Spiral extrusion type solid-liquid separator

A solid-liquid separator and screw extrusion technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor solid-liquid separation effect, low material dehydration rate, reducing the length of the drainage area, etc., to achieve high water absorption and ensure separation efficiency. , the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

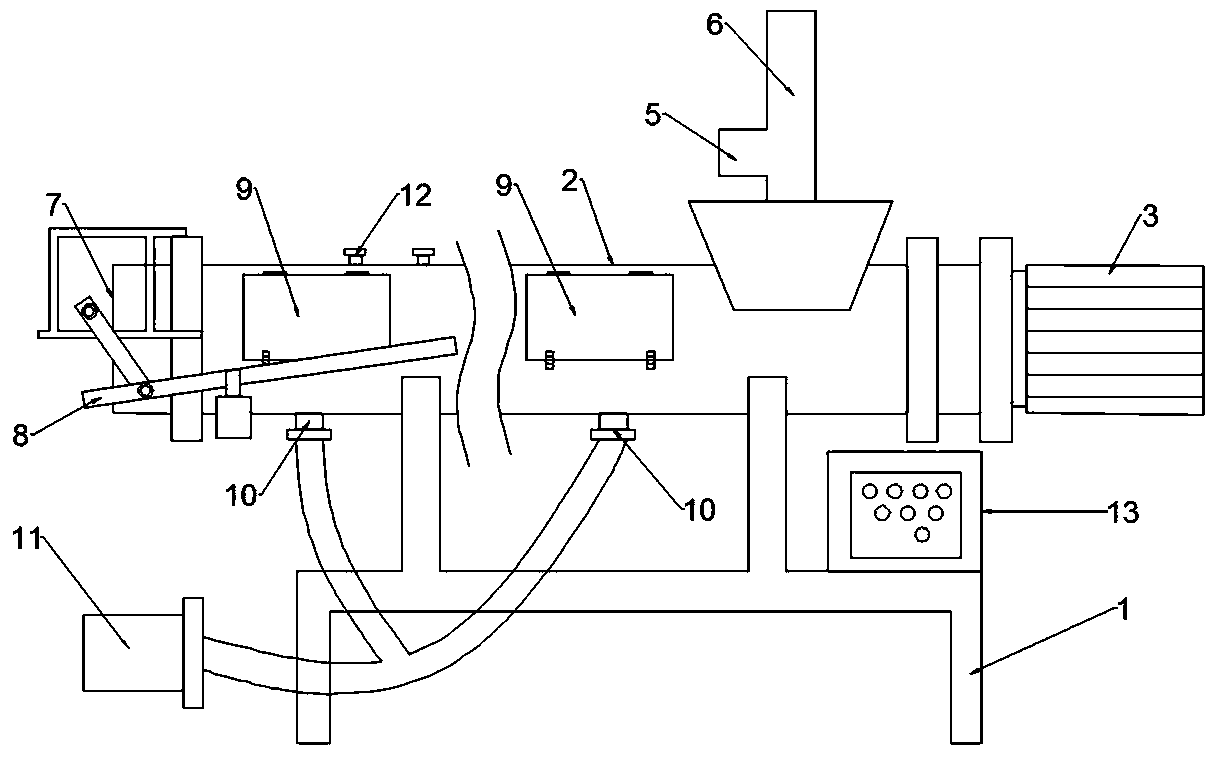

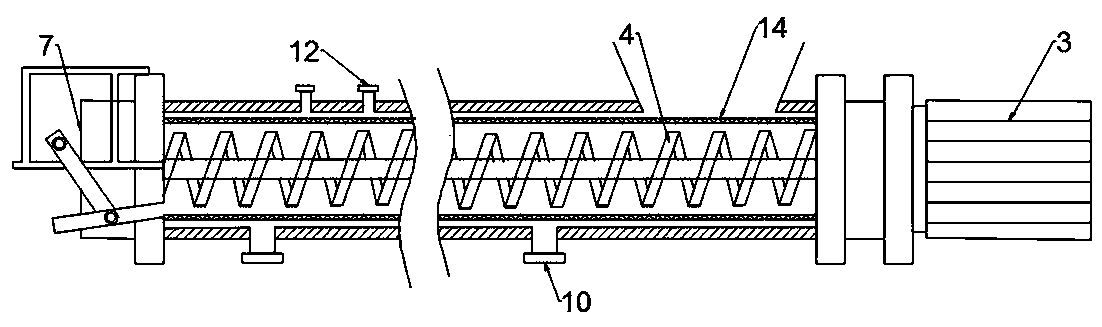

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

[0019] A screw extrusion solid-liquid separator, comprising a frame 1, a casing 2, a sieve cylinder 14 and an auger 4, the sieve cylinder 14 is arranged in the casing 2, and the left end of the casing 2 is a solid discharge port, The right end is provided with a motor 3 for driving the auger 4, and a water pump 11 is connected to the water outlet 10 at the bottom of the casing 2. The water pump 11 increases the pressure in the casing 2, and can timely extract the waste water extruded by the auger 4, which greatly improves the solid-liquid separation efficiency and drainage efficiency. combine figure 1 , The frame 1 is also provided with a distribution box, and the solid discharge port 7 is provided with a counterweight mechanism 8 .

[0020] In the above-mentioned screw extrusion solid-liquid separator, the housing 1 is provided with a feed pipe 5, and an overflow pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com