Stop lever type double-channel membrane packaging machine

A dual-channel, film-packing machine technology, applied in the direction of packaging, packaging bottles, transportation packaging, etc., can solve the problems of low production efficiency, restricting the development of enterprises in the beverage product industry, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The invention discloses a bar-type double-channel film wrapping machine, which is a machine for grouping and wrapping products, and is usually used in the beverage industry. The following are specific examples:

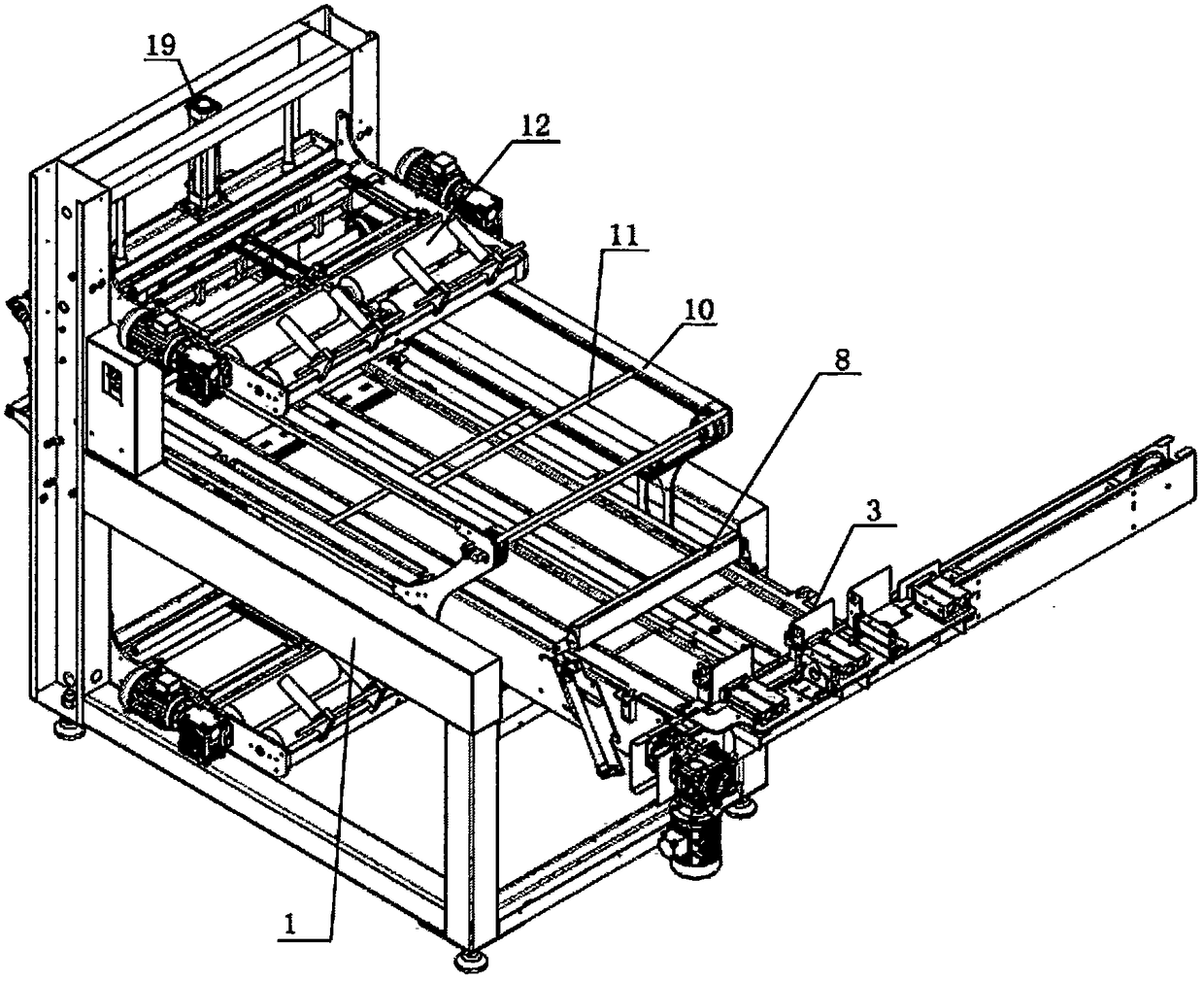

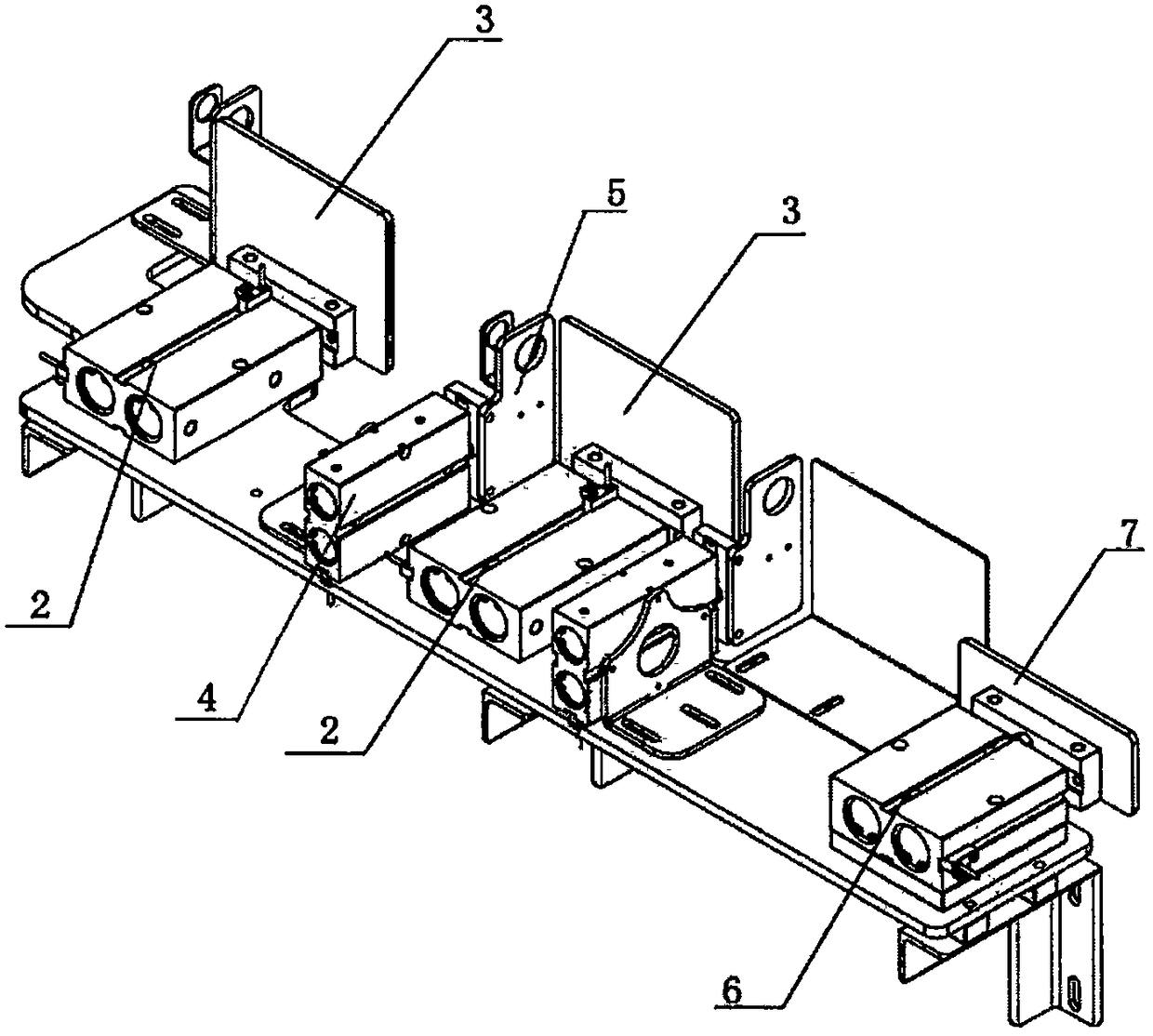

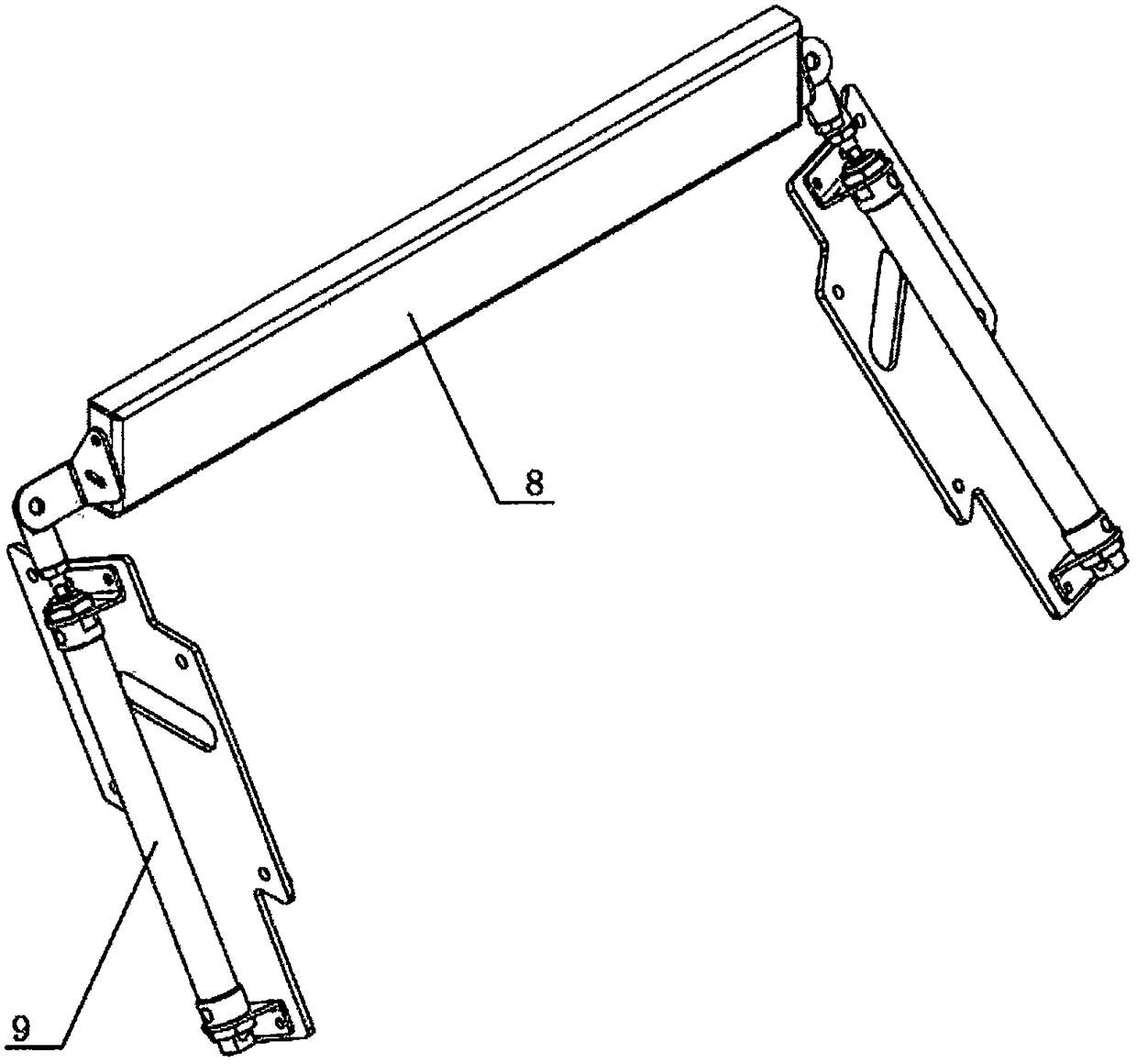

[0029] Barrier-type double-channel film charter of the present invention, such as figure 1 As shown, it includes the main frame 1 and the two-group packaging assembly, the bar assembly, the bottle pushing assembly, the film releasing assembly and the sealing and cutting parts arranged on the main frame 1 in sequence in working order. The sub-packaging component is used to divide the products that need to be coated into two columns according to the demand; the stop bar component is used to cache and group the grouped products; the push bottle component is used to push the grouped and arranged products to the film release componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com