Gas surge slag collection device

A technology of slag gathering and gas supply pipe, which is applied in the field of metallurgy, can solve the problems that the gas injection port cannot be adjusted in the circumferential direction, the work platform is time-consuming and laborious, and the scum cannot be completely removed, so as to avoid the pollution of the environment by the overflow of smoke, save costs, and realize The effect of erasing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings.

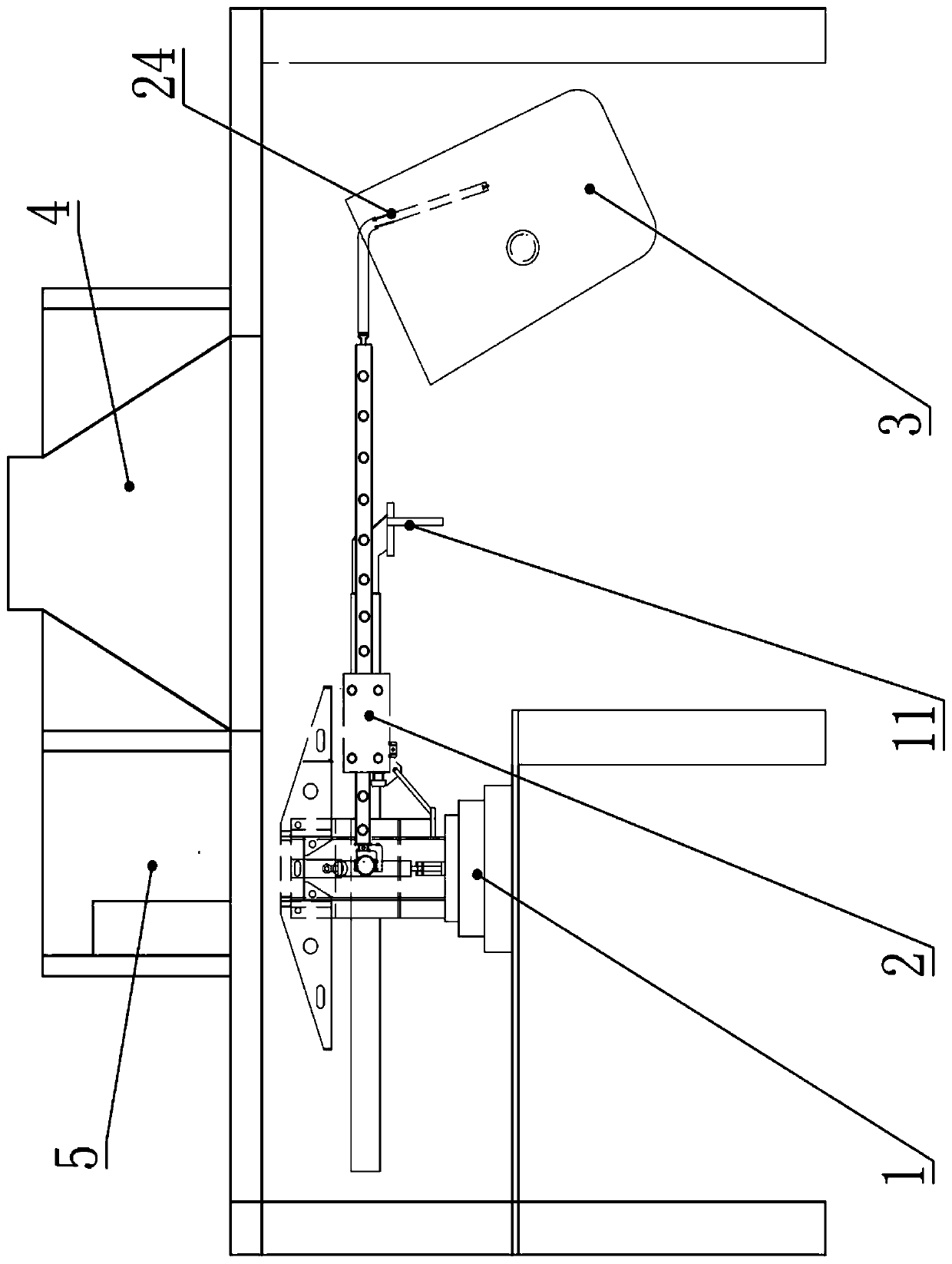

[0025] Such as Figure 1 to Figure 4 As shown, the gas surge slag accumulation device of the present invention includes a slag scraper 1 and a slag accumulation device 2. The slag scraper 1 is set on a horizontal workbench, and the slag scraper 1 and the slag accumulation device 2 can be detachably connected without additional construction. The slag accumulation device 2 is placed on the workbench, which takes up a small space;

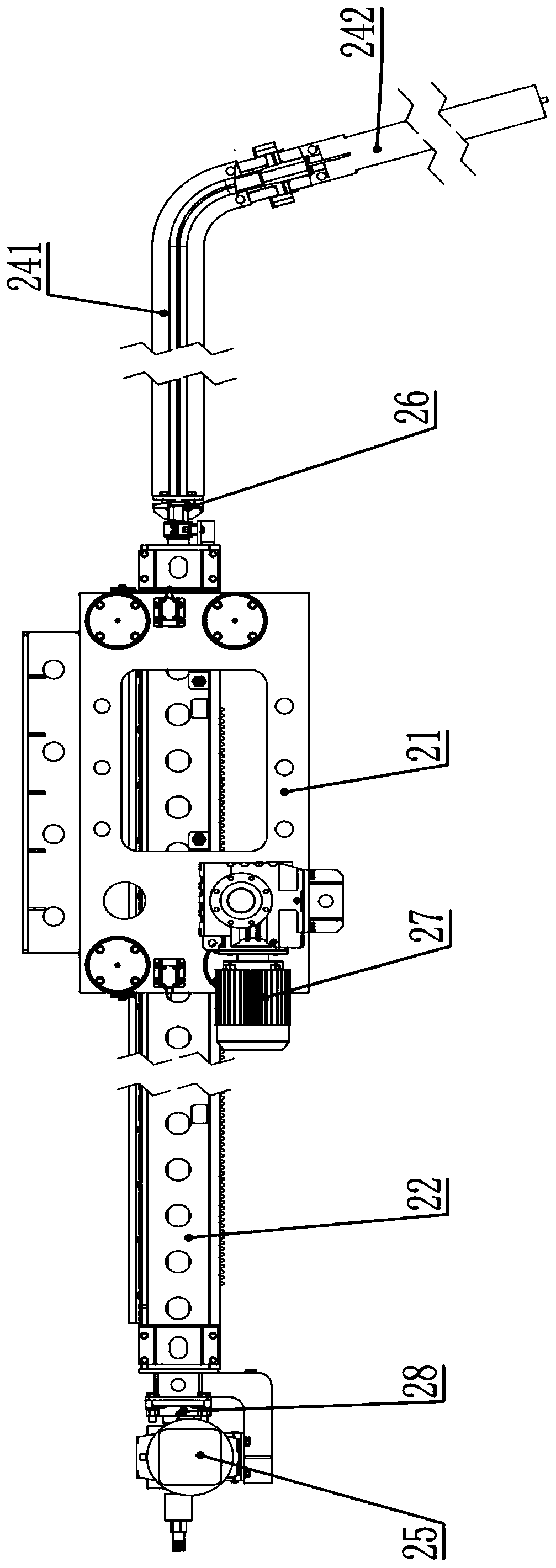

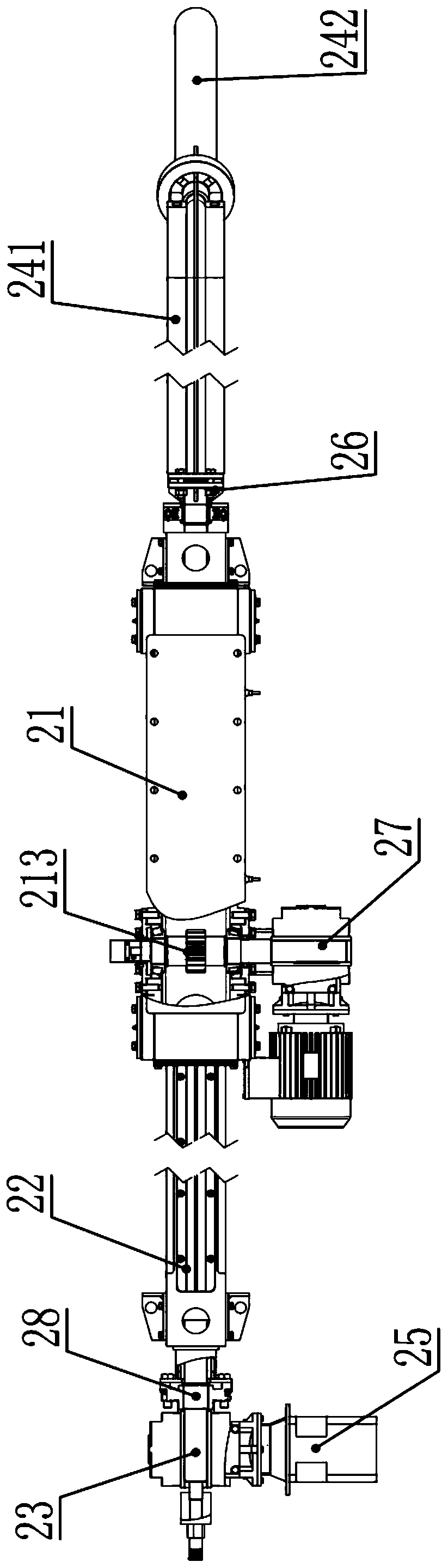

[0026] The slag accumulating device 2 includes a gear box 21, a rack box 22, an air supply pipe 23, an air gun 24, and a servo motor 25. The rack box 22 is elongated, and the bottom center of the rack box 22 is provided with a rack along the length direction. The rack box 22 is driven by the gear box 21, and the rack box 22 can reciprocate in the horizontal direction through the gear box 21; the air supply pipe 23 is arranged in the rack box 22, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com