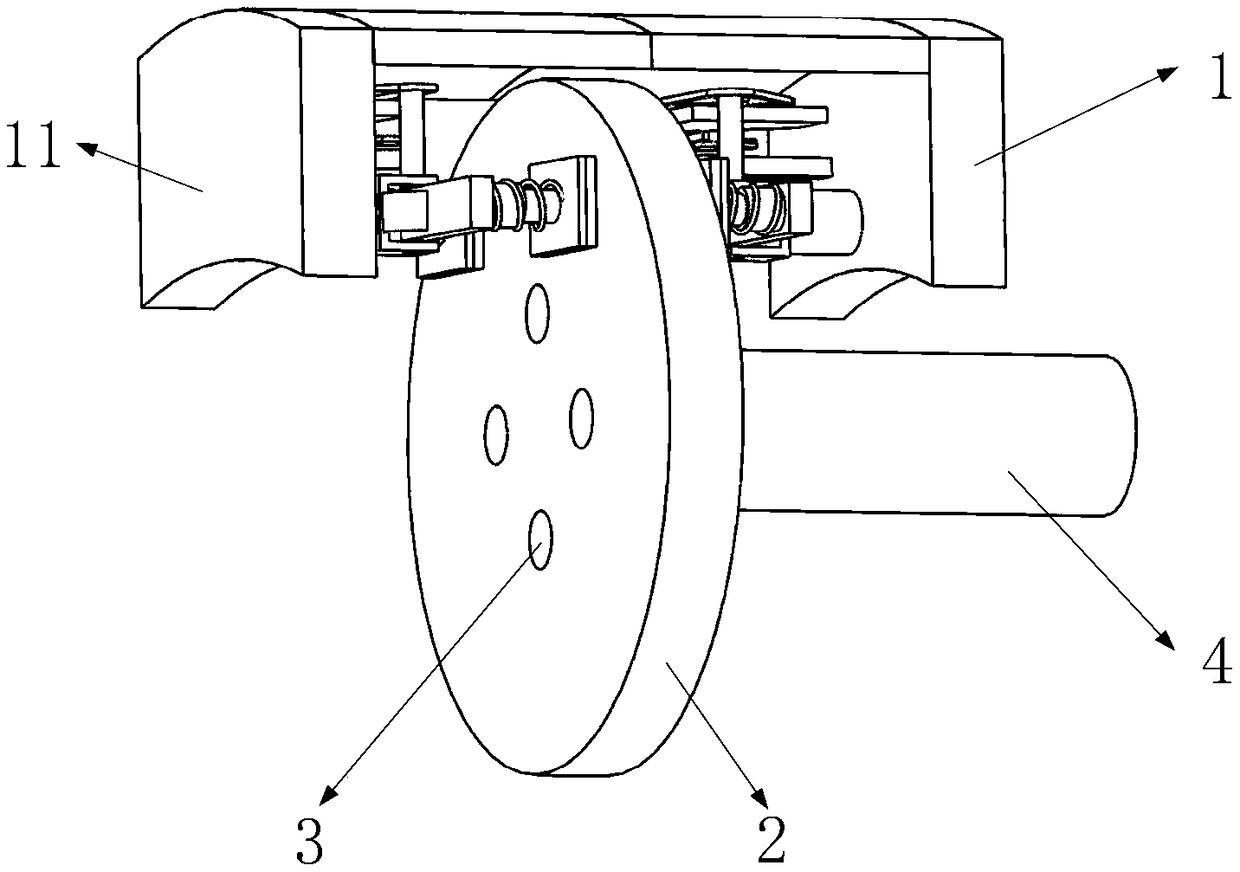

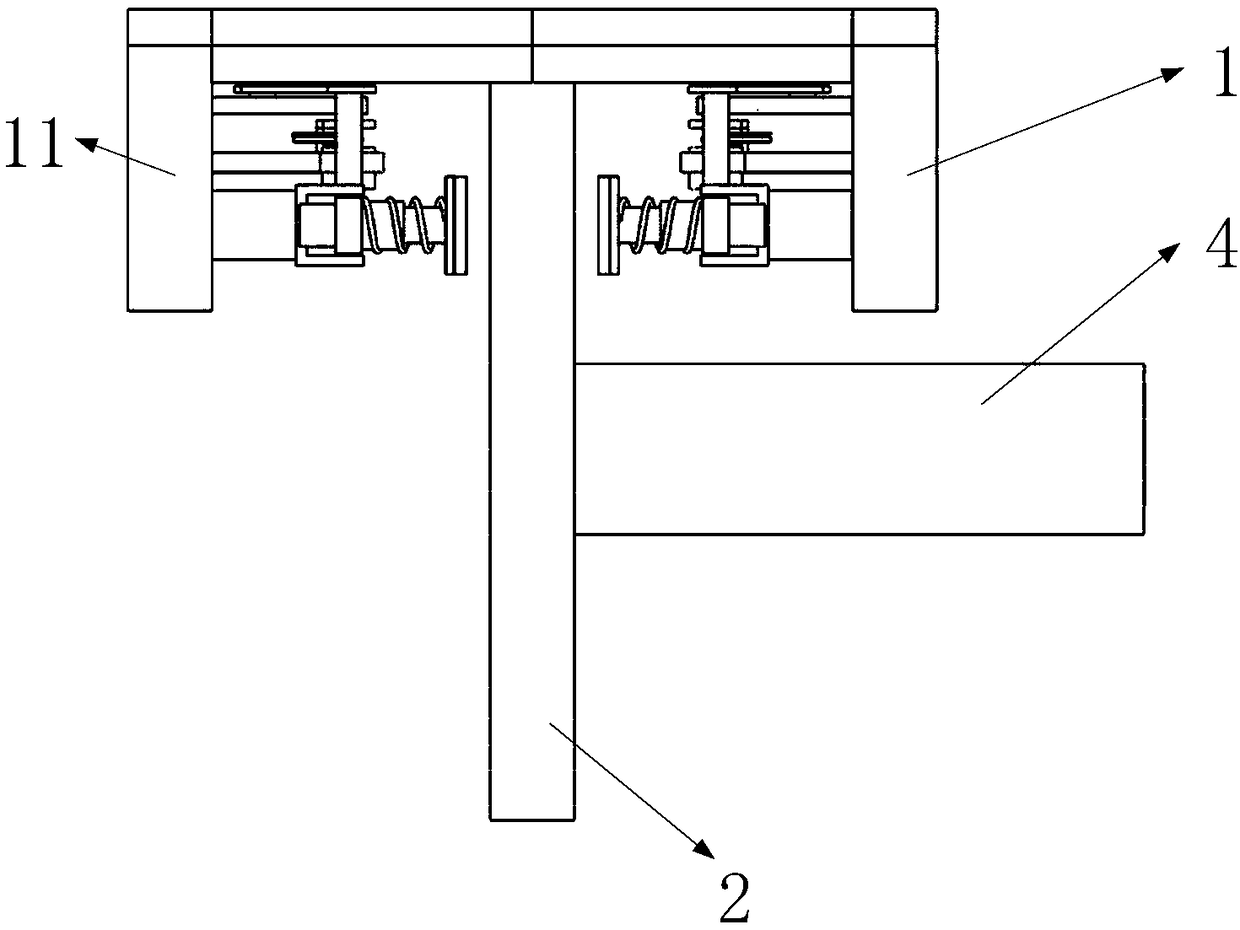

Double brake system based on crank-slider mechanism

A crank-slider mechanism and double-brake technology, which is applied in the field of double-brake systems, can solve problems such as poor braking effect of brake pads and driving hazards, and achieve the effects of simple structure, reduced brake wear, and good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

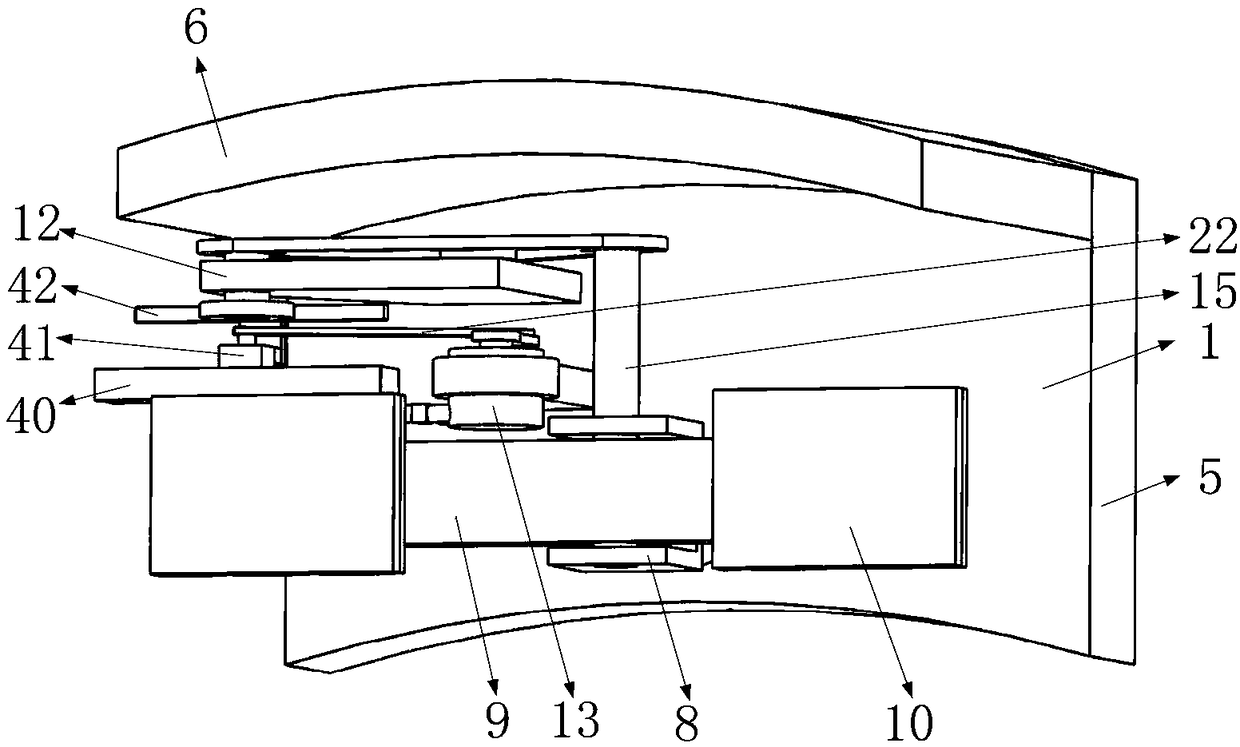

[0056] Specific embodiments: when the automobile does not need to be braked, the hydraulic system on the automobile will not extend the hydraulic column 7, and the hydraulic motor 13 will not work.

[0057] When the automobile needs to be braked, the hydraulic system on the automobile starts to provide hydraulic oil, so the hydraulic column 7 elongates; when the oil pressure changes slowly, the electromagnetic valve 47 is in an open state, and the hydraulic motor 13 works now. After the hydraulic oil flows into the hydraulic motor 13 through the hydraulic inlet pipe 48, the electromagnetic valve 47 and the hydraulic inlet 28, and then flows out from the hydraulic outlet 29, the hydraulic motor 13 starts to work, and the hydraulic motor 13 rotating shaft 4 makes the slider crank mechanism start to work. Slider 41 drives gear 44 to do reciprocating rotation through L-shaped plate 46 and rack 42, and gear 44 can drive first synchronous wheel 27 to do reciprocating rotation through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com