Track-type support carrying vehicle

A support truck and crawler type technology, applied in the direction of crawler vehicles, motor vehicles, underground transportation, etc., can solve the problems of harsh underground environment, unsafe, large walking gradient, etc., and achieve high safety factor, less slip phenomenon, and stable center of gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

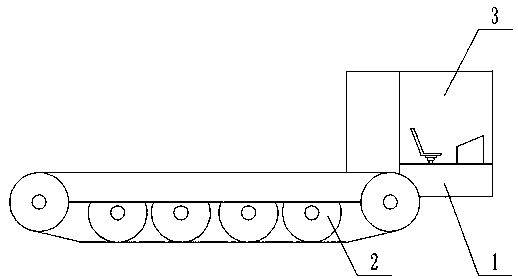

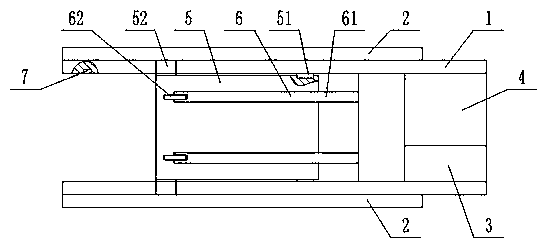

[0022] Such as figure 1 , figure 2 所示,本发明履带式支架搬运车,包括行走机构2、驾驶室3、车架1和驱动机构4,驾驶室3和驱动机构4设置在车架1前端,行走机构2设置在车架1两侧,驾驶室3设置在车架1前端右侧,驱动机构4设置在车架1前端左侧,驱动机构4与驾驶室3平行设置,车架1后端为Π形结构,车架1本体后方下方设置有铲运板5,铲运板5上沿着车辆前进方向设置有拉架机构6,车架1后端的Π形结构靠近车架1前端的两侧设置有固定座51,远离车架1前端的两侧对称位置设置有提升机构52,所述的铲运板5一端设置在固定座51上,一端与提升机构52相连,拉架机构6包括推移杆61和设置在推移杆61前端的挂钩62,所述的挂钩62与推移杆61之间的连接方式为铰接,拉架机构6、提升机构52均为液压机构,固定座51为圆柱形固定座,所述的铲运板5对应设置有半圆形凹槽,铲运板51长度小于车架1后端的Π形结构长度,车架1后端两侧设置有限位装置7,所述的限位装置7为L型限位块,所述的L型限位块后方设置有推移油缸,行走机构2为履带式行走机构,拉架机构6数量为2。

[0023] 本发明在使用时,将车辆移动至待搬运支架前方,将车架1后方的Π形结构对准支架,通过放下提升机构52,将铲运板5放下,车辆后移,将支架部分铲运至铲运板5上,然后拉架机构6进行工作,将支架大部分拉伸至铲运板5上,同时提升机构52上移,将支架抬起,后方的限位装置7伸出,将支架固定,防止左右摇摆,通过履带式行走机构2进行平稳的移动,将支架搬运至准确位置,在卸架时,限位装置7收回,提升机构52先将铲运板5后方放下,拉架机构6伸出,变拉为推,将支架推出,同时自动脱钩,操作简单,降低了搬家成本,提高了搬家的工作效率。

[0024] 上面结合附图对本发明的实施例作了详细说明,但是本发明并不限于上述实施例,在本领域普通技术人员所具备的知识范围内,还可以在不脱离本发明宗旨的前提下作出各种变化。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com