Self-adjustment type nozzle assembly for full encapsulation mold

A fully encapsulated and self-adjusting technology, applied in the field of self-adjusting nozzle assemblies for fully encapsulated molds, can solve the problems of affecting quality, unable to achieve regional adjustment, affecting appearance, etc., and achieve the effect of ensuring the upper and lower pressure values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

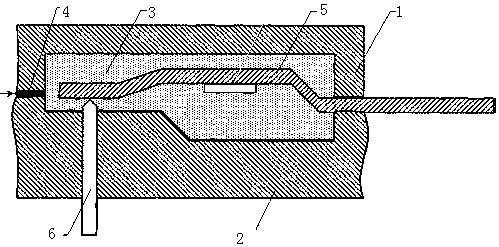

[0019] Such as Figure 1~5 As shown, a self-adjusting nozzle assembly for a fully encapsulated mold disclosed in this embodiment, the structure of the fully encapsulated mold includes an upper mold 1 and a lower mold 2, and a glue injection cavity 3 is formed inside after the mold is closed. And form a glue injection port 4 at the front end, the lead frame 5 is placed in the glue injection cavity, and is supported by the thimble 6 inserted in the lower mold to ensure that it is horizontal and located at the mold line of the upper mold and the lower mold.

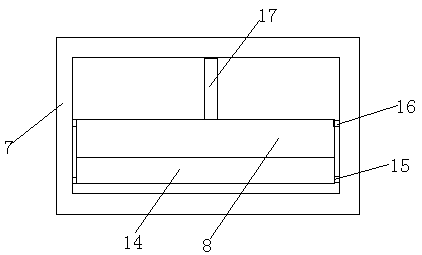

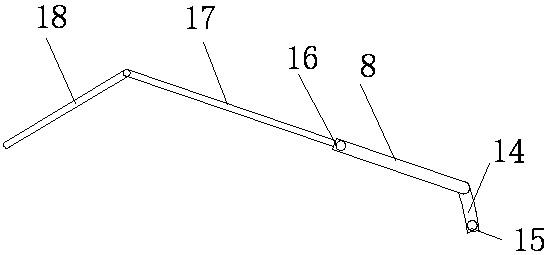

[0020] One end of the nozzle assembly is installed at the front end of the L-shaped rubber hose, and the other end is inserted into the glue injection port 4. The specific nozzle assembly includes a glue spray pipe 7 and an adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com