Method for making multiple gradient tipping paper

A production method and tipping paper technology, applied in the directions of wrapping paper, wrapping paper, and crafts for producing decorative surface effects, etc., can solve problems such as high cost and complicated craftsmanship, and achieve rich suction sensory experience and good visual effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

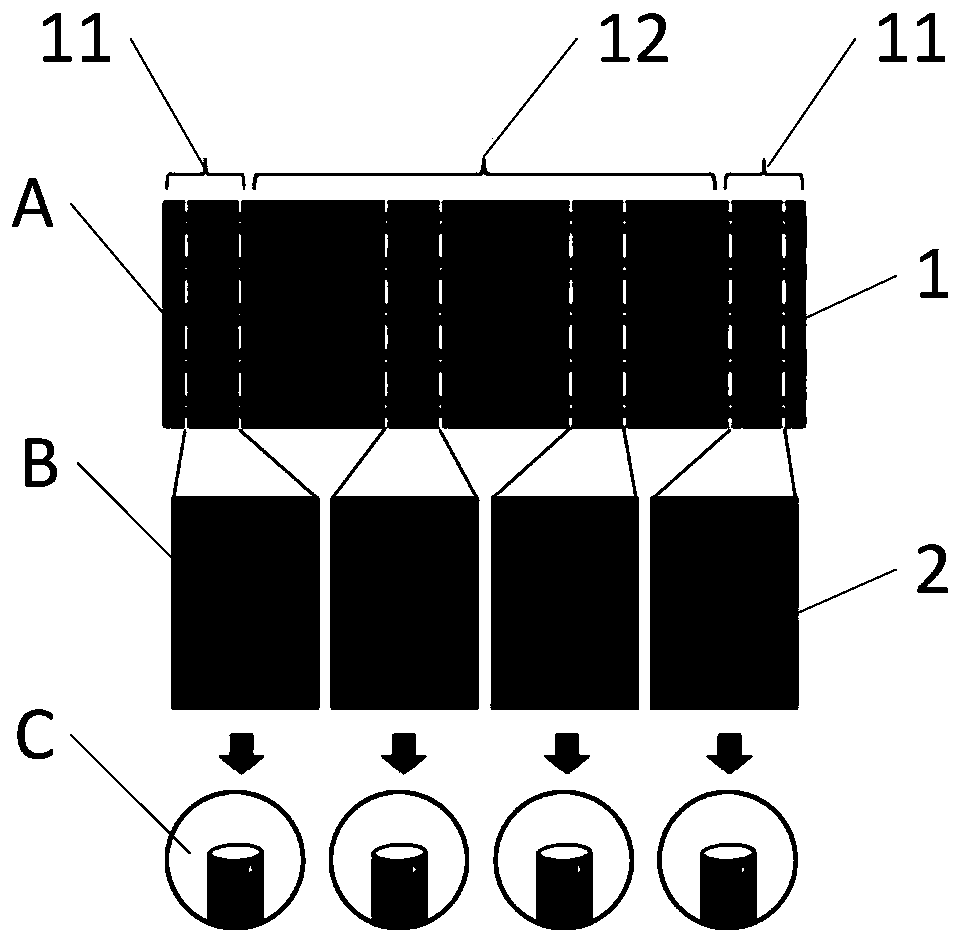

[0059] Example 1 Design Scheme of Tipping Paper with Gradient Background Color

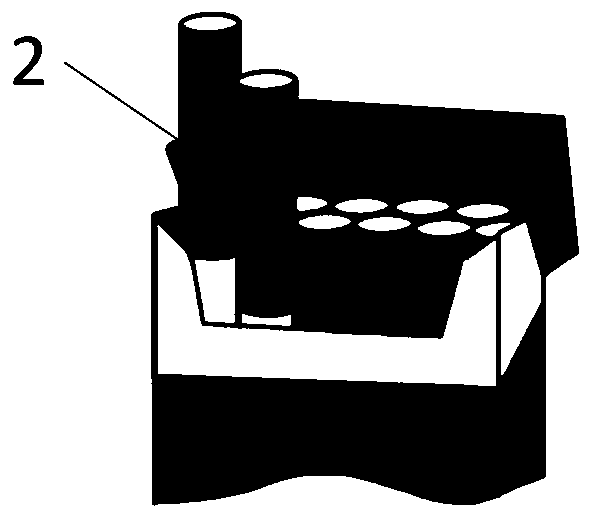

[0060] as attached figure 1 Shown is a design scheme of tipping paper with gradient background color, and the variation primitive of the scheme is the color of tipping paper. The starting mutation primitive is the dark blue on the left side of A in the figure (CMYK=87,78,9,0), and the ending mutation primitive is the orange on the right side of A in the figure (CMYK=7,73,74,0 ), the mutation rule is linear gradient, with figure 1 Part B in the middle is the cut four-color tipping paper fragment 2, with figure 1 Center C is a partial view of the cigarette product made from the tipping paper segment 2. Cycle unit length (L C ) is 312mm, cutting length (L S ) is 26mm, the ratio is 12:1. The arrangement of the circulating units is arranged in the first position, that is, the above-mentioned circulating units are mirror-symmetrical along one edge, and then alternately arranged in a circular manne...

Embodiment 2

[0062] Embodiment 2 Combination gradient tipping paper design scheme

[0063] as attached Figure 5 Shown is a combination gradient tipping paper design. The gradient tipping paper design scheme is a combined design scheme of background color gradient and pattern gradient. The scheme consists of three cyclic units:

[0064] The first cyclic unit is the base color cyclic unit, the starting mutation primitive is orange red on the left (CMYK=18,81,100,0), and the ending mutation primitive is purple on the right (CMYK=85,86,0, 0), the mutation rule is linear gradient, the length of the cycle unit is 520mm, the cutting length is 26mm, and the ratio is 20:1.

[0065] The second cyclic unit is a pattern transformation cyclic unit, the variation primitive is a white ring and the "S" pattern inside, the diameter of the ring is 3mm, and the diameter of the "S" pattern is 2.5mm. The transformation mode of the circulation unit is the superposition of the position gradient and the orie...

Embodiment 3

[0068] Embodiment 3 Fragrance gradient tipping paper design scheme

[0069] In addition to visual design elements such as visible colors and shapes, the variation primitives of the circulation unit of the present invention can also be other design elements, such as sense of smell (such as adding smell essence), taste (such as adding taste essence), Tactile (such as embossing, suede treatment, etc.), etc.

[0070] This embodiment provides a design proposal for the tipping paper with gradual changes in fragrance. The variant base of the fragrance gradient tipping paper is the type and content of the smelling essence, and its production method is as follows:

[0071] 1. Dissolve the expected prepared orange flavor in the orange printing ink;

[0072] 2. Dissolve the pre-prepared blueberry essence in the blue printing ink;

[0073] 3. According to the attached Figure 9 Gradient units design gradient plates respectively (see attached Image 6 with 7 )

[0074] 4. Use the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com