Liquid-gas converting type gas pulsating pressure amplifying device

A technology of liquid-gas conversion and pulsating pressure, which is applied in the direction of fluid pressure actuators, fluid pressure converters, mechanical equipment, etc., can solve the problems of unadjustable amplitude and small amplitude of high-frequency gas pulsating pressure signals, and achieve improved Accuracy, increasing amplitude, widening the effect of pulsating pressure frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

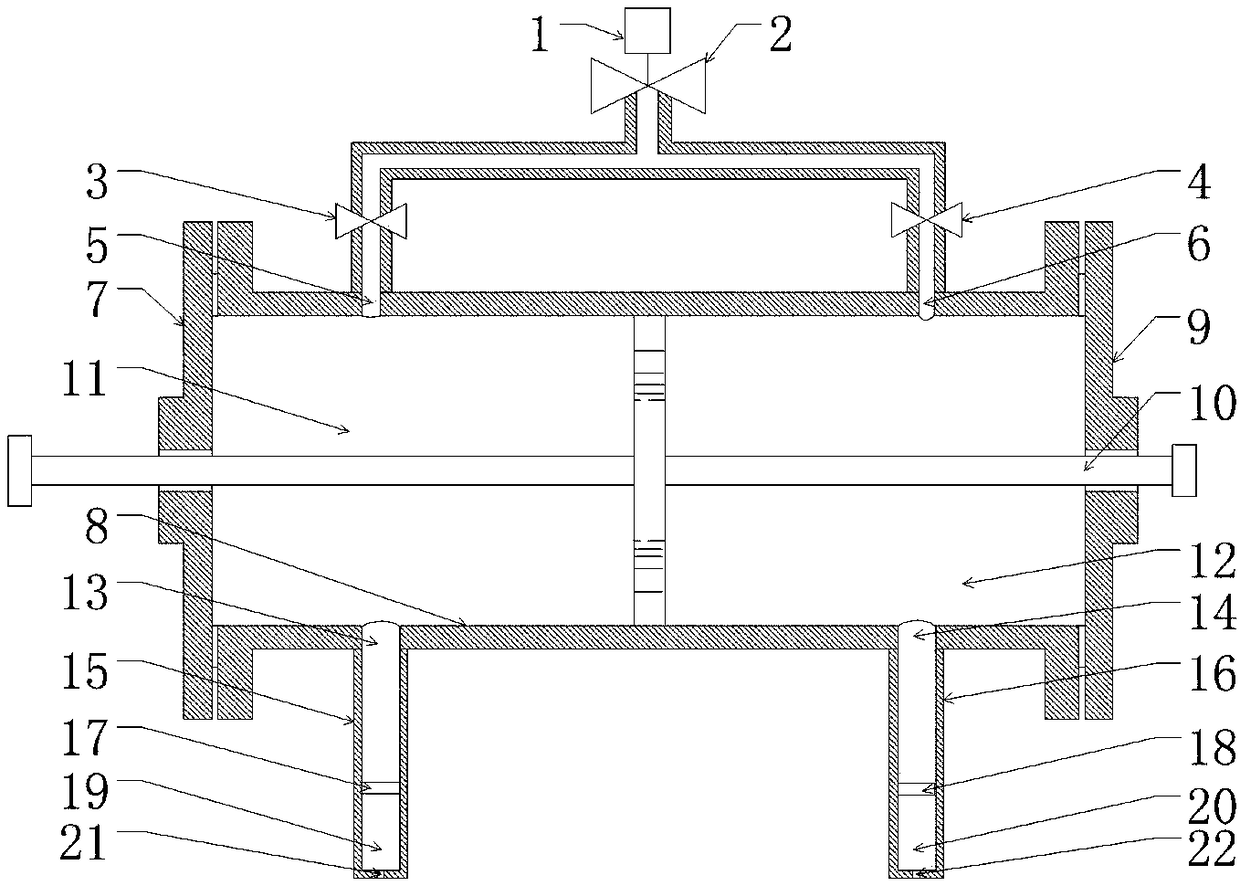

[0025] Through the following examples, combined with the attached figure 1 , further specifying the technical solution of the present invention.

[0026] The present invention will be further described below through specific examples, but not in order to limit the present invention, all within the spirit and principle of the present invention, any modification, equivalent replacement, improvement etc. all should be included within the scope of protection of the present invention .

[0027] A liquid-gas conversion type gas pulsation pressure amplifying device includes a hydraulic control unit, a pulsation generating unit and a liquid-gas conversion unit.

[0028] The pulsation generating unit includes a hydraulic cylinder 8 , an end cover 7 , an end cover 9 , a piston and a connecting rod 10 . The end cap 7 and the end cap 9 are respectively connected to the two ends of the liquid cylinder 8, the piston and the connecting rod 10 are cross-symmetrical structures, and the ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com