Roller extrusion type washing machine

A squeeze-type, washing machine technology, applied in the field of washing machines, can solve the problems of high energy consumption, low washing capacity, long washing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

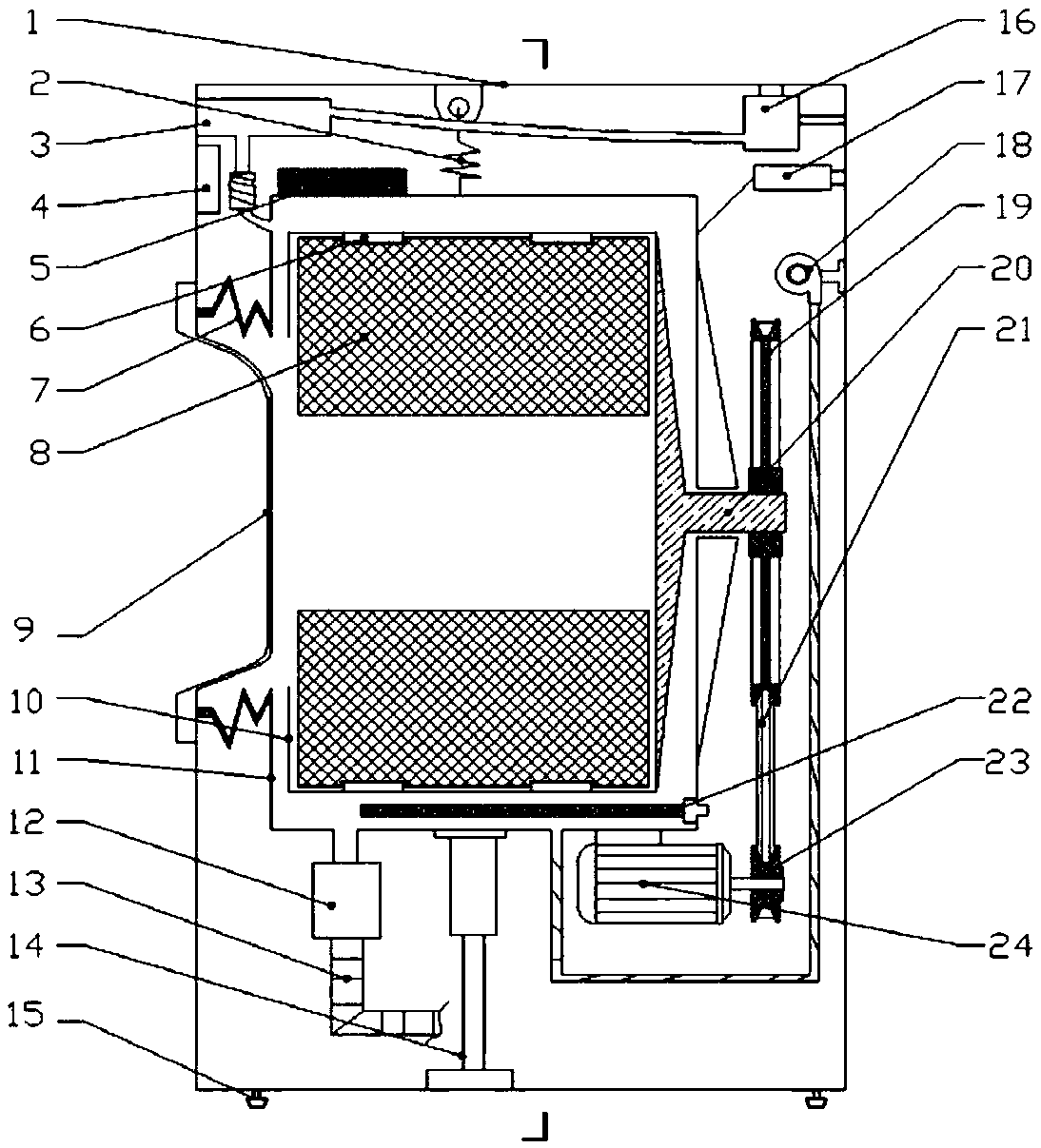

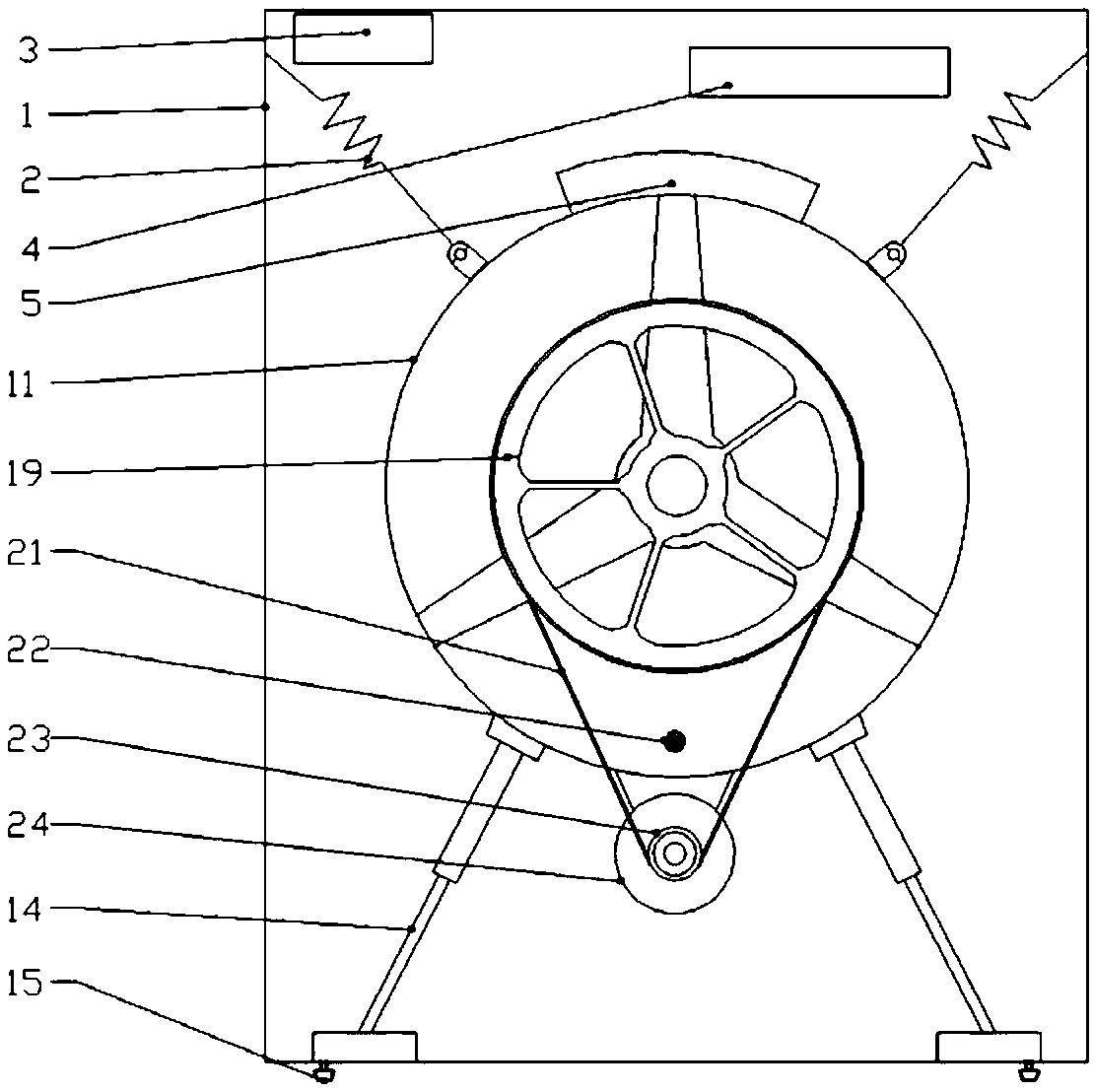

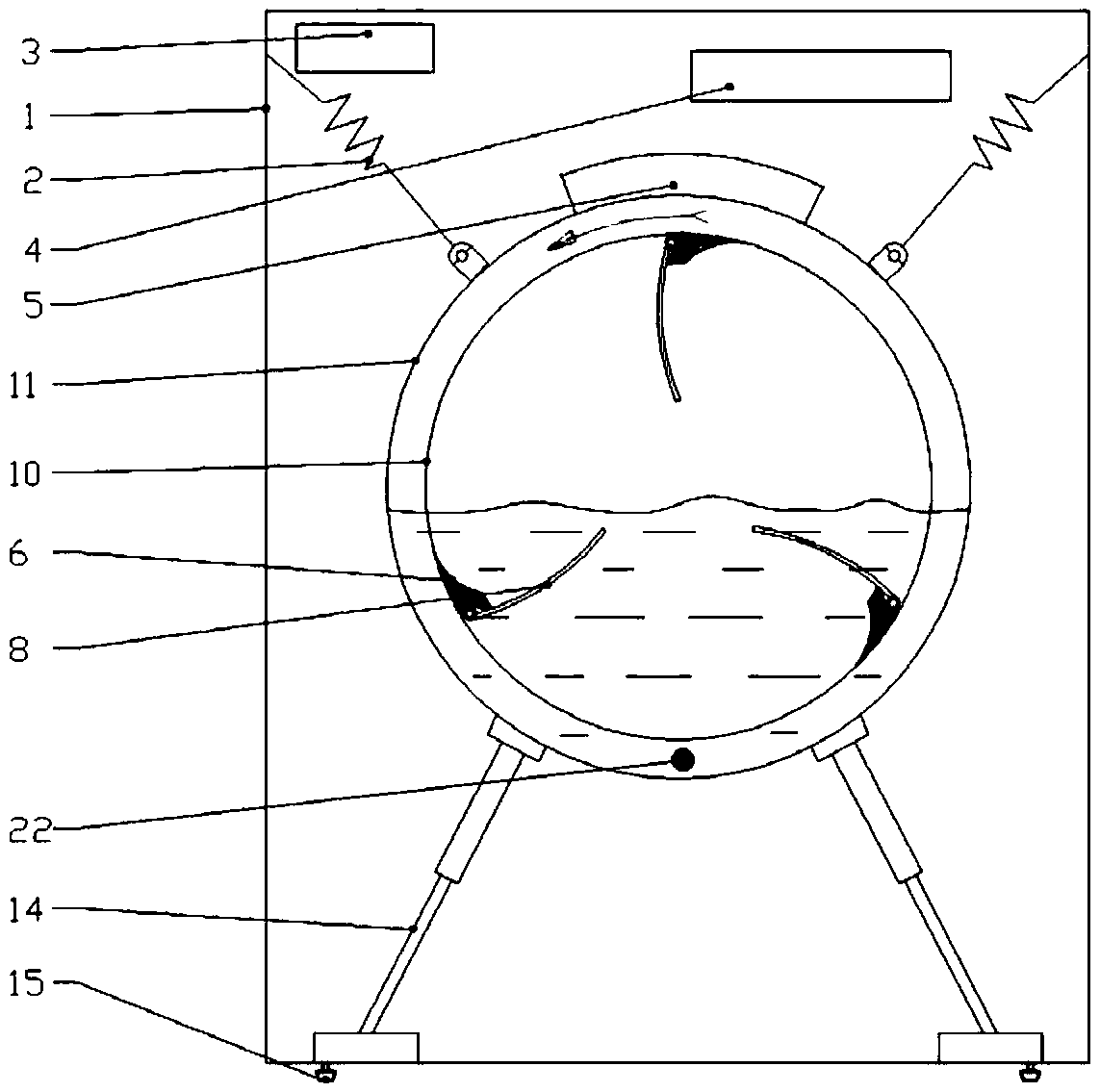

[0020] like figure 1 As shown, the drum extrusion washing machine in the present invention mainly includes a casing, a shock absorbing device, a water tank, a dehydrating bucket, an extruding device, an electric control device, a feeding and discharging device, a driving device, a heating device, a drying device and other components. .

[0021] The shell includes a washing machine box 1, a washing machine door 9 with a glass observation window, and a cuboid box composed of feet 15. The washing machine door 9 with the glass observation window is convenient for putting in and taking out clothes, and the glass window can observe the washing process of the washing machine , the foot 15 adjusts the level and support of the whole machine, the tank 7 hangs the water bucket 11 through the suspension spring 2 and the shock absorber 14, the electric control device 4 and the detergent box 3 are installed on the front top, and the water supply solenoid valve 16, Liquid level sensor 17, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com