Raw material mixing device for film production

A mixing device and raw material technology, applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of reducing raw material mixing efficiency, cumbersome cleaning process, time-consuming and labor-intensive, etc., to reduce temperature loss, scrape In addition to the effect of fast speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

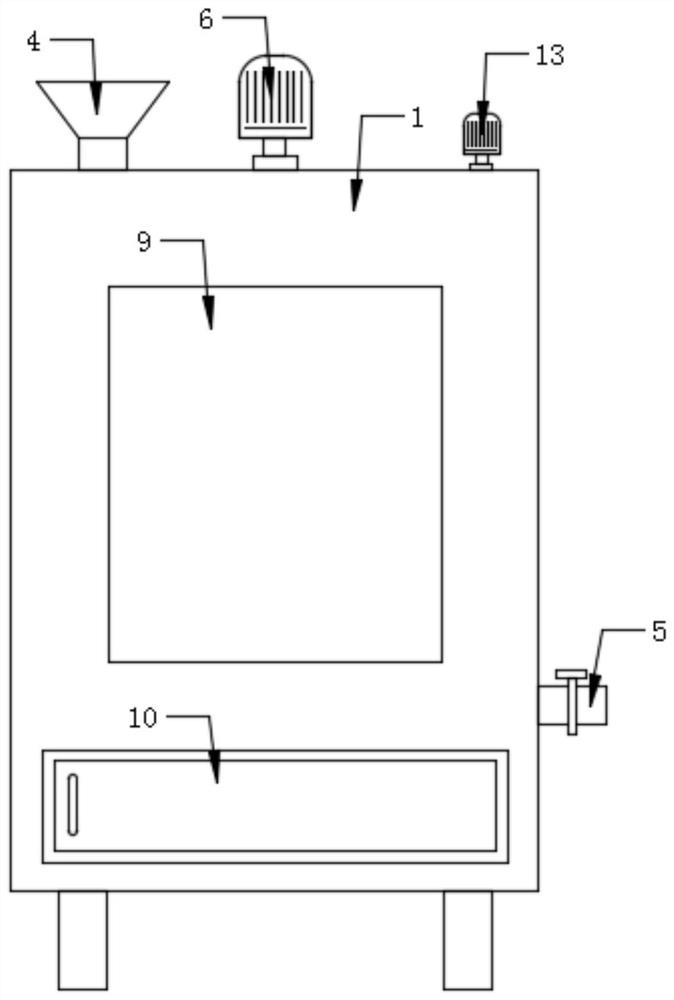

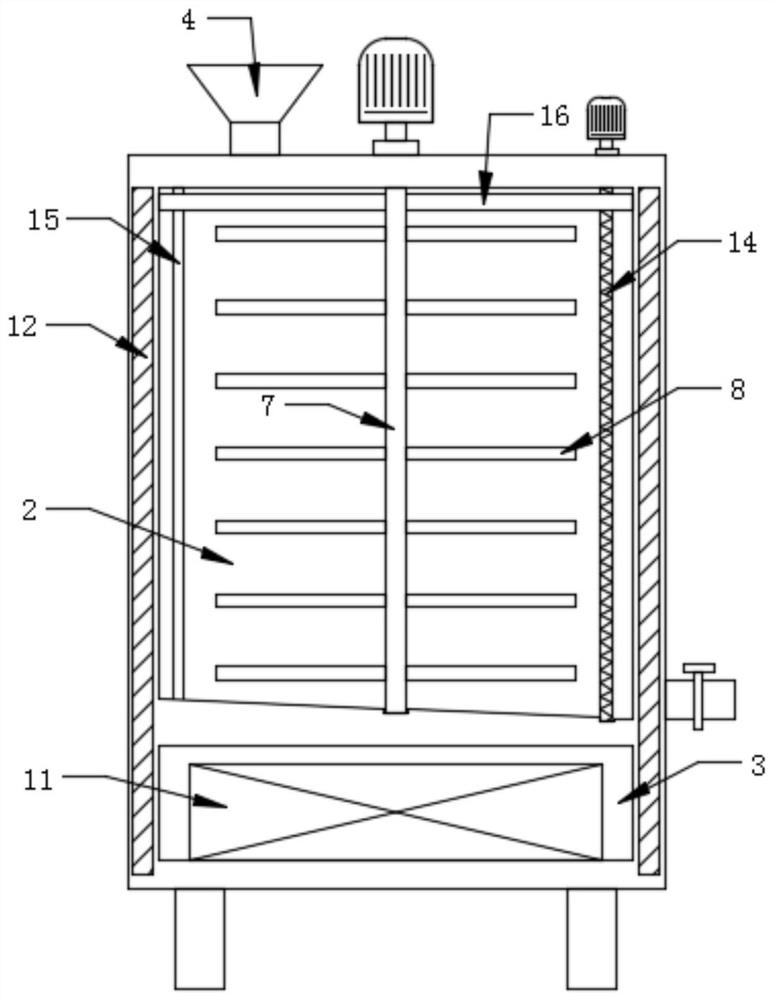

[0022] like Figure 1-4 As shown, the present invention provides a technical solution: a raw material mixing device for film production, including a main body 1 of the device, a stirring structure for stirring the raw materials, a heating structure for heating the inside of the main body 1, and a heating structure for The cleaning structure for cleaning the inner wall of the main body 1, the main body 1 includes a stirring bin 2 and a heating bin 3, and the heating bin 3 is located below the stirring, supporting legs are installed around the lower end surface of the main body 1, and the main body The top side of 1 and the bottom of one side are respectively provided with a feed funnel 4 and a discharge pipe 5. The stirring structure is installed on the top of the main body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com