Deep foundation pit soil withdrawing equipment and construction method

A construction method and technology for deep foundation pits, which are applied in basic structure engineering, excavation, lifting devices, etc., can solve the problems of earthwork excavation speed affecting lining construction progress, high risk of borrowing from deep pits, and large excavation volume. , to achieve the effect of saving labor and material resources, improving soil borrowing efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

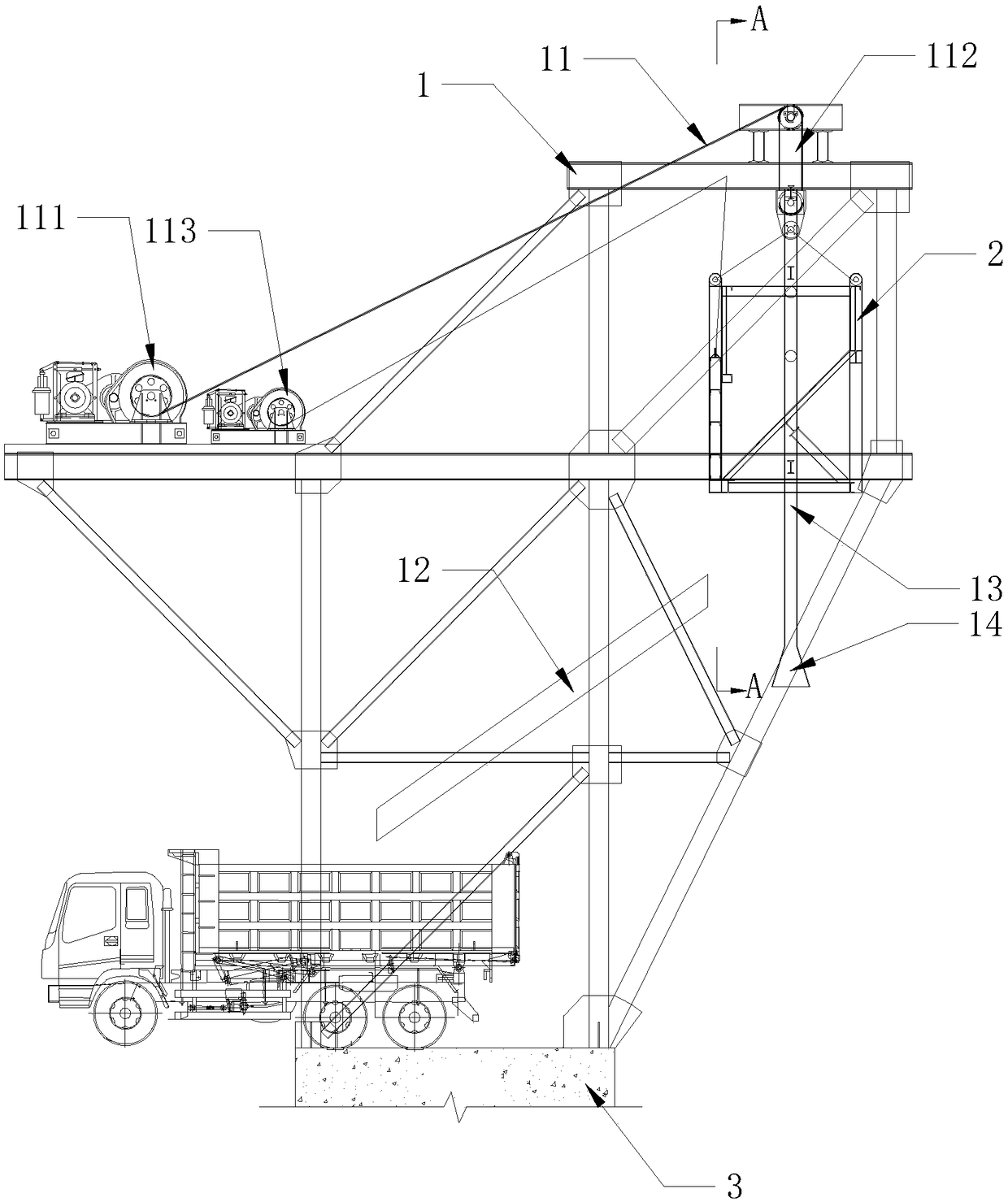

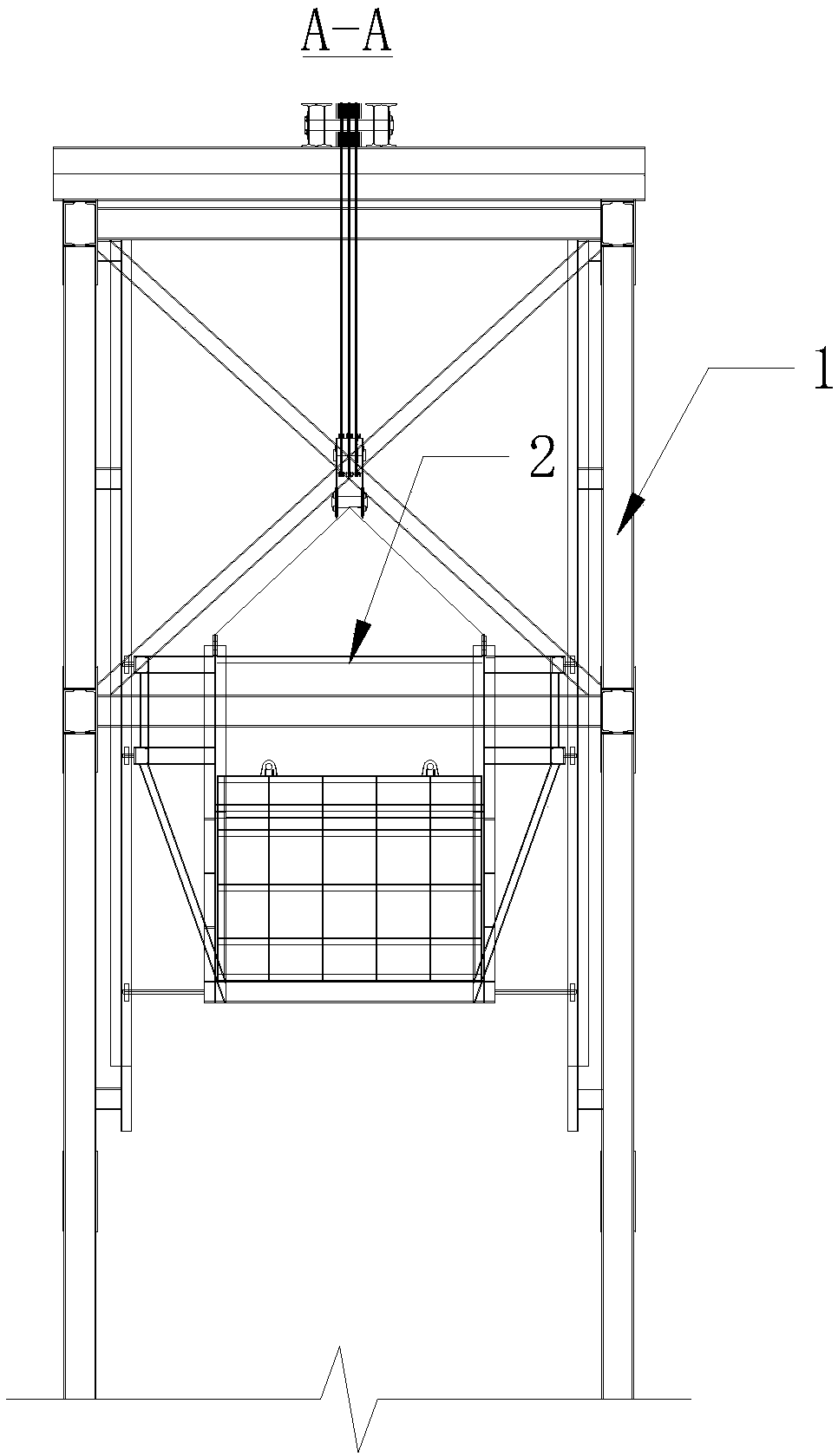

[0031] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a deep foundation pit soil extraction equipment, including:

[0032] The lifting frame 1 fixedly arranged above the foundation pit cap beam 3, the upper part of the lifting frame 1 is provided with a lifting mechanism 11;

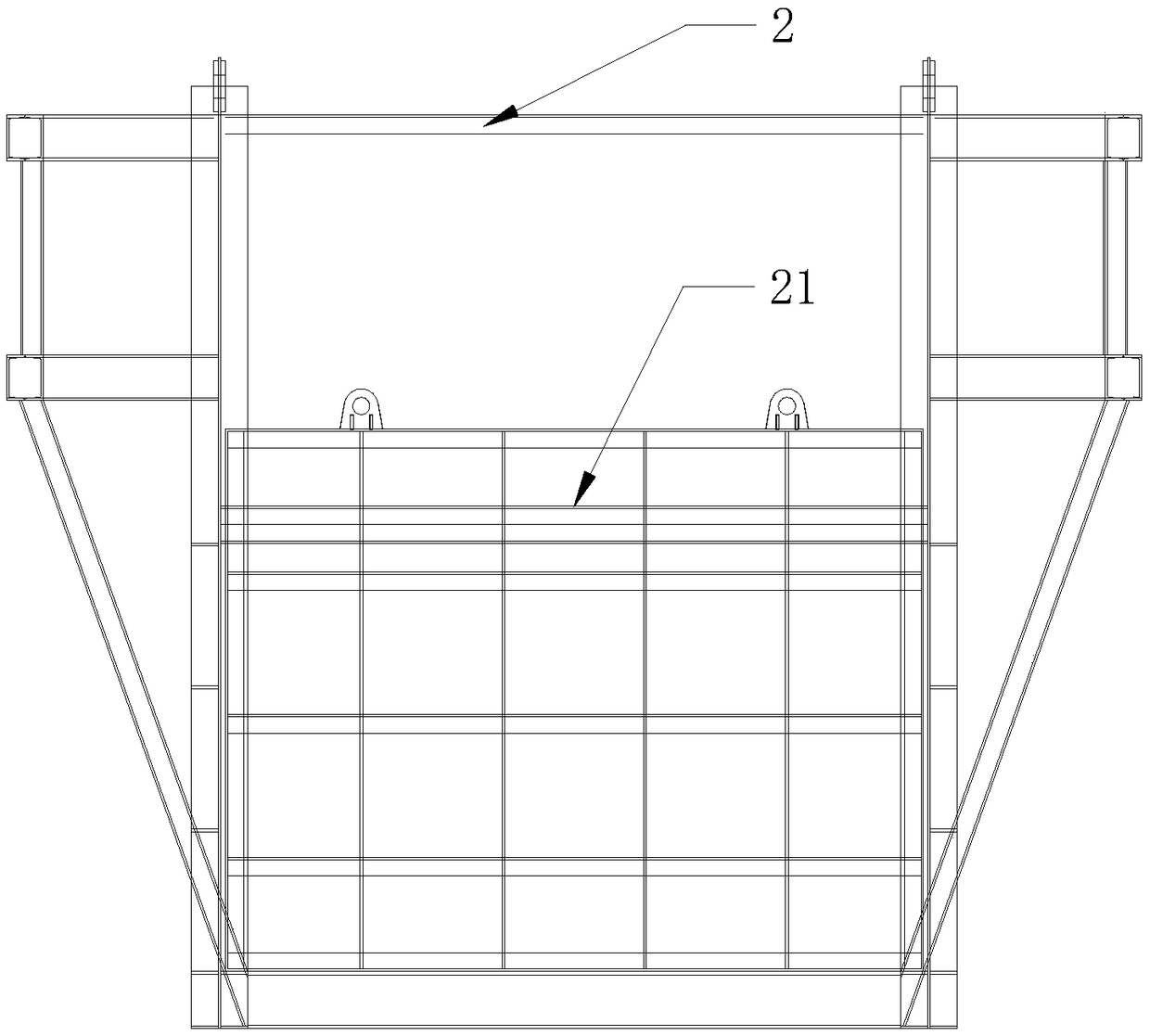

[0033] The hoisting bucket 2 that moves up and down is driven by the lifting mechanism 11, and an openable sliding door 21 is provided on one side of the hoisting bucket 2;

[0034] A chute 12 for soil sliding is provided on the middle part of the lifting frame 1 on a side close to the sliding door 21 .

[0035] A deep foundation pit soil extraction equipment of the present invention, the lifting frame 1 is set on the foundation pit cap beam 3, fully considers the self-weight of the lifting frame 1, the load of the hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com