NaBH4 sponge and preparation method thereof

A sponge and catalyst technology, which is applied in the field of NaBH4 sponge and its preparation, can solve the problems of insufficient reaction, uneven mixing of solid-phase hydrolysis materials, low tap density of sponge single-loaded catalyst, etc., to achieve the best reaction performance and improve conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] a NaBH 4 The preparation method of sponge, comprises the following steps:

[0040] 1. Select the catalyst, use anhydrous or transition metal salt or complex containing a small amount of crystal water as the catalyst precursor, and the transition metal salt can be any one or a mixture of two or more of the following:

[0041] Chloride, sulfate, nitrate, acetate of Fe;

[0042] Chloride, sulfate, nitrate, acetate of Co;

[0043] Ni chloride, sulfate, nitrate, acetate.

[0044] 2. Prepare the precursor solution, mix the catalyst precursor with NaBH 4 Mix at a mass ratio of 0.01 to 0.2:1 and dissolve in an organic solvent at the same time. The organic solvent includes but is not limited to: methylamine, ethylamine, ethylenediamine, triethylamine, dimethylformamide and other amine organic solvents. Organic solvents and NaBH 4 The mass ratio of the catalyst precursor is 1:0.01~0.3, and the dissolution can be carried out at room temperature, or it can be heated and stirre...

Embodiment 1

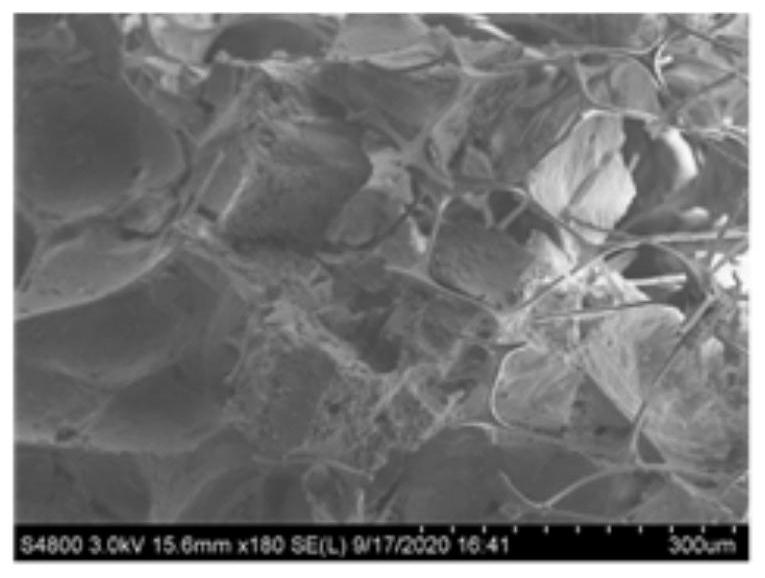

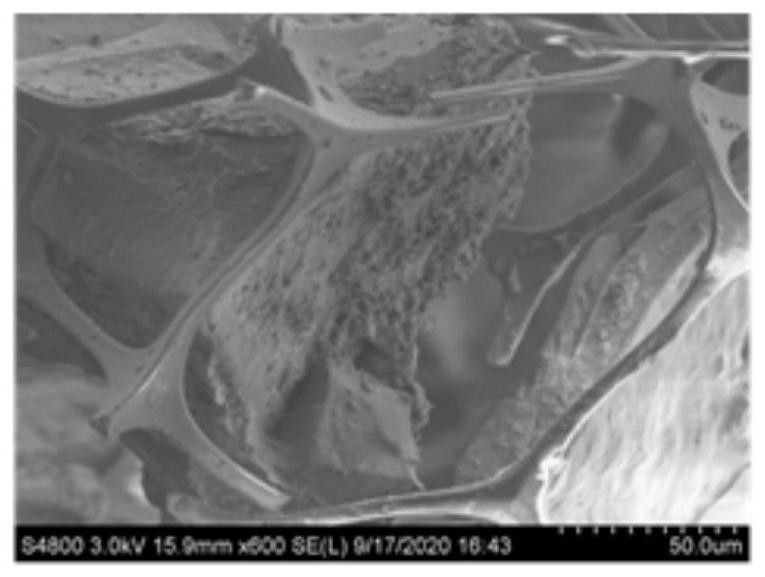

[0049] CoCl 2 ·6H 2 O was dehydrated at 230 °C for 12 h to obtain anhydrous CoCl 2 . Take 0.25g or 0.5g or 1g of anhydrous CoCl 2 Dissolve in 40mL ethylenediamine, stir for 10min, then add 10g NaBH 4 , and continue to stir for 5 minutes until all solids are completely dissolved to obtain a precursor solution. Take the apparent density as 8mg·cm -3 A melamine resin (MF) sponge is used as a carrier, which is cut into a volume of 0.125cm -3 Take 0.35g of the above cube to make it fully absorb the precursor solution.

[0050] Put the sponge particles absorbing the precursor solution into a branched-necked flask with a volume of more than 100mL, and perform a vacuum distillation operation. The reaction temperature is 120°C, and the vacuum degree is controlled to be 4 The sponges were stored in a vacuum desiccator or in an Ar-filled glove box until use. The ethylenediamine obtained by distillation can be recovered and reused.

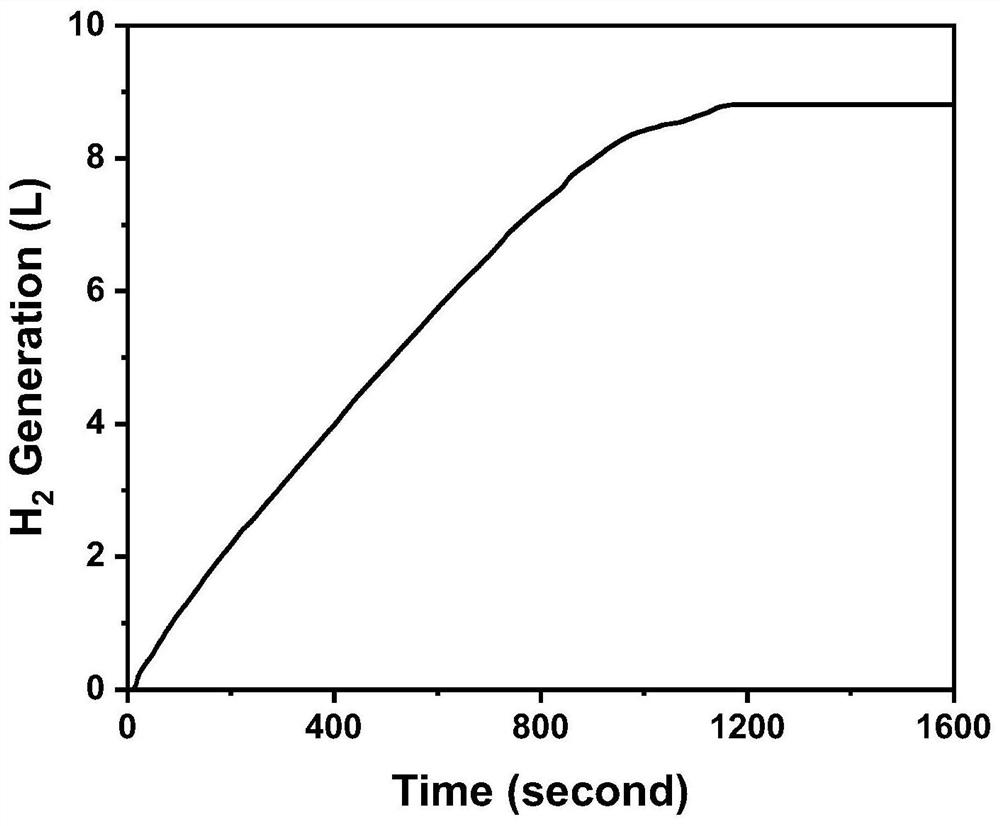

[0051] Take the above NaBH 4 Sponge 5g, placed...

Embodiment 2

[0054] Take 0.25g CoCl 2 ·H 2 O with 5g NaBH 4 , was added into 20 mL of ethylenediamine, and stirred for 10 min until all solids were completely dissolved to obtain a precursor solution. Take the apparent density as 8mg·cm -3 A melamine resin (MF) sponge was used as a carrier, which was cut into a volume of 1cm -3 cube. Take more than 20 cubes above to make them fully absorb the precursor solution.

[0055] Put the sponge particles absorbing the precursor solution into a branched-necked flask with a volume of 100ml, and carry out the standard operation of vacuum distillation. The reaction temperature is 80°C, and the vacuum degree is 4 The sponges were stored in a vacuum desiccator or in an Ar-filled glove box until use. The ethylenediamine obtained by distillation can be recovered and reused.

[0056] Take 1 block of the above-mentioned NaBH with a total mass of about 0.3g 4 Sponge, placed in the reactor, the reactor has a water inlet and a gas outlet, and can open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com