Marine bioactive peptide capable of effectively relieving skin sunburn, and preparation method and application of marine bioactive peptide

A technology for marine organisms and active peptides, applied in the field of biomedicine, can solve the problems of difficult large-scale industrial production and application, low yield of active peptides, complicated preparation methods, etc., and achieves short production cycle, simple preparation process and good physiological effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

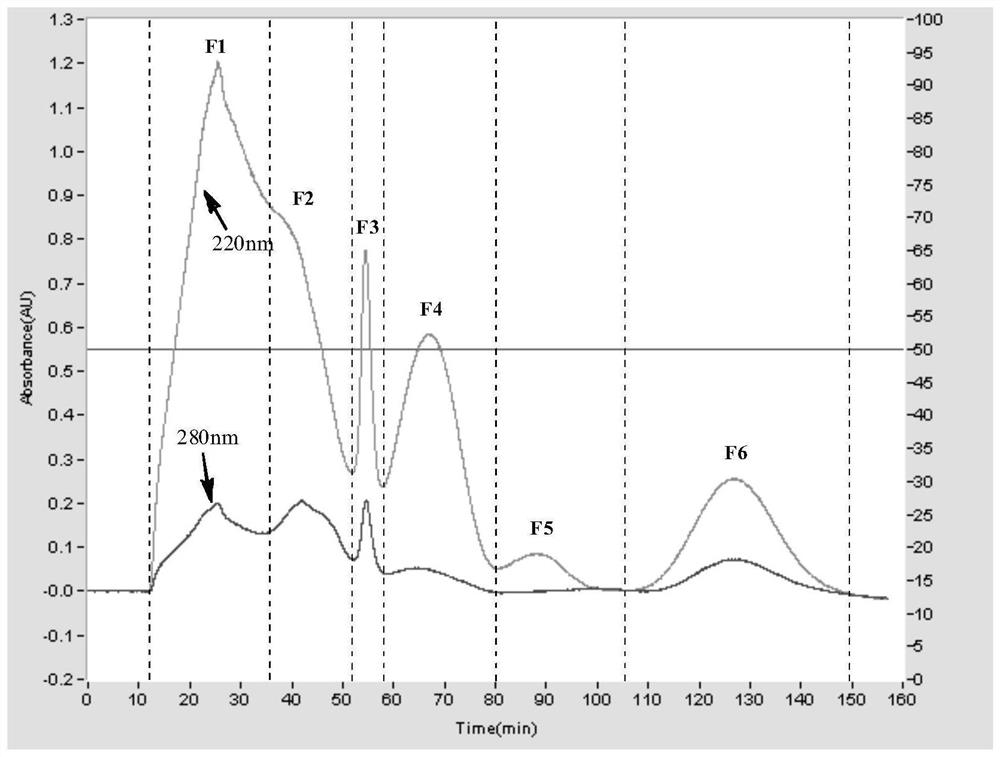

[0068] Take fresh and live clam scallops that meet the standards for the use of relevant seafood in my country, remove the shell, homogenize the soft body, and add 3 times the volume of PBS buffer (0.01M, pH7.5), neutral protease (3000U / g shellfish) , temperature 45°C, enzymatic hydrolysis for 4h. The enzymolysis solution was boiled for 10 minutes and centrifuged at 7000×g for 12 minutes. The supernatant was ultrafiltered sequentially through ultrafiltration membranes with a molecular weight cut-off of 10 kDa and 3 kDa. Among them, the 3kDa-10kDa active peptide component is recorded as N1, and the active peptide component less than 3kDa is recorded as N2. Concentrate the N1 and N2 components to a concentration of about 100mg / mL, and then separate them with Sephadex G-15 (100×4.0cm): the loading volume is 15mL, the mobile phase is distilled water, the flow rate is 10mL / min, and the detection wavelength 220nm, 280nm.

[0069] The N1 (3kDa-10kDa) fraction was separated by Sepha...

Embodiment 2

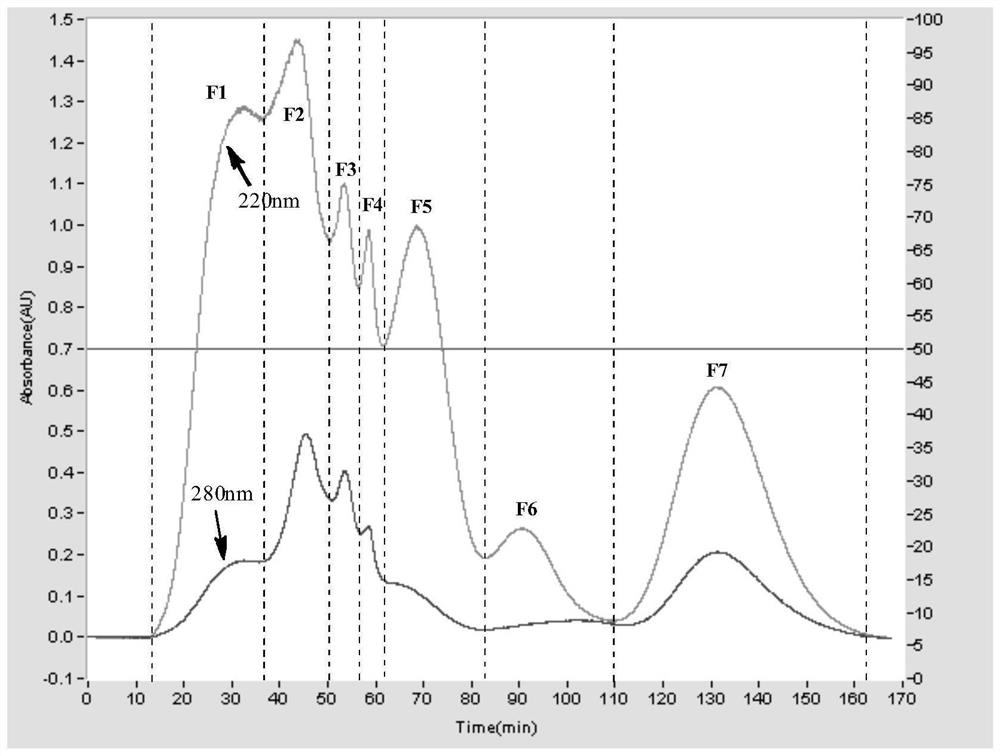

[0075] Take fresh and live clam scallops that meet the standards for the use of relevant seafood in my country, remove the shell, homogenize the soft body, add 2.5 times the volume of distilled water, adjust the pH value to 7.0, add neutral protease (2000U / g shellfish), and the temperature is 50°C , enzymatic hydrolysis for 5h. The enzymolysis solution was boiled for 10 minutes and centrifuged at 6000×g for 15 minutes. The supernatant was ultrafiltered sequentially through ultrafiltration membranes with a molecular weight cut-off of 10 kDa and 3 kDa. Among them, the 3kDa-10kDa active peptide component is recorded as N1, and the active peptide component less than 3kDa is recorded as N2. Concentrate the N1 and N2 components to a concentration of about 200mg / mL, and then separate them with Sephadex G-15 (100×4.0cm): the loading volume is 7mL, the mobile phase is distilled water, the flow rate is 10mL / min, and the detection wavelength 220nm, 280nm.

[0076] Separate the N1 (3kDa...

Embodiment 3

[0081]Take the fresh and live clam shells that meet the standards for the use of relevant seafood in my country, remove the shells, take the soft part of the homogenate, add 4 times the volume of deionized water, adjust the pH to 6.5, add neutral protease (4000U / g shellfish), and in the Temperature 37 ℃, enzymatic hydrolysis 6h. The enzymolysis solution was boiled for 10 minutes and centrifuged at 9000×g for 10 minutes. The supernatant was ultrafiltered through an ultrafiltration membrane with a molecular weight cut-off of 10 kDa, and the filtrate (active peptide fraction less than 10 kDa) was recorded as N. Concentrate the N component to a concentration of about 100mg / mL, and then separate it with Sephadex G-15 (100×4.0cm): the loading volume is 16mL, the mobile phase is distilled water, the flow rate is 10mL / min, and the detection wavelength is 220nm and 280nm .

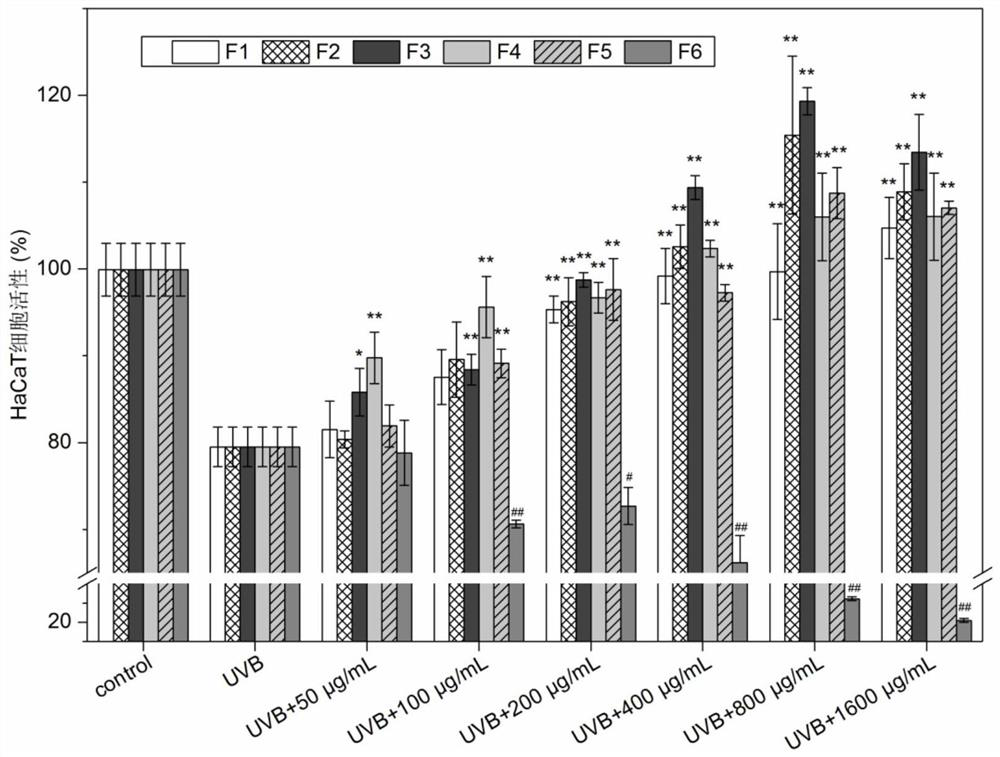

[0082] After the N (less than 10kDa) fraction is separated by Sephadex G-15, the first to sixth elution peak fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com