Methods and system for central fuel injection

A fuel injector and fuel technology, which is applied in the directions of low pressure fuel injection, fuel injection device, fuel injection control, etc., can solve the problems of emission quality and fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

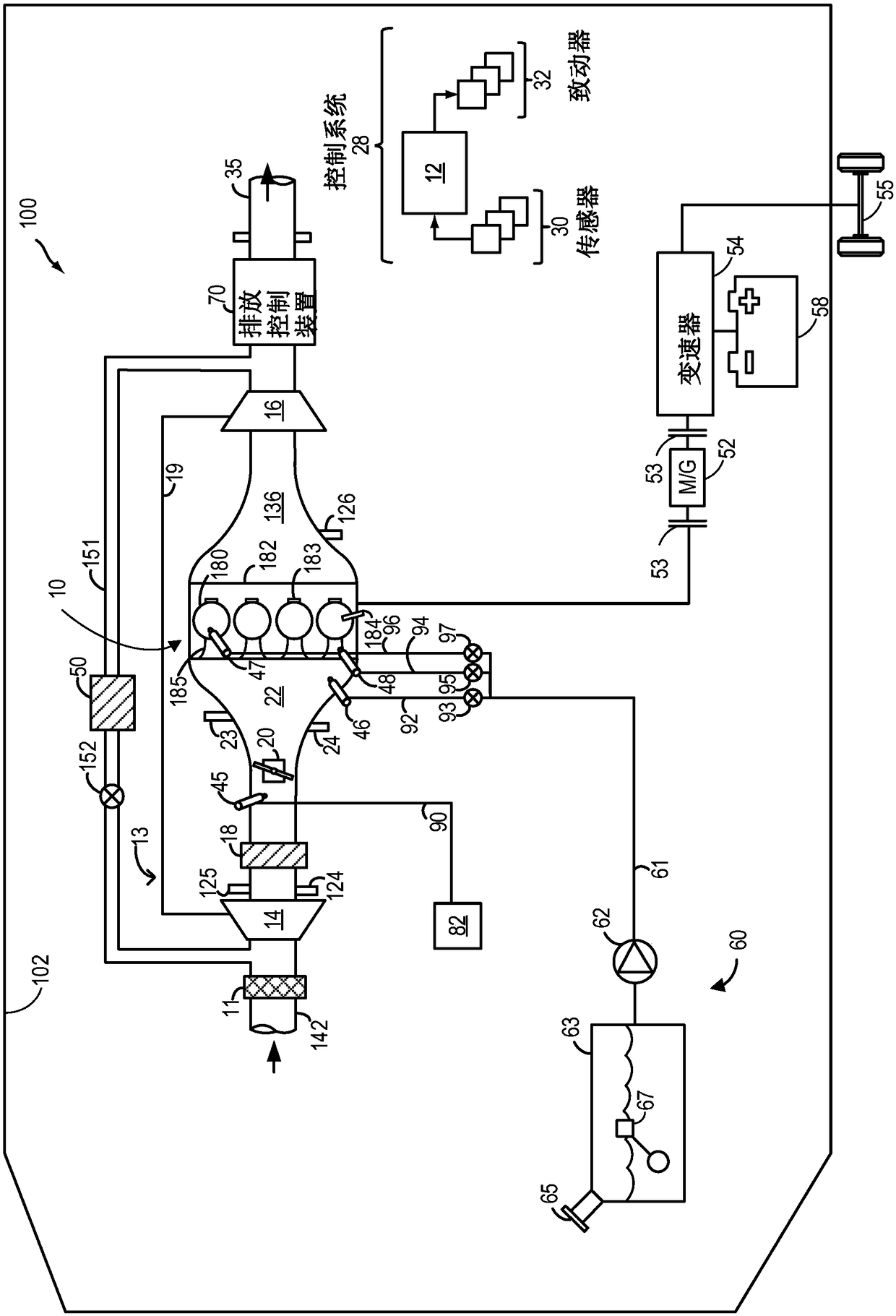

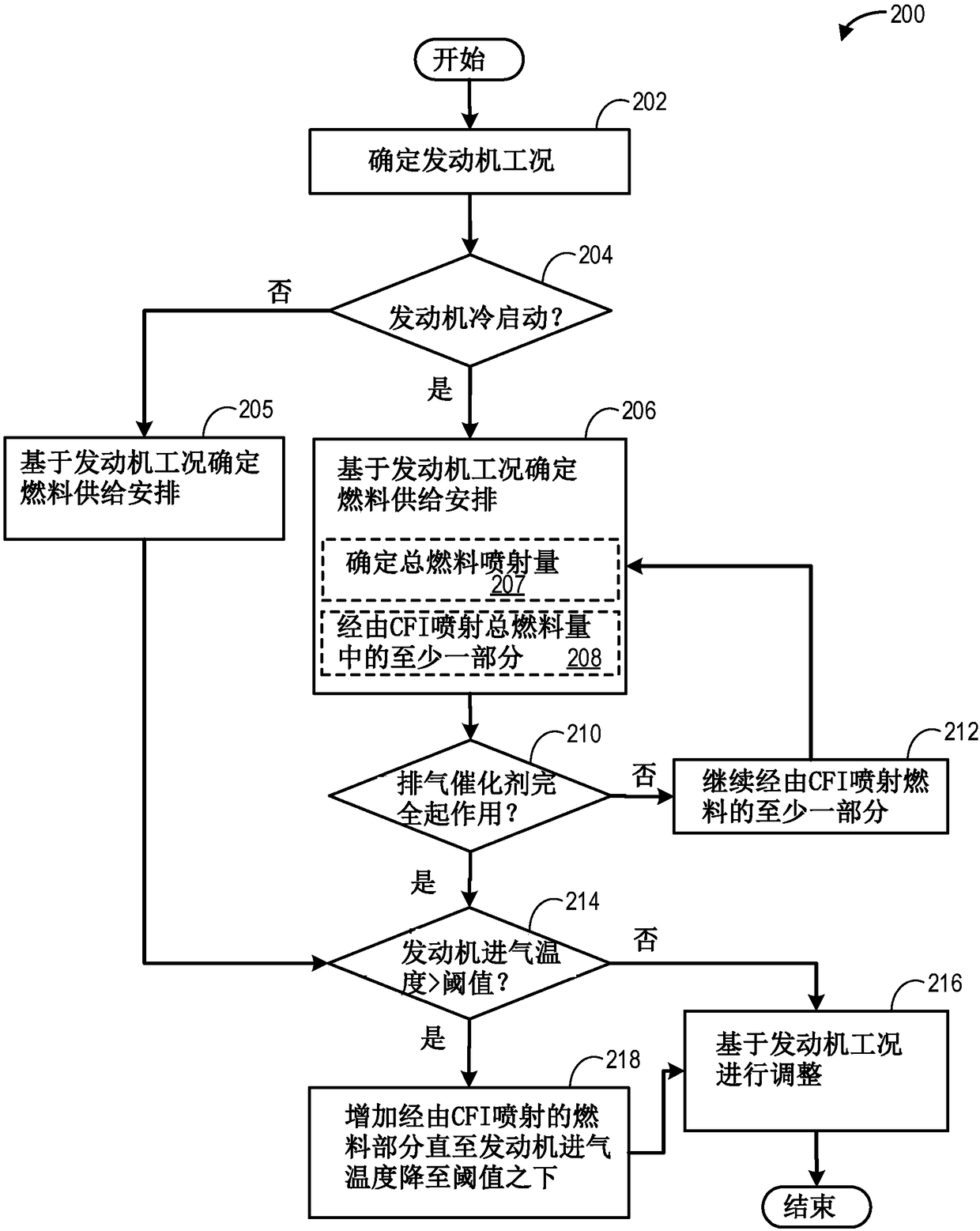

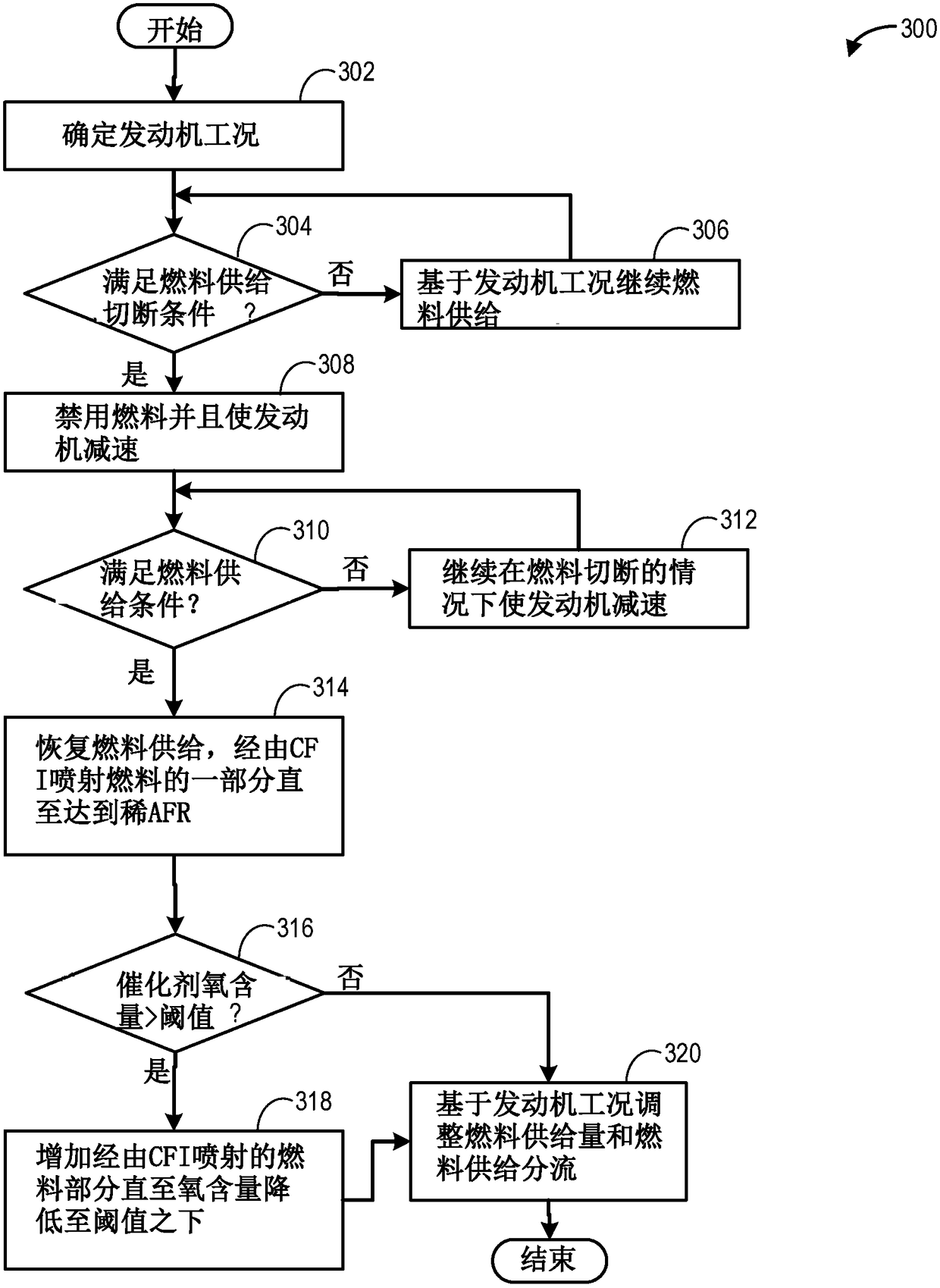

[0017] The following description relates to systems and methods for utilizing manifold fuel injection for increasing charge air cooling, for reducing NOx emissions, and for pre-ignition mitigation. The methods herein can be applied to engine systems with manifold, direct and port fuel injection capabilities such as figure 1 engine system). The engine controller can be configured to execute control programs such as figure 2 , image 3 and Figure 5 example routines) to adjust fueling schedules (including adjusting the amount of fuel delivered via manifold injection relative to the amount of fuel delivered via port injection and / or direct injection), for reducing NOx production and for pre-ignition mitigation. exist Figure 4 and Figure 8 An example adjustment of the fueling schedule to achieve desired charge cooling for NOx reduction and pre-ignition mitigation is shown at . exist Figure 6 and Figure 7 An example of fuel split ratios between manifold injection and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com