A pulverized coal gasification flash condensation system and process

A pulverized coal and flash evaporation technology, applied in the field of coal chemical industry, can solve the problems of reducing heat transfer effect, temperature rise, system pressure rise, etc., and achieve the effect of increasing condensation, reducing pressure and temperature, and ensuring heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

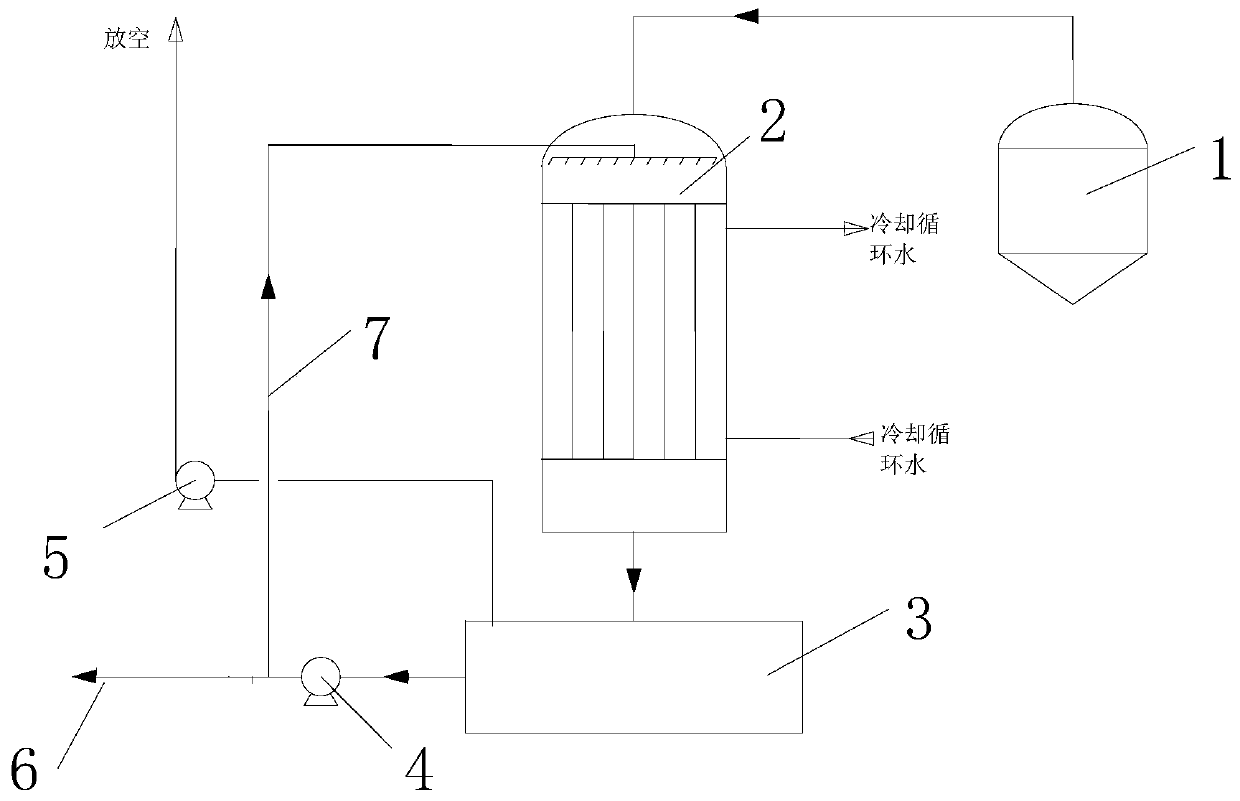

[0034] A pulverized coal gasification flash condensation system, such as figure 1 As shown, the gray water pipe used to transport the gray water produced by pulverized coal gasification is then connected to the true flash tank 1, the vertical tube condenser 2, the condensate tank 3, the condensate pump 4, and the vacuum pump 5, wherein the true flash tank 1 The gas phase outlet of the gas phase is connected with the inlet of the vertical tube condenser 2, the inlet of the vertical tube condenser 2 is connected with the inlet of the condensate tank 3, the bottom outlet of the condensate tank 3 is connected with the inlet of the condensate pump 4, and the condensate The outlet of the pump 4 is connected to the settling tank pipeline 6 and the tube top flushing line 7 to the vertical tube condenser, and the outlet of the tube top flushing line 7 to the vertical tube condenser is connected to the vertical tube condenser 2 The top inlet of the column tube is connected, and the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com