Pipe section punching machine, pipe section feeding device and pipe section processing equipment

A punching device and punching machine technology, applied in metal processing equipment, feeding device, positioning device and other directions, can solve the problems of high cost, complicated structure of feeding device, complicated high-precision control method, etc., and achieve reasonable structure, The effect of improving production efficiency and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0038] Example of pipe punching machine

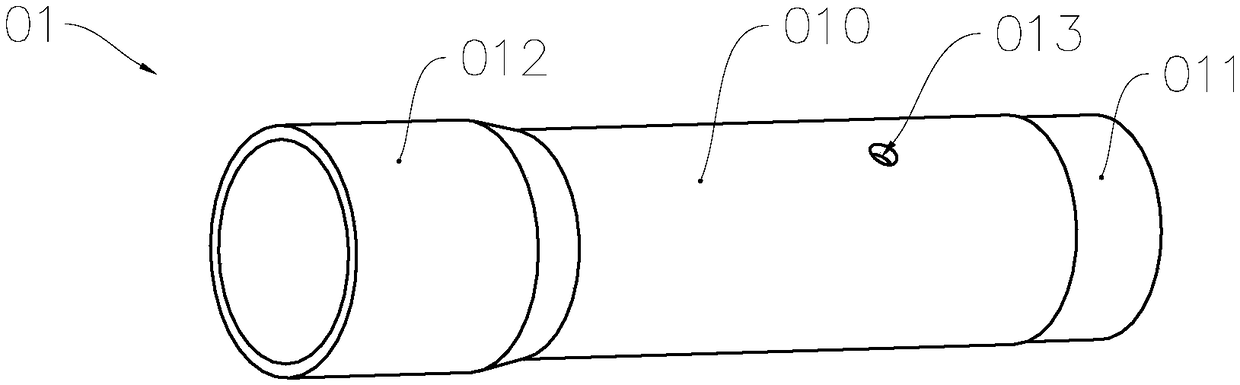

[0039] see Figure 4 to Figure 7 , The pipe section punching machine of the present invention includes a pipe section punching device 18 and a pipe section feeding device 17 . Wherein, the pipe section punching device 18 includes a discharge unit 51 , a punching core 54 , a punching needle 53 and a punching needle driving unit 55 .

[0040] The unloading unit 51 includes a fixed seat 510, a guide seat 511, a pusher plate 512 and a discharge driver 513 for driving the pusher plate 512 to reciprocate along the Y axis. In this embodiment, the discharge driver 513 adopts linear displacement Cylinder in output device. The pusher plate 512 has a semicircular hole that matches the punching core, and the unloading driver 513 drives the pusher plate 512 to reciprocate along the Y axis through two guide connecting rods 514 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com