Whole station water stop structure and construction method during construction of mined metro station

A construction method and station technology, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of high cost, difficult to guarantee the effect, and limited space for underground excavation stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention.

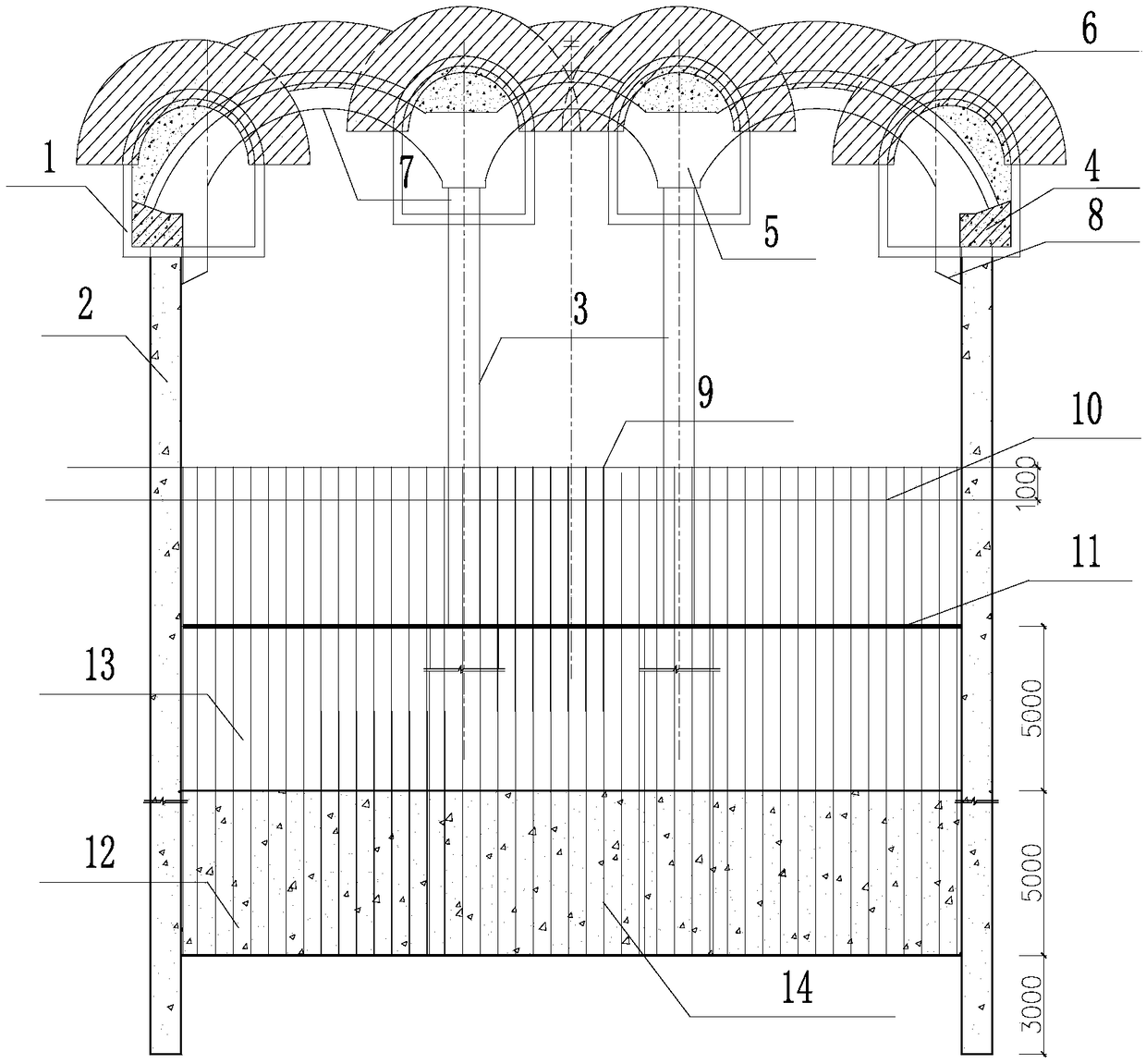

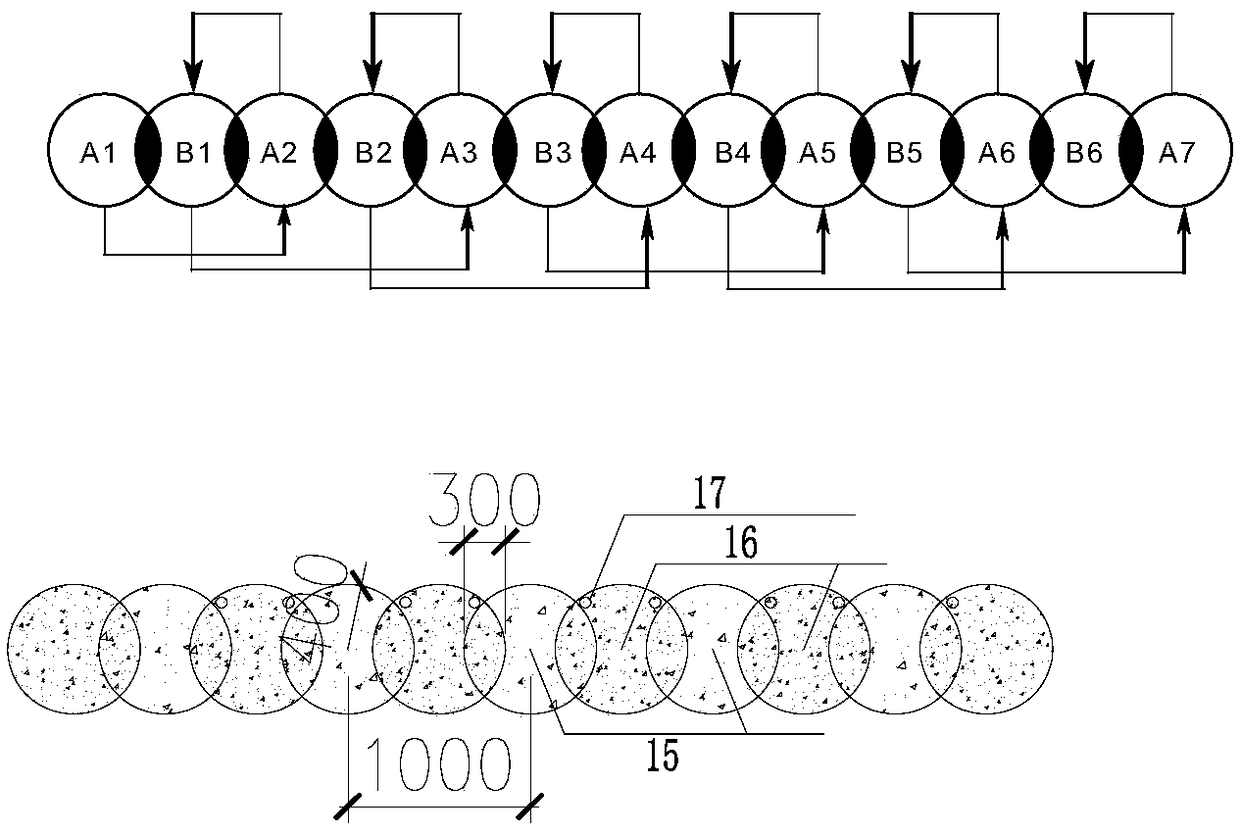

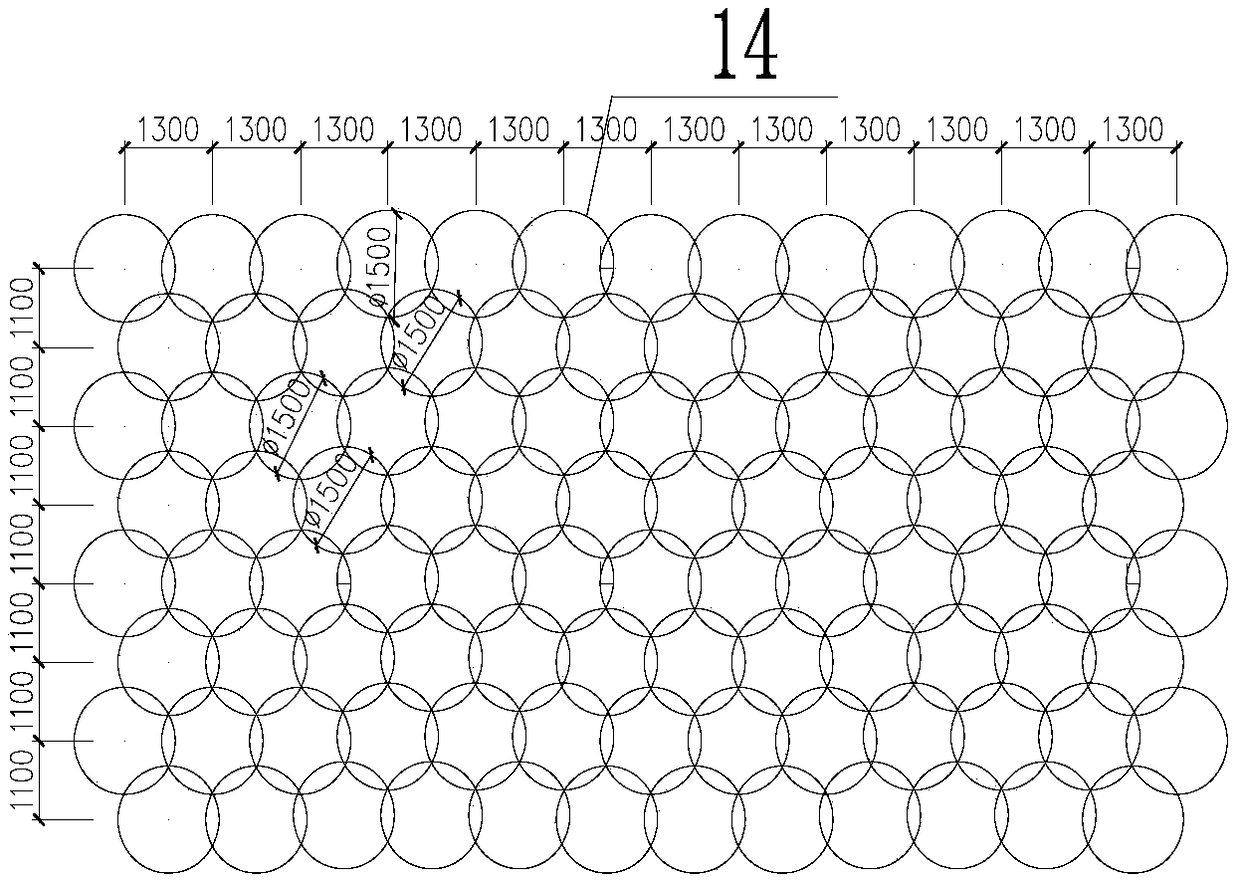

[0035] In a broad embodiment of the present invention, a construction method for water-stopping of the whole station during the construction of underground excavation stations of subways, the water-stopping method is to combine occlusal piles and super jet grouting piles to underground excavation during construction of underground excavation stations During the water-stop construction of the station, the side wall occlusal piles of the excavation surface and the base rotary grouting piles work together to form a box body, which isolates groundwater from entering the excavation range.

[0036] like Figure 1-3 As shown, the structure of the water stop of the whole station during the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com