A self-hydrating flowerpot

An automatic water replenishment and flowerpot technology, which is applied in automatic watering devices, horticulture, agriculture, etc., can solve problems such as dry green plants, and achieve the effect of constant nutrient solution concentration, constant water level, and normal growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

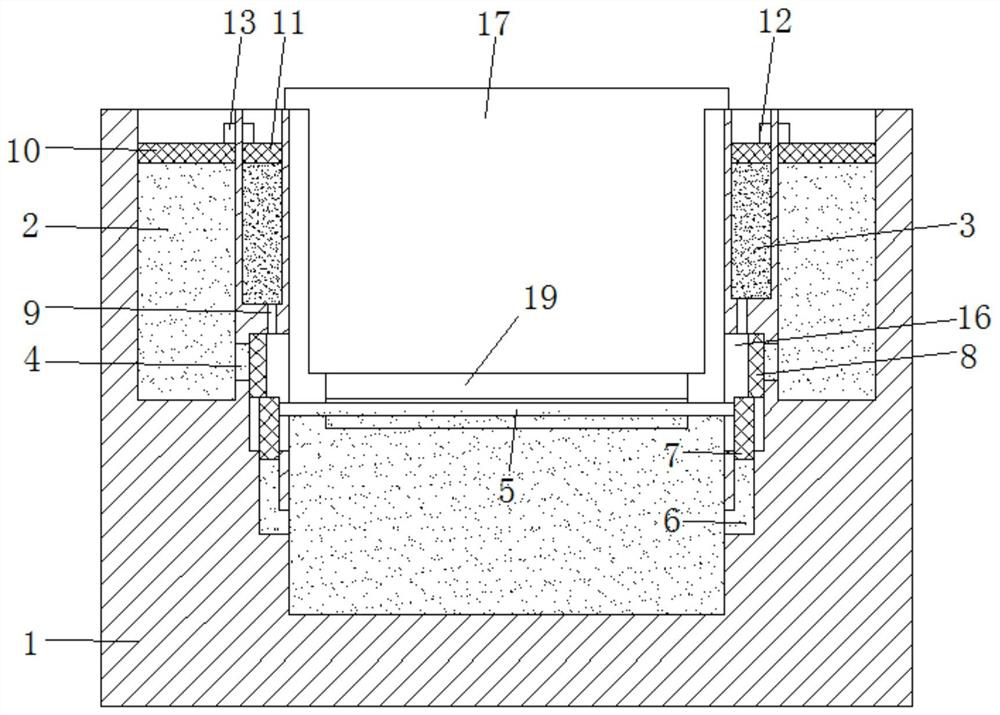

[0015] refer to figure 1 , a kind of automatic replenishing water flower pot, comprises catchment basin 1, the planting pot 17 that is arranged on the inside of catchment basin, and the sponge block 19 that is arranged on the bottom of planting pot, and the upper end surface of catchment basin 1 is provided with annular water storage tank 2 and The annular liquid storage tank 3, the left and right inner cavity walls of the water collection basin 1 are vertically provided with chutes 16, and the two chute 16 and the annular water storage tank 2 are provided with water holes 4, and the two chute 16 There are capillary holes 9 running through the ring-shaped liquid storage tank 3. Because the pore diameter of the capillary holes 9 is small, it can reach the level of liquid seal, so the nutrient solution in the annular liquid storage tank 3 cannot flow out under its own gravity. The bottom side wall of chute 16 is all provided with the L-shaped passage 6 that is communicated with ...

Embodiment 2

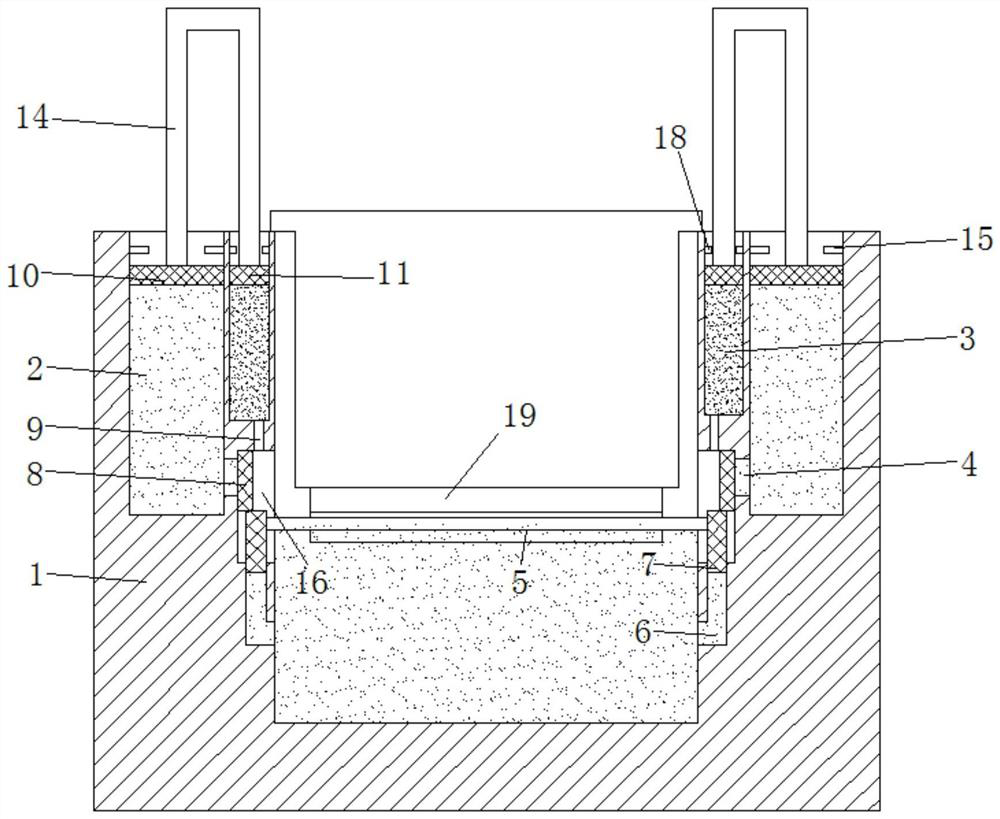

[0019] refer to figure 2 , The difference between this embodiment and Embodiment 1 is that the connection mechanism includes an inverted U-shaped rod 14, and the two ends of the inverted U-shaped rod 14 are respectively connected to the upper end side wall of the first annular piston 10 and the upper end of the second annular piston 11. The side walls are fixedly connected, and the inner wall of the annular water storage tank 2 is provided with a first limiting block 18 , and the inner wall of the annular liquid storage tank 3 is provided with a second limiting block 15 .

[0020] Compared with Embodiment 1, the advantage of this embodiment is that the first magnet 13 and the second magnet 12 are replaced by inverted U-shaped rods 14, and the inner sidewalls of the annular water storage tank 2 and the annular liquid storage tank 3 are respectively provided with a plurality of first magnets. Two limit blocks 15 and a plurality of first limit blocks 18, when the first annular p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com