A kind of preparation method of polyimide/metal organic framework composite thin film

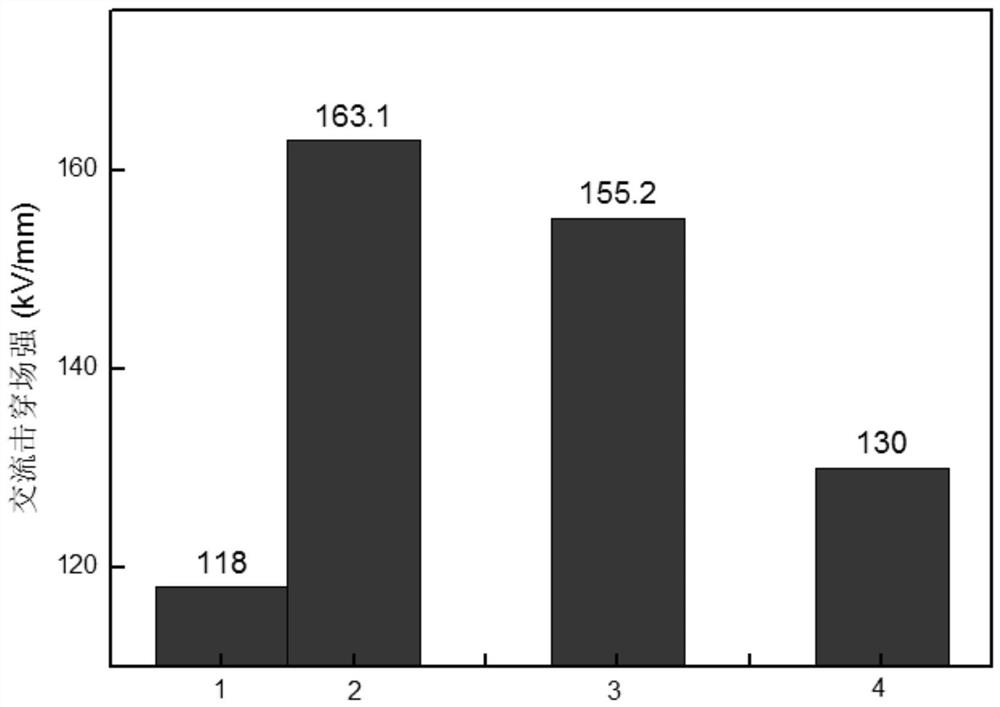

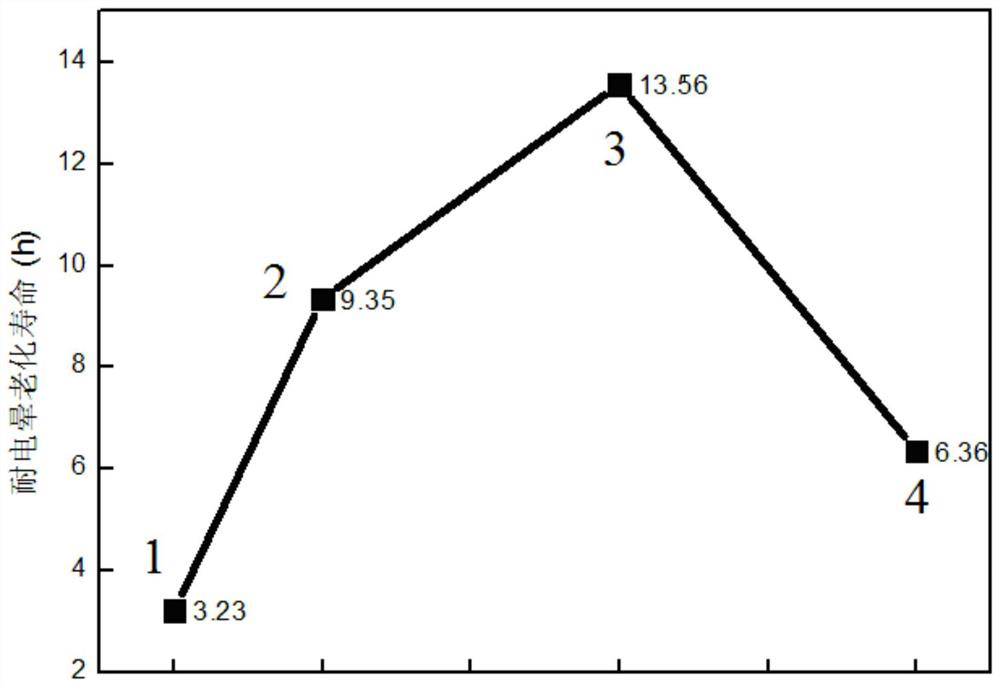

A metal-organic framework and composite film technology, which is applied in the field of polyimide composite film preparation, can solve the problems of short corona aging resistance life, polyimide AC breakdown field strength, etc., and achieve high AC breakdown Effects of field strength, excellent electric strength, and high corona aging resistance life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0082] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Zn(CH 3 COO) 2 2H 2 The mass ratio of O to the volume of deionized water is (250mg ~ 300mg): 5mL. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0083] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the volume ratio (6.4-6.8) of the 2-methylimidazole solution to the zinc acetate solution described in step 1.2. Other steps are the same as those in Embodiment 1 or 2.

specific Embodiment approach 4

[0084] Embodiment 4: The difference between this embodiment and Embodiments 1 to 3 is that the concentration of the 2-methylimidazole solution in Step 1 ② is 2.5 mol / L-2.72 mol / L. Other steps are the same as those in Embodiments 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com