Monitoring systems for gas engines

A gas engine and monitoring system technology, applied in the direction of engine components, engine control, combustion engine, etc., can solve problems such as long flushing time, achieve short flushing time and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

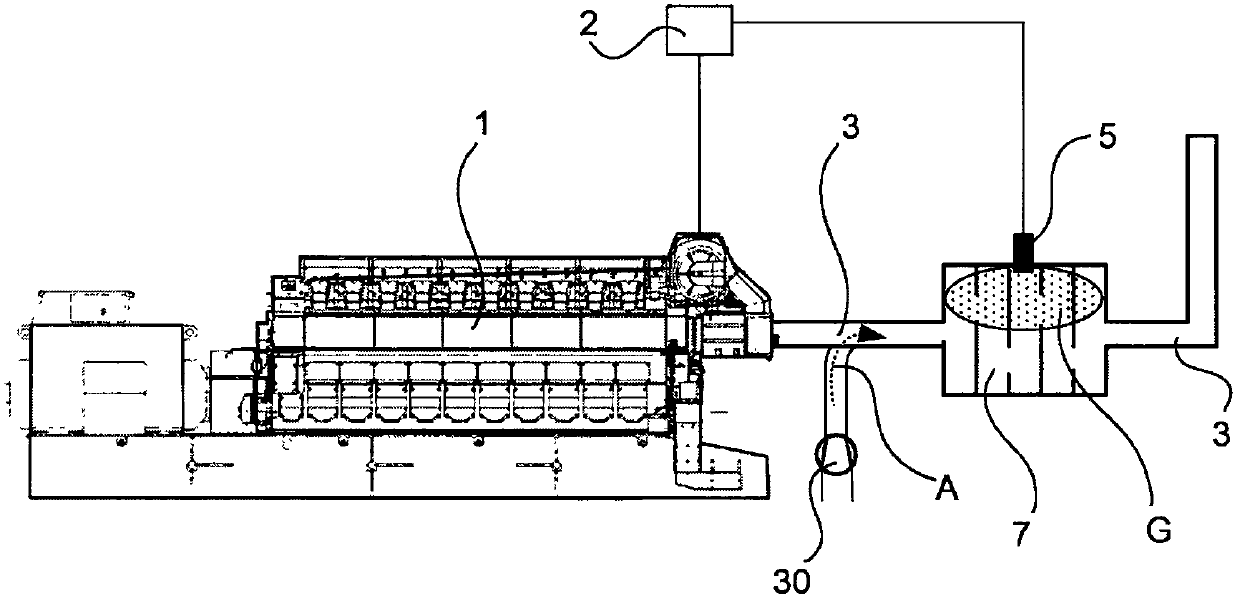

[0017] exist figure 1 , it shows an engine 1 apparatus including a monitoring system 2 for a gas engine 1, a reciprocating internal combustion engine 1 using gas as fuel, connected to a Outlet channel 3 of the outlet channel 3 is arranged with a fan 30 associated with the outlet channel 3 for use when the engine 1 is not started (in other words, when the engine has not started operation based on the combustion of fuel) and in the outlet channel 3 Air A is used to flush the outlet channel 3 where unburned fuel gas G may accumulate. At least one NOx sensor 5 is positioned in the outlet channel 3 at a location where unburned fuel gas G may accumulate. The location where the sensor 5 is positioned and where unburned fuel gas G may accumulate can be, for example, a muffler 7, such as figure 1 shown, but it could also be some kind of closed curved top of the boiler, catalytic converter, heat recovery system, outlet channel or corresponding position.

[0018] The arrangement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com