Tensile glucomannan sponge and preparation method thereof

The technology of polysaccharide sponge and glucomannan is applied in the field of anti-stretching glucomannan sponge and its manufacture, and can solve the problems of increasing the sponge, unsatisfactory structural strength, and limiting the appearance and shape of the sponge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

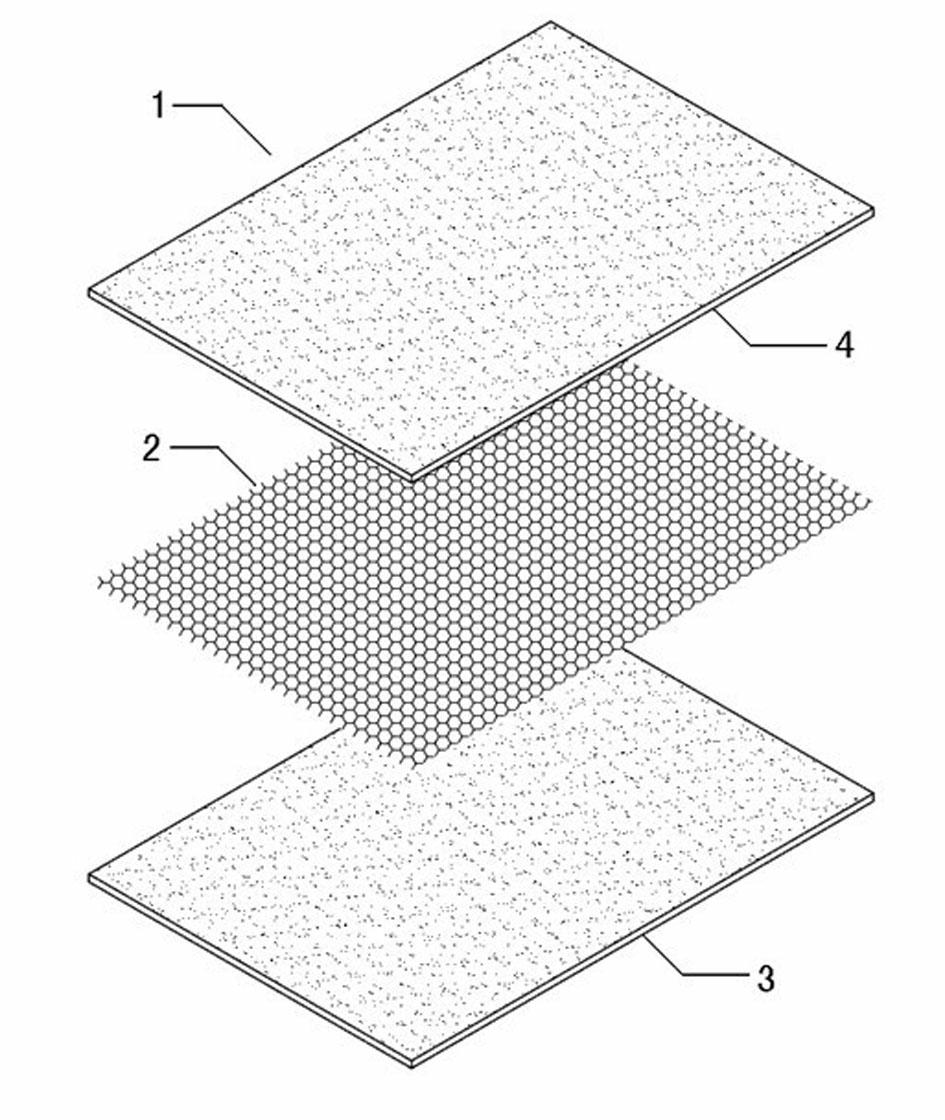

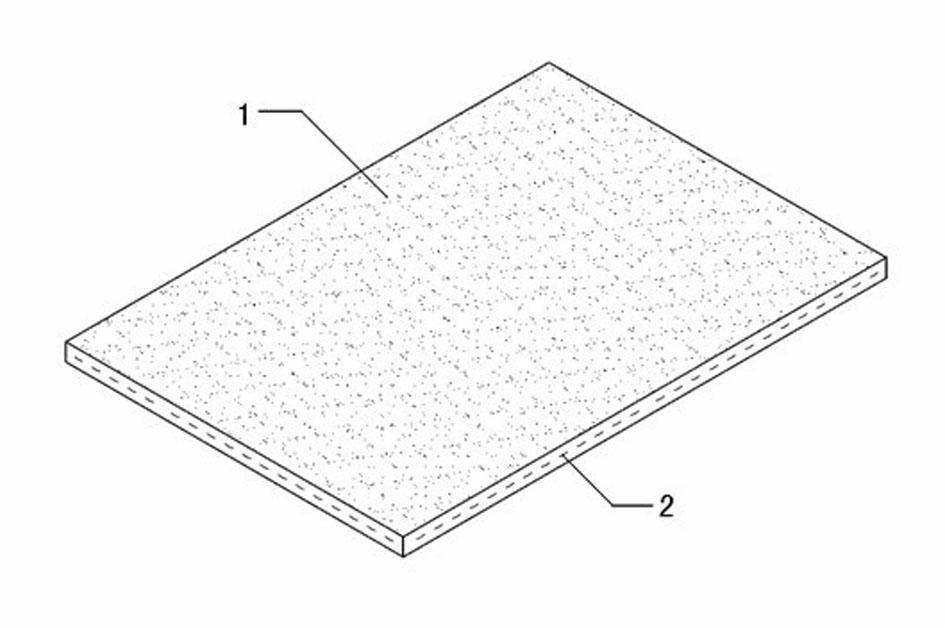

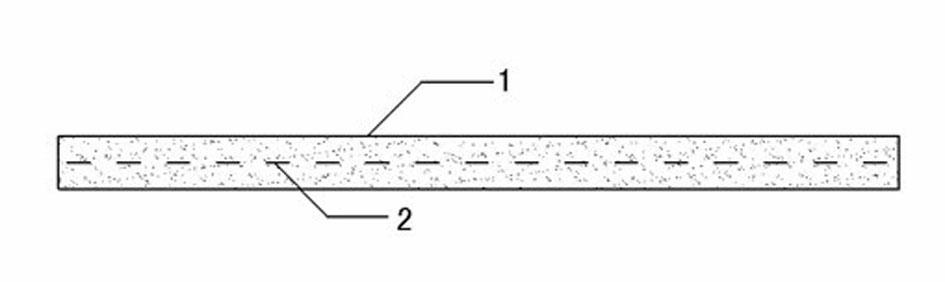

[0033] Such as Figure 1 to Figure 4 As shown, the tensile glucomannan sponge of the present invention is composed of a sponge body 1 and a strengthening layer 2 .

[0034] The sponge body 1 is a thin sheet made of glucomannan, and the reinforcement layer 2 is a mesh body woven from fibers with regular hexagonal honeycomb mesh, and embedded in the sponge body 1 The interior of the structure is similar in shape to the sponge body 1, so that the reinforcing layer 2 and the sponge body 1 are multi-layered in cross section.

[0035] In this way, the glucomannan sponge can provide better strength by means of the reinforcing layer 2, and reinforce the deficiency of the sheet-shaped sponge body 1, so that the stretch-resistant glucomannan sponge can have better tensile strength, It can still maintain the integrity of the sponge body 1 when it is stretched and stretched, so as to maintain the use effect that the sponge body 1 can provide to the user, and avoid deriving the fragile an...

Embodiment 2

[0051]The above-mentioned embodiment 1 is particularly suitable for manufacturing tensile glucomannan sponges in batches. In terms of industry, batch-type manufacturing methods are more suitable for different types of sponges because they can provide molded shapes by means of molds. Fabrication of regular-shaped tensile glucomannan sponges.

[0052] In contrast, the continuous process has the advantage of low shape variability but high efficiency. The method for manufacturing the stretch-resistant glucomannan sponge in a continuous process will be further described below.

[0053] Such as Figure 4 As shown, the manufacturing method of the tensile glucomannan sponge disclosed by the present invention contains the following steps:

[0054] a. Dissolve 2%~10% edible alkali into an aqueous edible alkali solution;

[0055] b. Mix 2%~5% glucomannan into an aqueous solution of edible alkali to form an aqueous solution of glucomannan, and stir quickly and evenly;

[0056] c. When...

Embodiment 3

[0071] Of course, implementing the technical content with two different storage tanks is only one of the specific feasible ways of the present invention, and the method of continuous process manufacturing should not be limited to this, in other words, this method can also be used A single storage tube contains the glucomannan mixture, so that the formed first layer 3 and second layer 4 are mixtures with the same composition and ratio.

[0072] Such as Figure 5 As shown, in this embodiment, a continuous manufacturing method is provided, which has similar process steps to that of Embodiment 2. Specifically, the steps that are different from Embodiment 2 are: replace the embodiment with the following steps Step f to h step in 2, and retain a step to e step and i step to n step in embodiment 2:

[0073] a, take a reinforcing layer 2, located on the top of the rolled base film 7, and move in the same direction with the same speed as the rolled base film 7;

[0074] b. Send the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com