Anti-seepage purification module for wetland

A purification module, wetland technology, applied in chemical instruments and methods, polluted waterway/lake/pond/river treatment, water/sludge/sewage treatment, etc. Long construction period and other problems, to achieve the effect of less personnel and materials, ensuring the quality of the project, and reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

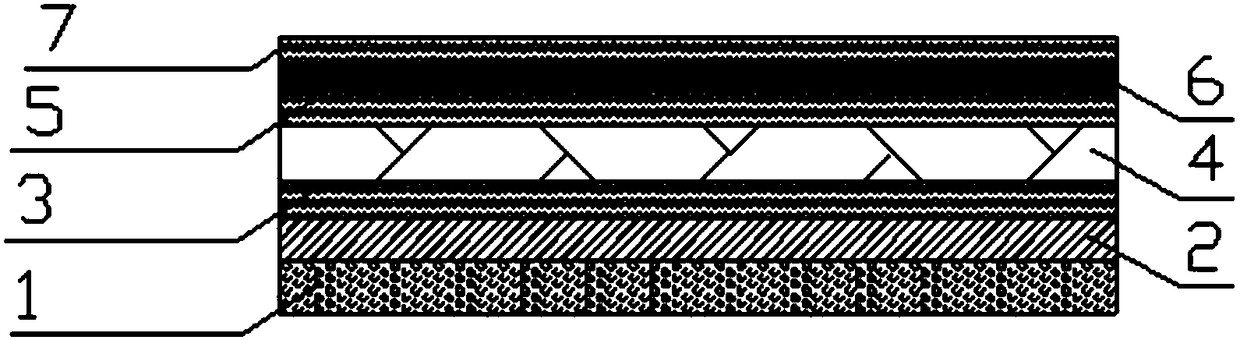

[0020] The invention provides an anti-seepage and purification module for wetlands, a novel anti-seepage and purification composite material, which forms a modular structure, reduces construction procedures, and achieves the purpose of water purification. Such as figure 1 As shown, a preferred embodiment of the present invention is shown therein.

[0021] Specifically, the anti-seepage purification module includes elastic flexible material layer 1, anti-seepage material layer 2, first geotextile layer 3, three-dimensional three-dimensional permeable material layer 4, second geotextile layer 5, microbial carrier layer 6, the third geotextile layer 7, the elastic flexible material layer 1 is laid by closed-cell foam board, the anti-seepage material layer 2 is laid by geomembrane, and the three-dimensional three-dimensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com