Spongy molecular sieve chitosan compound rapid hemostatic material as well as preparation method and application thereof

A hemostatic material and molecular sieve technology, which can be used in medical preparations with non-active ingredients, pharmaceutical formulations, inorganic non-active ingredients, etc., and can solve the problems of muscle, tissue, nerve burns, low hemostatic efficiency of chitosan, and unfavorable cleaning of wounds. , to achieve the effects of large specific surface area, good adsorption and exchange properties, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

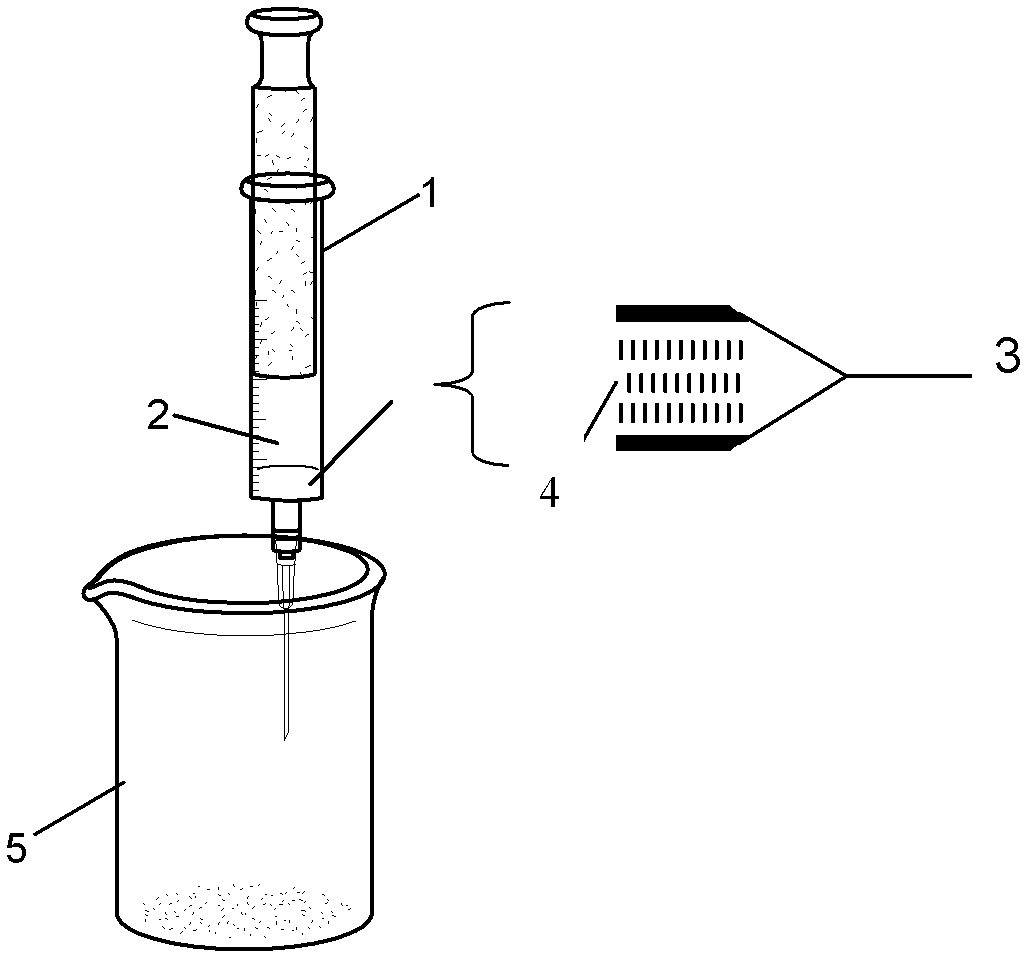

Method used

Image

Examples

Embodiment 1

[0019] For the preparation method of NaA(LTA) molecular sieve, please refer to Jilin University doctoral dissertation "Preparation and Properties of Zeolite Molecular Sieve Membrane", Yin Xiaoju. The obtained product was filtered and washed until the pH was 8, and dried at room temperature.

[0020] The obtained product was prepared according to the mass ratio of molecular sieve: 1mol / L calcium chloride solution: deionized water = 5:18:18, and the pH was adjusted to 11 with sodium hydroxide, and then reflux exchanged in a water bath at 100°C for 1h. After cooling to room temperature, the obtained product was filtered and washed to pH 8. As determined by XRF (PANALYTICAL 4400), a NaA (LTA) molecular sieve with a calcium ion exchange degree of 50±5% was obtained.

Embodiment 2

[0022] Get the calcium ion exchange degree prepared in Example 1 and be 50 ± 5% NaA (LTA) molecular sieve, then according to the mass ratio is molecular sieve: 1mol / L calcium chloride solution: deionized water=5: 18: 18 configuration solution, with Sodium hydroxide was used to adjust the pH to 11, and then refluxed in a water bath at 100°C for 1 hour. After cooling to room temperature, the obtained product was filtered and washed to pH 8. As determined by XRF (PANALYTICAL 4400), a NaA (LTA) molecular sieve with a calcium ion exchange degree of 90±5% was obtained.

Embodiment 3

[0024] For the preparation method of NaX(FAU) molecular sieve, refer to Olson, D.H. Zeolites, 15, 439-443 (1995). The obtained product was filtered and washed until the pH was 8, and dried at room temperature. The obtained product was prepared according to the mass ratio of molecular sieve: 1mol / L calcium chloride solution: deionized water = 5:18:18, and the pH was adjusted to 11 with sodium hydroxide, and then reflux exchanged in a water bath at 100°C for 1h. After cooling to room temperature, the obtained product was filtered and washed to pH 8. As determined by XRF (PANALYTICAL 4400), a NaX (FAU) molecular sieve with a calcium ion exchange degree of 55±2% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com