104 is connected to the industrial computer 11 on the outer wall of the mixing box 1 , the humidity detector 4 is connected to the top wall of the mixing chamber 3 , and the temperature detector 6 is connected to the side wall of the discharge chamber 10 . The mixing chamber 3 and the discharge...

Embodiment 2

[0044] Such as Figure 4 Shown, a kind of using method of construction cement mixing device comprises the following steps:

[0045] S1: Input cement mixing parameters into the industrial computer 11, such as raw materials and dosage for cement mixing, cement mixing time, mixing speed of each mixing component, etc.;

[0046] S2: preparing cement mortar, sending cement, sand and water into the mixing chamber 3 for mixing;

[0047] S3: the industrial computer 11 reads the parameters of the temperature detector 6 and the humidity detector 4 in the mixing box 1;

[0048] S4: the industrial computer 11 optimizes the stirring parameters using a calculation program;

[0049] S5: preparing cement concrete mixture, sending crushed stone and water into the mixing chamber 3 for mixing;

[0050] S6: discharge, end the program. During the mixing process, the operating parameters of each component are controlled by the industrial computer 11, and the monitoring parameters of the humidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com