Novel high-speed magnetic levitation motor and method for detecting rotor position of motor

A high-speed motor and rotor position technology, applied in the direction of electromechanical devices, magnetic attraction or thrust holding devices, electrical components, etc., can solve the problems of impact, small installation size, etc., to prevent motor out of step, prevent irreversible demagnetization, Provides control over the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

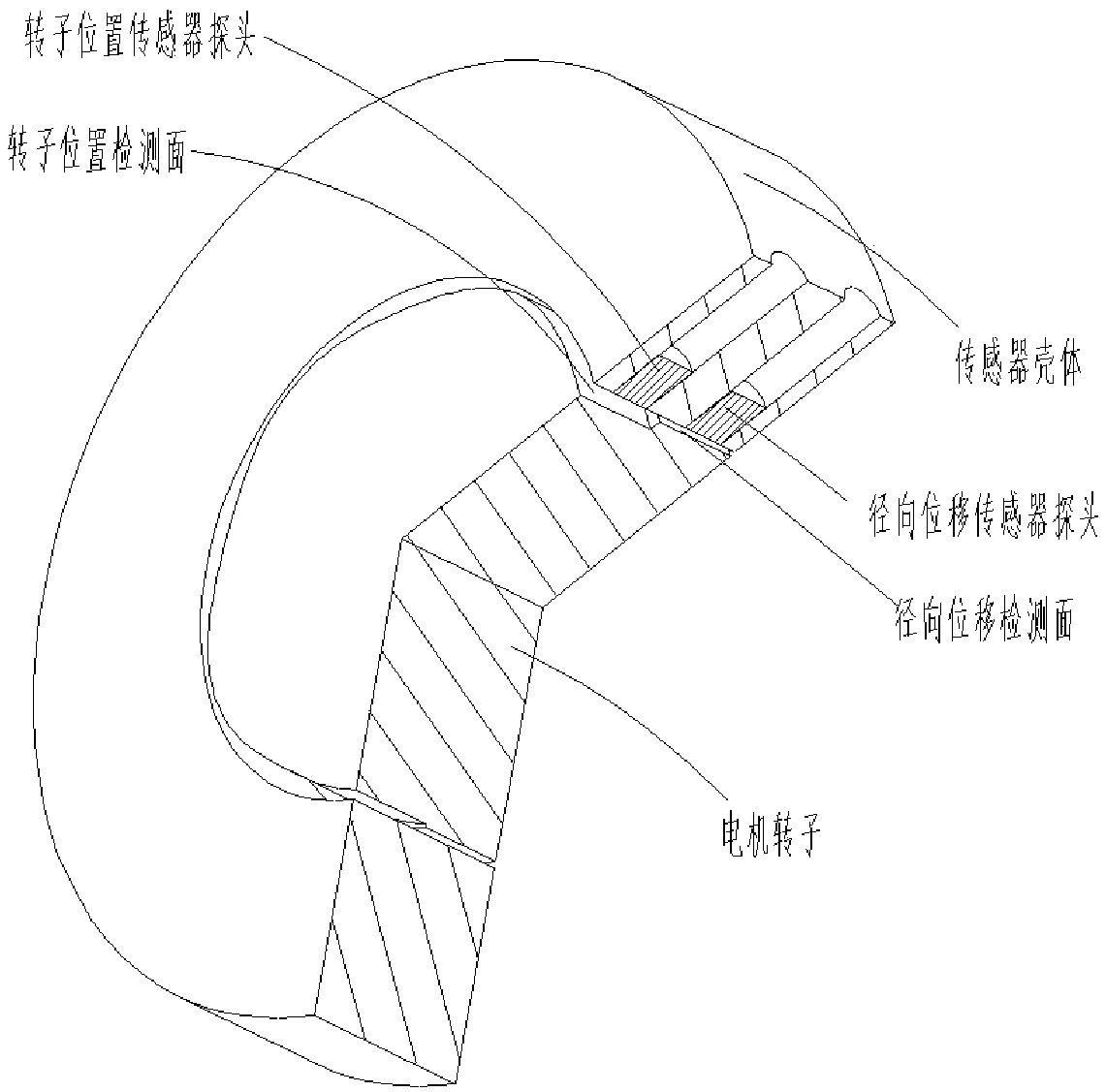

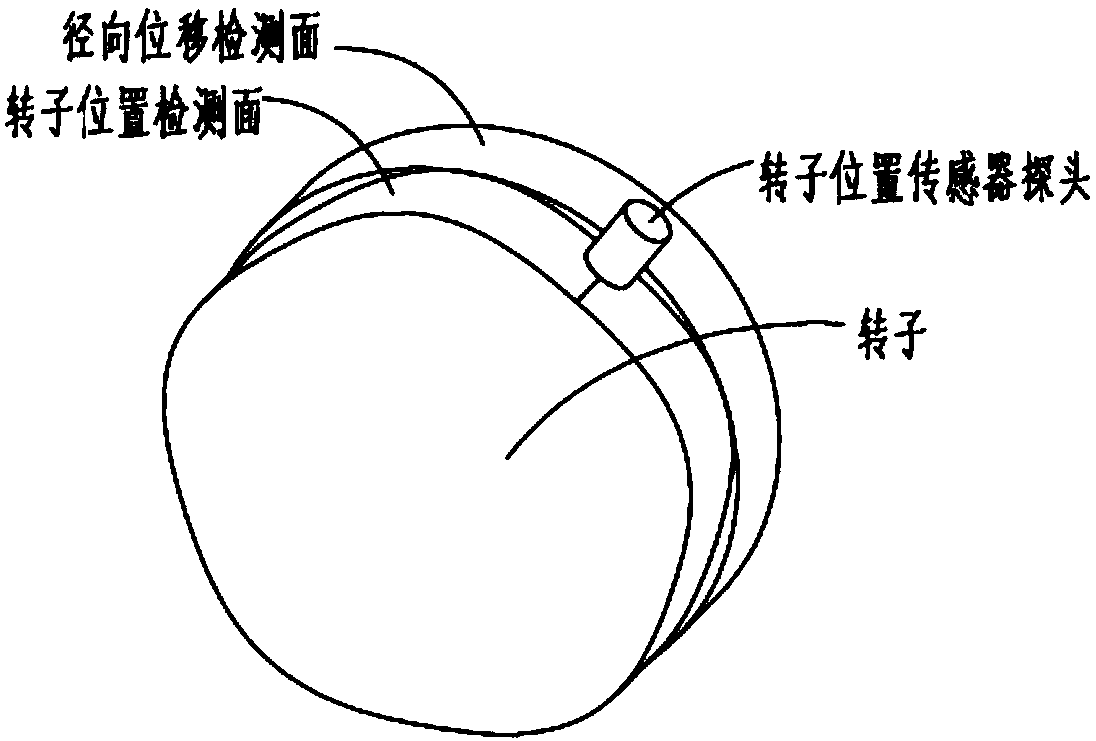

[0028] The invention provides a novel magnetic levitation high-speed motor, such as figure 1 As shown, it includes a rotor and a stator, and the rotor includes: a radial displacement detection cylinder and a position detection cylinder.

[0029] Wherein, the radial displacement detection cylinder and the position detection cylinder are coaxially arranged, and the radial displacement detection cylinder is a cylinder with a radius R, the position detection cylinder is a cylinder with regular arc-shaped edges, and the position detection cylinder The maximum radius of the body is R.

[0030] Optionally, the regular arc shape includes: at least one protrusion and at least one depression, where the protrusion and the depression appear sequentially at intervals.

[0031] Optionally, the arc-shaped detection surface of the position detection cylinder of the motor rotor is designed according to the following formula. A cylindrical coordinate system is established with the axis of the ...

Embodiment 2

[0041] Based on the same inventive idea, the present invention provides a method for detecting the position of the motor rotor, which is used to detect the position of any of the above-mentioned new magnetic levitation high-speed motor rotors, including:

[0042] Detect the position of the radial displacement detection cylinder;

[0043] The position of the rotor is calculated from this position.

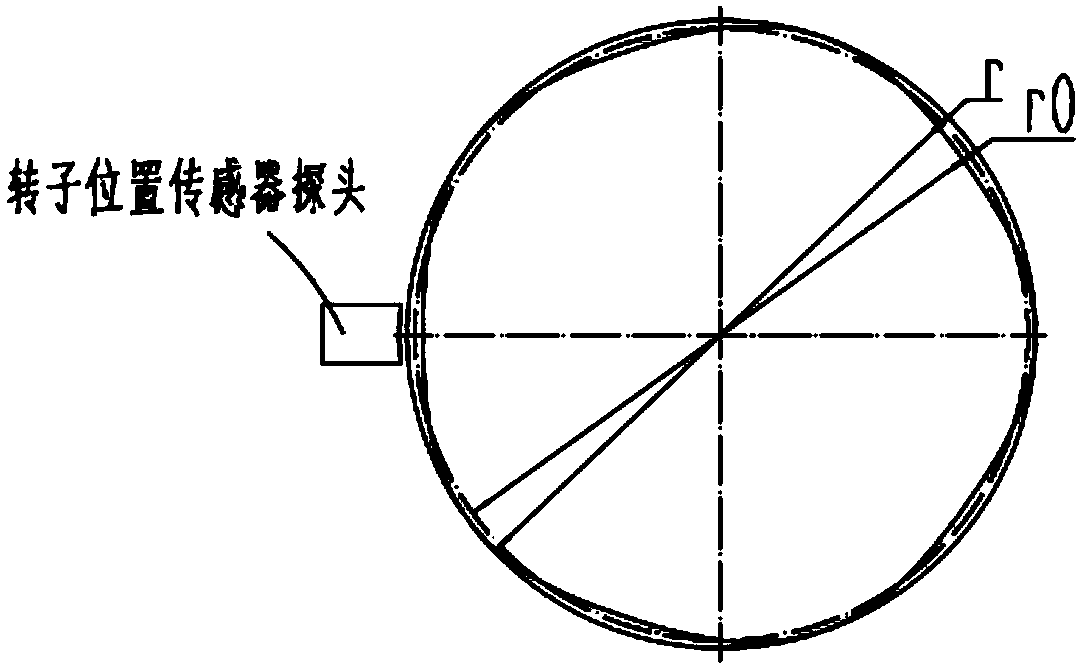

[0044] Wherein, the position of the radial displacement detection cylinder is the distance from the radial displacement sensor probe to the arc surface of the radial displacement detection cylinder. Such as Figure 4 Shown is a schematic diagram of the relationship between the detection distance change and the rotor position when the rotor rotates.

[0045] Optionally, calculating the position of the rotor includes: calculating the distance between the probe of the rotor position sensor and the arc surface of the position detection cylinder according to the following formula,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com