Safety protection device of railroad platform door

A safety protection device and platform door technology, which is applied to railway car body components, roads, stations, etc., can solve the problems of complex structure of the device and high construction cost, and achieve the effects of expanding the scope of application, reducing construction costs, and avoiding congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

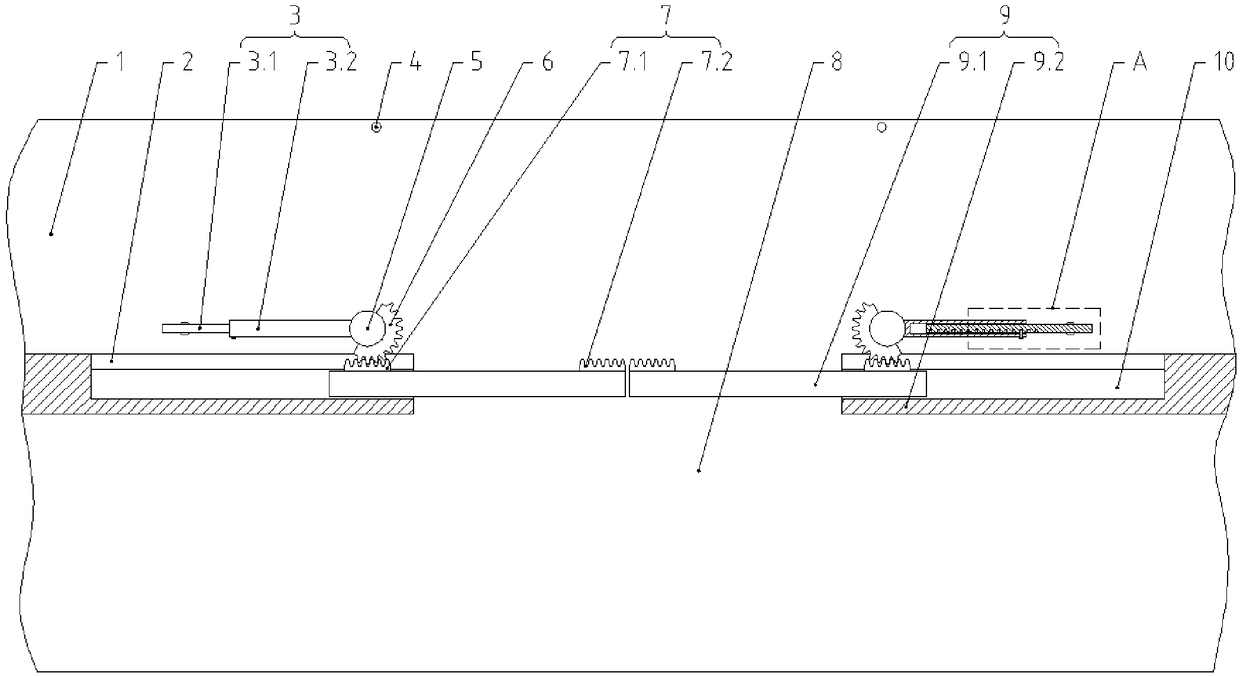

[0025] A safety protection device for a railway platform door, comprising a platform door 9, which divides the platform into a waiting area 8 and a boarding area 1, and the platform door 9 includes fixed parts 9.2 on both sides and sliding doors 9.1 set on the fixed part 9.2 The fixed part 9.2 is provided with an installation groove 10 for accommodating the sliding door 9.1, the surface of the fixed part 9.2 located on the side of the boarding area 1 is horizontally provided with a strip opening 2 connected with the installation groove 10, and the surface of the sliding door 9.1 is horizontally provided with a The rack mechanism 7 corresponding to the strip-shaped opening 2 is provided with a rotatable column 5 near the notch of the installation groove 10 on the boarding area 1, and a surface on one side of the column 5 is provided to cooperate with the rack mechanism 7 through the strip-shaped opening 2. The half gear 6, the other side surface of the column 5 is fixed with a b...

Embodiment 2

[0030] This embodiment improves on the basis of Embodiment 1:

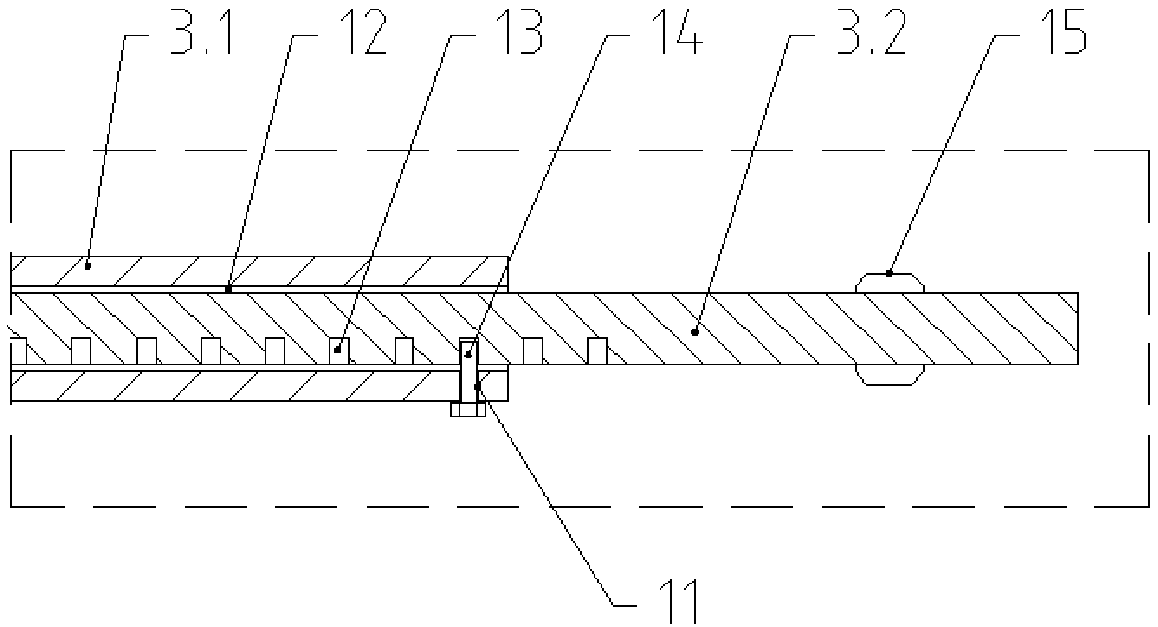

[0031] The rack mechanism 7 is divided into a rack a7.1 and a rack b7.2 respectively fixed on two ends of the sliding door 9.1, and the rack a7.1 and the rack b7.2 can mesh with the half gear 6.

[0032] Working principle: when the sliding door 9.1 moves to open and close, the rack a7.1 and the rack b7.2 respectively cooperate with the half gear 6 to drive its rotation, and the rack a7.1 and the rack b7.2 drive the half gear 6 The total angle of rotation is 90°. Among them, when the sliding door 9.1 is closed, the baffle plate 3 is in a storage state parallel to the fixed part 9.2, and the rack a7.1 keeps meshing with the half gear 6; 9.2 In the vertical working state, the rack b7.2 keeps meshing with the half gear 6 at this moment.

[0033] The advantage of the above improvement is that when the sliding door and the baffle are in two different states synchronously, the rack a and the rack b respectively maintai...

Embodiment 3

[0035] This embodiment improves on the basis of Embodiment 1:

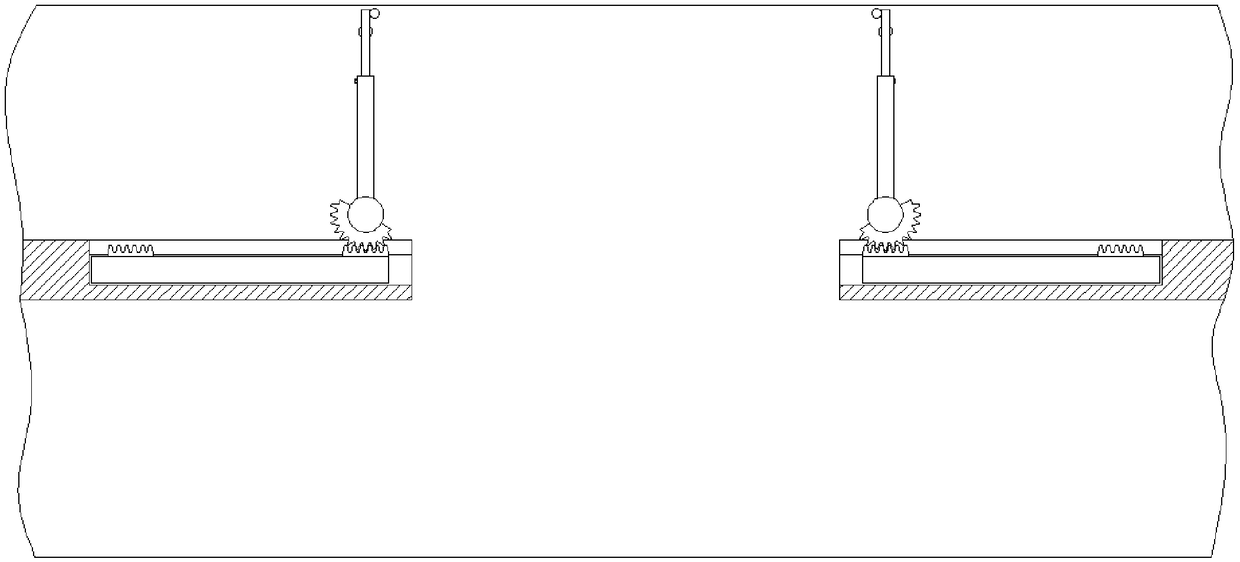

[0036] The bottom of the baffle plate 3 is provided with a roller 15 which is in contact with the ground of the boarding area 1 of the platform.

[0037] The advantages of the above improvements are that the rollers play an auxiliary supporting role for the baffle, and when the half gear drives the column and the baffle to rotate, the rollers make the baffle rotate more smoothly by rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com