Patents

Literature

74 results about "Spongia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spongia is a genus of marine sponges in the family Spongiidae, originally described by Linnaeus in 1759, containing more than 60 species. Some species, including Spongia officinalis, are used as cleaning tools, but have mostly been replaced in that use by synthetic or plant material.

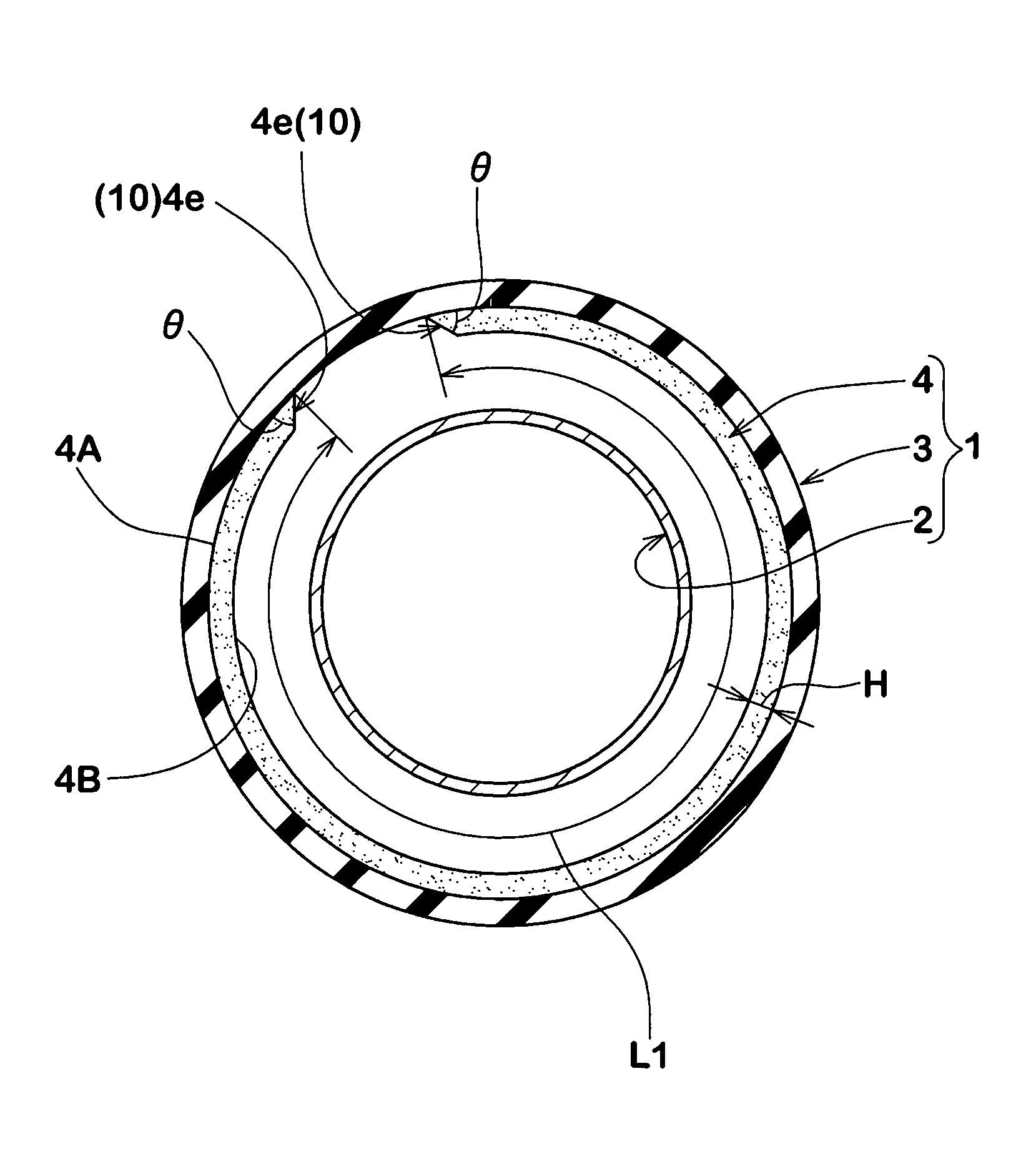

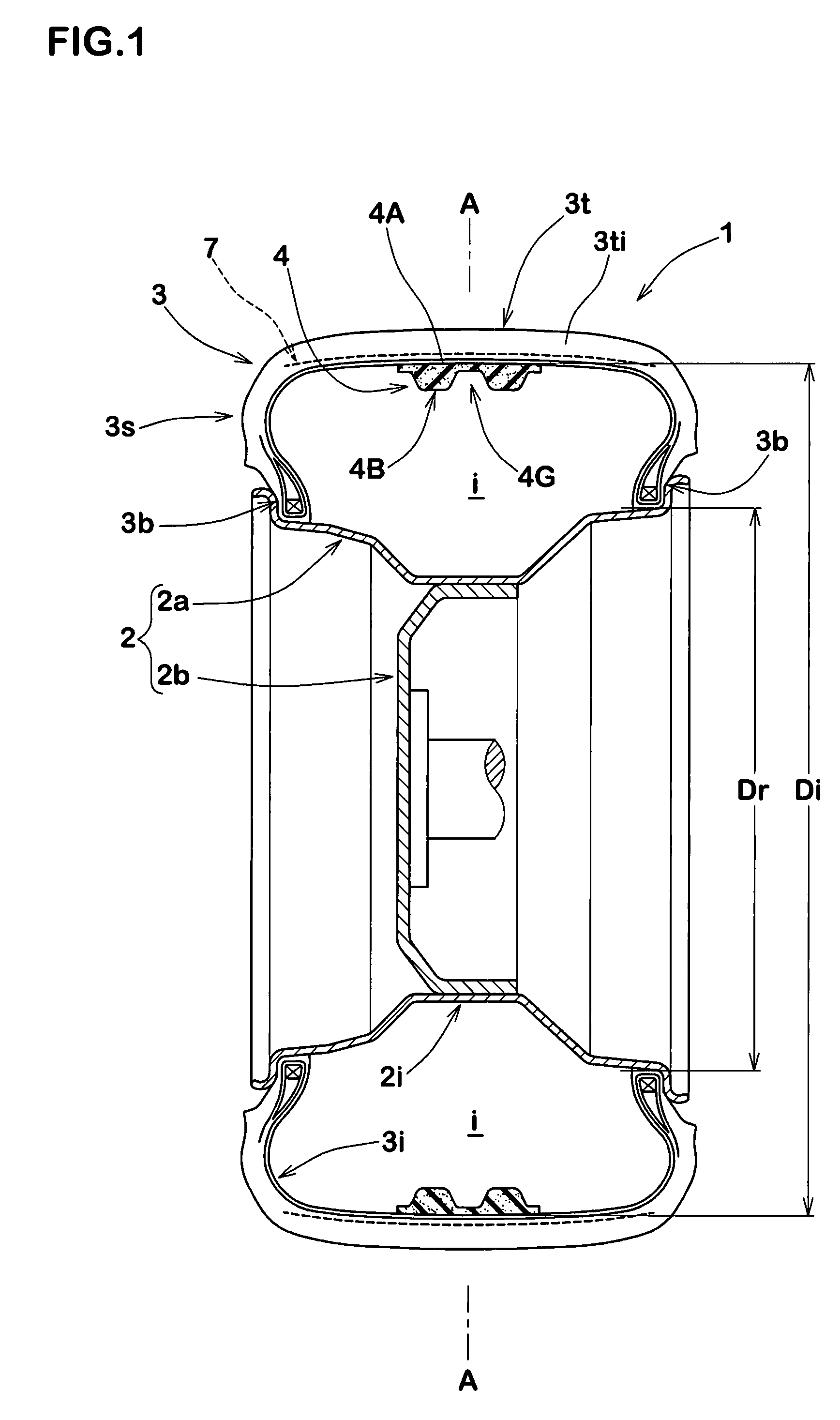

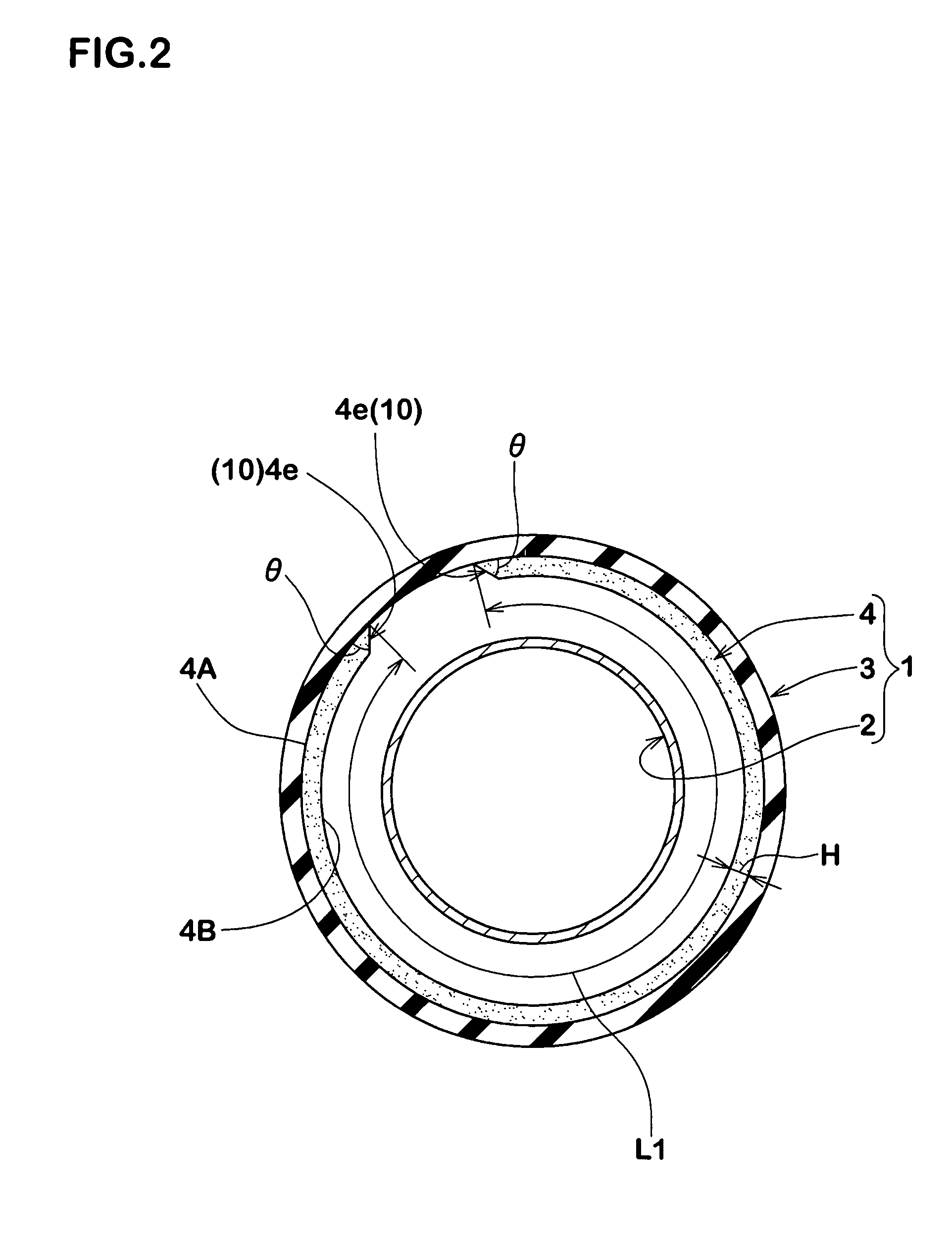

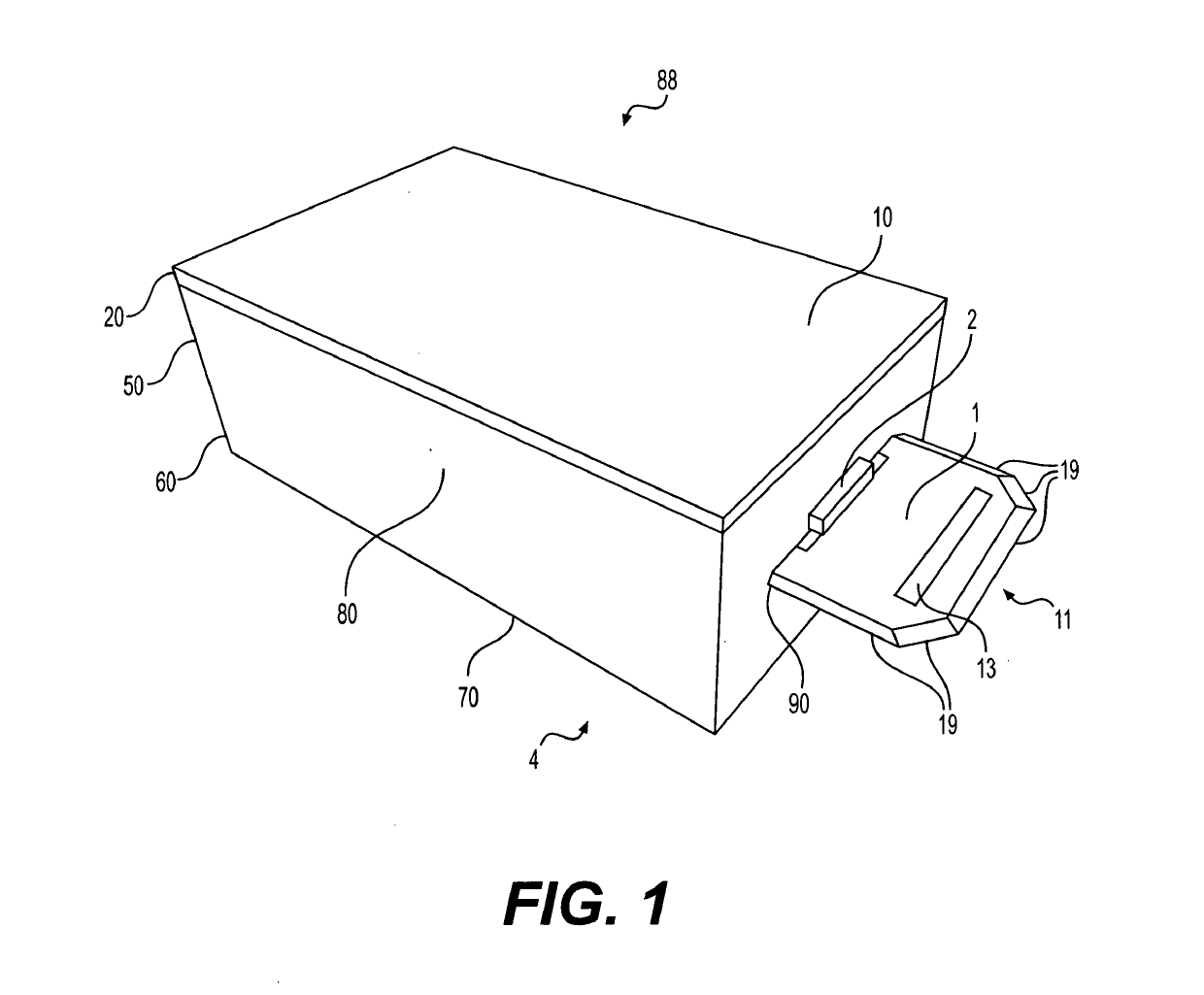

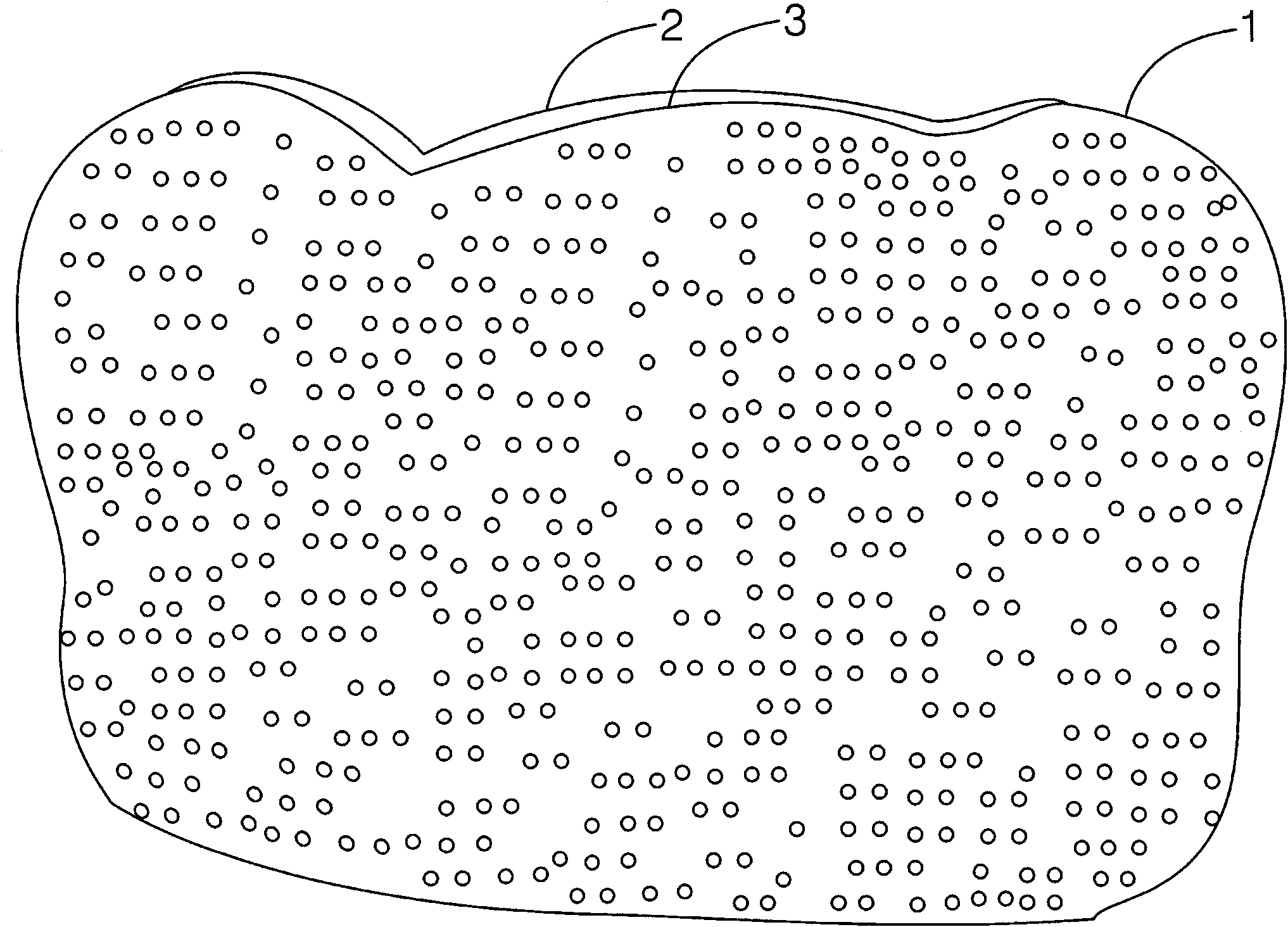

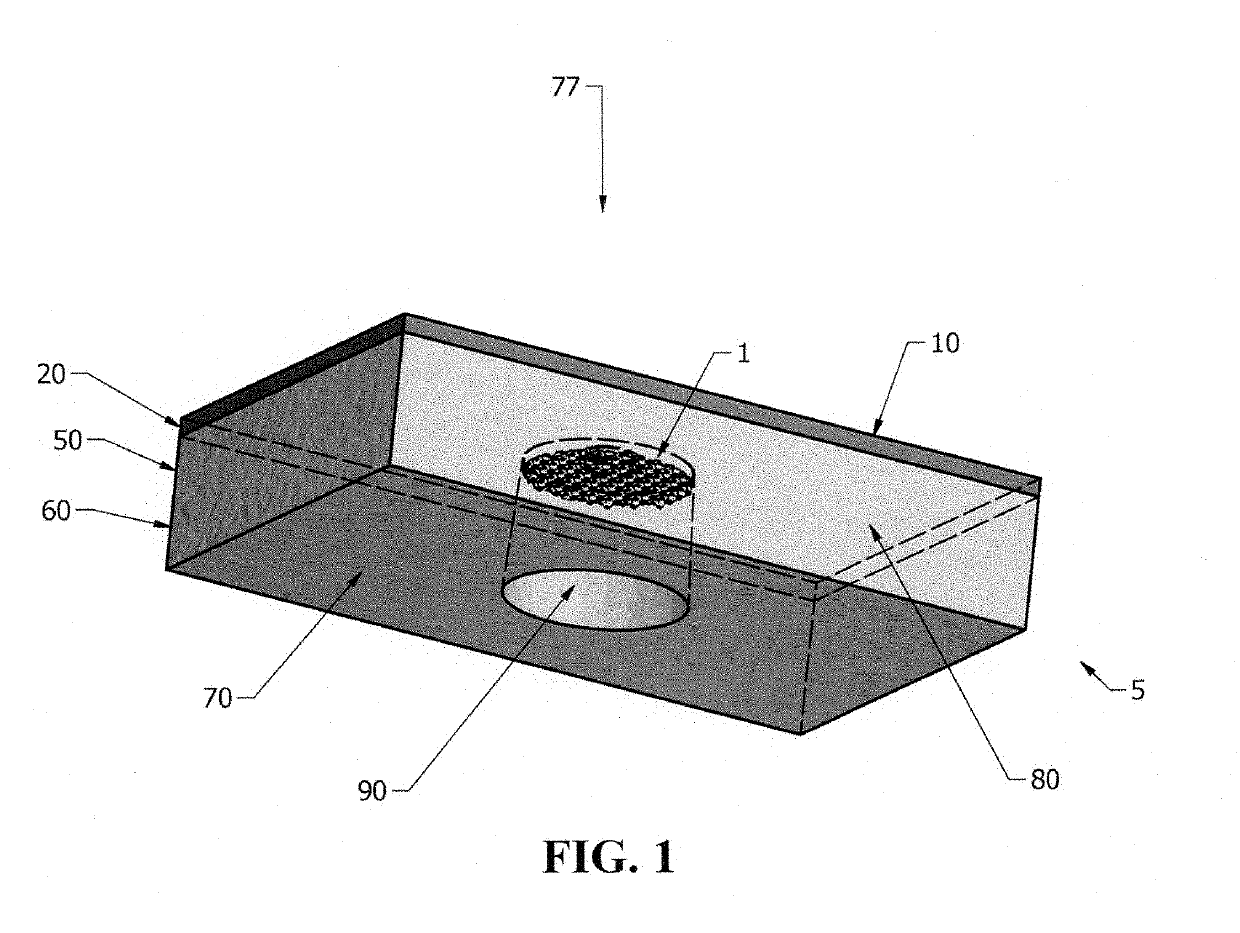

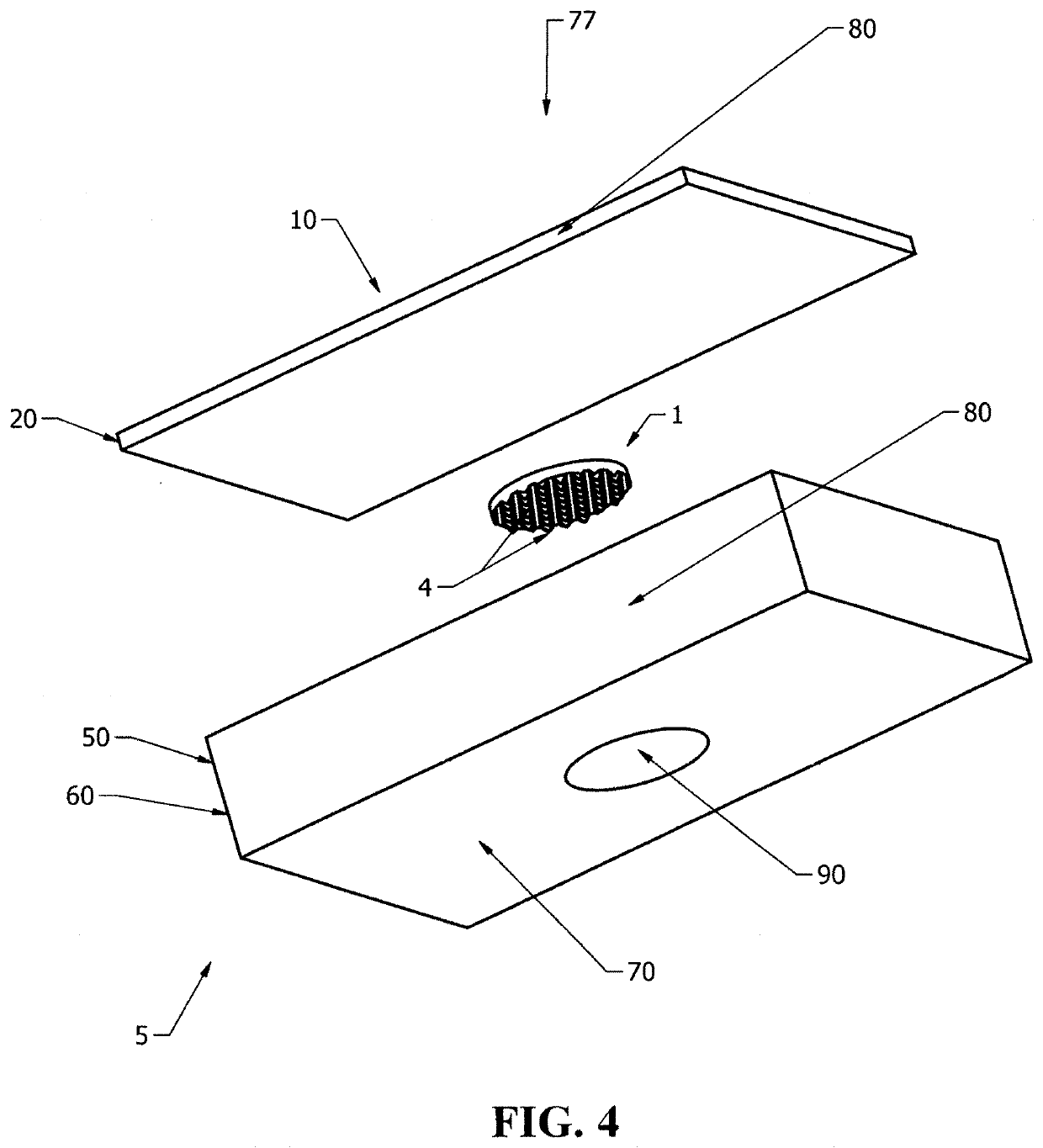

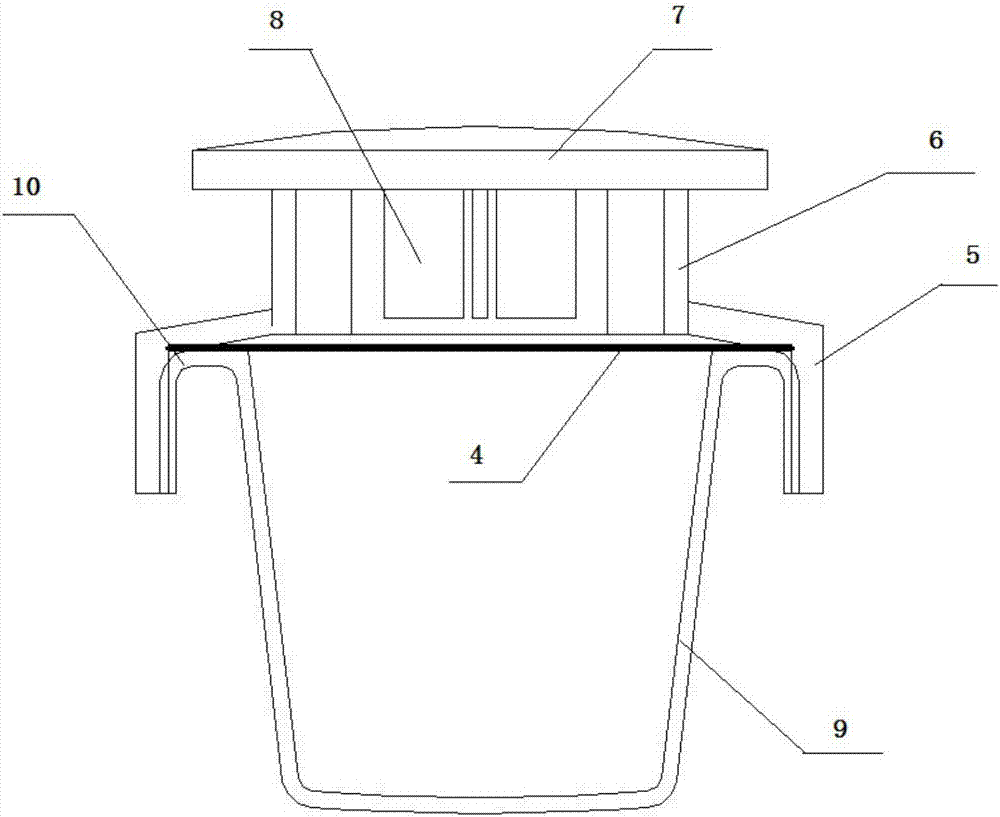

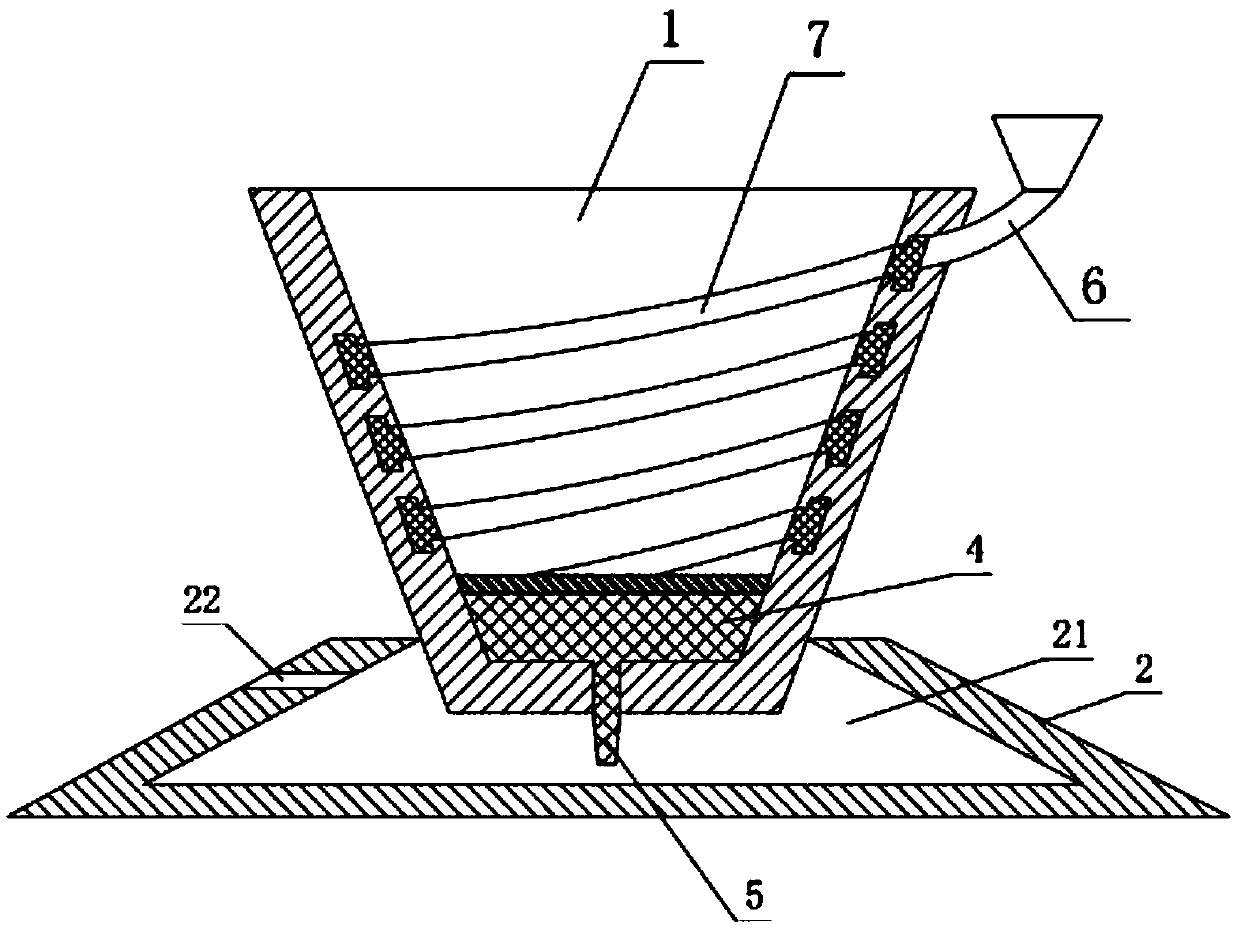

Pneumatic tire and rim assembly with noise damper and pneumatic tire with noise damper

InactiveUS7975740B2Prevent peelingIncreased durabilityWithout separate inflatable insertsRimsEngineeringSpongia

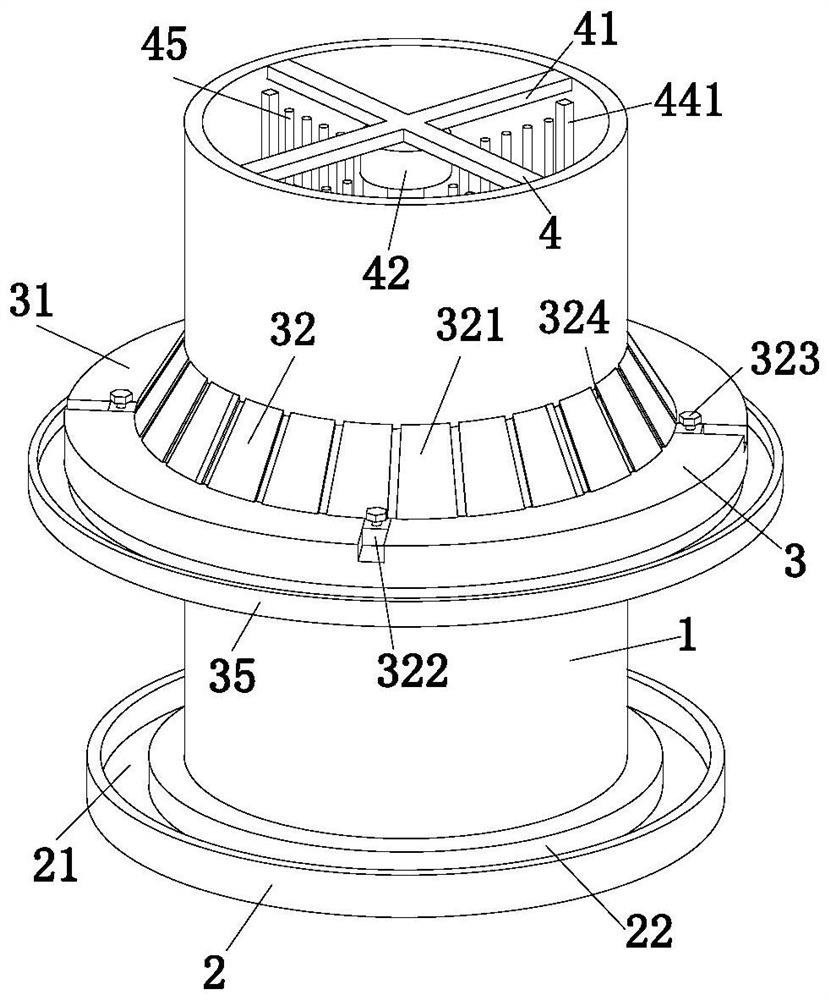

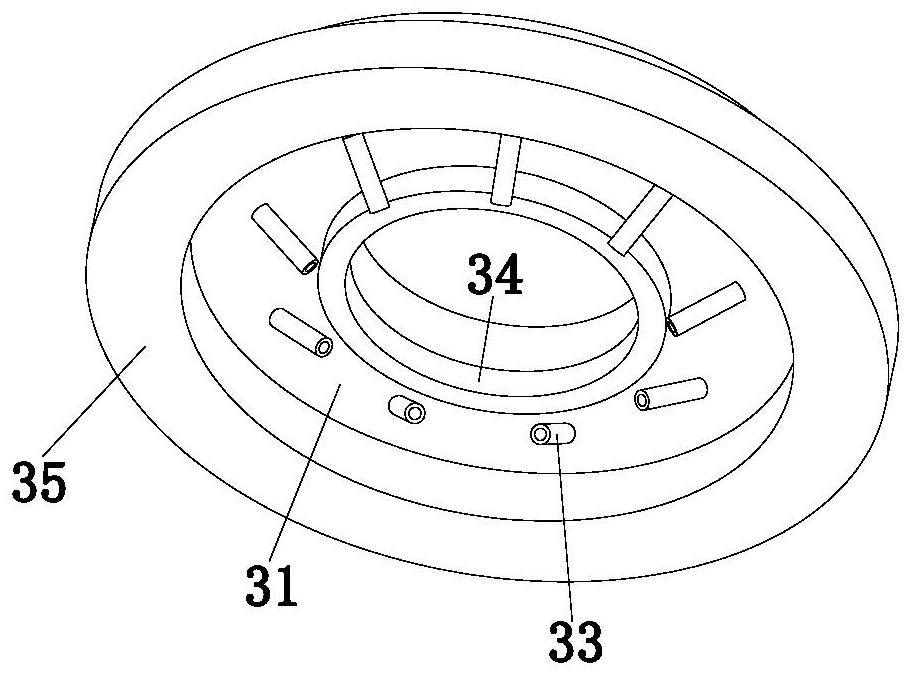

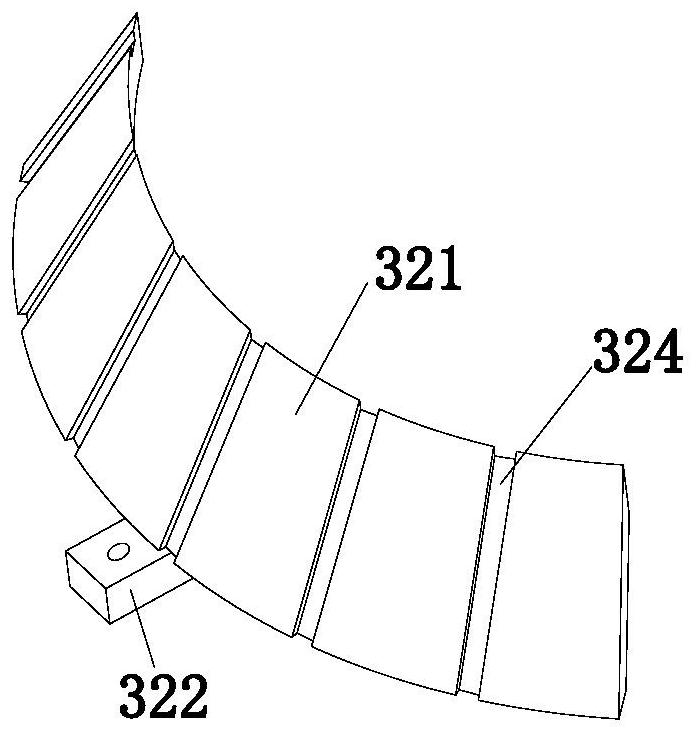

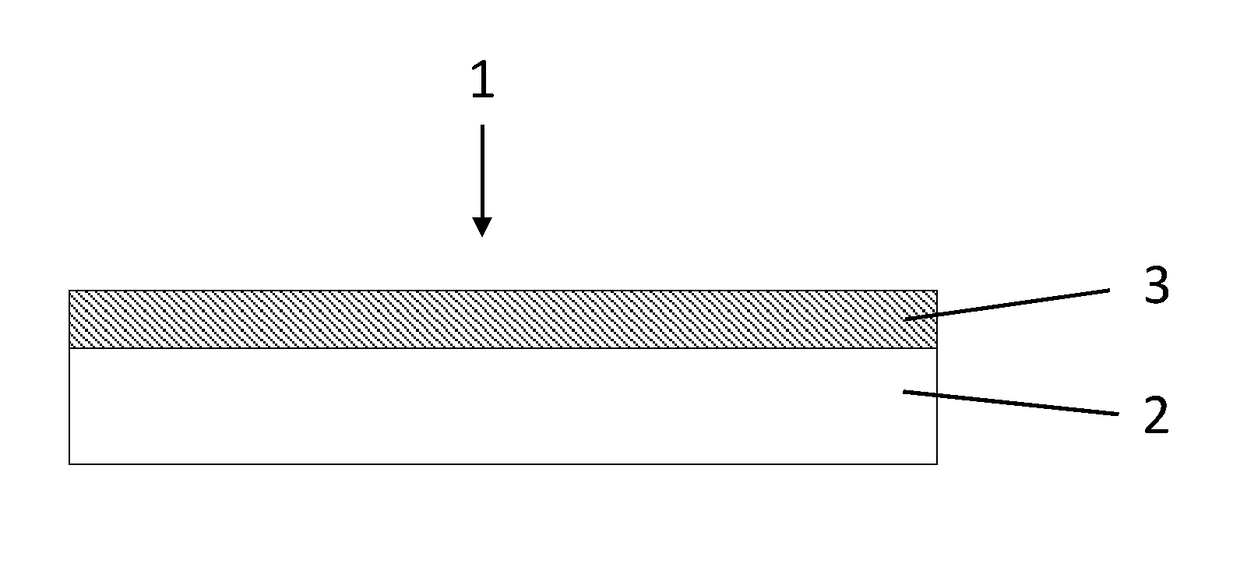

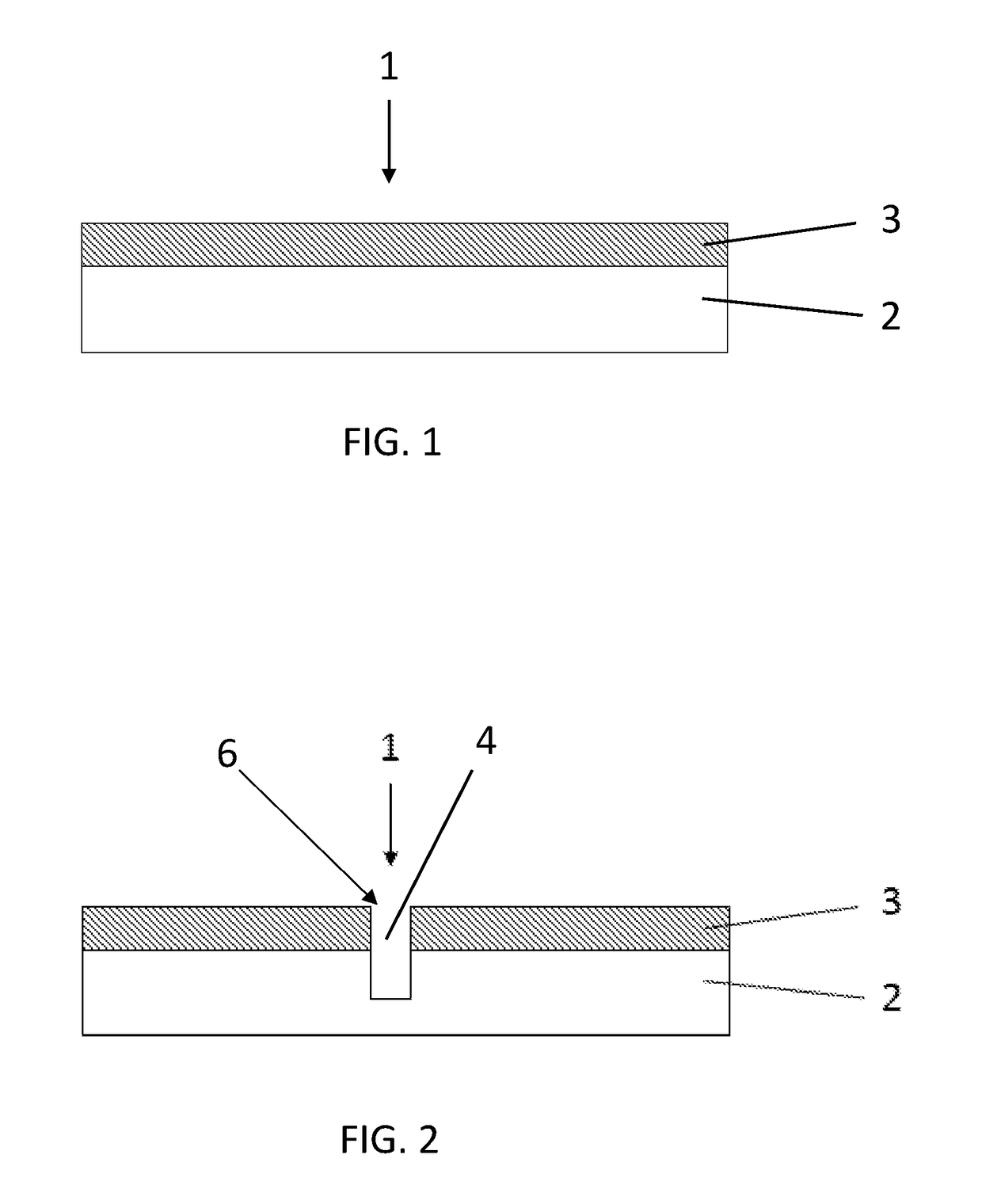

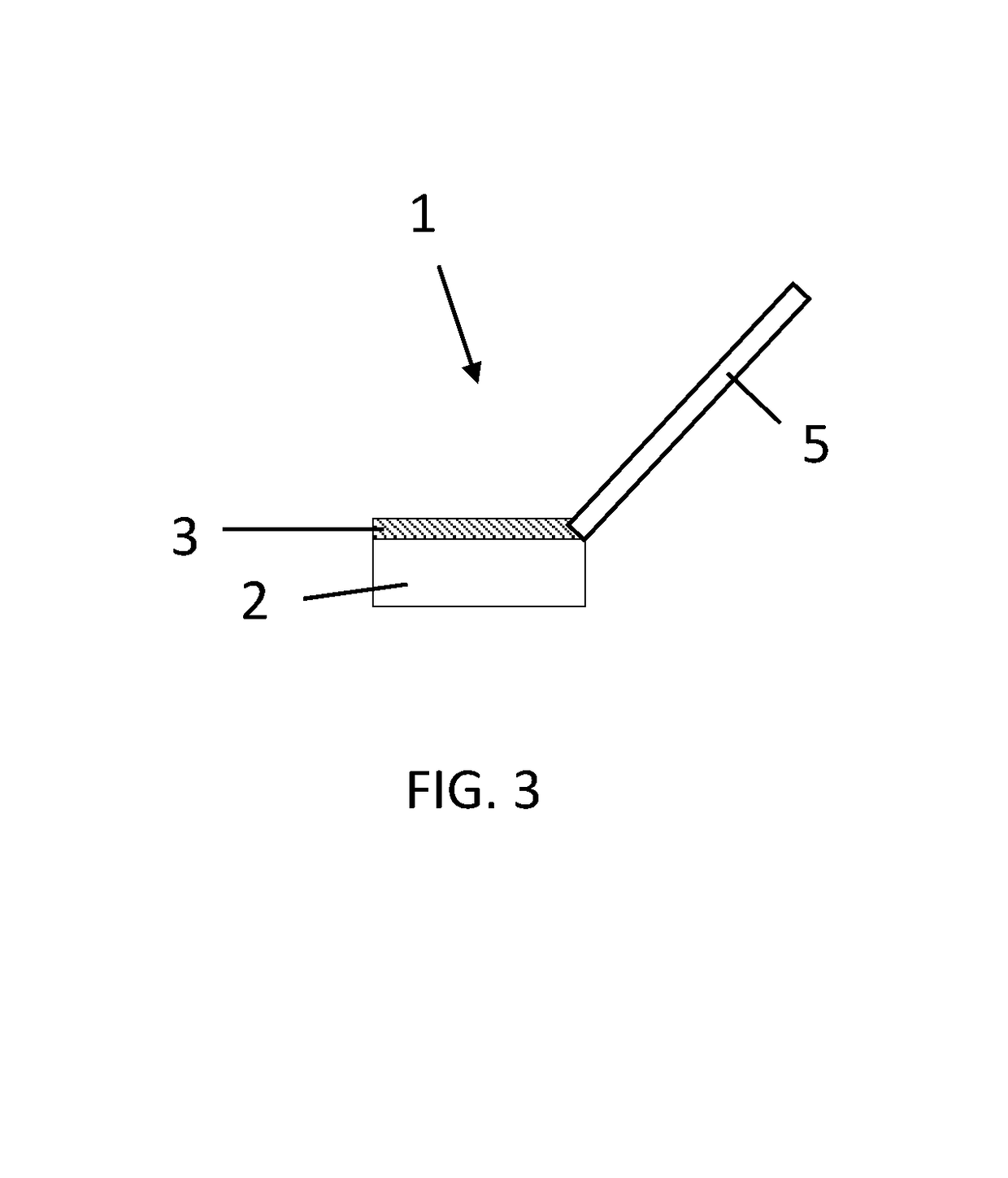

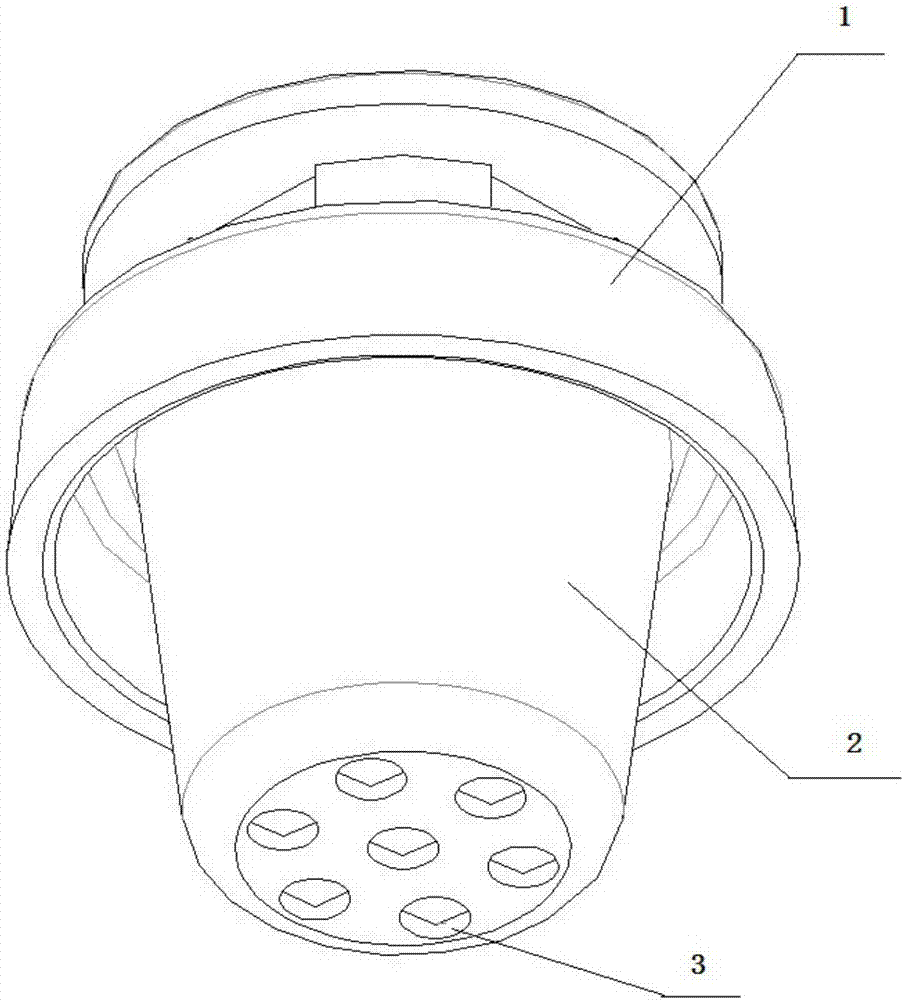

To reduce road noise in running by disposing a noise damper made of a spongy material in a cavity of a tire, a tire and rim assembly is provided. The tire and rim assembly 1 including a rim 2, a pneumatic tire 3 attached to the rim 2, and a noise damper 4 made of a spongy material which is disposed in a tire cavity “i” surrounded by the rim 2 and the pneumatic tire 3 and extends in the tire circumferential direction, wherein the noise damper 4 has a volume of 0.4 to 20% of the whole volume of the tire cavity “i” and is fixed to an inner surface 2i or 3i of the tire or rim, the noise damper 4 has a height of 30 mm or less from the inner surface, and the spongy material of the noise damper 4 has a hardness of 10 to 250 N, a tensile strength of 70 kPa or more and a specific gravity of 0.014 to 0.052.

Owner:SUMITOMO RUBBER IND LTD

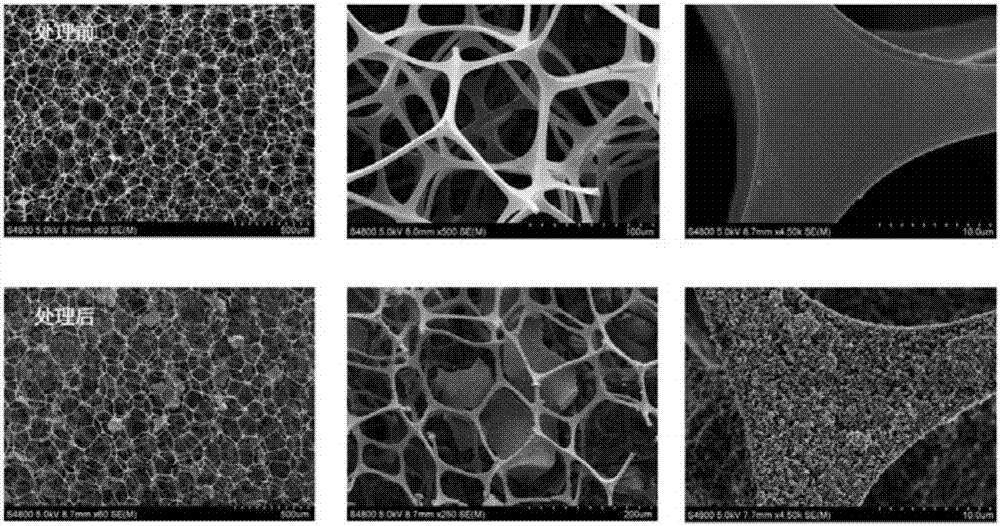

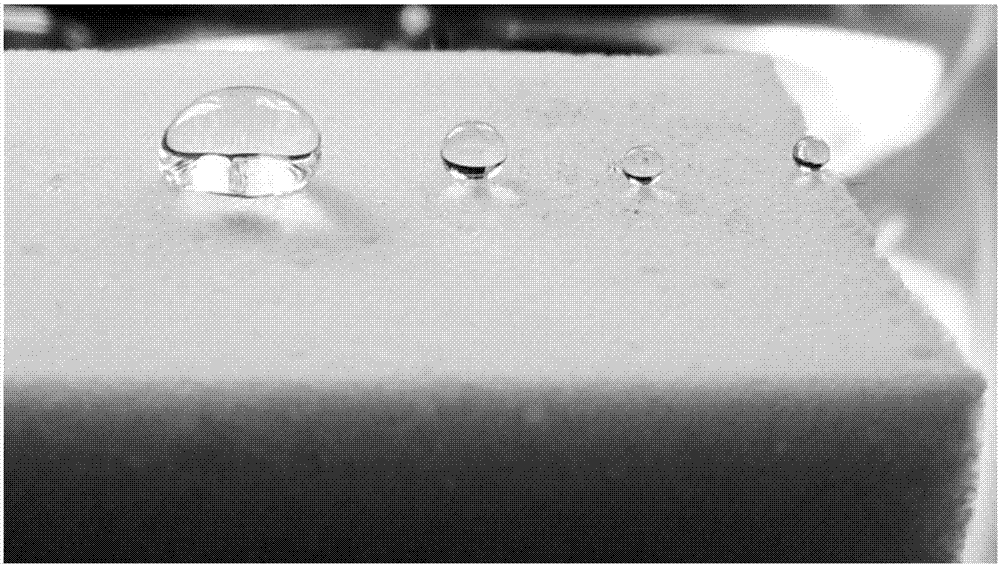

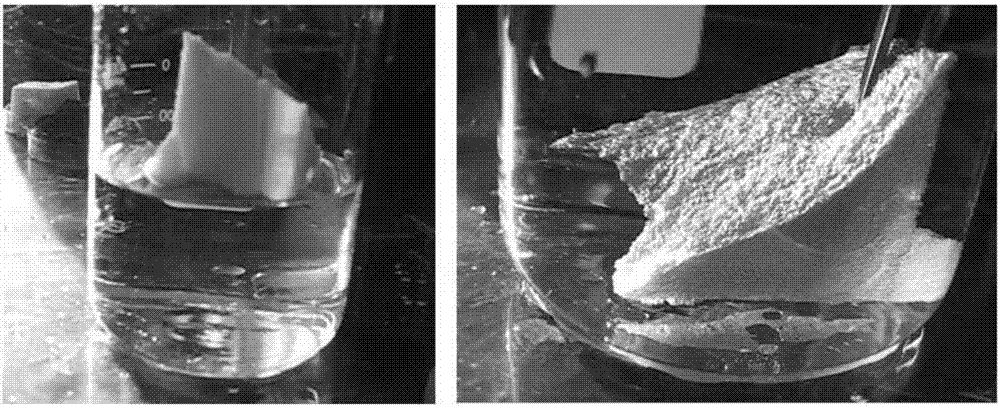

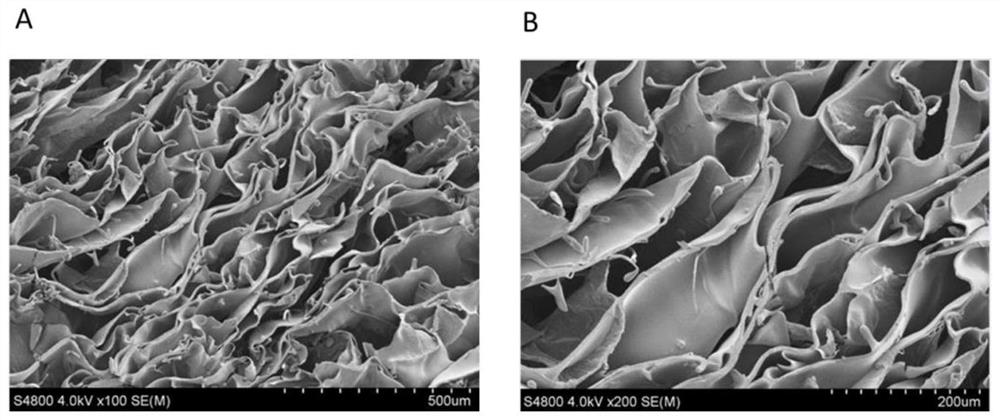

Superhydrophobic sponge body and preparation method thereof

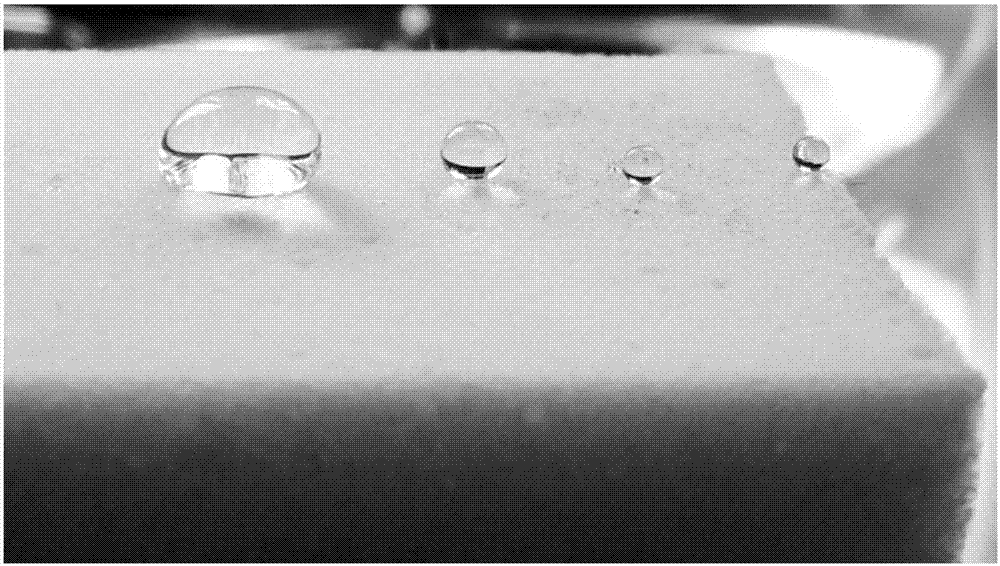

The present invention relates to a superhydrophobic sponge body and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge body and a preparation method thereof, wherein the superhydrophobic sponge body comprises a sponge body and a nanometer modifier, the sponge body is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge bodies.

Owner:CHINA PETROLEUM & CHEM CORP +1

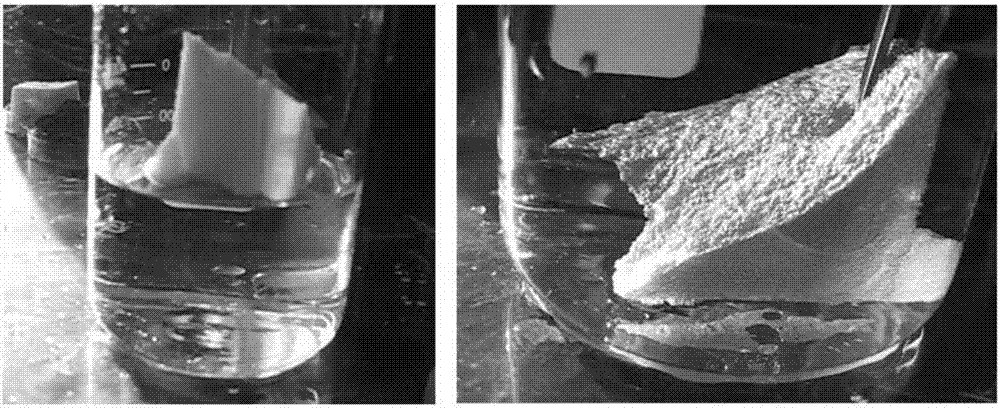

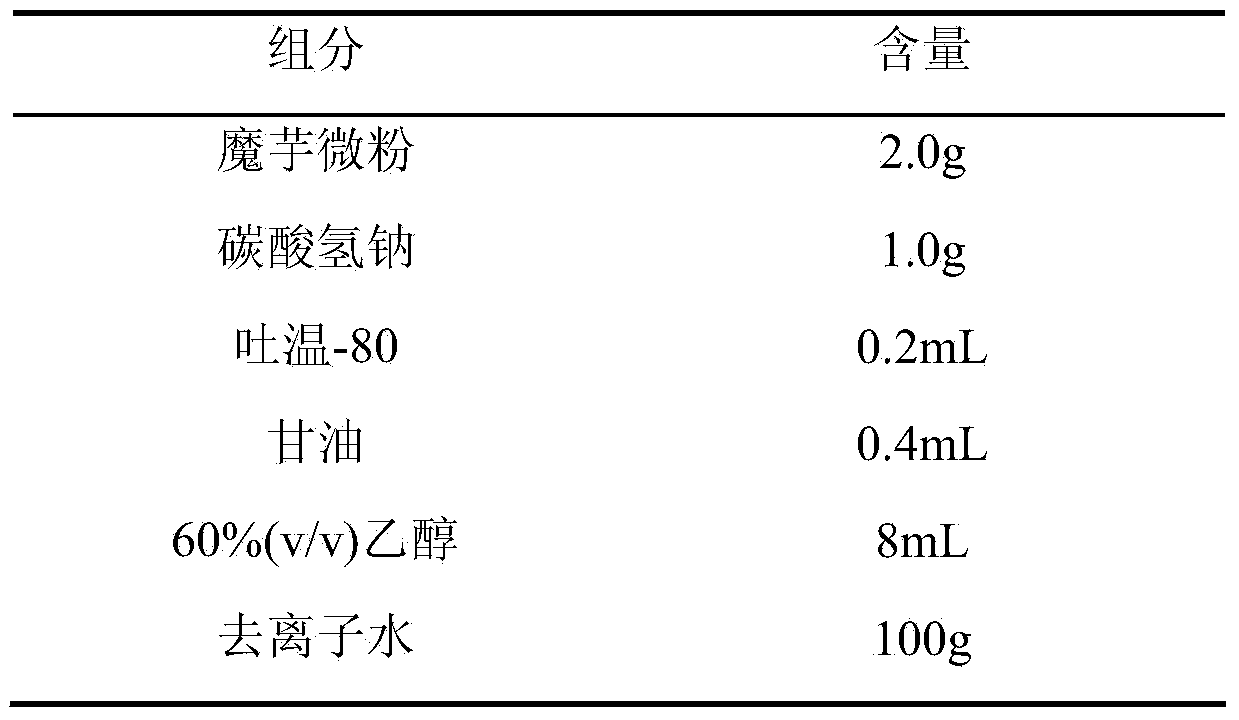

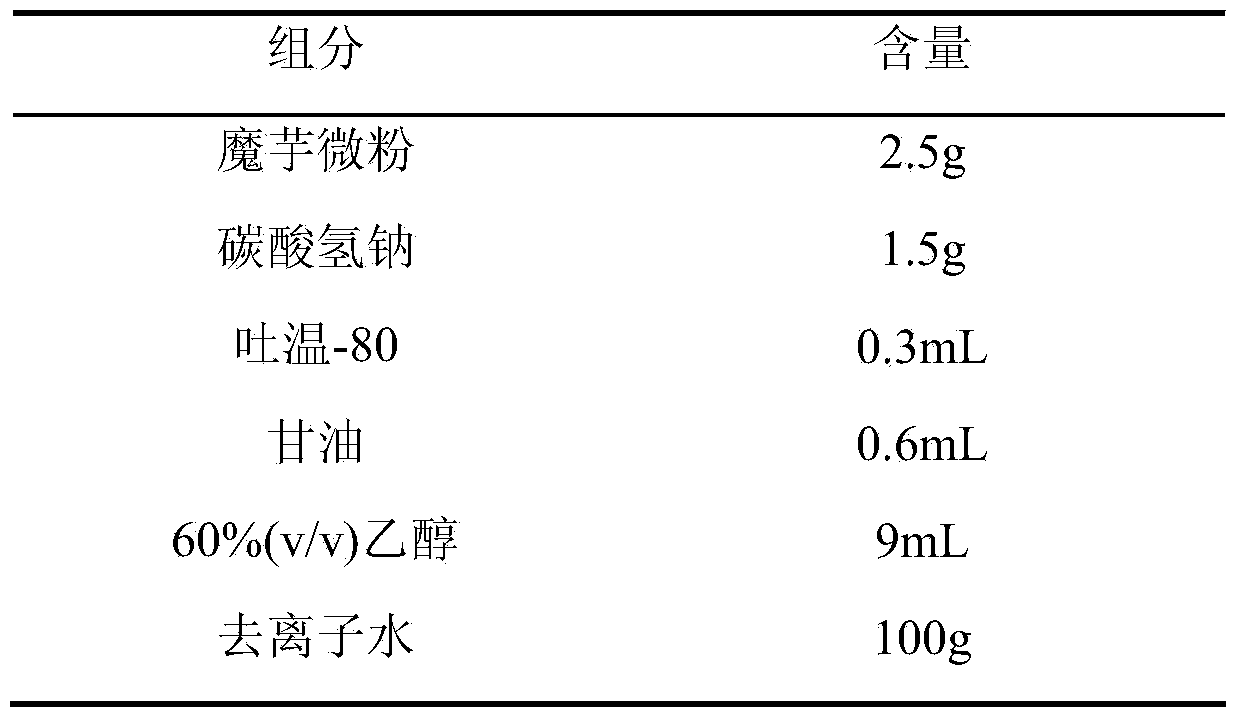

Devilstongue gulcomannan hemostatic sponge and preparation method thereof

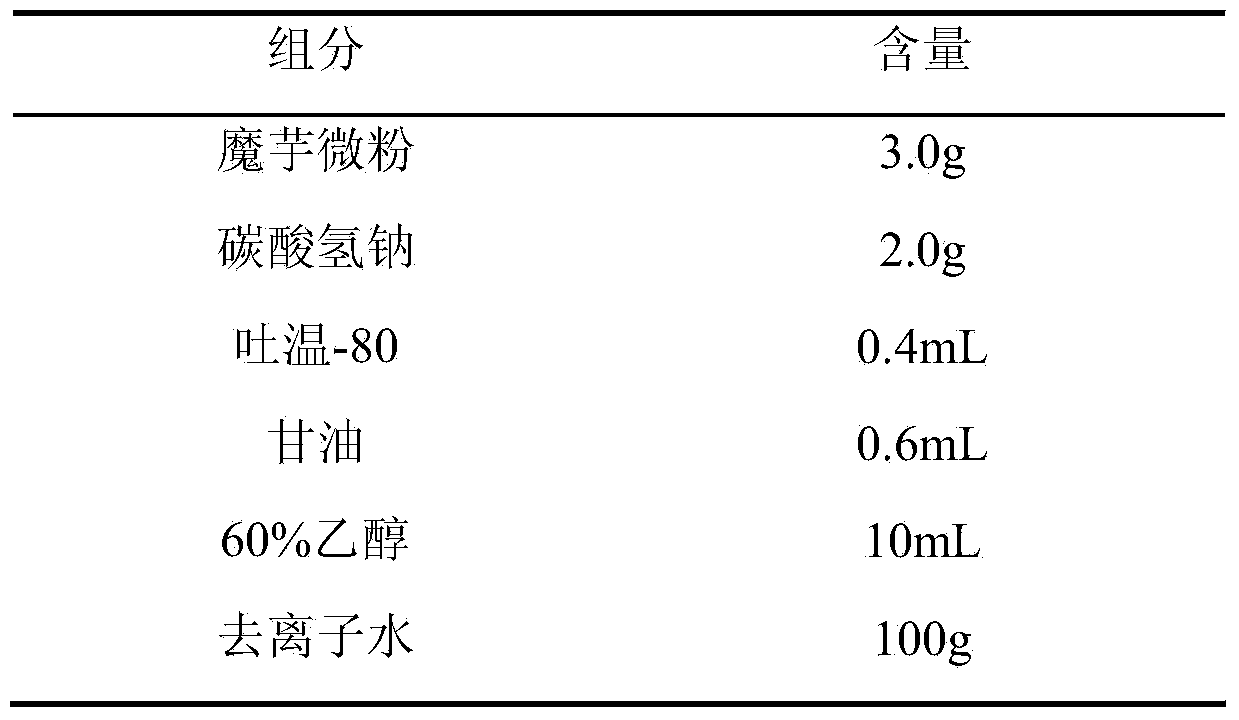

ActiveCN103418020AGood flexibilityUniform pore sizeAbsorbent padsBandagesChemistrySodium bicarbonate

The invention discloses a devilstongue gulcomannan hemostatic sponge. The devilstongue gulcomannan hemostatic sponge comprises 2-4g of devilstongue fine powder, 1-3g of sodium bicarbonate, 0.2-0.6mL of Tween 80, 0.6mL of glycerinum, 8-12mL of ethyl alcohol with volume fraction being 60%, and 100g of water. According to the devilstongue gulcomannan hemostatic sponge, the devilstongue fine powder containing high-purity gulcomannan (>90%) serves as raw materials, gel with even froth is prepared by regulating the amount of the sodium bicarbonate, the amount of the Tween 80 and the amount of the glycerinum, and then the thickness of gel solution in a grinding tool, the pre-freezing temperature and time and time of vacuum freeze and drying are controlled to prepare the devilstongue gulcomannan hemostatic sponge which is good in flexibility, even in pore diameter and high in air permeability and water absorption. The prepared devilstongue gulcomannan hemostatic sponge has water-absorbing quality, can not be dissolved in water, and can not be cracked after being seriously rubbed. When the devilstongue gulcomannan hemostatic sponge is immerged in water at the temperature of 20 DEG C, the amount of water absorbed by the sponge is 25 times larger than the weight of a sample.

Owner:SOUTHWEST UNIVERSITY

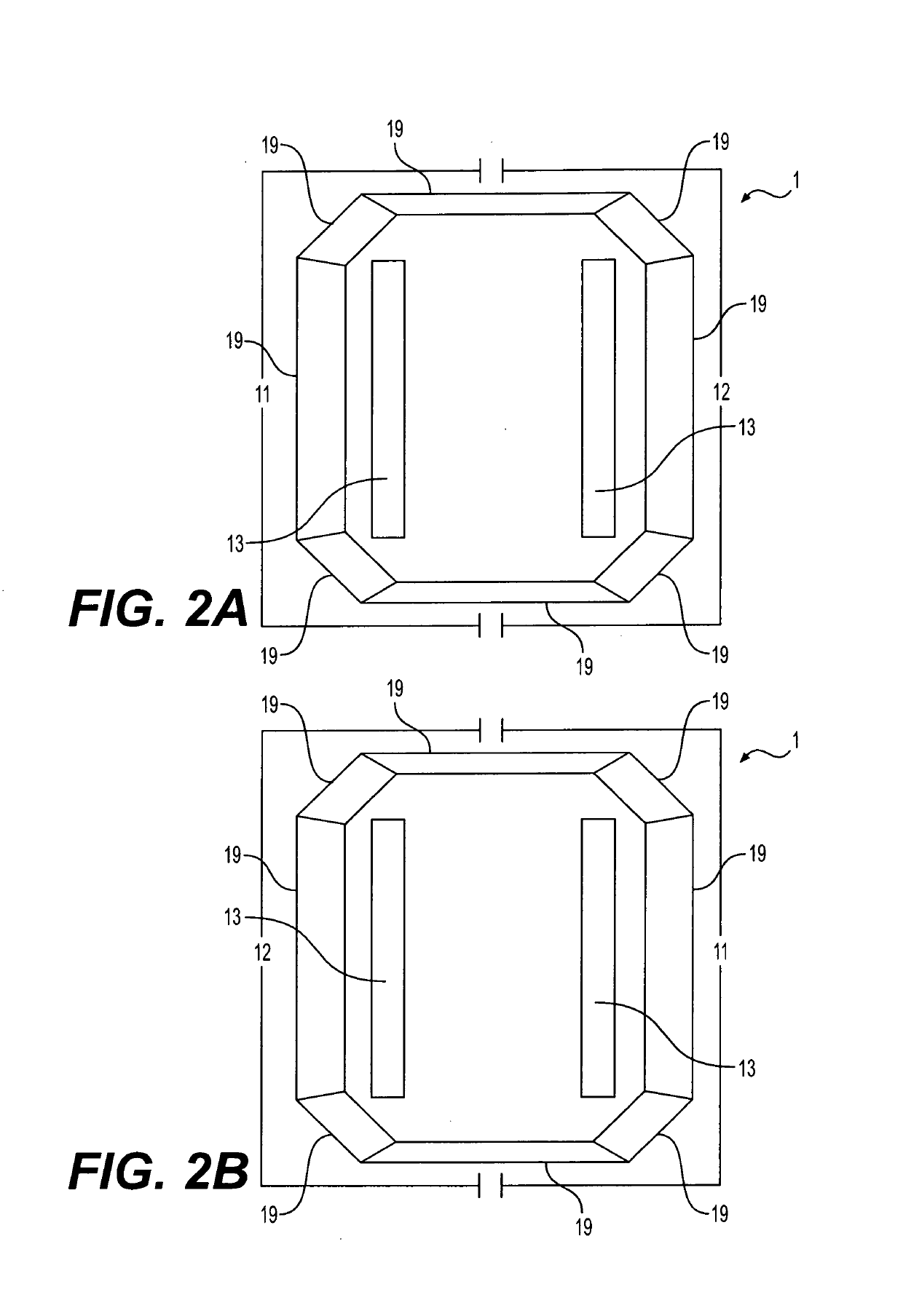

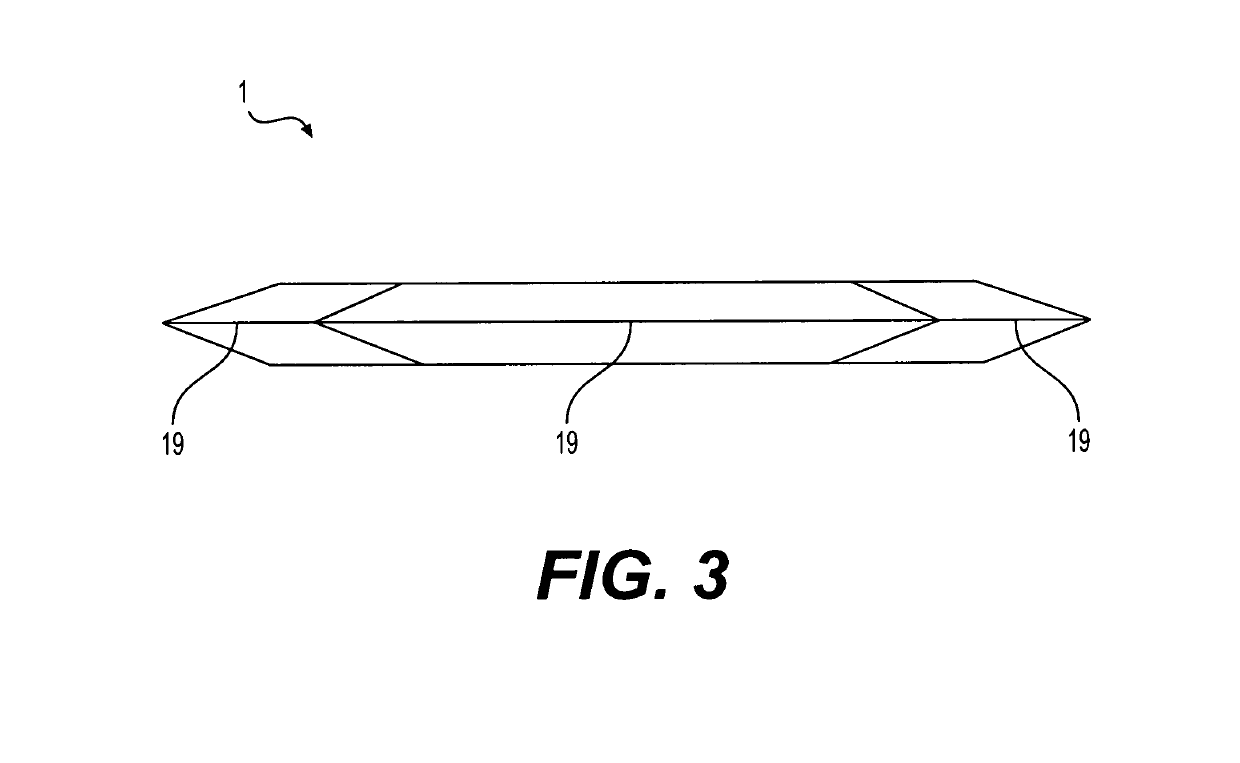

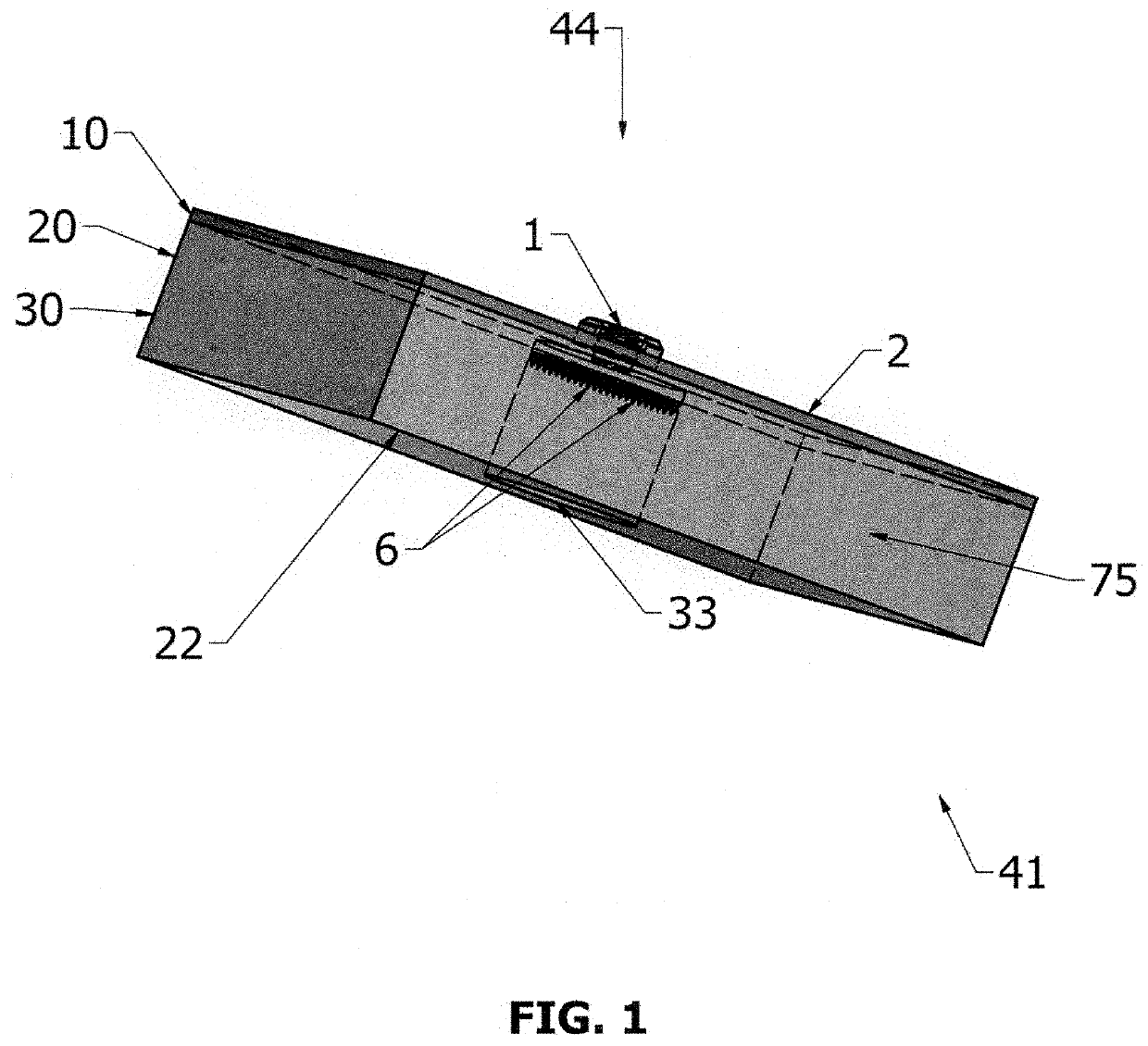

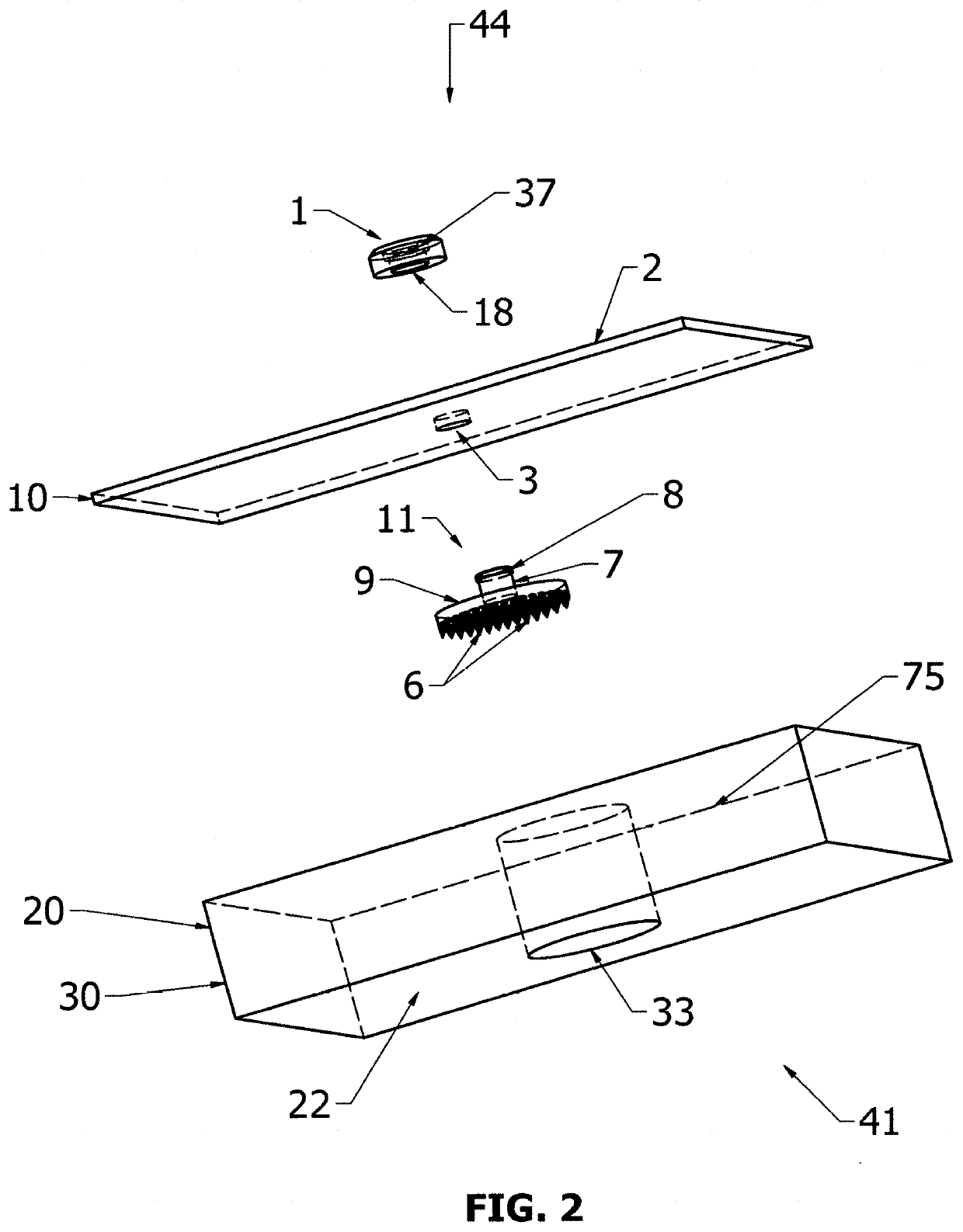

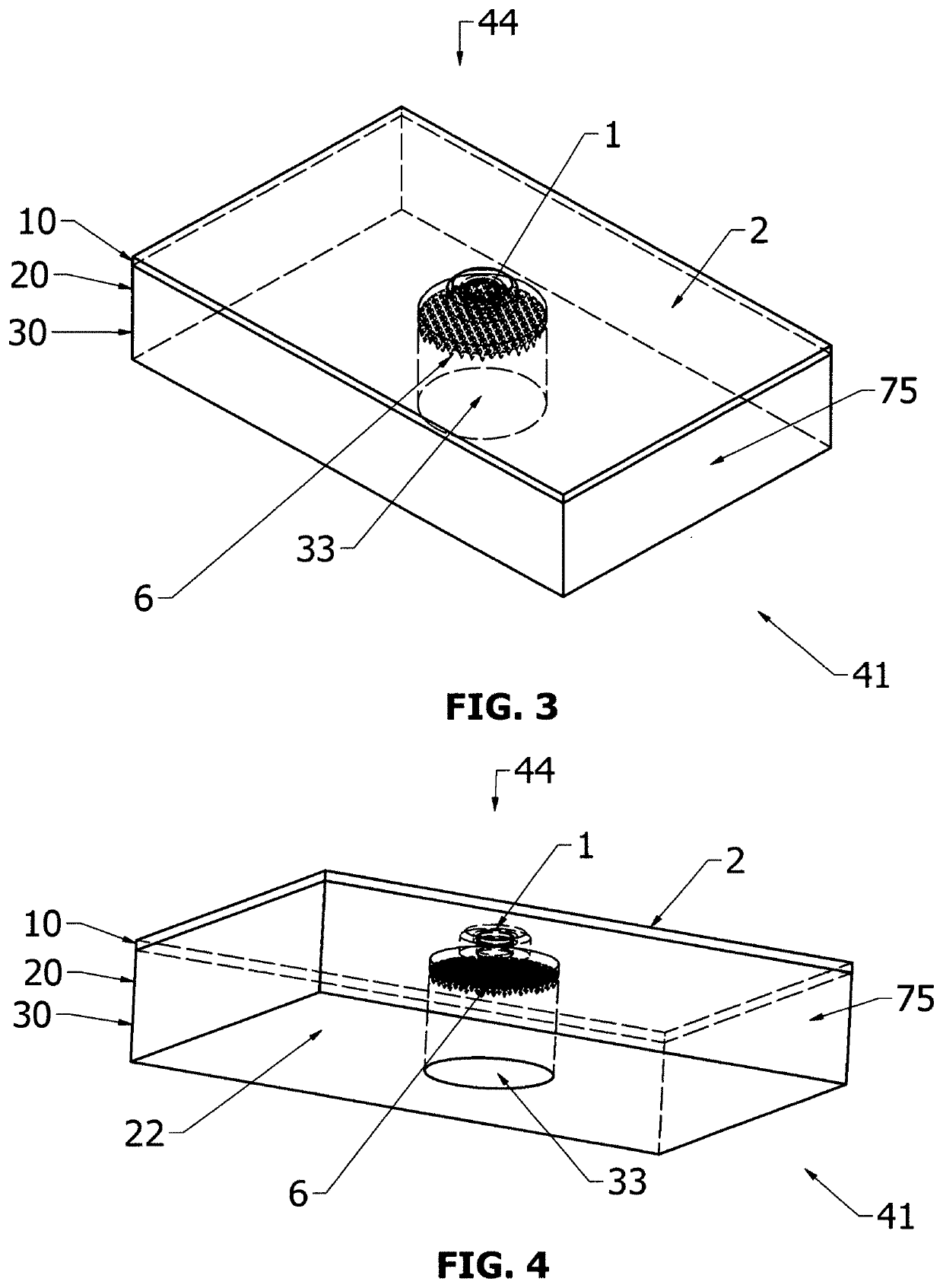

Scraper sponge

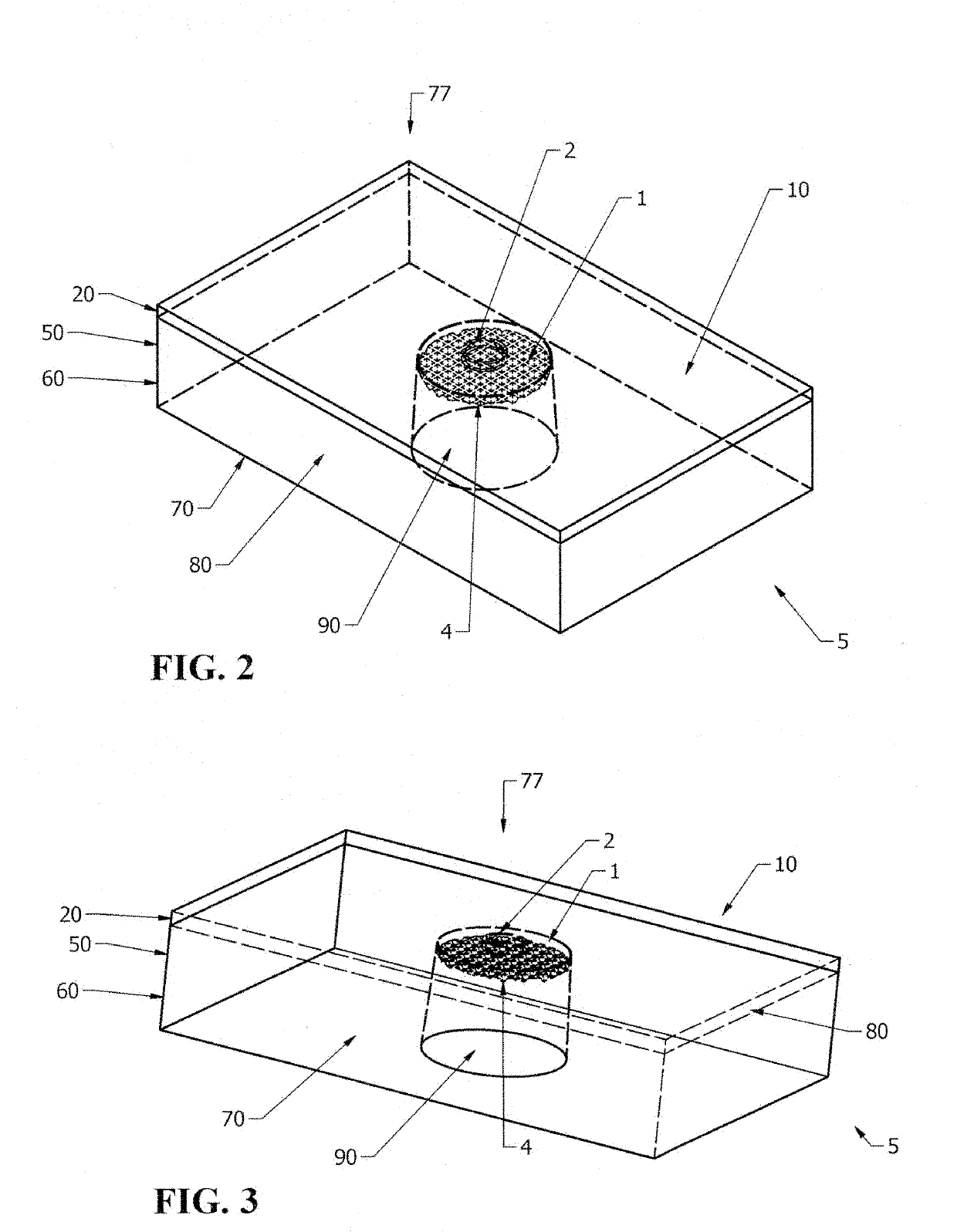

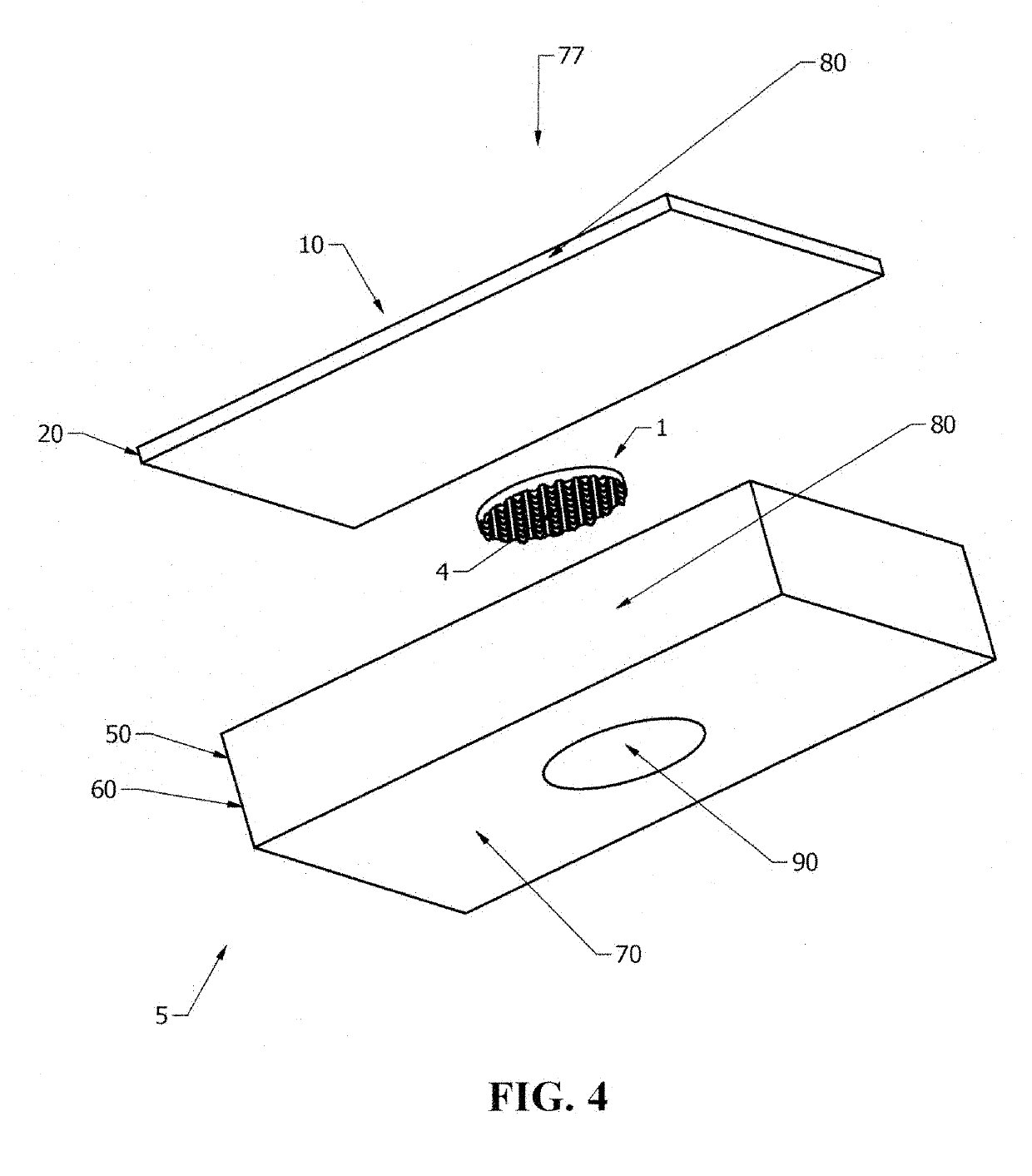

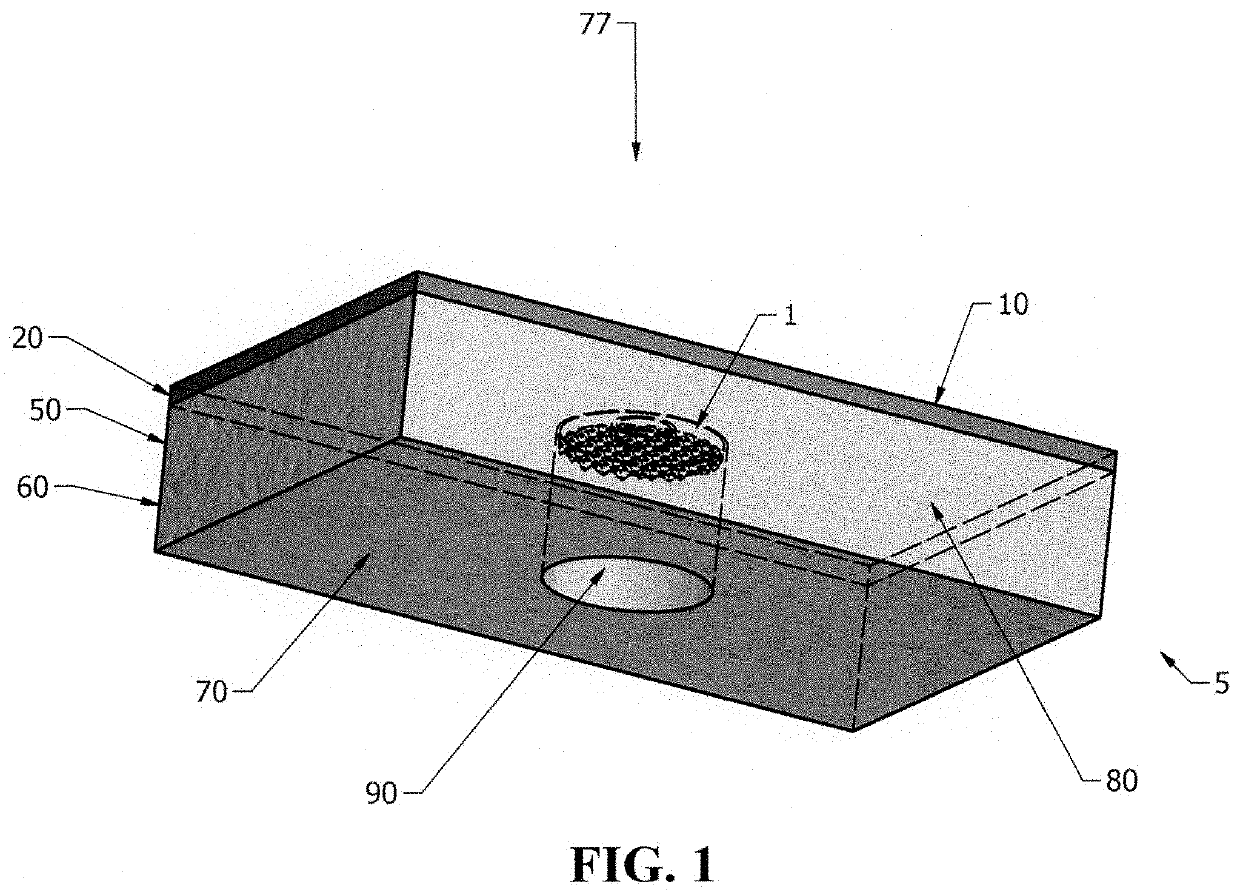

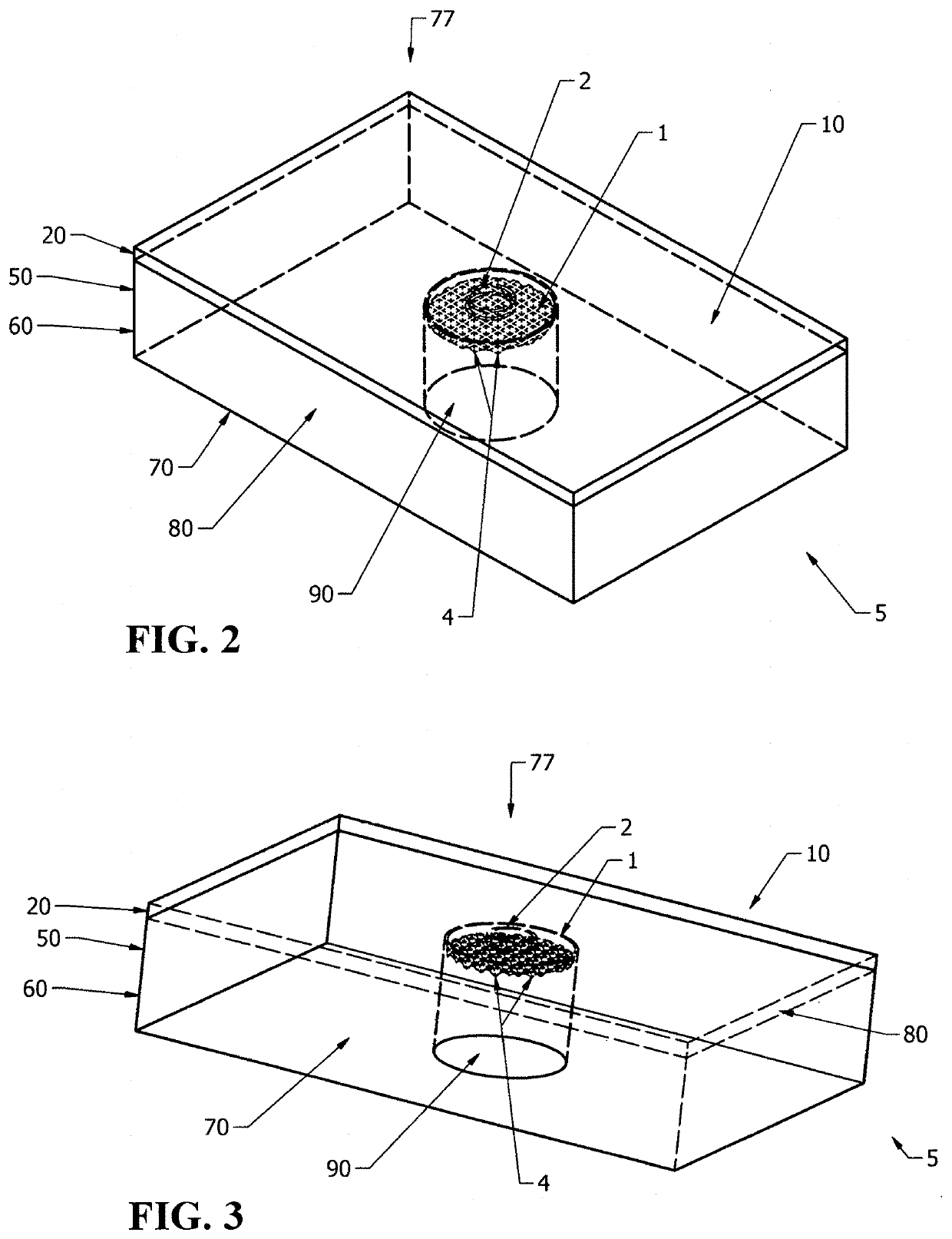

A scraper sponge for cleaning and scraping away unwanted substances from an object or surface comprising a sponge body defining a first surface, a first layer, second layer, third layer, second surface opposite the first surface, a continuous side surface around the perimeter; and a scraper and scraper holder secured in an aperture defining the scraper holder approximately between the first surface and second surface of the sponge body. The scraper, after being inserted into the scraper holder has a tip portion extending outwardly from the scraper holder within the aperture within the sponge body and defining at least 5 edges and a depressible surface concave female groove to which forces are applied to manipulate the rigid scraper. The sponge body is usable with or without the scraper and has two surfaces available for cleaning and scouring; the first surface and second surface. The second layer, third layer, third surface, and continuous side surface are made of the same sponge-like cellulose material. As an alternative, the second layer, third layer, third surface, and a portion of the continuous side surface are not made of the same material and the sponge body has at least three surfaces adapted for cleaning and scouring; the first surface, second surface, and a portion of the continuous side surface. The sponge body is also usable with or without the scraper.

Owner:OMOTOLA ALAHANDRO OLATUNDE

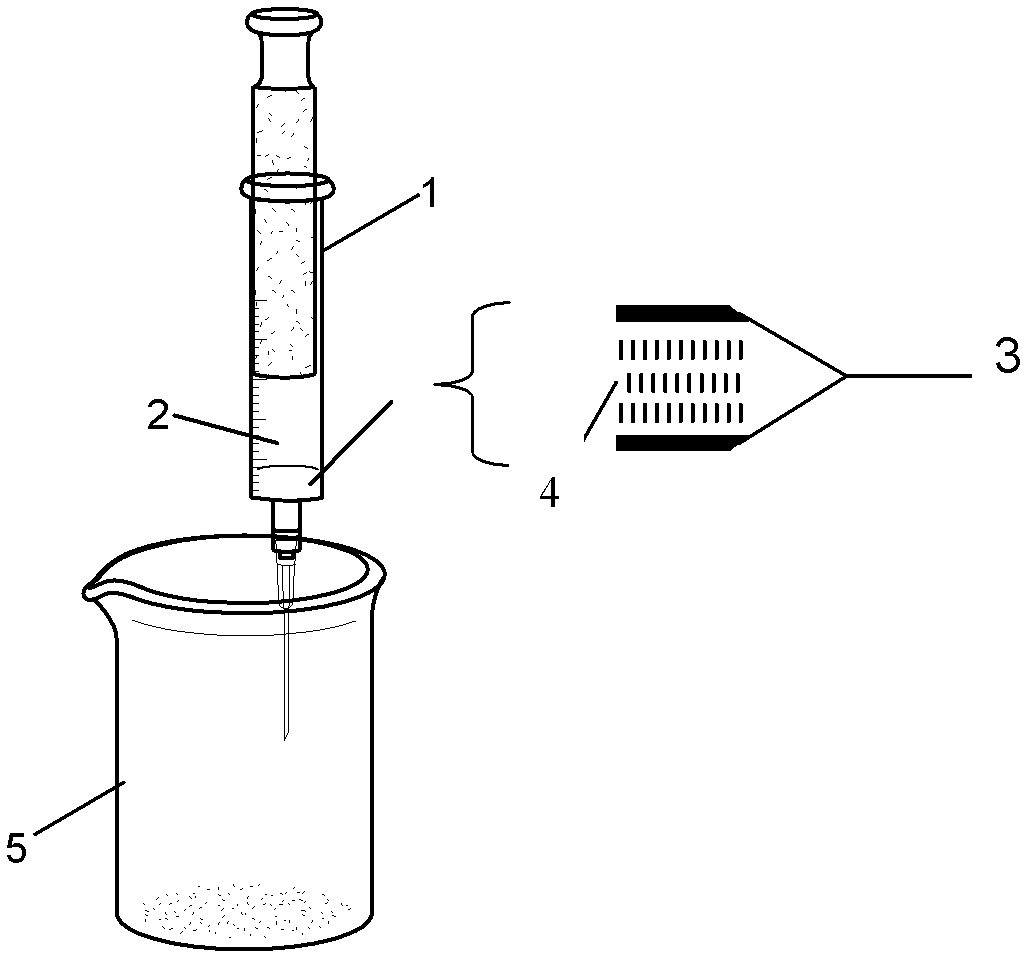

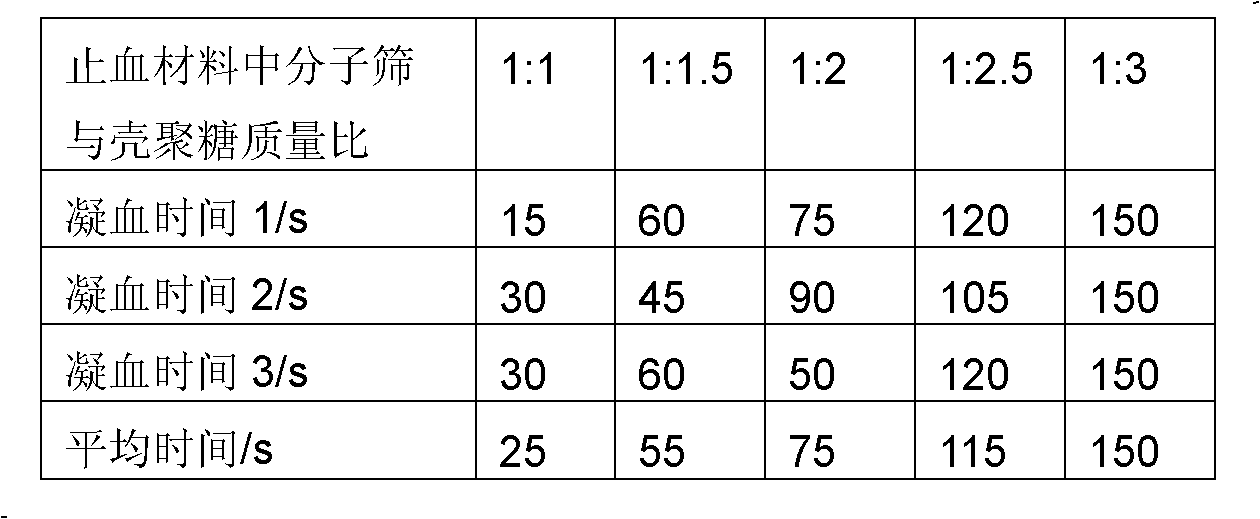

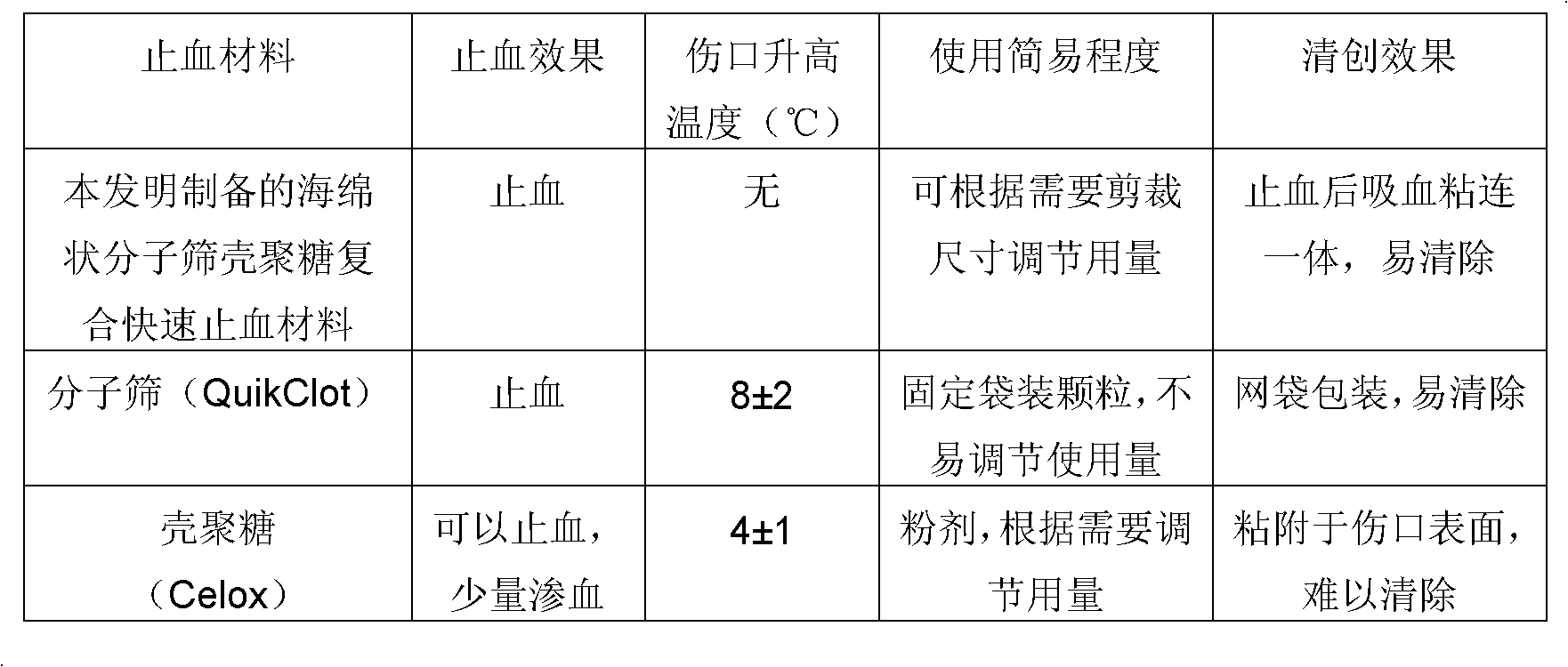

Spongy molecular sieve chitosan compound rapid hemostatic material as well as preparation method and application thereof

InactiveCN102205143ASolve the shortcomings of low hemostasis efficiencyEliminate local overheatingInorganic non-active ingredientsAbsorbent padsMolecular sieveMedicine

The invention discloses a spongy molecular sieve chitosan compound rapid hemostatic material as well as a preparation method and application thereof, belonging to the technical field of hemostatic dressings, and particularly relating to a spongy molecular sieve chitosan compound material for rapid hemostasis as well as a preparation method and application thereof to preparation of hemostatic patches, hemostatic sponges, hemostatic bandages and medicament release carriers. The hemostatic material is a mixture of a molecular sieve and chitosan in the ratio of 1:1-1:3, wherein the molecular sieve is an FAU, LTA, VPI-5 or ALPO-5 type molecular sieve material for exchanging Ca<+> and Ag<+>; the total exchanging degree of the Ca<+> and the Ag<+> is 50-95 percent; and the exchanging degree of silver ions is 0-40 percent. Due to the adoption of the hemostatic material prepared with the method, the defects such as large thermal discharge of the molecular sieve during hemostasis, an adverse effect on cleaning a wounded area and low hemostasis efficiency of chitosan are overcome.

Owner:JILIN UNIV

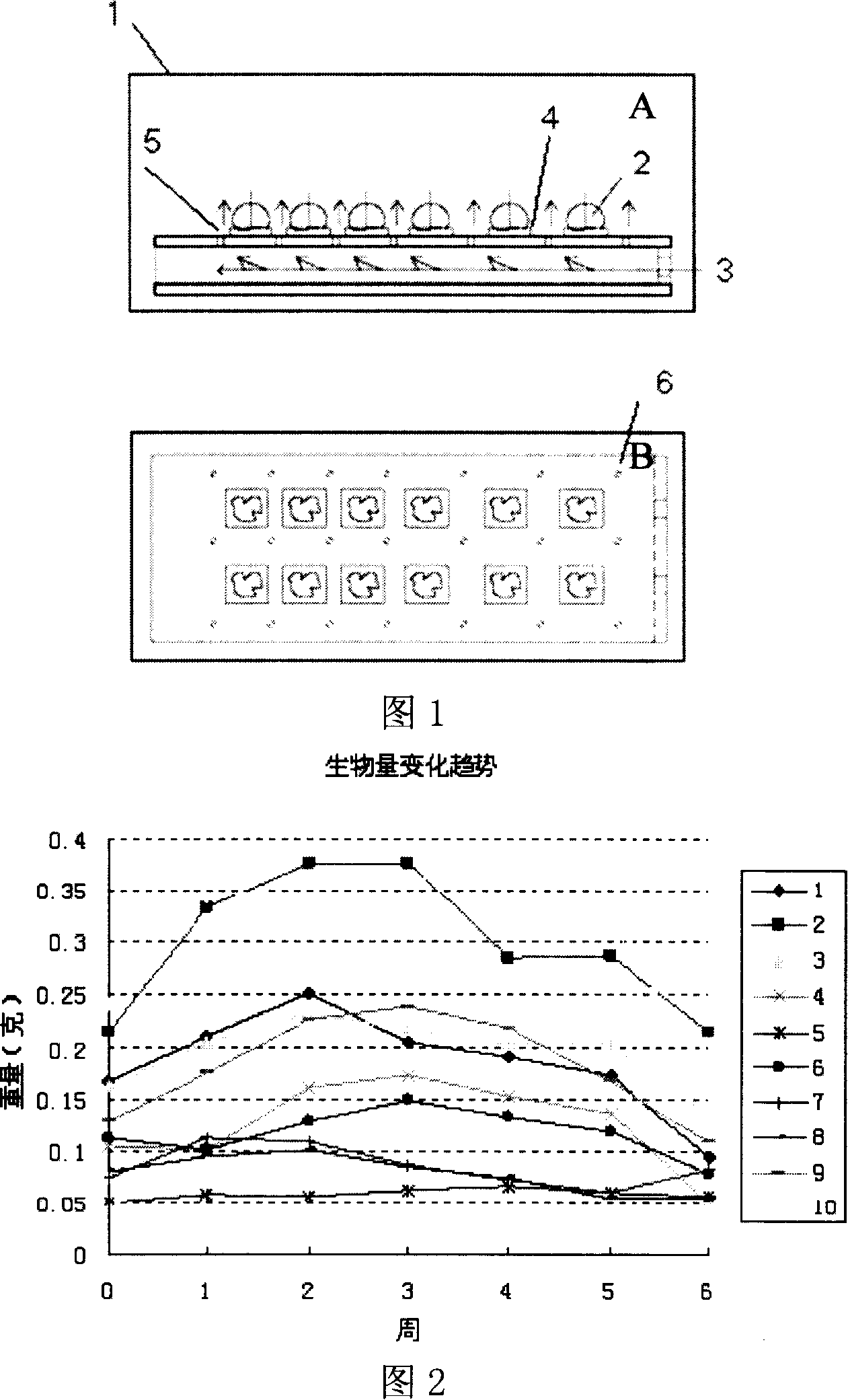

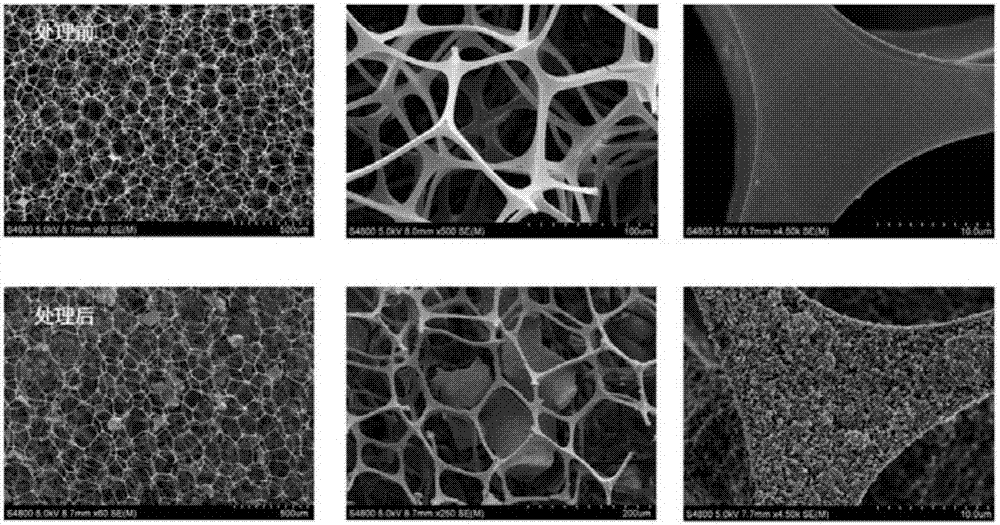

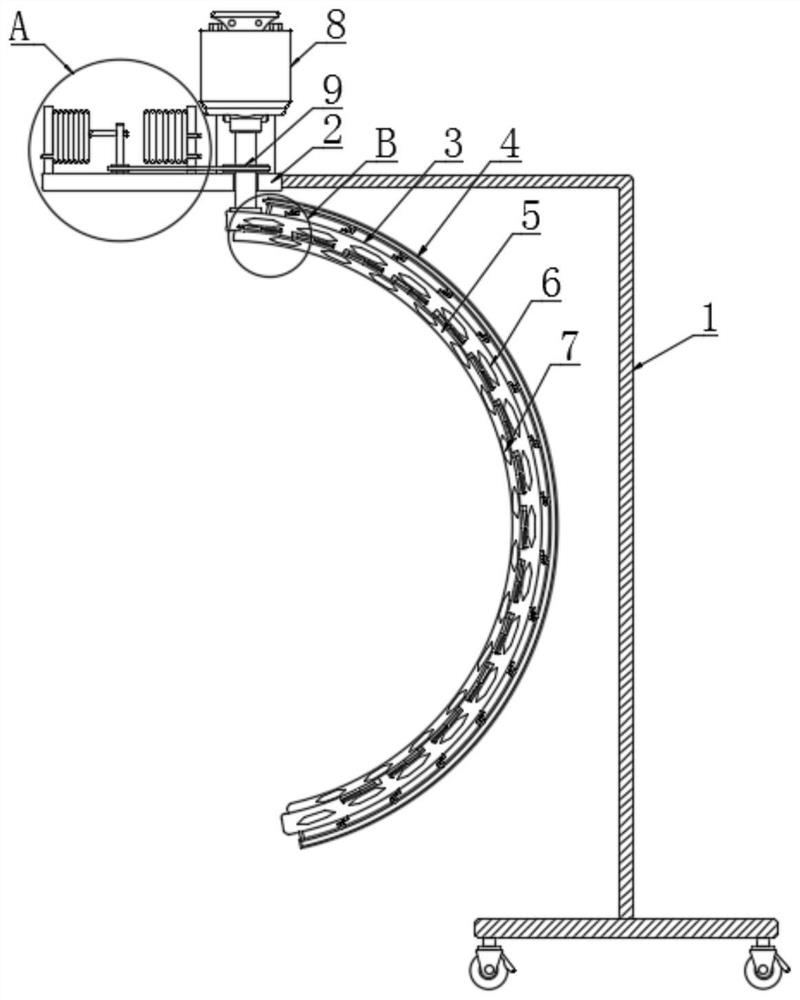

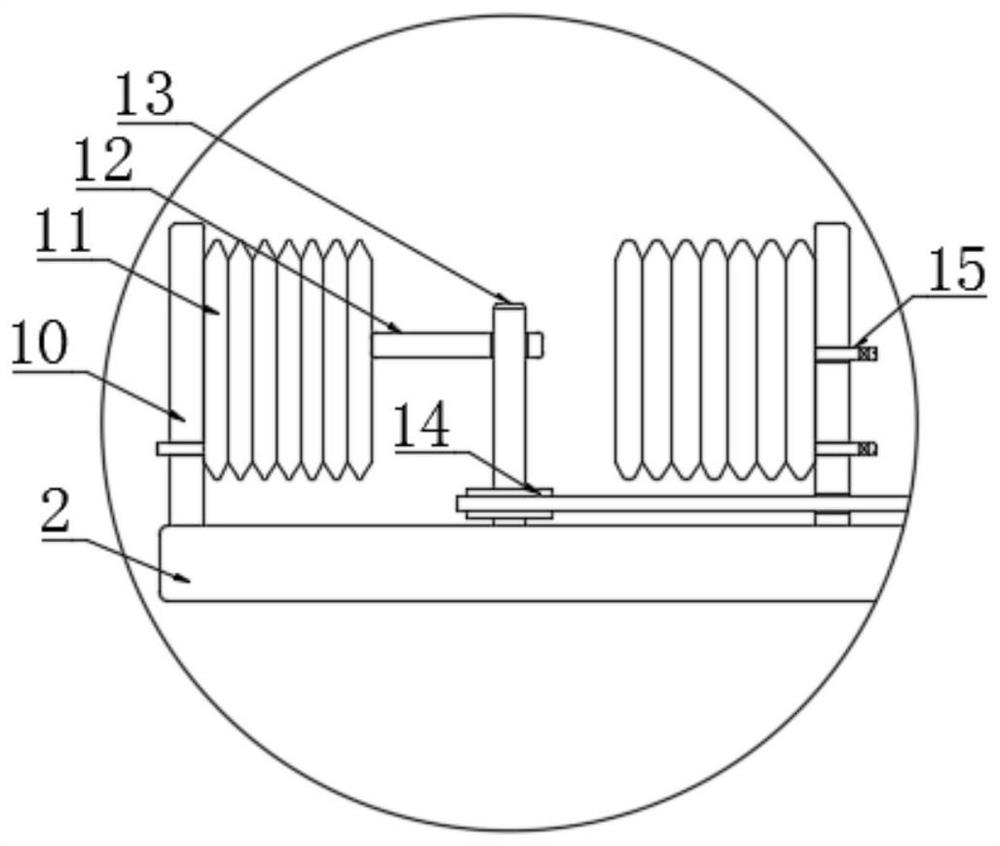

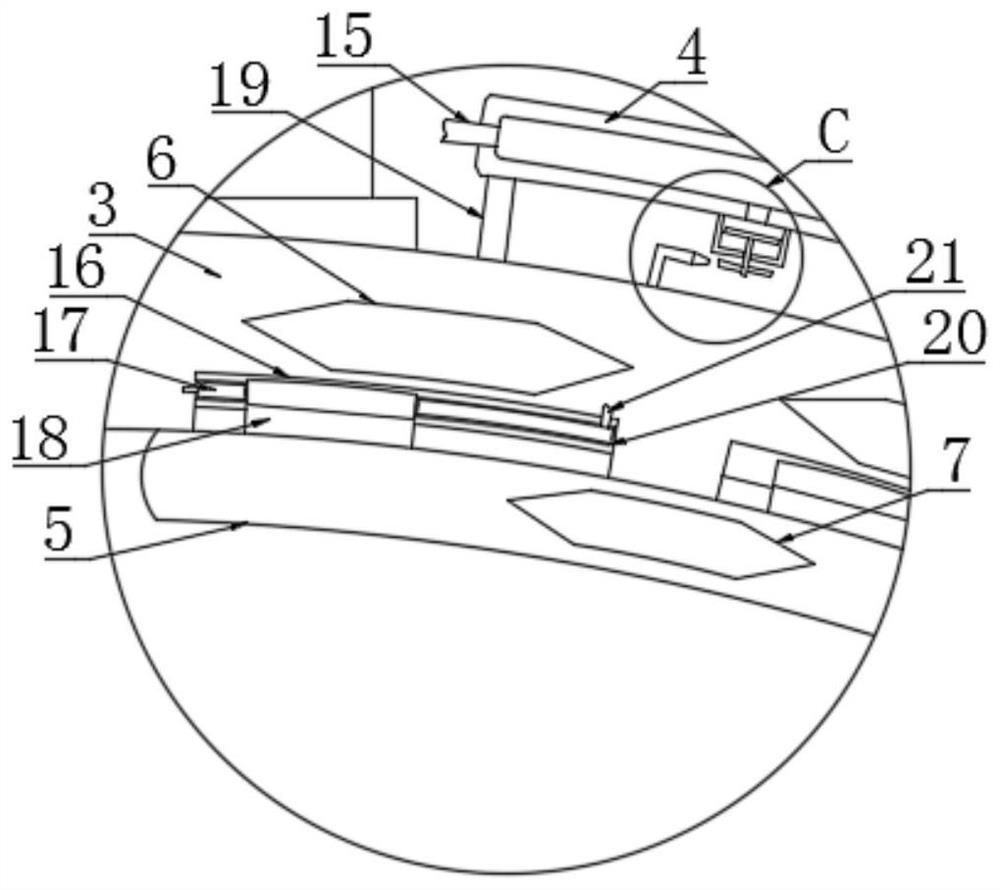

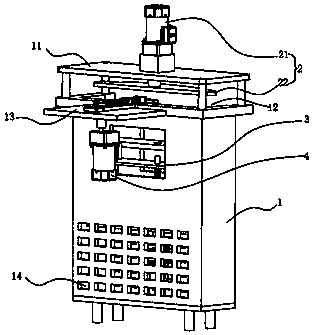

Method and device for producing biological siliceous material with reactor culture sponge or its cell

The invention relates to a method and a device of reactor culture sponge or the cell production biological siliceous material. The reactor applies natural seawater, micro algae culture sponge of the normal sponge bait, wherein the adhesion base of the growth face which forms 45-135 degree with the horizontal direction, the sponge or the cell can grow along the growth surface, the natural seawater has silane coupling agent, the bone spicule is acquired with the phenomenon that the original skeleton is abandoned in the growth and motion process of the sponge structure, or the biological siliceous material is acquired by producing bone spicule in the exsomatize sponge cell culture system. The production method introduces silane coupling agent by constructing the sponge culture reactor, which proceeds with the biological synthesis of the siliceous material with the chemical modification in order to make the sponge or the sponge cell into 'factory' of specific biological siliceous material, and provides the probability of the application for synthesizing the sponge siliceous bone spicule.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Superhydrophobic sponge material and preparation method thereof

The present invention relates to a superhydrophobic sponge material and a preparation method thereof. A purpose of the present invention is to mainly solve the problem of poor hydrophobic effect of the existing adsorption recovery material. The technical scheme of the present invention comprises a superhydrophobic sponge material and a preparation method thereof, wherein the superhydrophobic sponge material comprises a sponge material and a nanometer modifier, the sponge material is a melamine sponge or a polyurethane sponge, and the nanometer modifier preparation method comprises: dissolving a nanometer material in a hydrophobic organosilicon compound agent, and stirring until completely dissolving so as to obtain the nanometer modifier. With the technical scheme of the present invention, the problem in the prior art is well solved. The preparation method of the present invention can be used in the preparation of superhydrophobic sponge materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

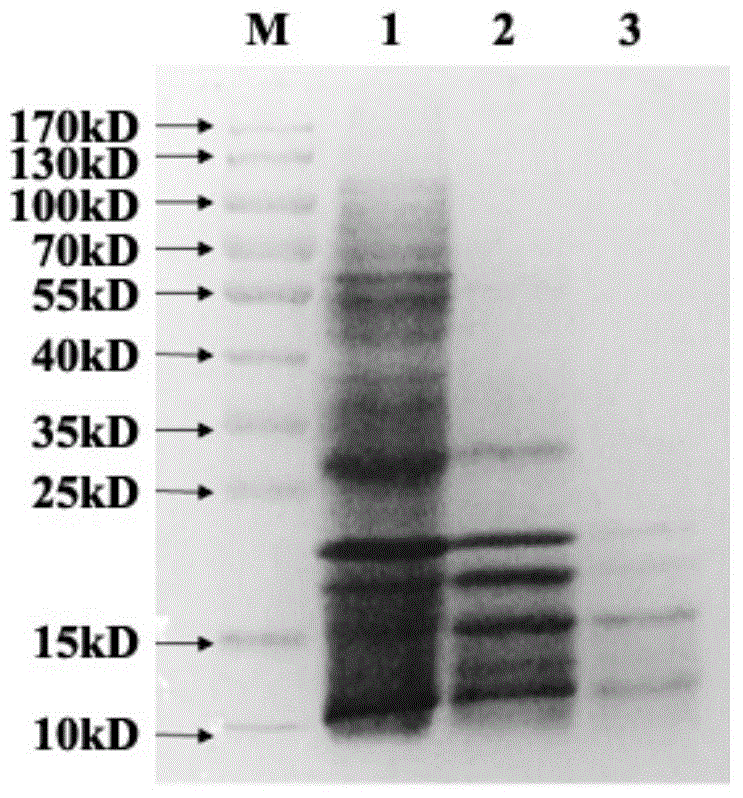

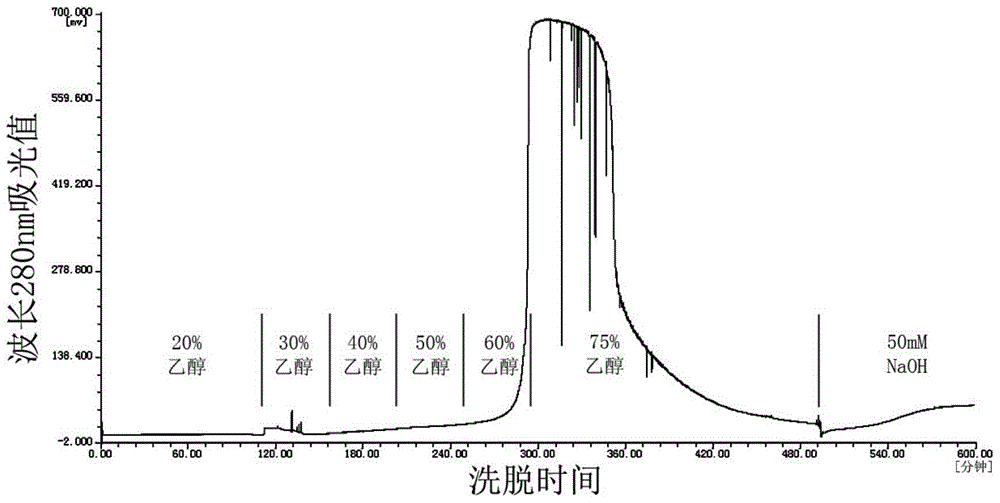

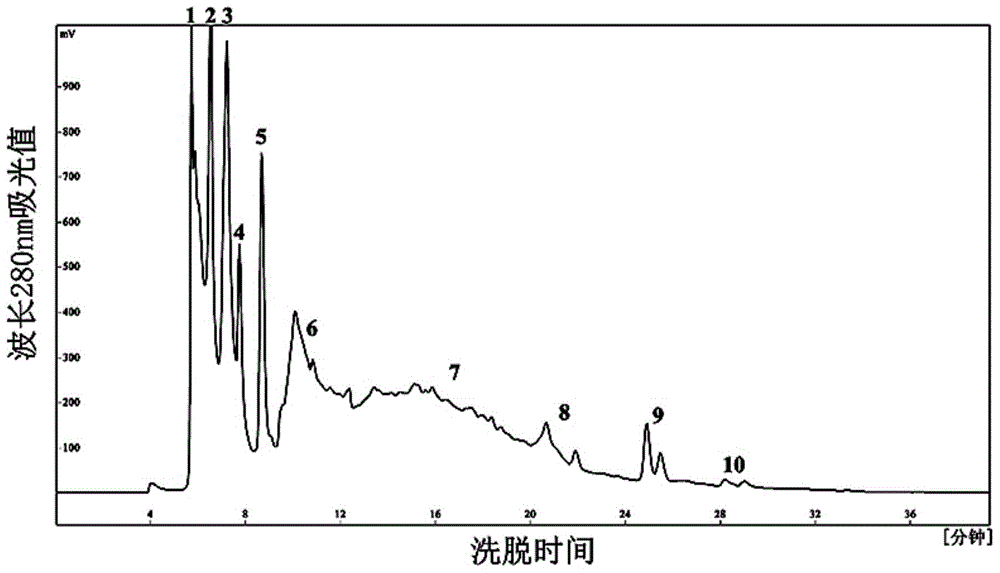

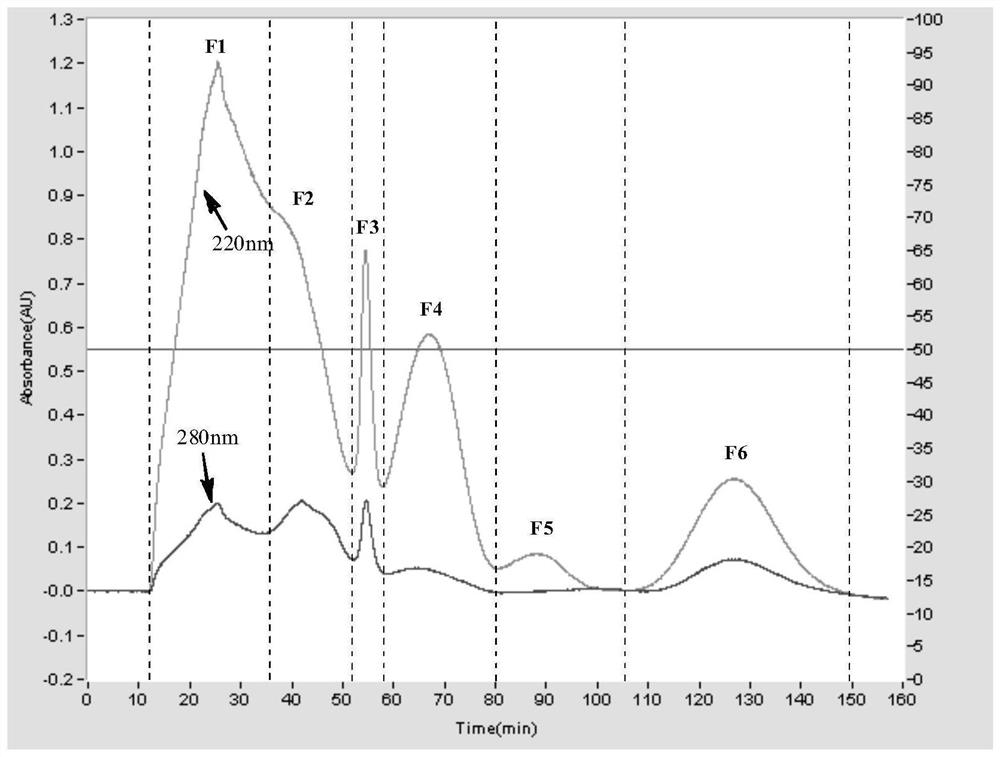

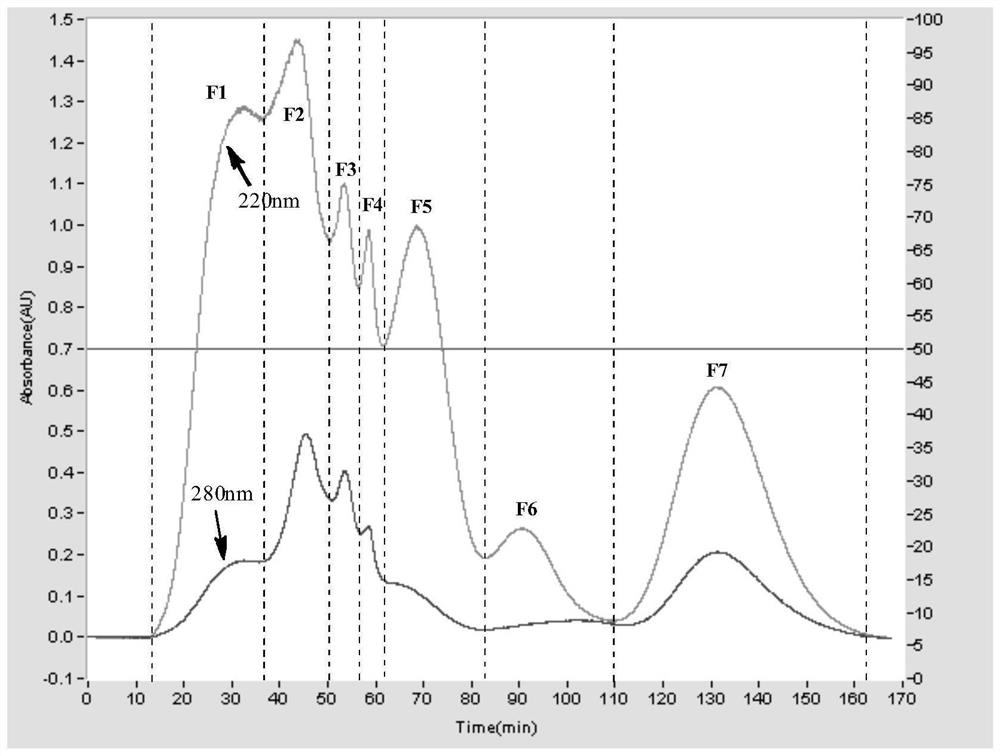

Preparation method of spongia water-soluble peptides

InactiveCN104558101AImprove adsorption capacitySmall amount of samplePeptide preparation methodsHplc methodFreeze-drying

The invention discloses a preparation method of spongia water-soluble peptides and relates to a preparation method of peptides. The method comprises the following steps: crushing the spongia and soaking in an extraction buffer liquid; performing ultrasonic treatment; centrifuging to obtain an aqueous solution of soluble protein / peptides; filtering and performing adsorption / desorption to obtain a desalted first-level crude extract of peptides; performing rotary evaporation and concentration on the first-level crude extract of peptides and performing second-level purification to obtain 10-30 second-level components, or performing freeze drying and storing for long time without light and at a low temperature in a form of powder, wherein the second-level purification specifically refers to obtaining 10-30 second-level components by an acetonitrile-water gradient reversed phase HPLC method; and performing rotary evaporation and concentration on the second-level components with less than 95% of main ingredient and then performing third-level purification to obtain the spongia water-soluble peptides, or performing freeze drying and storing for long time without light and at a low temperature in a form of powder. The species of peptides can be increased, and the processing scale and separation efficiency are improved so as to facilitate the development of spongia active peptide drugs.

Owner:XIAMEN UNIV

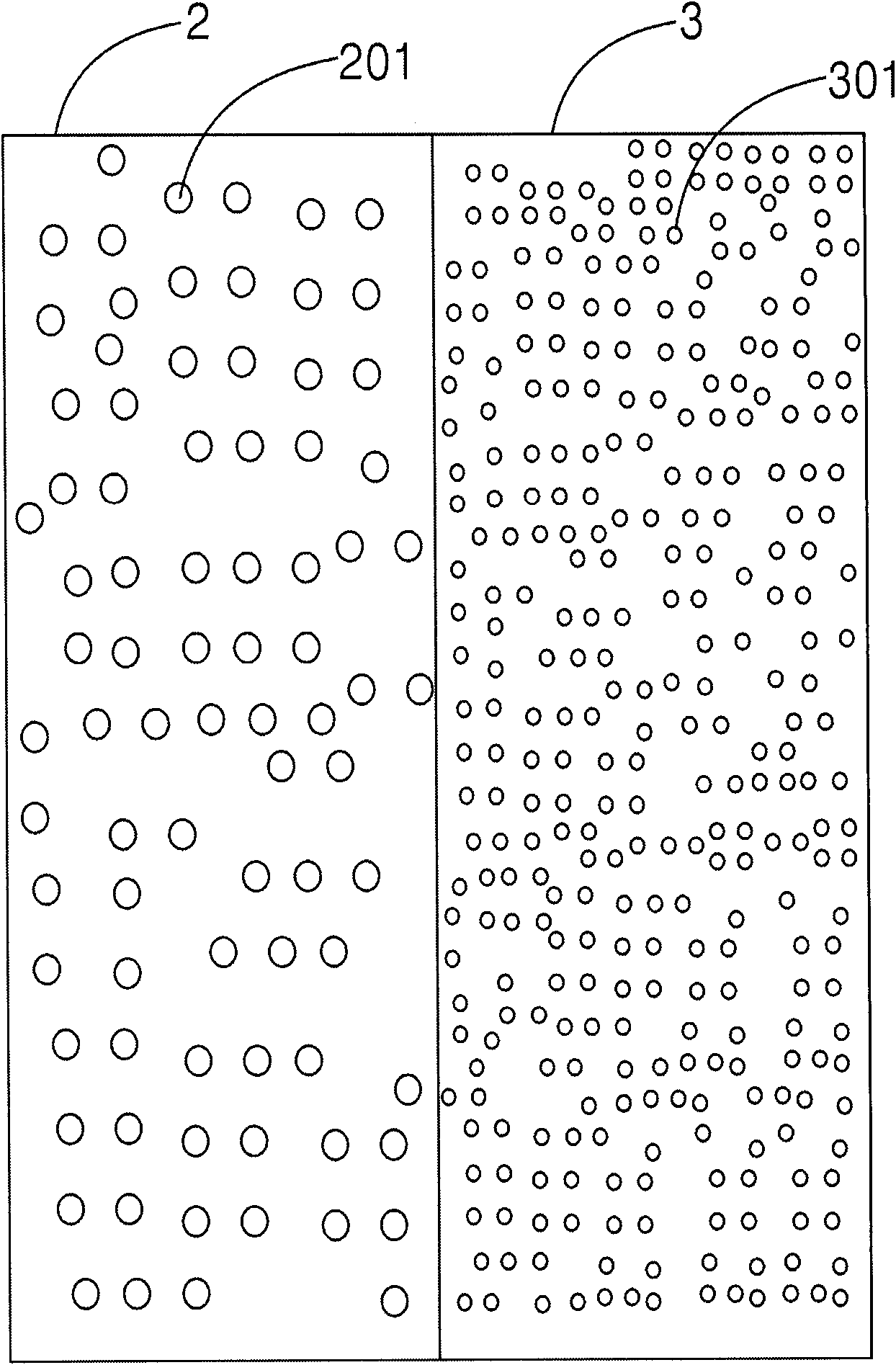

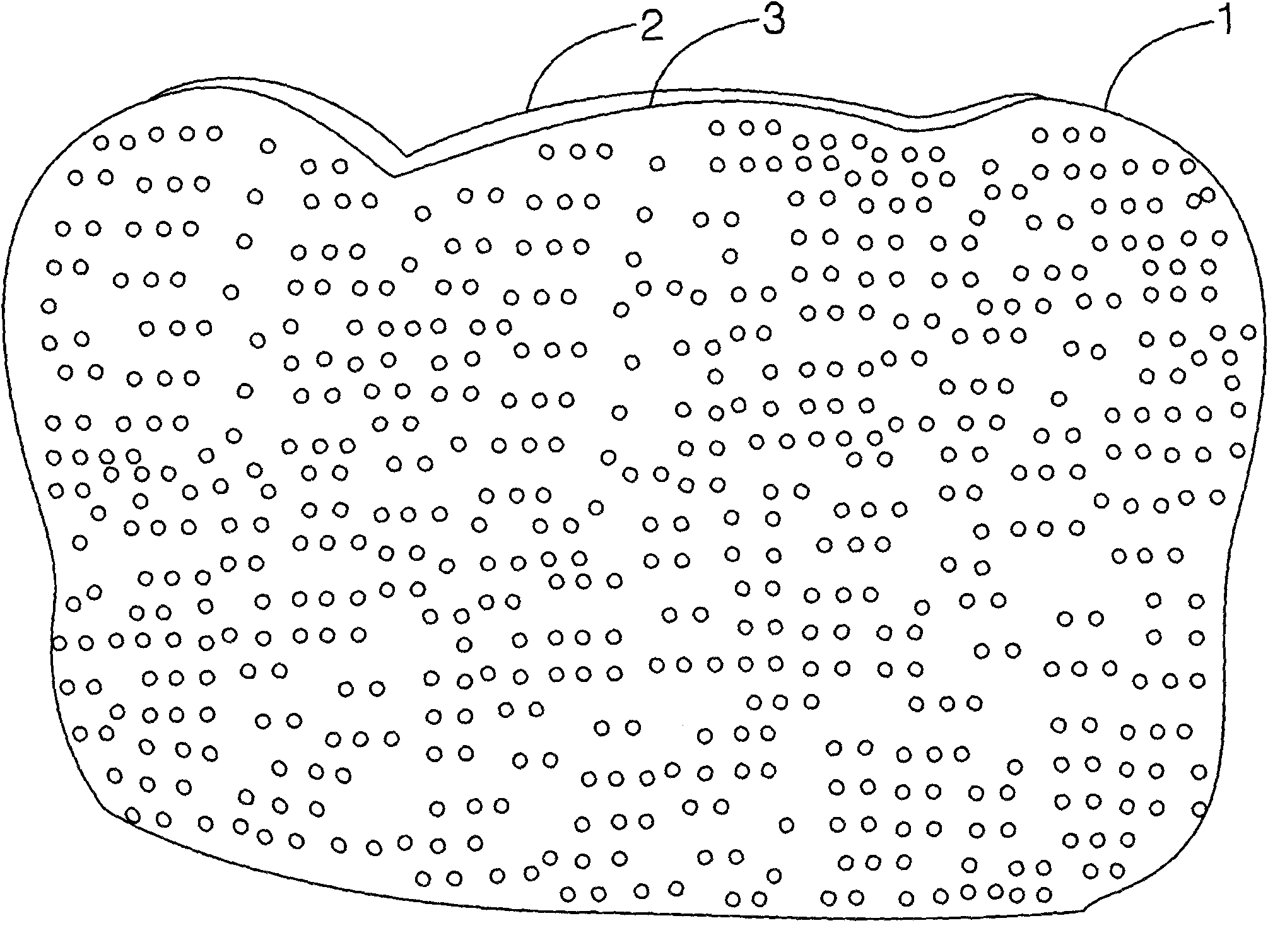

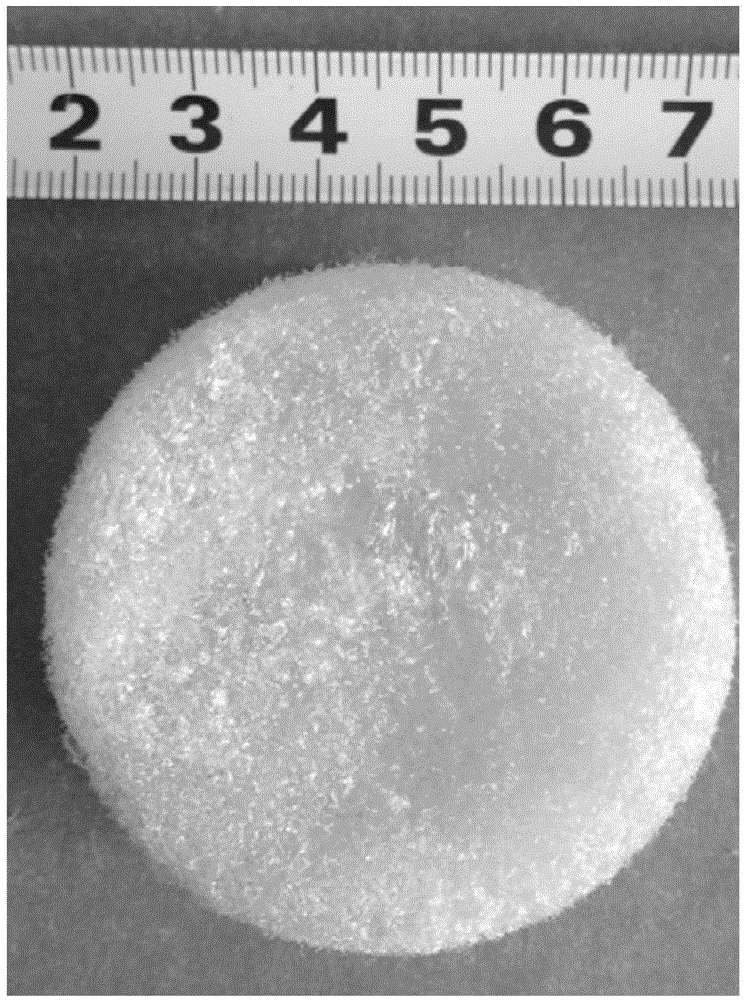

Double-sided heterogeneous glucomannan sponge and manufacturing method thereof

InactiveCN101816525ASimplify complex proceduresShorten production timeBathroom accessoriesColloidVolumetric Mass Density

The invention provides a double-sided heterogeneous glucomannan sponge and a manufacturing method thereof. The sponge comprises a first sponge and a second sponge. The manufacturing method comprises the following steps of: preparing a glucomannan mixture, heating the glucomannan mixture for a certain time to form first colloid, covering the first colloid on the un-reacted glucomannan mixture, further heating the first colloid and the un-reacted glucomannan mixture to make the un-reacted glucomannan mixture form second colloid, and sticking the first colloid and the second colloid on a joint face so that the first colloid and the second colloid are relatively combined to integrally form the double-sided heterogeneous glucomannan sponge. The first sponge and the second sponge are manufactured in different reaction time so that the interiors of the two sponges have different hole densities, and the double-sided heterogeneous glucomannan sponge with two surfaces with different roughness degrees can be applied to different textures of human bodies and achieve double effects of cleaning and maintenance.

Owner:GUANGZHOU CITY LITI TRADING

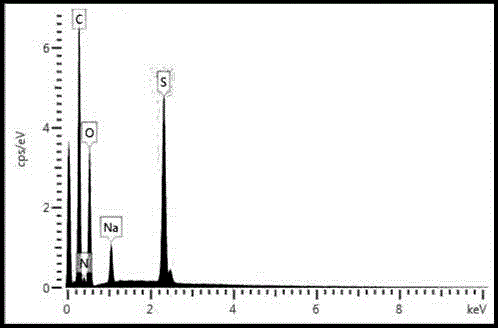

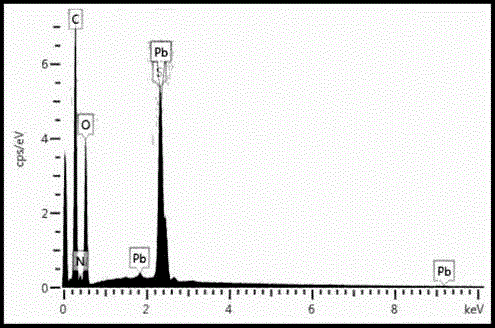

Method for preparing modified chitosan sponge structure material and appliance

ActiveCN105061796AIncrease active adsorption sitesSimple processOther chemical processesWater/sewage treatment by sorptionThioureaReaction temperature

The invention discloses a method for preparing a modified chitosan sponge structure material and an appliance, which relate to a method for preparing the modified chitosan sponge structure material and the appliance, and aim to solve the problems that existing chitosan modification methods are harsh in reaction conditions, high in reaction temperature, detailed and complicated in process, difficult in using of noxious reagent and forming of materials, low in yield and low in adsorption efficiency. The method for preparing the modified chitosan sponge structure material comprises steps: 1 preparation of pale yellow suspensions; 2 preparation of light yellow powder thiourea chitosan; 3 preparation of orange suspension; 4 preparation of washed solid product; and 5 freezing and drying, thereby completing the method for preparing the modified chitosan sponge structure material. The method for preparing the modified chitosan sponge structure material and the appliance are used to modify the modified chitosan sponge structure material.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Scraper sponge

A scraper sponge for cleaning and scraping away unwanted substances from an object or surface comprising a sponge body defining a first surface, first layer, second layer, third layer, second surface opposite the first surface, a continuous side surface around the perimeter; and the back of a scraper attachment that is inserted through an aperture in layers two and three then rests firmly against the first layer where it borders the second layer and a smaller cylinder shaped part on the back of the scraper attachment is inserted through a smaller aperture approximately through the middle of the first layer and first surface and held in place by a scraper cap and fixedly secured with adhesive. The entire surface area of the scraper, on its front surface, is covered with pyramid shaped points extending outwardly in the direction of the second surface of the sponge body and is made level with the second surface of the sponge body when forces are applied to the top surface of the scraper cap and subsequent back of scraper attachment to manipulate the rigid scraper on a hard surface. The sponge body has three surfaces available for cleaning and scouring: the first surface, front scraper attachment surface and second surface. The seamless second layer, third layer, and continuous side surface of the second and third layer are made of the same sponge-like cellulose material. As an alternative, the second layer, third layer, second surface, and the continuous side surface of the second and third layer are not made of the same material and the sponge body has at least four surfaces adapted for cleaning and scouring; the first surface, scraper attachment front surface, the continuous side surface of layer two and the second surface.

Owner:PHIISAGEN CORP

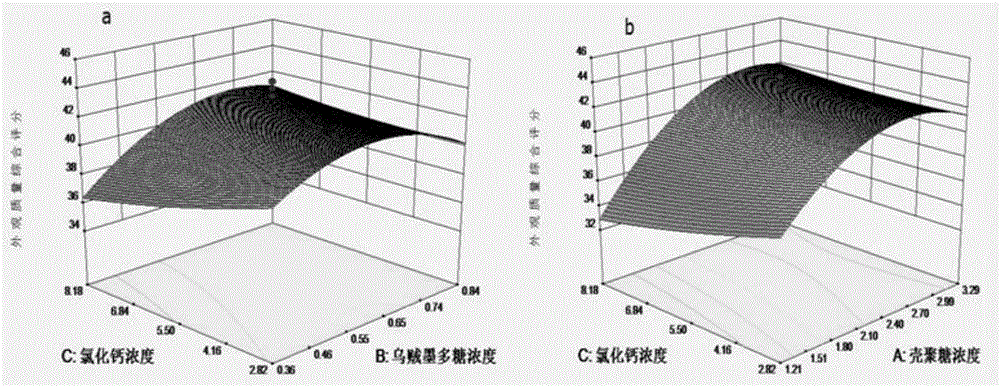

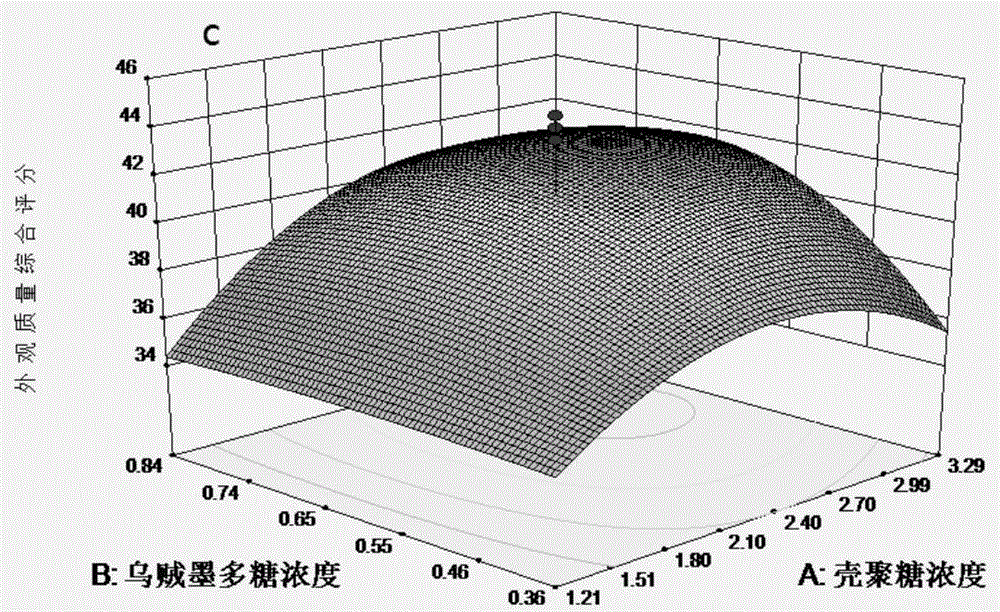

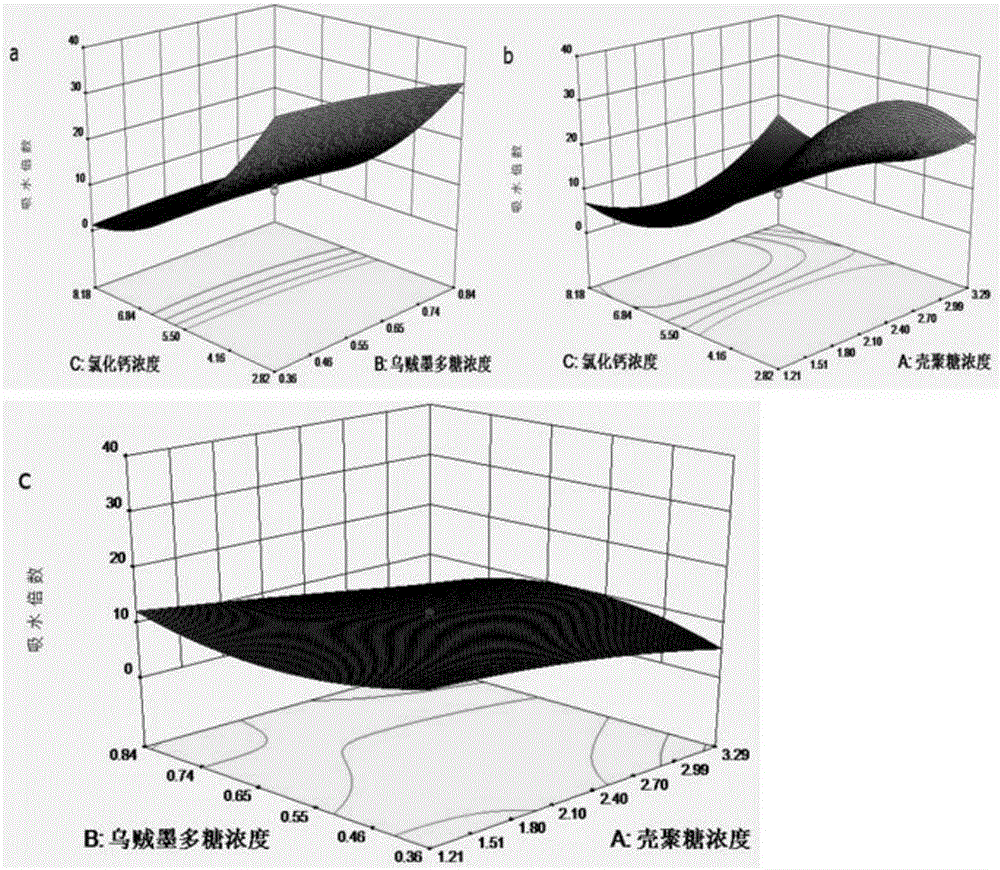

Sepia polysaccharide/chitosan hemostatic sponge and preparation method and application thereof

ActiveCN106421880AQuality improvementNice appearanceSurgical adhesivesDrying solid materials without heatFreeze-dryingBiocompatibility

The invention provides a preparation method of sepia polysaccharide / chitosan hemostatic sponge. The preparation method includes slowly adding 0.4-0.8mg / mL of sepia polysaccharide solution into 1.5-3.5% of chitosan solution, after mixing, adding 2-6% of calcium chloride solution, freezing gel after being formed, and then freezing-drying. With the star point design effect surface method to preferably prepare the hemostatic sponge, the sepia polysaccharide / chitosan hemostatic sponge good in quality is obtained by analyzing the effect surface figure and comparing the sponge products prepared by the optimal method given by the software with the predictive indexes. In the invention, time for the preparation method of the whole hemostatic sponge is shorter than that of most of the existing studies, which not only reduces the energy consumption but also improves the production efficiency. The hemostatic sponge has good biocompatibility, short stopping time, good in bleeding absorption effect, high in trauma repair ability, comprehensive in hemostatic effect, and weak in toxic and side effects or irritation. In addition, the method has a wide range of applications.

Owner:GUANGDONG OCEAN UNIVERSITY

Scraper sponge

A scraper sponge for cleaning and scraping away unwanted substances from an object or surface comprising a sponge body defining a first surface, first layer, second layer, third layer, second surface opposite the first surface, a continuous side surface around the perimeter; and the back of a scraper secured to the first layer opposite the first surface and the scraper defined by the first layer and an aperture through and approximately in the middle of the second layer, third layer and second surface of the sponge body. The entire surface area of the scraper, on it's front surface, is covered with pyramid shaped points extending outwardly in the direction of the second surface of the sponge body and is made level with the second surface of the sponge body when forces are applied to the first surface and subsequent back of scraper to manipulate the rigid scraper on a hard surface. The sponge body has three surfaces available for cleaning and scouring: the first surface, front scraper surface and second surface. The seamless second layer, third layer, third surface, and continuous side surface of the second and third layer are made of the same sponge-like cellulose material. As an alternative, the second layer, third layer, second surface, and the continuous side surface of the second and third layer are not made of the same material and the sponge body has at least four surfaces adapted for cleaning and scouring; the first surface, scraper front surface, the continuous side surface of layer two and the second surface.

Owner:OMOTOLA ALAHANDRO OLATUNDE

Scraper sponge

A scraper sponge for cleaning and scraping away unwanted substances from an object or surface comprising a sponge body defining a first surface, first layer, second layer, third layer, second surface opposite the first surface, a continuous side surface around the perimeter; and the back of a scraper secured to the first layer opposite the first surface and the scraper defined by the first layer and an aperture through and approximately in the middle of the second layer, third layer and second surface of the sponge body. The entire surface area of the scraper, on it's front surface, is covered with pyramid shaped points extending outwardly in the direction of the second surface of the sponge body and is made level with the second surface of the sponge body when forces are applied to the first surface and subsequent back of scraper to manipulate the rigid scraper on a hard surface. The sponge body has three surfaces available for cleaning and scouring: the first surface, front scraper surface and second surface. The seamless second layer, third layer, third surface, and continuous side surface of the second and third layer are made of the same sponge-like cellulose material. As an alternative, the second layer, third layer, second surface, and the continuous side surface of the second and third layer are not made of the same material and the sponge body has at least four surfaces adapted for cleaning and scouring; the first surface, scraper front surface, the continuous side surface of layer two and the second surface. As a second alternative, the scraper and aperture are placed on the width side of the scraper sponge.

Owner:PHIISAGEN CORP

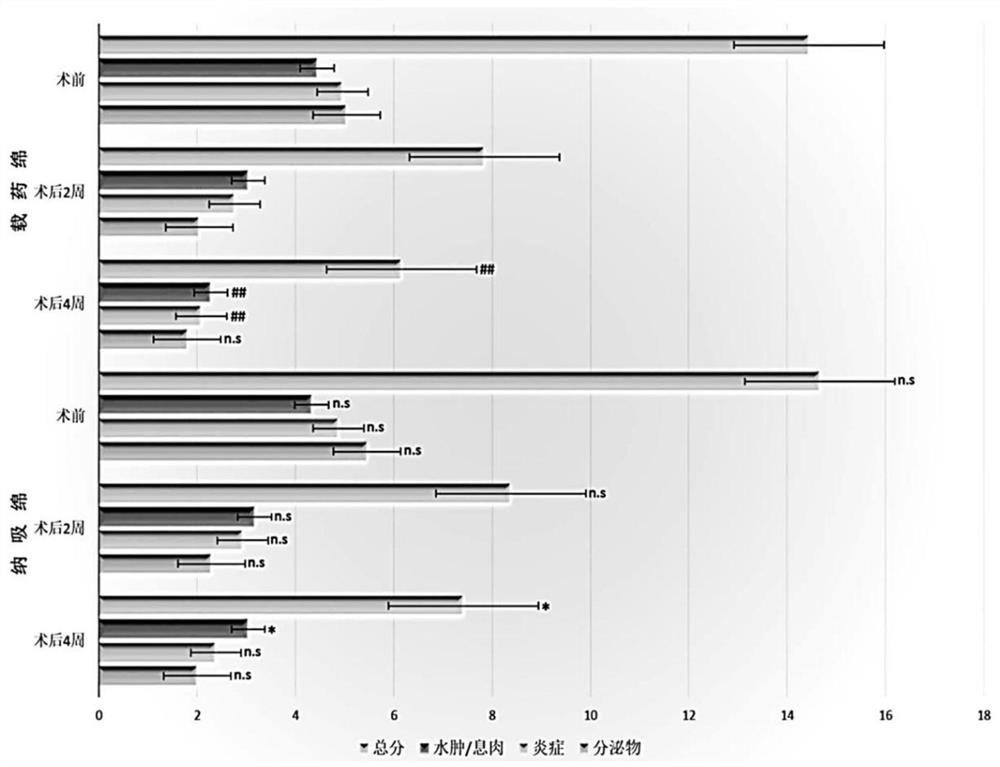

Budesonide-loaded chitosan sponge

InactiveCN111686296AFast water absorptionStrong water absorptionPharmaceutical delivery mechanismAbsorbent padsFreeze-dryingActive agent

The invention discloses a budesonide-loaded chitosan sponge. The prepared sponge is uniform in pore size distribution, and the pore size is about 200 microns. A porous material is prepared by combining a freeze drying technology and applying high-speed stirring of a surfactant and polysaccharide, so that the product is uniform in structure and high in porosity, the mechanical strength of the product is better enhanced, hemostasis acceleration is facilitated, and the budesonide anti-inflammatory effect can be degraded and slowly released during filling of an operation cavity.

Owner:宁波旸曜医疗科技有限公司

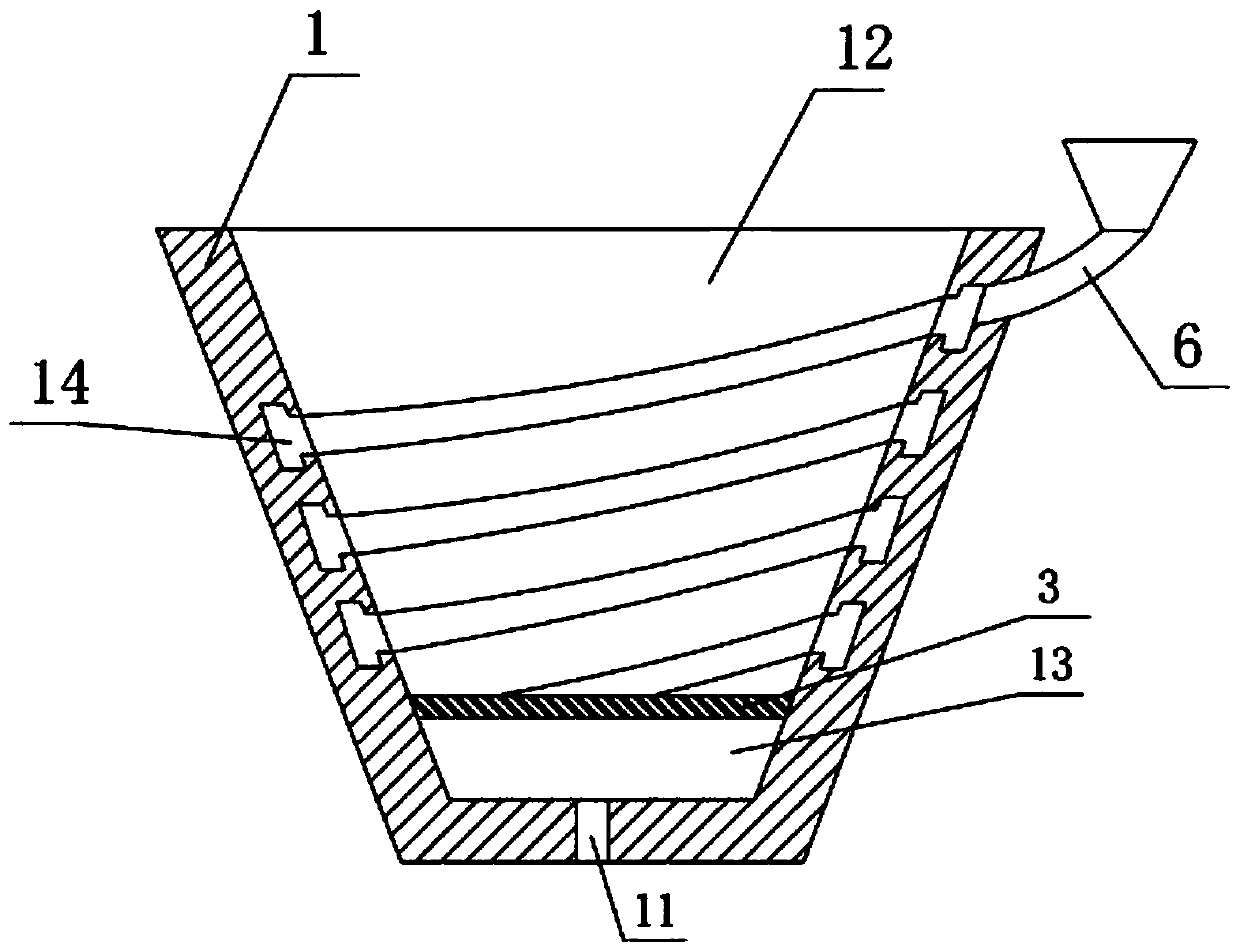

Tensile glucomannan sponge and preparation method thereof

The invention provides tensile glucomannan sponge, which structurally comprises a sponge body and a flexible netlike reinforcing layer, wherein the sponge body is made of glucomannan serving as a raw material; in a molding process of forming a specific shape for the sponge body, the reinforcing layer is arranged in the sponge body to be wrapped in the sponge body during formation of the sponge body; the situation of damage produced due to poor strength can be avoided even though the sponge body is thinned, and changeability of appearance of the sponge is improved, so that application range of the glucomannan sponge is increased, the changeability of the appearance of the sponge is improved, and broad market prospect is achieved.

Owner:黄建辉

Dissolvable nasal sinus sponge

An implantable article comprises a dissolvable sponge derived from the mixture of chitosan, a first polysaccharide and a second polysaccharides. The polysaccharides have different number average molecular weight characteristics to enable the control of the mechanical features of the sponge.

Owner:MEDTRONIC INC

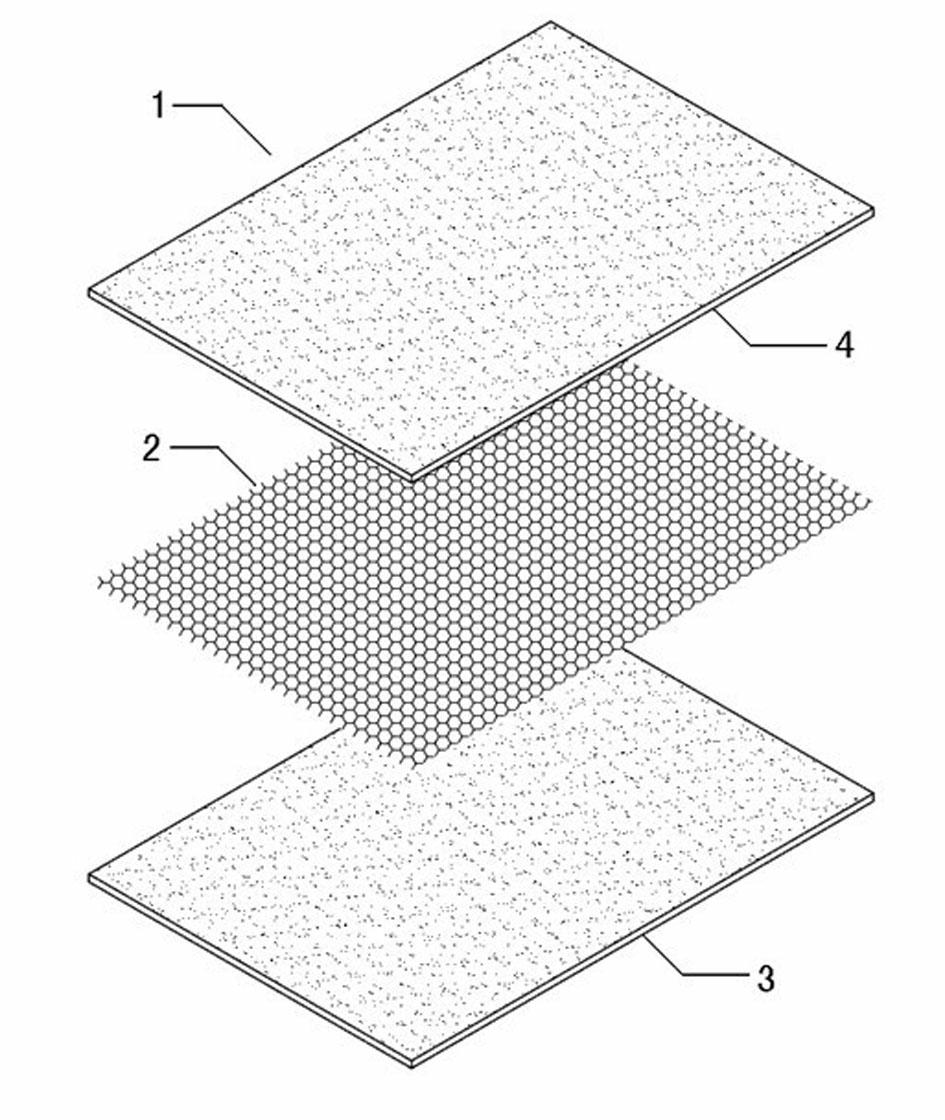

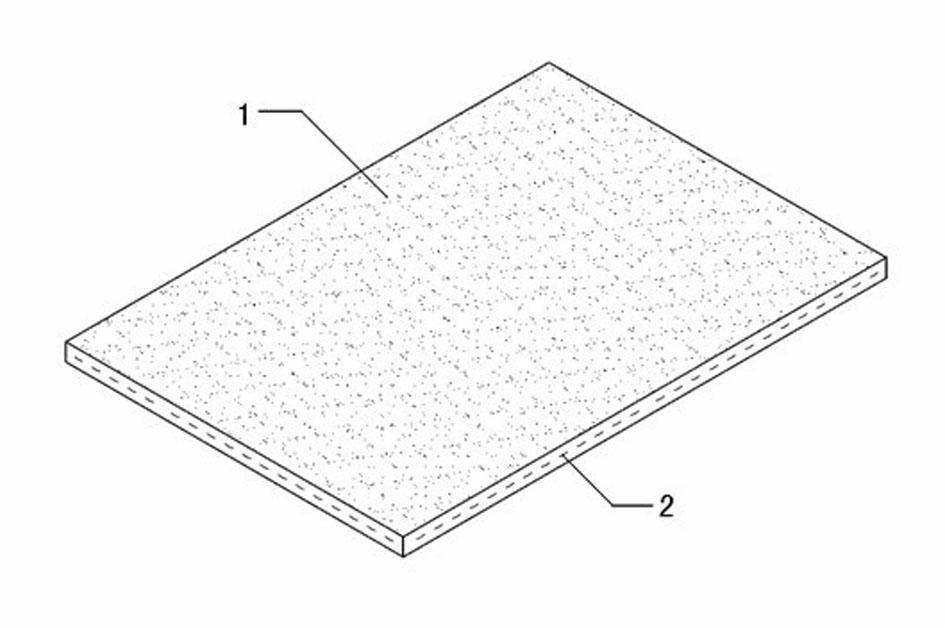

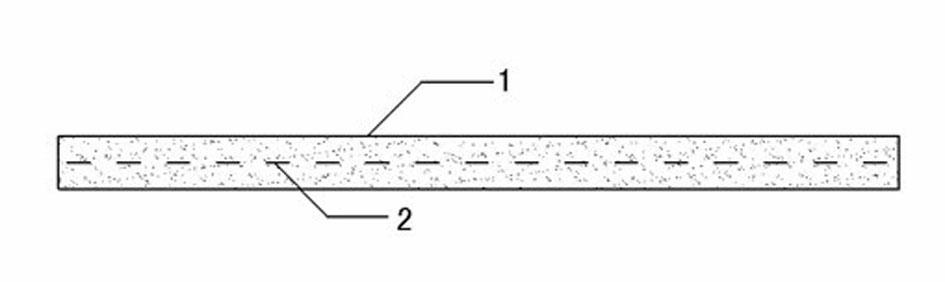

Microfibre-based cleaning sponge

ActiveUS20160296095A1Easy to manufactureLarge capacityCarpet cleanersLayered product treatmentFiberEngineering

The present invention concerns a sponge including a layer of an absorbent material and a layer of a textile material made of microfibres and strengthened by a binding agent, said textile layer at least partially covering one or more of the surfaces of the layer of absorbent material.

Owner:EURVEST

Algae organism culture system and culture method

ActiveCN114514877AHigh transparencyImprove growthClimate change adaptationDirt cleaningFisheryChlorella sp.

The invention relates to the technical field of algal organism cultivation, in particular to an algal organism cultivation system and method.The algal organism cultivation system comprises a cultivation box, a base, a scraping mechanism and a feeding mechanism, in the scraping mechanism, an annular plate moves upwards, chlorella attached to the outer side wall of the cultivation box can be scraped through an annular scraping plate, and the feeding mechanism is used for feeding the chlorella; after the chlorella is scraped, an annular plate moves downwards, and secondary cleaning treatment is conducted on the outer wall of the breeding box through a spray head and a wiping sponge, so that the transparency of the breeding box is improved, and it is guaranteed that breeding personnel can clearly observe the growth condition of the chlorella in the breeding box; in the feeding mechanism, a rotating motor drives a rotating shaft to rotate, connecting frames evenly distributed on the rotating shaft in the circumferential direction can evenly pump air into the chlorella in the circumferential direction through mutual cooperation with a feeding round pipe, it is guaranteed that the air pumped into the breeding box from top to bottom is evenly distributed, and the growth condition of the chlorella is improved.

Owner:湖南康大生物药品有限责任公司

Microfibre-based cleaning sponge

ActiveUS10130236B2Easy to manufactureLarge capacityLayered product treatmentCarpet cleanersPolymer scienceAbsorbent material

The present invention concerns a sponge including a layer of an absorbent material and a layer of a textile material made of microfibers and strengthened by a binding agent, said textile layer at least partially covering one or more of the surfaces of the layer of absorbent material.

Owner:EURVEST

Ventilation processing method applicable to pot opening fungi bag and vent cap

PendingCN107873403AEasy to useReasonable structural designCultivating equipmentsMushroom cultivationEngineeringMechanical engineering

The invention discloses a ventilation processing method applicable to a pot opening fungi bag. The method comprises the steps that a vent cap with a filter film is used for replacing a hollow plasticrod and a ventilation sponge plug; during fungi bag manufacturing, the vent cap is plugged into the end of the center hole of the pot opening fungi bag; during inoculation of the fungi bag, the vent cap is pulled up and moved artificially or by adopting a machine, after strain inoculation, the vent cap is plugged into the end of the center hole, and the requirement for ventilation inside the pot opening fungi bag in the mycelial growth process can be met through the vent cap. The invention further discloses the vent cap. The method adopts the vent cap with the filter film for replacing the hollow plastic rod and the ventilation sponge plug; the filter film arranged by the vent cap can filter air, and the requirement for ventilation of the pot opening fungi bag in the mycelial growth process is met; the ventilation effect is good; due to the fact that the vent cap can be repeatedly used for about 2 years, the cost is greatly saved, and the vent cap is beneficial to environmental protection. The vent cap is reasonable in structural design, convenient to use and capable of being used in cooperation with an automatic machine.

Owner:LIANYUNGANG GUOXIN EDIBLE FUNGUS OF COMPLETE SETSOF EQUIP

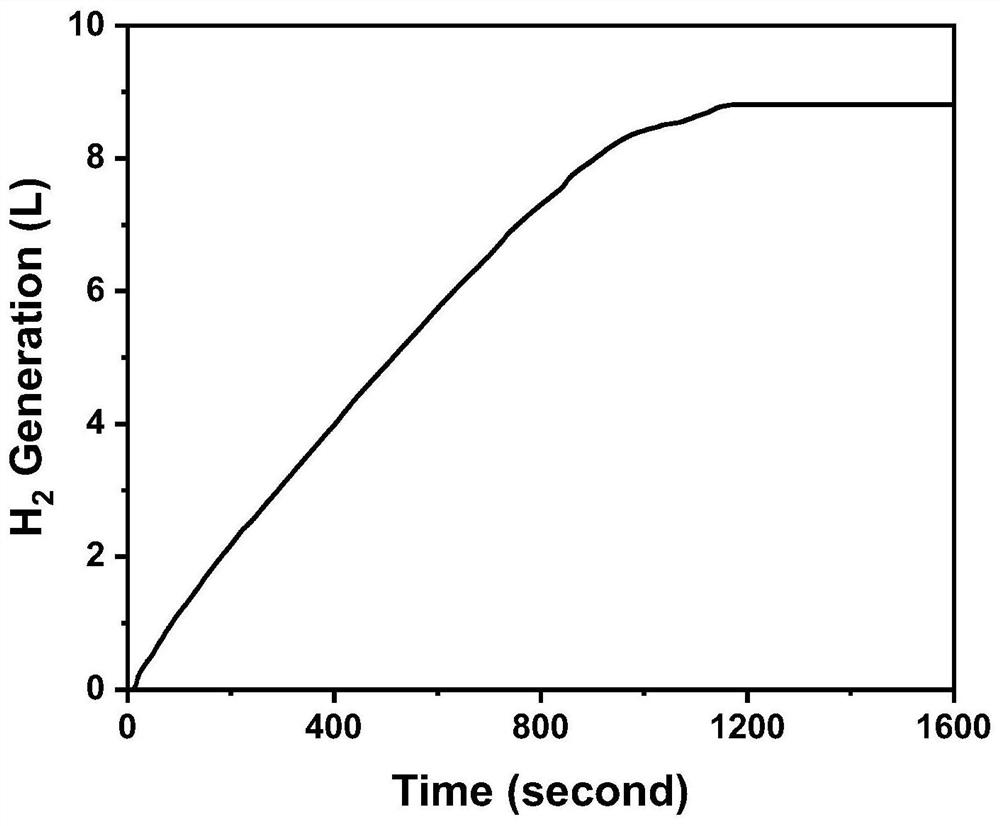

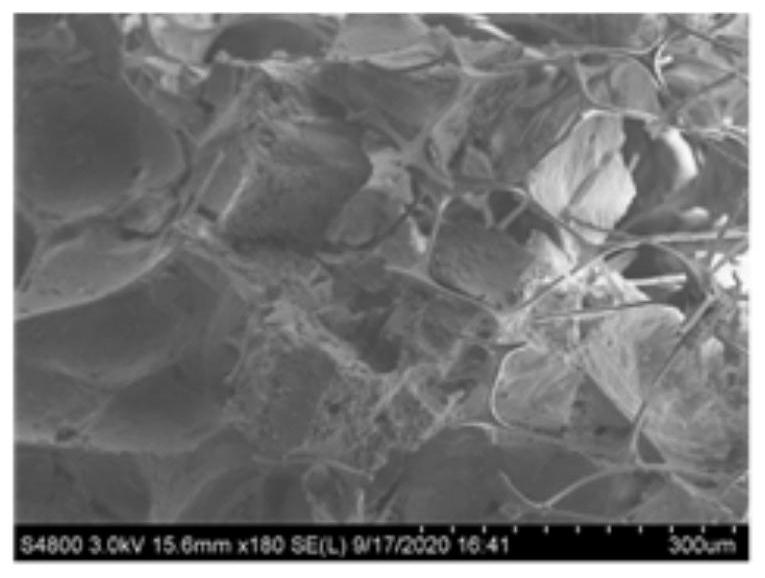

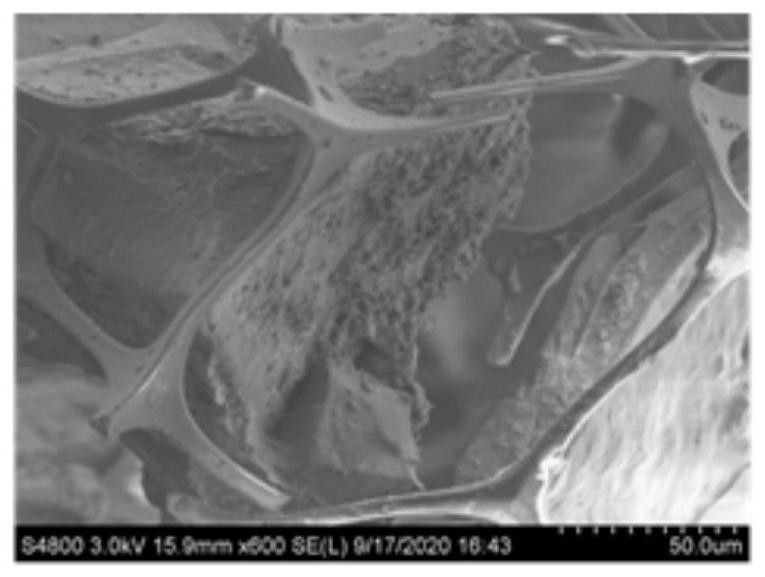

NaBH4 sponge and preparation method thereof

ActiveCN112599798AWell mixedSmooth transmissionMaterial nanotechnologyCell electrodesPtru catalystOrganosolv

The invention discloses NaBH4 sponge and a preparation method thereof. The preparation method comprises steps that a transition metal salt catalyst and a NaBH4 material are mixed and dissolved in an amine organic solvent at the same time, the mixture is evenly mixed and filled in the sponge, and the NaBH4 sponge is obtained after the solvent in the sponge is completely removed; the NaBH4 materialand the transition metal salt catalyst are uniformly mixed in the NaBH4 sponge on a nanometer scale. When water is added to NaBH4 sponge, NaBH4 is subjected to a hydrolysis reaction rapidly under theaction of a catalyst, water can be conveyed rapidly and effectively through the water absorption effect of the sponge, all parts in the system make uniform contact with water, and the hydrogen generation rate is more stable.

Owner:PEKING UNIV

Buxus megistophylla ball shape trimming and cleaning device for sponge city

InactiveCN112868412AGuaranteed pruning effectReduce laborHedge trimming apparatusUsing liquid separation agentBuxusWater flow

The invention discloses a buxus megistophylla ball shape trimming and cleaning device for a sponge city. The device comprises a support; a mounting plate is fixedly connected to the side wall of the support; a vertical plate is fixedly connected to the upper wall of the mounting plate; a motor is fixedly connected to the side wall of the vertical plate; and a trimming mechanism for trimming buxus megistophylla is arranged on the mounting plate. According to the device, the buxus megistophylla can be trimmed into a standard ball structure; a traditional manual trimming mode is replaced; the labor amount of workers is greatly reduced and the trimming effect on buxus megistophylla balls can be guaranteed; meanwhile, dust flying around is prevented from polluting the environment, and the dust can be prevented from being inhaled into the bodies of the workers, so that the health of the workers is ensured; and secondly, water flow can also play a role in watering the buxus megistophylla balls, so that the normal growth of the buxus megistophylla balls is ensured.

Owner:李和平

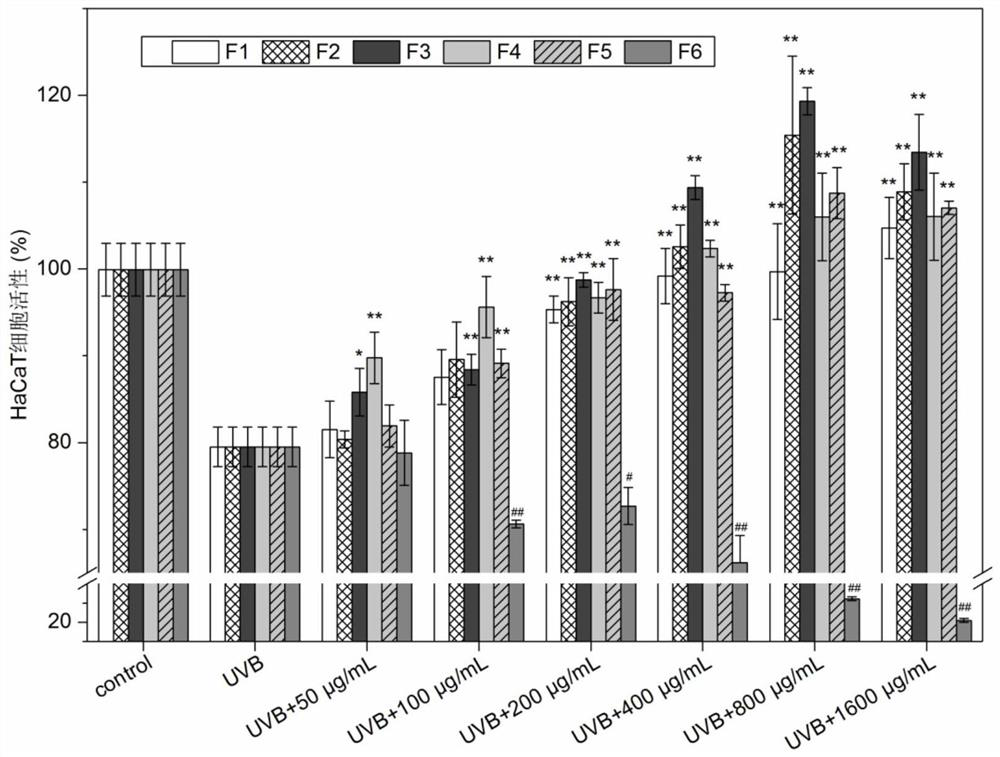

Marine bioactive peptide capable of effectively relieving skin sunburn, and preparation method and application of marine bioactive peptide

ActiveCN113481271AReduce sunburnFunction increaseCosmetic preparationsHydrolysed protein ingredientsUltrafiltrationLotion

The invention discloses a marine bioactive peptide capable of effectively relieving skin sunburn, and a preparation method and application of the marine bioactive peptide. The marine bioactive peptide is small in molecular weight, good in skin compatibility and capable of remarkably reducing apoptosis and necrosis of cells irradiated by ultraviolet rays and reducing true dermatitis exudation and elastic fibre degradation. The preparation method of the marine bioactive peptide comprises the following steps of: taking a soft part of a fresh marine shellfish, carrying out protease enzymolysis, ultrafiltration and sephadex separation, discarding the last elution single peak, respectively collecting or mixing other elution components, and performing freeze-drying to obtain the marine bioactive peptide. The method is simple, low in cost, green, environment-friendly, short in production cycle and suitable for industrial production; the prepared active peptide has the effects of preventing and repairing skin sunburn and can be applied to cosmetics and biomedical materials; the cosmetic dosage forms include cream, emulsion, gel, jelly, water aqua, mist spray and the like; and dosage forms of the biomedical material comprise lotion, solution, dressing (thin film, hydrocolloid, hydrogel, sponge and spray), ointment, injection and the like.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

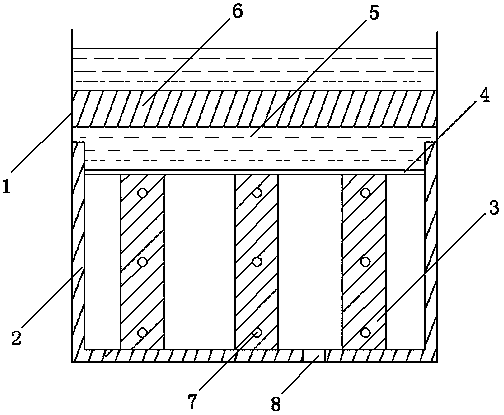

Vertical pipeline water storing and spongy earth cultivating device of plant

InactiveCN104067874APrevent collapsePromote growthSelf-acting watering devicesReceptacle cultivationGrowth plantWater storage

The invention discloses a vertical pipeline water storing and spongy earth cultivating device of a plant. The device mainly comprises an outer pot, first sponge layers, a water storing layer, a water storing pipe, a cover plate, earth layers, a second sponge layer, a leaking hole and a draining hole. The device is characterized in that the first sponge layers are arranged on the bottom part and the outer wall of the outer pot; the water storing pipe is arranged on the sponge layer; the cover plate is arranged on the water storing pipe, with four sides connected with the first sponge layers; the second sponge layer is arranged between the earth layers; the leaking hole is arranged in the water storing pipe; the draining hole is formed in the bottom part of the outer pot. According to the vertical pipeline water storing and spongy earth cultivating device of the plant, a vertical water storing pipe arranged below the cover plate can prevent the cover plate from being pressed and collapsed by earth; the sponge layer arranged between the earth layers is able to lower down the total weight of the device, and the internal loosing structure of the sponge provides air to the plant roots to promote the plant growth; the device is simple in structure and easy to be operated.

Owner:吕孝明

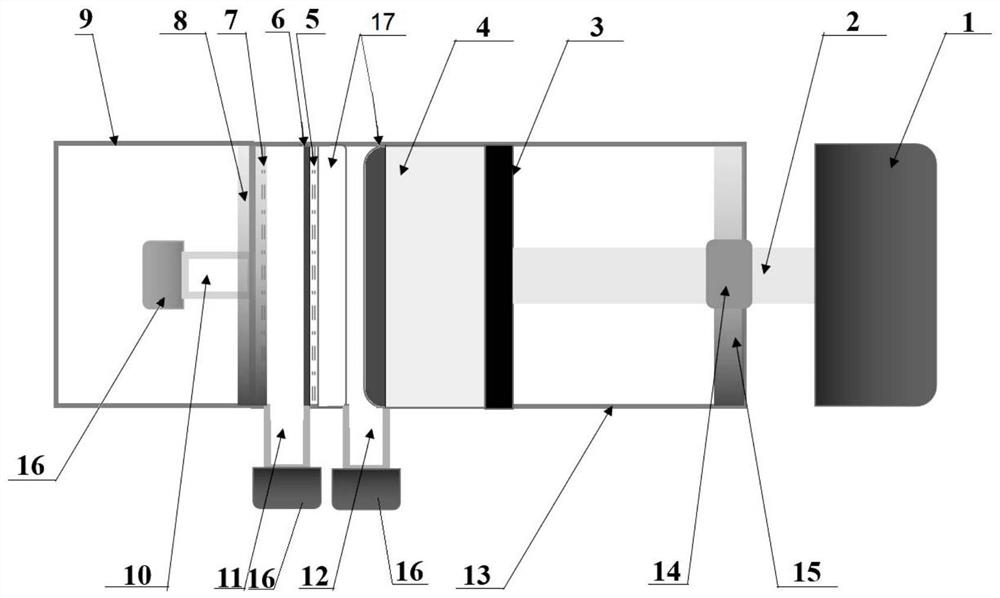

Sputum microorganism detection biosafety collection processor and operation method thereof

PendingCN112179736AImprove the detection rateReduced Chances of ContaminationPreparing sample for investigationMicroorganismStructural engineering

The invention discloses a sputum microorganism detection biosafety collection processor. An end cover is arranged at one end of a cylindrical shell, the other end of the cylindrical shell is sealed bya rear cover, a piston is arranged in the shell, the rear end of the piston is connected with one end of a push rod, a guide hole is formed in the center of the rear cover, and the other end of the push rod extends out of the shell through the guide hole and is connected with a push handle. A waste liquid outlet is formed in the end cover, a partition plate is arranged at the position, close to the front end, of the shell, the partition plate is a latticed plate, a first filtering membrane is fixed to the partition plate, protruding sample openings are formed in the positions, on the two sides of the partition plate, of the shell, a sponge layer is fixed to the piston, and scouring pad layers are arranged on the opposite faces of the sponge layer and the partition plate. The processor issimple in structure, sputum can be pretreated, and pollution can be avoided.

Owner:ANHUI GUOKE BIOTECH CO LTD

Papaya tissue culture seedling rooting and transplanting method

InactiveCN109220806AHigh rooting rateReduce generationGrowth substratesCulture mediaCarrageenanMonopotassium phosphate

The invention belongs to a papaya tissue culture seedling rooting and transplanting method, which has the steps of using papaya field matured lateral buds as explants; after disinfection and sterilization, planting the explants into a culture medium for primary induction culture and subculture rejuvenation culture to obtain adventitious buds; cutting down the adventitious buds from the base part;transplanting the adventitious buds to a mixed culture medium containing improved 1 / 2MS+0.8mg / LIBA+20g / L saccharose and vermiculite according to a ratio of 1:1 for rooting culture to obtain young seedlings; after 15 days, putting the obtained young seedlings at the normal temperature environment; performing seedling domestication for 2 to 3 days at the normal temperature environment; cleanly washing vermiculite; eliminating leaf-free rootless and damage seedlings; then, performing transplanting. The improved 1 / 2MS culture medium is a condensing agent culture liquid with halved major elements and no carrageenan / agar, wherein the monopotassium phosphate content in the major elements is improved from the conventional 170mg / L to 270mg / L. The rooting rate of the papaya tissue culture seedlingscan be improved; the generation of inflated monstrous spongy roots is reduced; the rooting culture link is simplified; the transplanting survival rate is improved.

Owner:云南省红河热带农业科学研究所

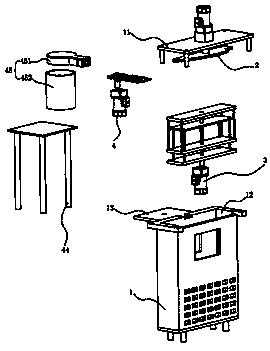

Sponge feeding device

The invention provides a sponge feeding device which comprises a feeding shell, a vibration separating device, an up-and-down pushing device and a first sponge pushing device. A feeding fixed plate and a feeding opening are arranged at the top of the feeding shell. The up-and-down pushing device is arranged on the feeding shell. The feeding fixed plate is arranged above the feeding opening. The vibration separating device is arranged above the feeding fixed plate. The sponge pushing device is arranged in front of the conveying direction of the feeding shell. The sponge feeding device has the advantages that to-be-processed sponges are automatically separated and fed.

Owner:GUANGZHOU COLLEGE OF SOUTH CHINA UNIV OF TECH

Flowerpot

InactiveCN110741836AAvoid churnPlay the role of water storageSelf-acting watering devicesCultivating equipmentsWater flowEnvironmental engineering

The invention provides a flowerpot and aims to solve the problem that soil fails to completely absorb water as water flowing out along a gap between the inner wall of the flowerpot and soil stays in the flowerpot for a short time. The flowerpot comprises a flowerpot body, a base, a water inlet pipe and an inner-wall sponge. The bottom of the flowerpot body is provided with a bottom hole, and the flowerpot body is internally provided with an upper cavity and a lower cavity; a mesh plate is arranged between the upper cavity and the lower cavity; the lower cavity is internally provided with a bottom sponge; the base is internally provided with a base cavity with the upper end open, and a cotton strip is arranged in the base cavity and penetrates the bottom hole to connect with the bottom sponge; the inner side wall of the upper cavity is provided with a groove in a helical surrounding manner; the inner-wall sponge is arranged in the groove. The flowerpot has a function of water accumulation and is capable of preventing water from quickly flowing away through the gap between the inner wall of the flowerpot and soil, and accidental injuries caused by plants with thorns can be avoided.

Owner:黄宇航

Fertilizer special for wax apple trees

InactiveCN106927928ANutritional diversityPromote absorptionClimate change adaptationExcrement fertilisersSnow moldSesame seed

The invention relates to the field of fertilizer, in particular to a fertilizer special for wax apple trees. The fertilizer is prepared from, by weight, 10-20 parts of sawdust, 10-12 parts of expanded perlite powder, 1-2 parts of a nitrification inhibitor DMPP, 0.3-0.5 part of tea saponin, 35-37 parts of soybean straw, 31-33 parts of rape straw, 26-28 parts of cucumber stems, 17-19 parts of dried pine needles, 20-22 parts of composted chick manure, 14-16 parts of sesame seed cake fertilizer, 10-12 parts of turf soil, 7-9 parts of 1-(2-chloro-4-pyridyl)-3-phenylurea, 6-8 parts of pea green fertilizer, 3-5 parts of furfural residues, 1-3 parts of ammonium humate, 2-4 parts of polyaspartic acid, 5-7 parts of mould fertilizer and 60-70 parts of water. The fertilizer is rich in nutritional substance and capable of enabling wax apples to be attractively-bright in color, spongeous in pulp, fresh and sweet in taste, cool and refreshing, the organic fertilizer is contained in the formula, the fruit bearing period of the wax apple trees is prolonged, and the yield of the wax apples is significantly increased.

Owner:青岛世纪星语通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com