Anti-skid system and adjustment method of AGV trolley

A small car, anti-skid technology, applied in the direction of vehicle components, elastic suspension, suspension, etc., can solve the problems of increasing the positive pressure of the driving wheel, slipping, etc., to achieve the effect of preventing slipping and anti-skid control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

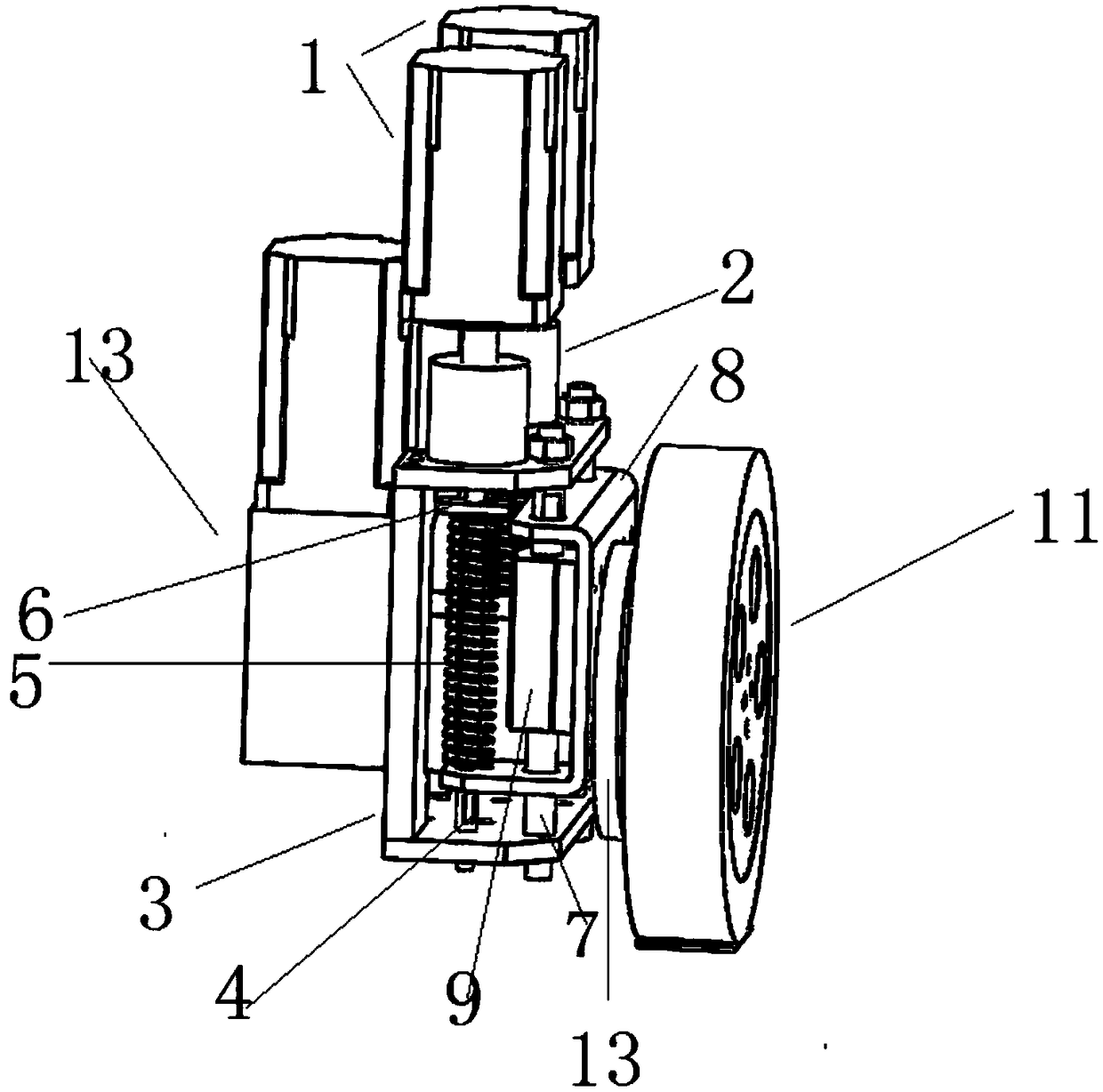

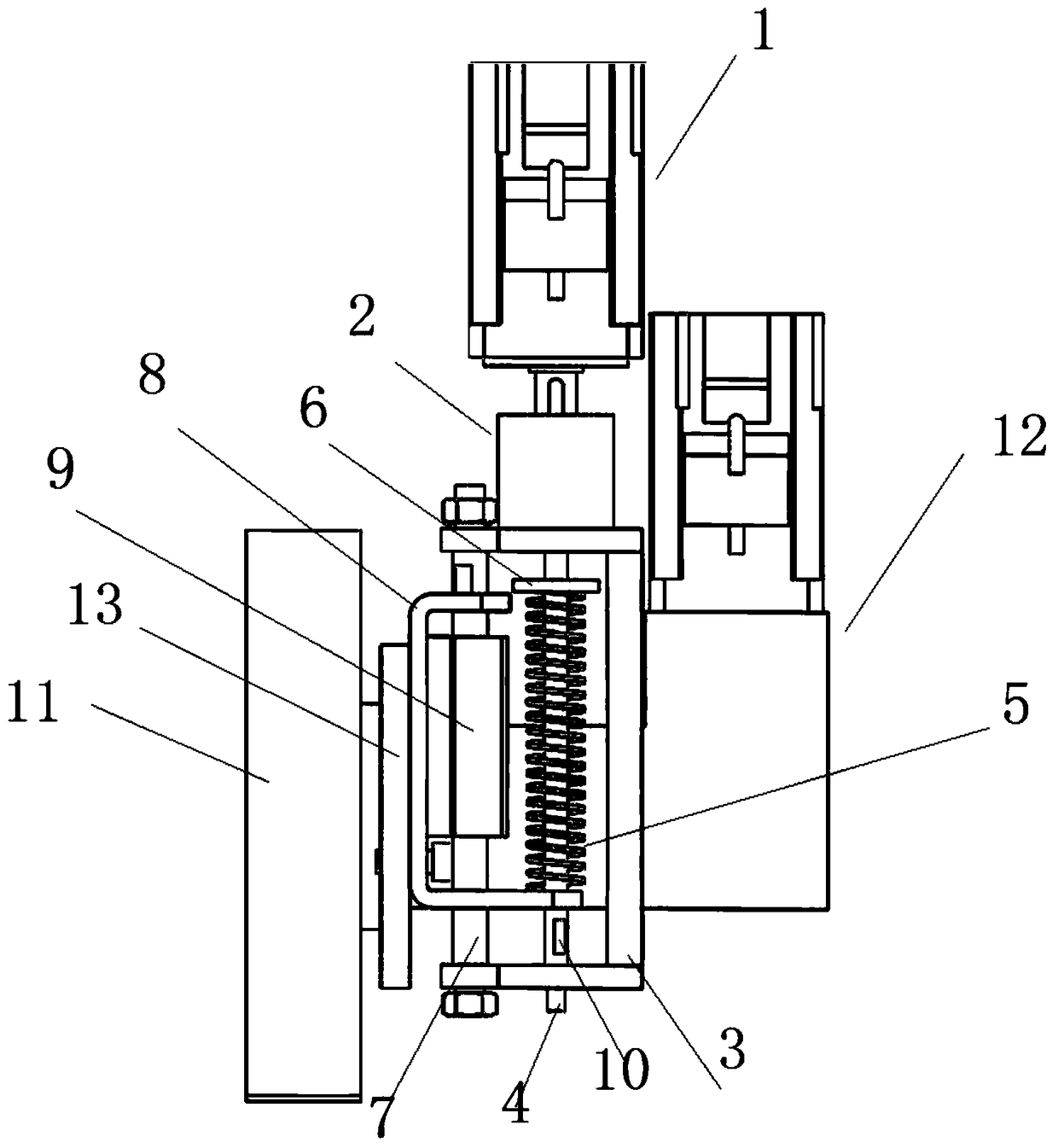

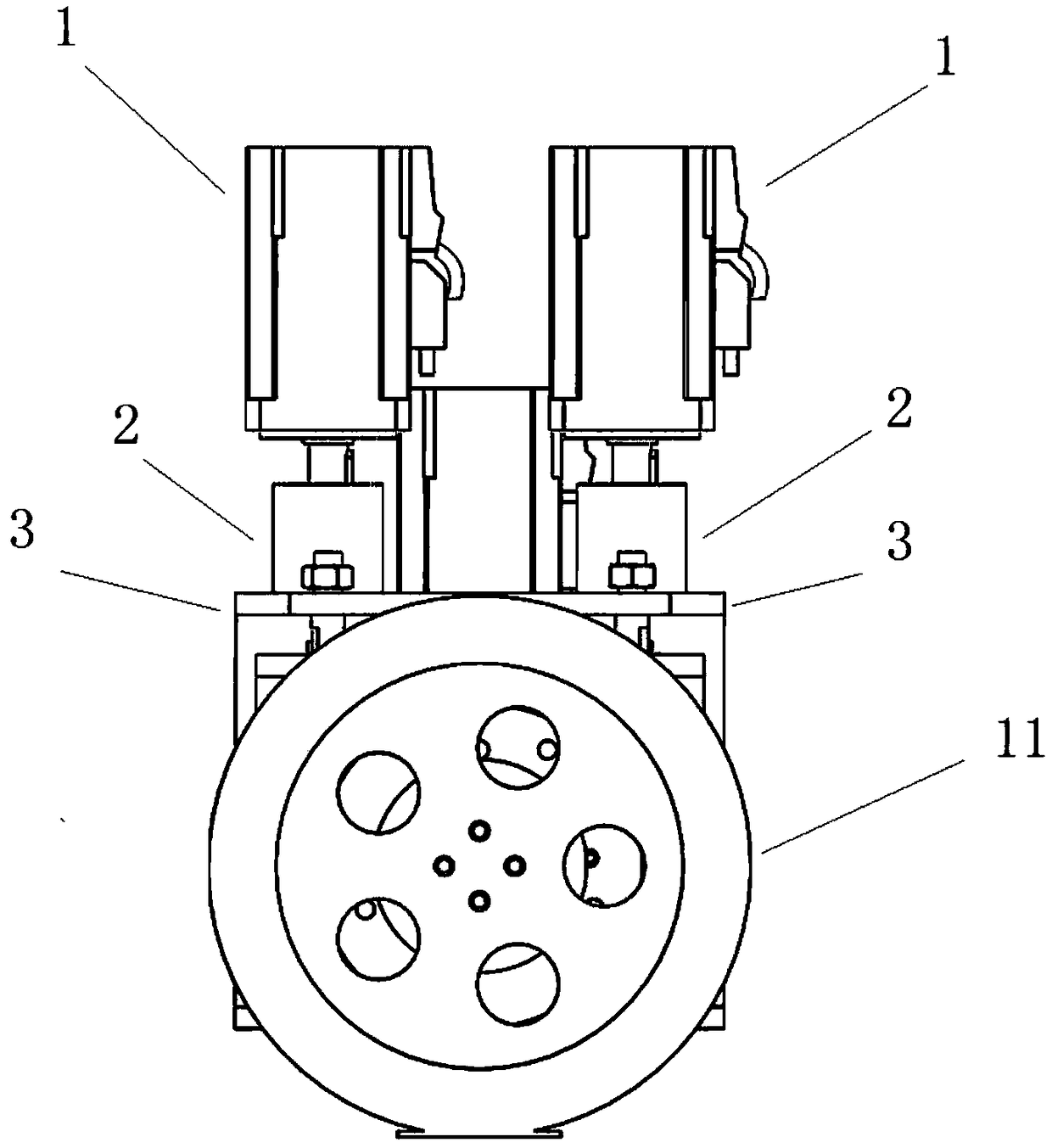

[0040] Such as figure 1 , 2 , As shown in 3, the present invention carries some active control spring units on each drive wheel of the AGV trolley, and this embodiment adopts 2, symmetrically distributed;

[0041] The active control spring unit is composed of a driving motor 1, a coupling 2, a main fixing assembly 3, a lead screw 4, a spring 5, a slider 6, a guide shaft 7, a U-shaped frame 8, a linear bearing 9, and a pressure sensor 10.

[0042] The main fixing assembly 3 is composed of an upper fixing plate, a lower fixing plate, and a middle connecting plate;

[0043] The drive motor 1 and the guide shaft 7 are all fixed on the main fixed assembly;

[0044] The slide block 6 is connected with the lead screw 4 through threads;

[0045] The spring 5 is set on the lead screw 4, the top is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com