Pilaf production line and preparation method thereof

A production line and hand-grabbing technology, which is applied in the production line and preparation field of pilaf rice, can solve the problems that affect the stability of pilaf ingredients, high water content, uneven heating of ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

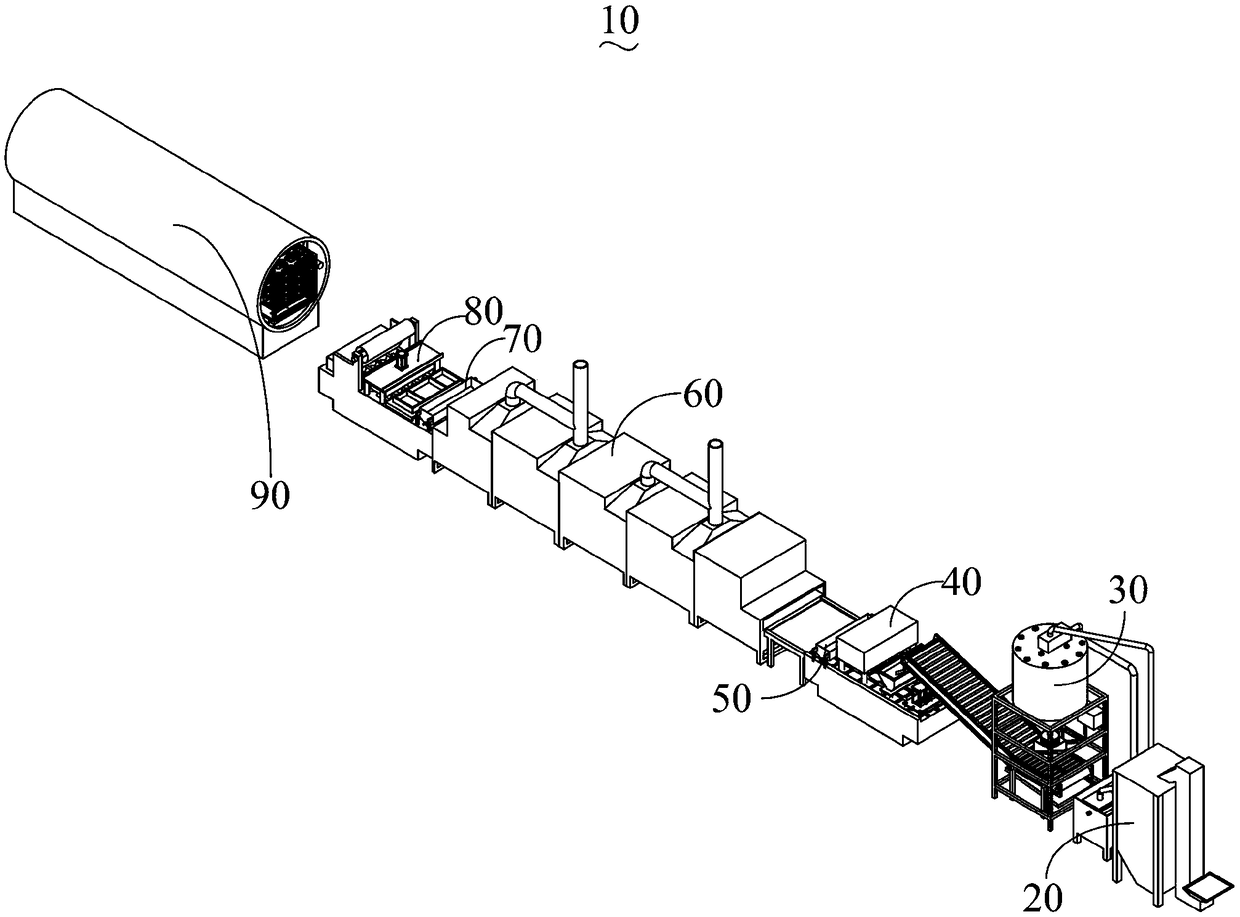

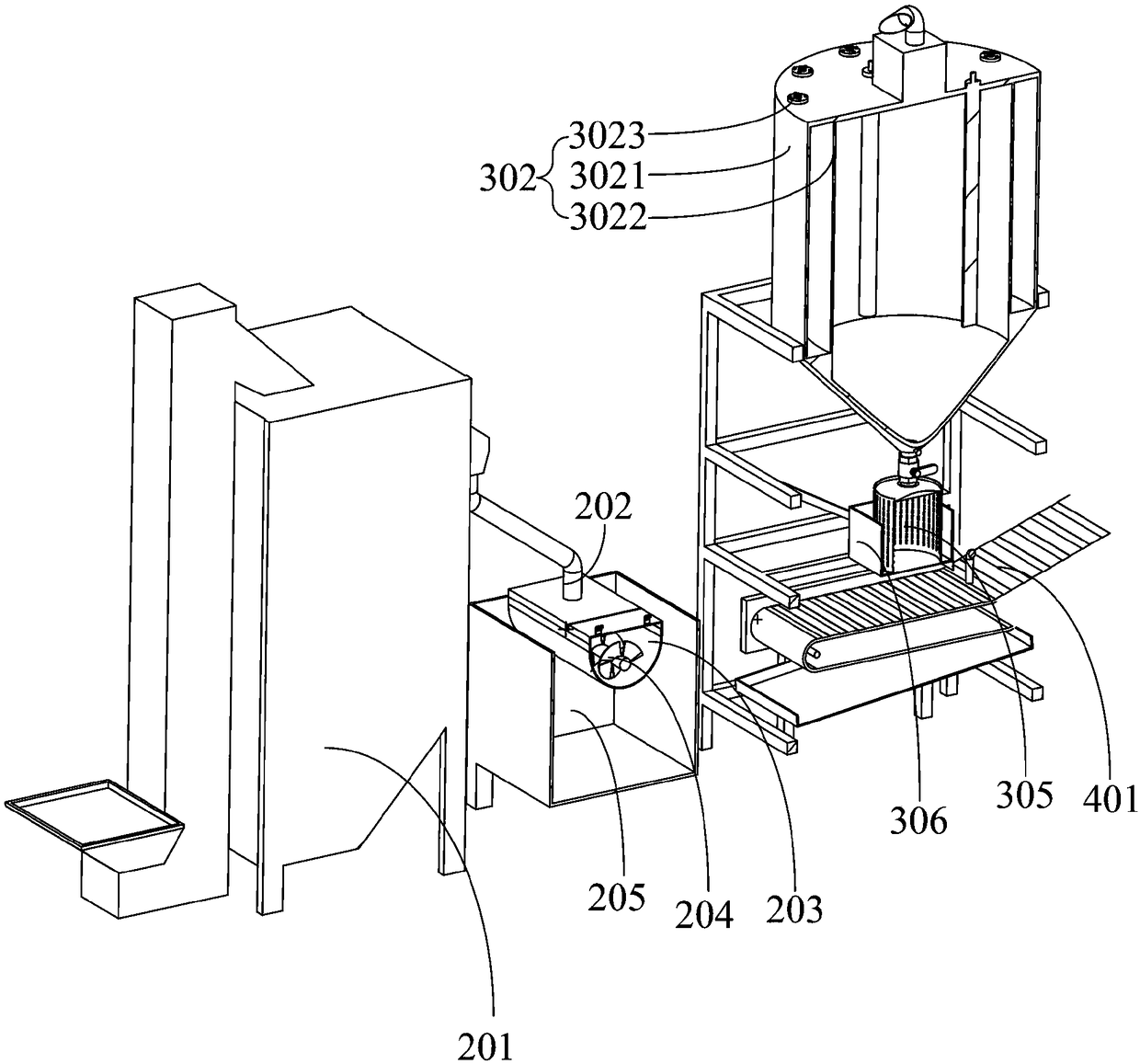

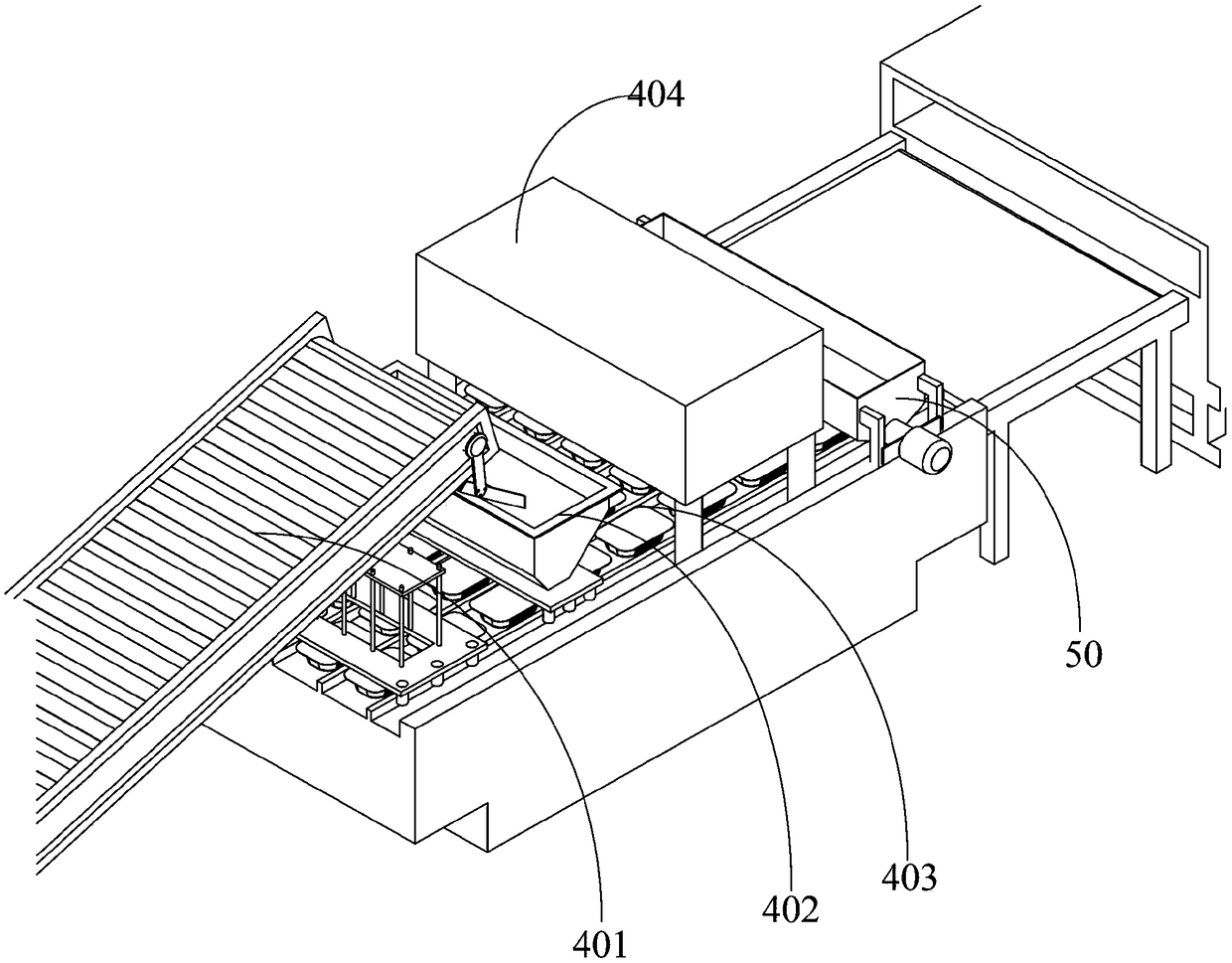

[0025] Please see Figure 1 to Figure 7, a hand pilaf production line 10 comprising a rice washing device 20, a rice soaking device 30, a filling device 40, a first material supply device 50, a microwave cooking device 60, a second material supply device 70, a film sealing device 80, a secondary aging Sterilization device 90, rice washing device 20, rice soaking device 30, filling device 40, first material supply device 50, microwave cooking device 60, second material supply device 70, film sealing device 80, and secondary ripening an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com