Chair plate punching die replacing system

A punching and mold technology, applied in the field of seat seat plate punching mold mold change system, can solve the problems of large screw and screw hole loss, heavy mold weight, large impact force, etc., to ensure the punching quality and process Safety, reduce adjustment time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

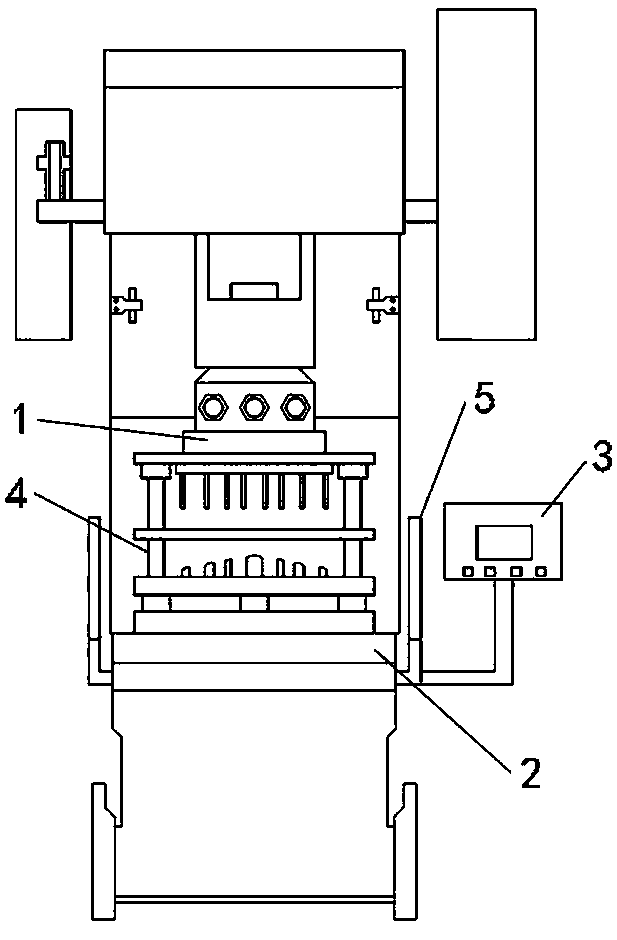

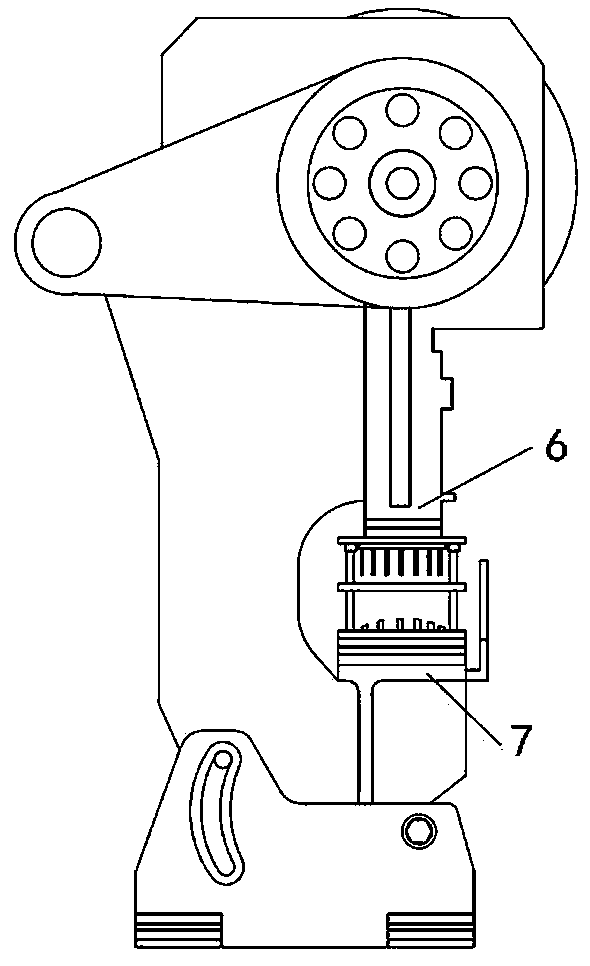

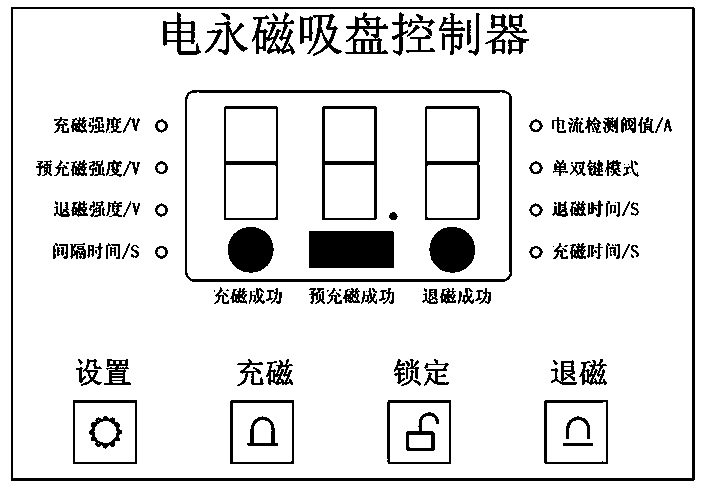

[0016] as attached figure 1 As shown, a mold change system for seat seat plate punching dies, including electro-permanent magnetic chuck I1, electro-permanent magnetic chuck II2 and electro-permanent magnetic chuck controller 3, said electro-permanent magnetic chuck I1 is fixed with punch slider 6 , the permanent magnetic chuck II2 is fixed to the punch table 7, the electro-permanent magnetic chuck controller 3 is arranged on one side of the punch table 7; a punching hole is placed between the electro-permanent magnetic chuck I1 and the electro-permanent magnetic chuck II2 Die 4; the electric permanent magnetic chuck controller 3 is respectively connected with the electric permanent magnetic chuck I1, the electric permanent magnetic chuck II2 and the circuit of the punch press control cabinet, and the punch press control cabinet is connected with a pedal circuit switch. A safety grating 5 is arranged on the front side of the punch table 7, and the safety grating 5 is composed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap