A motor control method and control device

A technology of motor control and controller, which is applied in the direction of motor control, motor generator control, and electromechanical transmission control, etc. It can solve problems such as insufficient torque boost, weak load capacity, and large motor heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

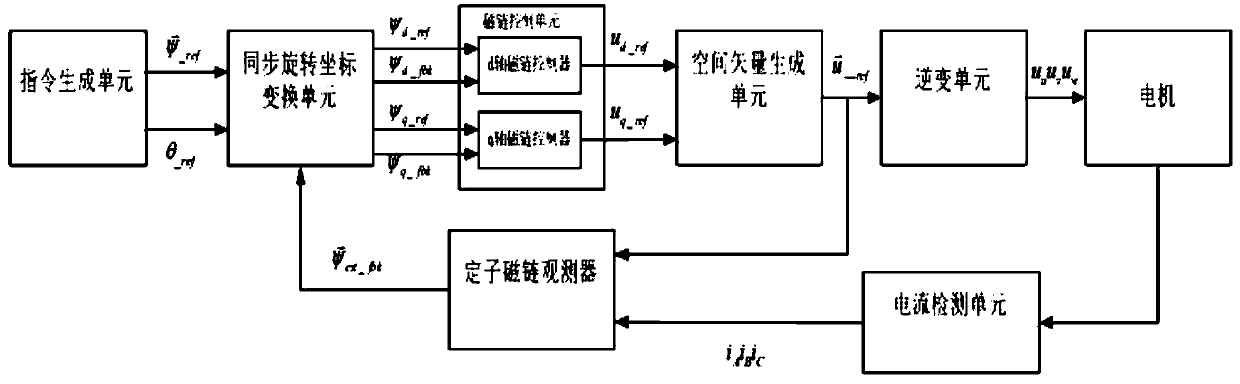

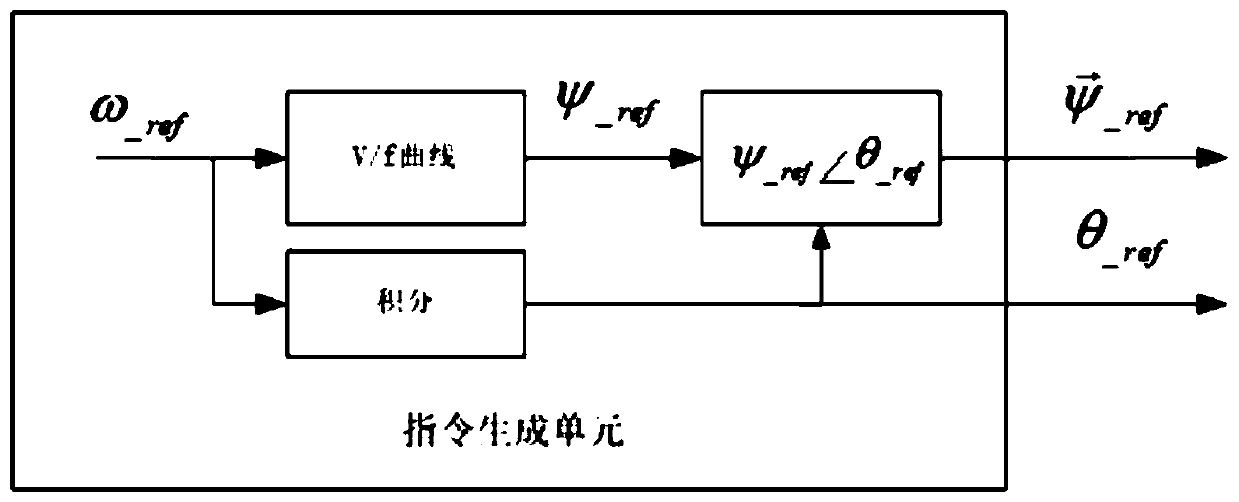

[0046] Aiming at the deficiencies of the existing V / f control method and the space vector control method, the solution of the present invention is to combine the two to pre-establish a voltage-frequency ratio (V / f) curve. When the motor operates at a constant power below the rated frequency , usually in V / f

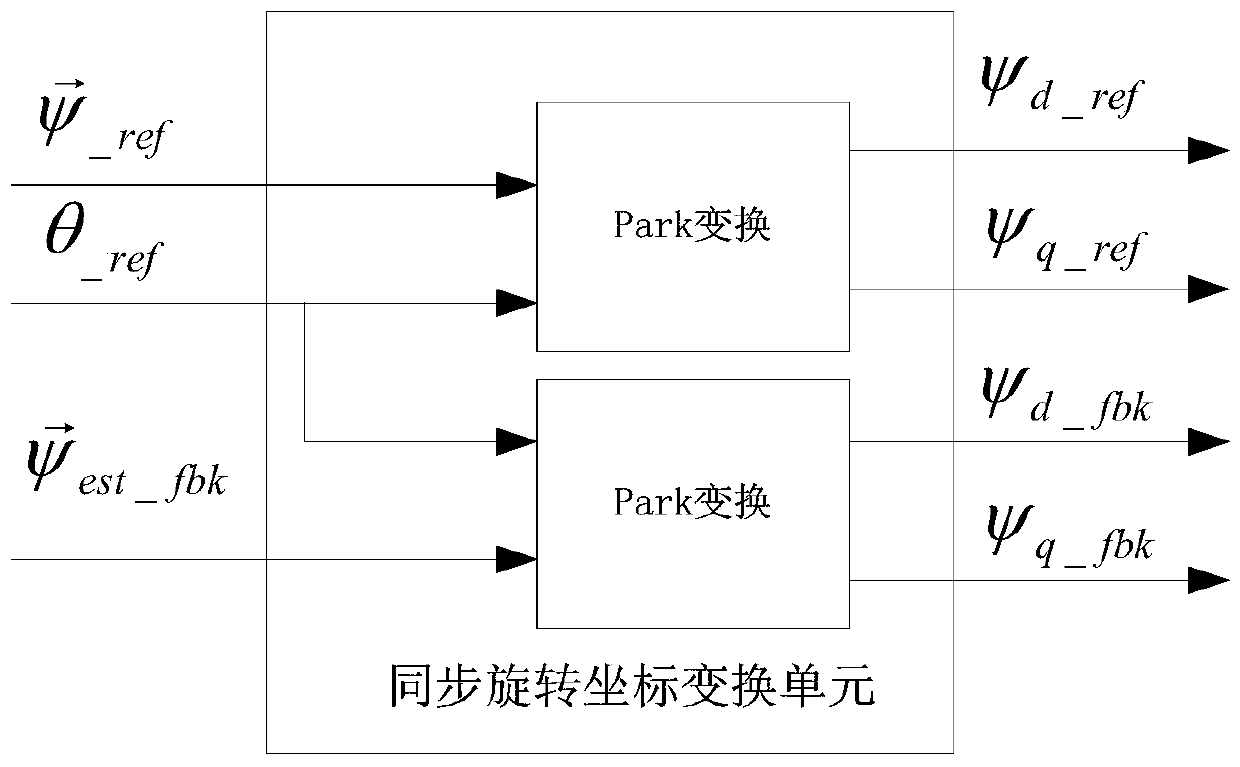

[0047] Each voltage-to-frequency ratio on the curve is taken as the flux linkage vector magnitude ψ at its corresponding frequency _ref , combined with the phase angle θ of the flux vector command obtained by integrating the target operating frequency command of the motor _ref , so as to get the flux vector instruction Then according to the flux vector instruction and the observed flux vector of the stator The motor is controlled to improve the low-speed load capacity, no need to artificially adjust the torque boost voltage, the dynamic performance is good, and it can quickly enter a stable state.

[0048] Specifically, the motor control device of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com